ASTM D3012-07

(Test Method)Standard Test Method for Thermal-Oxidative Stability of Polypropylene Using a Specimen Rotator Within an Oven

Standard Test Method for Thermal-Oxidative Stability of Polypropylene Using a Specimen Rotator Within an Oven

SIGNIFICANCE AND USE

Under the severe conditions of this test method, the specimens undergo degradation at a rate that is dependent upon the thermal endurance of the polypropylene material under examination.

The thermal level of this test method is considered sufficiently severe to cause failure of commercial grades of heat-stable polypropylene within a reasonable period of time. If desired, lower temperatures can be applied to estimate the performance of polypropylene materials with lower heat stability.

The technique of specimen rotation described in this test method provides an estimate of the life-temperature relationship of polypropylene. If this test method is conducted at different temperatures on the same material, a more reliable estimate of the life-temperature relationship of polypropylene is determined. This test method can be conducted at several temperatures and the data interpreted through use of the Arrhenius relation, by plotting the logarithms of times to failure against the reciprocals of the temperatures in kelvins (K). Temperatures in the range from 100 to 150°C, with intervals of 10°C, are suggested for this purpose.

The stability as determined under the prescribed test method is not directly related to the suitability of the compound for a use where different conditions prevail.

The specimen rotation technique of thermal aging increases the probability that all specimens will be exposed similarly and that the effect of temperature gradients in an oven will be minimized.

SCOPE

1.1 This test method provides a means for estimating the resistance of polypropylene, in molded form, to accelerated aging by heat in the presence of air using a forced draft oven.

1.2 The stability determined by this test method is not directly related to the suitability of the material for use when different environmental conditions prevail and shall not be used to predict performance.Note 1

The specified thermal levels in this test method are considered sufficiently severe to cause failure of commercial grades of heat-stable polypropylene within a reasonable period of time. If desired, lower temperatures can be applied to estimate the performance of polypropylene with lower heat stabilities.

1.3 The values stated in SI units are to be regarded as the standard. The values in brackets are for information only.

This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.Note 2

This test method and ISO 4577-1983 are technically similar but different in preparation of test specimens, thickness of test specimen, measurement of the number of air flow changes in the ovens, and the number of air changes per hour required.

1.4 The purpose of this appendix is to provide a secondary method for determining the number of air exchanges that occur within the forced draft oven used for measurement of thermal oxidative stability.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: D3012 − 07

StandardTest Method for

Thermal-Oxidative Stability of Polypropylene Using a

1

Specimen Rotator Within an Oven

This standard is issued under the fixed designation D3012; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope* D5374 Test Methods for Forced-Convection Laboratory Ov-

ens for Evaluation of Electrical Insulation

1.1 This test method provides a means for estimating the

E77 Test Method for Inspection and Verification of Ther-

resistance of polypropylene, in molded form, to accelerated

mometers

aging by heat in the presence of air using a forced draft oven.

E220 Test Method for Calibration of Thermocouples By

1.2 The stability determined by this test method is not

Comparison Techniques

directly related to the suitability of the material for use when

E608 Specification for Mineral-Insulated, Metal-Sheathed

different environmental conditions prevail and shall not be

Base Metal Thermocouples

used to predict performance.

E644 Test Methods for Testing Industrial Resistance Ther-

mometers

NOTE1—Thespecifiedthermallevelsinthistestmethodareconsidered

sufficiently severe to cause failure of commercial grades of heat-stable

E691 Practice for Conducting an Interlaboratory Study to

polypropylene within a reasonable period of time. If desired, lower

Determine the Precision of a Test Method

temperatures can be applied to estimate the performance of polypropylene

E1137/E1137M Specification for Industrial Platinum Resis-

with lower heat stabilities.

tance Thermometers

1.3 The values stated in SI units are to be regarded as the

E2251 Specification for Liquid-in-Glass ASTM Thermom-

standard. The values in brackets are for information only.

eters with Low-Hazard Precision Liquids

3

1.4 This standard does not purport to address all of the

2.2 ISO Standard:

safety concerns, if any, associated with its use. It is the

ISO 4577–1983 Plastics—Polypropylene and Propylene

responsibility of the user of this standard to establish appro-

Copolymers—Determination of Thermal Oxidative Sta-

priate safety and health practices and determine the applica-

bility in Air-Oven Method

bility of regulatory limitations prior to use.

