ASTM D7269/D7269M-11

(Test Method)Standard Test Methods for Tensile Testing of Aramid Yarns

Standard Test Methods for Tensile Testing of Aramid Yarns

SIGNIFICANCE AND USE

The levels of tensile properties obtained when testing aramid yarns and cords are dependent on the age and history of the specimen and on the specific conditions used during the test. Among these conditions are rate of stretching, type of clamps, gage length of specimen, temperature and humidity of the atmosphere, rate of airflow across the specimen, and temperature and moisture content of the specimen. Testing conditions accordingly are specified precisely to obtain reproducible test results on a specific sample.

Because the force-bearing ability of a reinforced product is related to the strength of the yarn or cord used as a reinforcing material, breaking strength is used in engineering calculations when designing various types of textile reinforced products. When needed to compare intrinsic strength characteristics of yarns or cords of different sizes or different types of fiber, breaking tenacity is very useful because, for a given type of fiber, breaking force is approximately proportional to linear density.

Elongation of yarn or cord is taken into consideration in the design and engineering of reinforced products because of its effect on uniformity of the finished product and its dimensional stability during service.

The FASE is used to monitor changes in characteristics of the textile material during the various stages involved in the processing and incorporation of yarn or cord into a product.

Modulus is a measure of the resistance of yarn or cord to extension as a force is applied. It is useful for estimating the response of a textile reinforced structure to the application of varying forces and rates of stretching. Although modulus may be determined at any specified force, initial modulus is the value most commonly used.

Work-to-break is dependent on the relationship of force to elongation. It is a measure of the ability of a textile structure to absorb mechanical energy. Breaking toughness is work-to-break per unit mass.

It should be emphasize...

SCOPE

1.1 These test methods cover the tensile testing of aramid yarns, cords twisted from such yarns, and fabrics woven from such cords. The yarn or cord may be wound on cones, tubes, bobbins, spools, or beams; may be woven into fabric; or may be in some other form. The methods include testing procedure only and include no specifications or tolerances.

1.2 The values stated in either SI units or inch-pound units are to be regarded separately as standard. The values stated in each system may not be exact equivalents; therefore, each system shall be used independently of the other. Combining values from the two systems may result in non-conformance with the standard.

General Information

Relations

Buy Standard

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: D7269/D7269M − 11

Standard Test Methods for

1

Tensile Testing of Aramid Yarns

This standard is issued under the fixed designation D7269/D7269M; the number immediately following the designation indicates the

year of original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last

reapproval. A superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope ber) by the Skein Method

D1909 Standard Tables of Commercial Moisture Regains

1.1 These test methods cover the tensile testing of aramid

and Commercial Allowances for Textile Fibers

yarns, cords twisted from such yarns, and fabrics woven from

D2258 Practice for Sampling Yarn for Testing

such cords. The yarn or cord may be wound on cones, tubes,

D4848 Terminology Related to Force, Deformation and

bobbins, spools, or beams; may be woven into fabric; or may

Related Properties of Textiles

be in some other form. The methods include testing procedure

D6587 Test Method for Yarn Number Using Automatic

only and include no specifications or tolerances.