ISO 1873 Plastics—Polypropylene and Propylene-

Copolymer Thermoplastics:

NOTE 2—This test method and ISO 4577–1983 are technically similar

but different in preparation of test specimens, thickness of test specimen, Part 1: Designation

measurement of the number of air flow changes in the ovens, and the

Part 2: Determination of Properties

number of air changes per hour required.

3. Terminology

2. Referenced Documents

2

3.1 Definitions—The definitions of plastics used in this test

2.1 ASTM Standards:

method are in accordance with Terminology D883 unless

D618 Practice for Conditioning Plastics for Testing

otherwise indicated.

D883 Terminology Relating to Plastics

D3641 Practice for Injection Molding Test Specimens of

4. Summary of Test Method

Thermoplastic Molding and Extrusion Materials

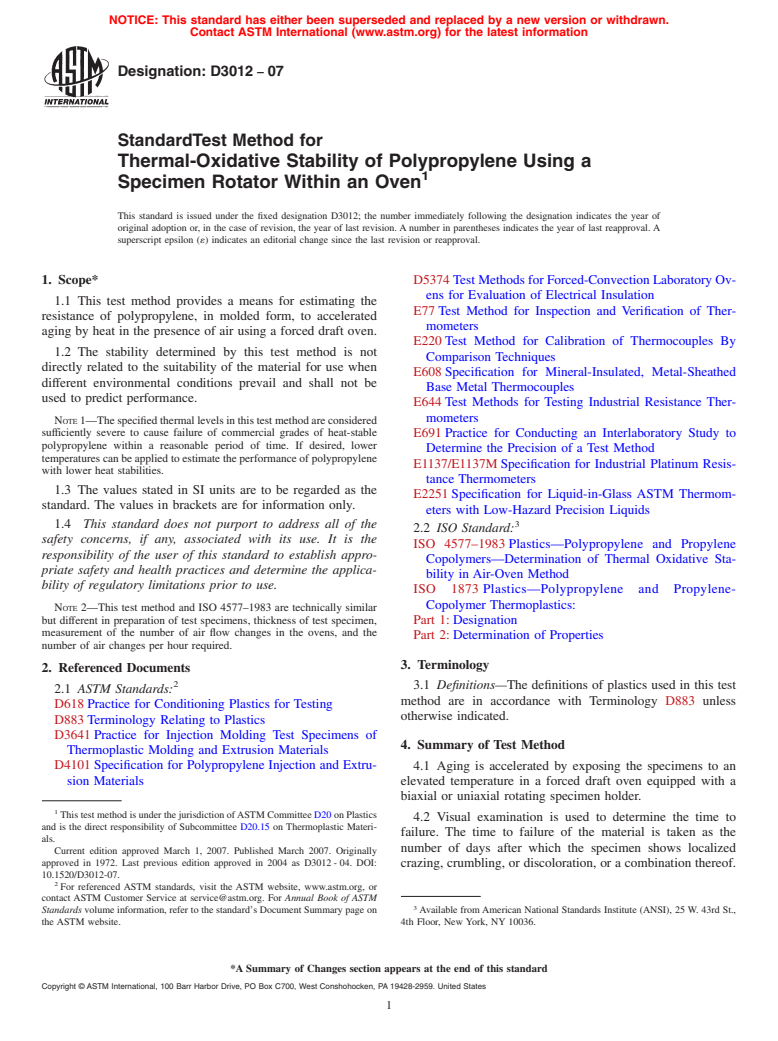

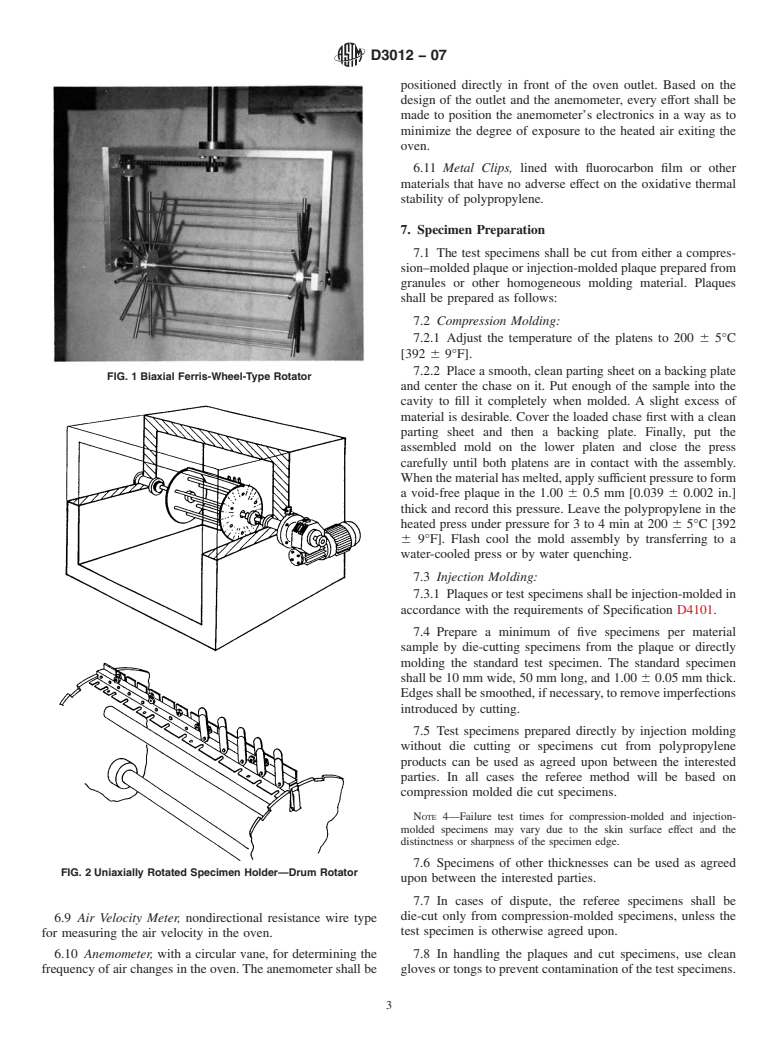

D4101 Specification for Polypropylene Injection and Extru- 4.1 Aging is accelerated by exposing the specimens to an

sion Materials elevated temperature in a forced draft oven equipped with a

biaxial or uniaxial rotating specimen holder.

1

This test method is under the jurisdiction ofASTM Committee D20 on Plastics

4.2 Visual examination is used to determine the time to

and is the direct responsibility of Subcommittee D20.15 on Thermoplastic Materi-

failure. The time to failure of the material is taken as the

als.

number of days after which the specimen shows localized

Current edition approved March 1, 2007. Published March 2007. Originally

approved in 1972. Last previous edition approved in 2004 as D3012 - 04. DOI:

crazing, crumbling, or discoloration, or a combination thereof.

10.1520/D3012-07.

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

3

Standards volume information, refer to the standard’s Document Summary page on Available fromAmerican National Standards Institute (ANSI), 25 W. 43rd St.,

the ASTM website. 4th Floor, New York, NY 10036.

*A Summary of Changes section appears at the end of this standard

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

D3012 − 07

5. Significance and Use 6.2.4 Resistance thermometers shall comply with the re-

quirements of Test Methods E644 and Specification E1137/

5.1 Under the severe conditions of this test method, the

E1137M, and be calibrated in

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.