Tester

1.2 The values stated in either SI units or inch-pound units

are to be regarded separately as standard. The values stated in

3. Terminology

each system may not be exact equivalents; therefore, each

3.1 Definitions:

system shall be used independently of the other. Combining

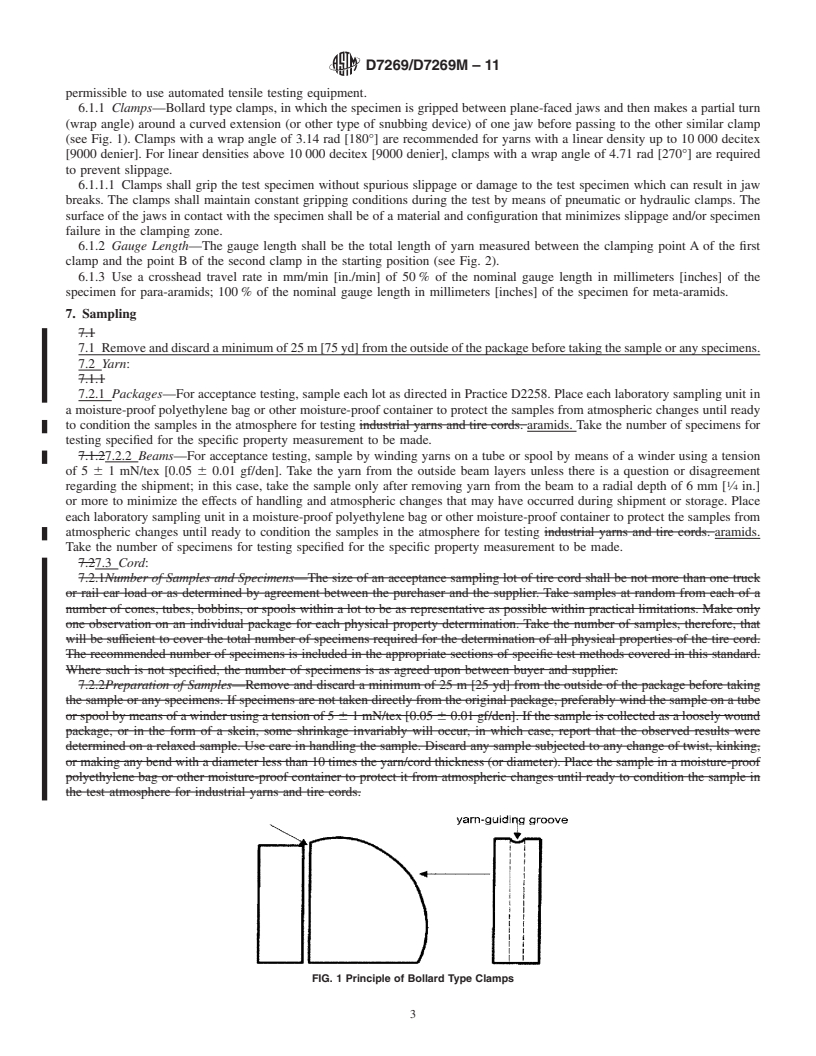

3.1.1 slippage, n—with tensile testing, insufficient quality of

values from the two systems may result in non-conformance

clamping, resulting in movement of the test material through

with the standard.

the total clamping surface. This can be visualized by the

1.3 This standard includes the following test methods:

movement of markers at the clamp exit, or by sudden changes

Section

in the strain-modulus curves (1st derivative of the strain-stress

Breaking Strength (Force) 11

curve).

Breaking Tenacity 12

Breaking Toughness 17

3.1.2 zero twist, n—twistless, devoid of twist.

Elongation at Break 13

Force at Specified Elongation (FASE) 14

3.2 The following terms are relevant to this standard:

Linear Density 10

industrial yarn, moisture equilibrium for testing, aramid, zero

Modulus 15

Work-to-Break 16 twist, standard atmosphere for testing textiles.

1.4 This standard does not purport to address all of the

3.3 For definitions of terms related to force and deformation

safety concerns, if any, associated with its use. It is the

in textiles, refer to Terminology D4848.

responsibility of the user of this standard to establish appro-

3.4 The following terms are relevant to this standard:

priate safety and health practices and determine the applica-

breaking force, breaking strength, breaking tenacity, breaking

bility of regulatory limitations prior to use.

toughness, chord modulus in a stress-strain curve, elongation,

force at specified elongation (FASE), initial modulus, tensile

2. Referenced Documents

strength, and work-to-break.

2

2.1 ASTM Standards:

3.5 For definitions of other terms related to textiles, refer to

D76 Specification for Tensile Testing Machines for Textiles

D123 Terminology Relating to Textiles Terminology D123.

D1776 Practice for Conditioning and Testing Textiles

D1907 Test Method for Linear Density of Yarn (Yarn Num- 4. Summary of Test Method

4.1 These test methods are used to determine the tensile

properties of aramid yarns or cords.

1

These test methods are under the jurisdiction of ASTM Committee D13 on

Textiles and are the direct responsibility of Subcommittee D13.19 on Industrial

4.2 Aconditioned or oven-dried specimen of aramid yarn or

Fibers and Metallic Reinforcements.

cord is clamped in a tensile testing machine and then stretched

Current edition approved May 1, 2011. Published June 2011. Originally

or loaded until broken. Breaking force, elongation, and force at

approved in 2006. Last previous edition approved in 2010 as D7269/D7269M–10.

DOI: 10.1520/D7269_D7269M-11.

specified elongation (FASE) are determined directly. Modulus

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

and work-to-break are calculated from the force-elongation

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

curve.Theoutputofaconstant-rate-of-extension(CRE)tensile

Standards volume information, refer to the standard’s Document Summary page on

the ASTM website. testingmachinecanbeconnectedwithelectronicrecordingand

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

D7269/D7269M − 11

computing equipment, which may be programmed to calculate should be compared using a statistical test for unpaired data, at

and print the test results of tensile properties of interest. a probability level chosen prior to the testing series. If

...

This document is not an ASTM standard and is intended only to provide the user of an ASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

Designation:D7269/D7269M–10 Designation:D7269/D7269M–11

Standard Test Methods for

1

Tensile Testing of Aramid Yarns

This standard is issued under the fixed designation D7269/D7269M; the number immediately following the designation indicates the

year of original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last

reapproval. A superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope

1.1 These test methods cover the tensile testing of aramid yarns, cords twisted from such yarns, and fabrics woven from such

cords. The yarn or cord may be wound on cones, tubes, bobbins, spools, or beams; may be woven into fabric; or may be in some

other form. The methods include testing procedure only and include no specifications or tolerances.

1.2 The values stated in either SI units or inch-pound units are to be regarded separately as standard. The values stated in each

system may not be exact equivalents; therefore, each system shall be used independently of the other. Combining values from the

two systems may result in non-conformance with the standard.

1.3 This standard includes the following test methods:

Section

Breaking Strength (Force) 11

Breaking Tenacity 12

Breaking Toughness 17

Elongation at Break 13

Force at Specified Elongation (FASE) 14

Linear Density 10

Modulus 15

Work-to-Break 16

1.4 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility

of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory

limitations prior to use.

2. Referenced Documents

2

2.1 ASTM Standards:

D76 Specification for Tensile Testing Machines for Textiles

D123 Terminology Relating to Textiles

D885Test Methods for Tire Cords, Tire Cord Fabrics, and Industrial Filament Yarns Made from Manufactured Organic-Base

Fibers

D1776 Practice for Conditioning and Testing Textiles

D1907 Test Method for Linear Density of Yarn (Yarn Number) by the Skein Method

D1909 Standard Table of Commercial Moisture Regains for Textile Fibers

D2258 Practice for Sampling Yarn for Testing

D4848 Terminology Related to Force, Deformation and Related Properties of Textiles

D6477Terminology Relating to Tire Cord, Bead Wire, Hose Reinforcing Wire, and Fabrics 6587 Test Method forYarn Number

Using Automatic Tester

3. Terminology

3.1Definitions:

3.1.1For definitions of terms relating to tire cord and tire cord fabrics, refer to Terminology D6477.

3.1.1.1The following terms are relevant to this standard: cord, cord twist, dip, dip pickup, in a textile cord or fabric, industrial

yarn, moisture equilibrium for testing, for industrial yarns and tire cords, pneumatic tire, single twist, standard atmosphere for

testing textiles, tabby sample, tire, and tire cord fabric.

1

These test methods are under the jurisdiction of ASTM Committee D13 on Textiles and are the direct responsibility of Subcommittee D13.19 on Industrial Fibers and

Metallic Reinforcements.

Current edition approved Jan.May 1, 2010.2011. Published August 2010.June 2011. Originally approved in 2006. Last previous edition approved in 20082010 as

D7269–08.D7269/D7269M–10. DOI: 10.1520/D7269_D7269M-101.

2

For referencedASTM standards, visit theASTM website, www.astm.org, or contactASTM Customer Service at service@astm.org. For Annual Book of ASTM Standards

volume information, refer to the standard’s Document Summary page on the ASTM website.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

1

---------------------- Page: 1 ----------------------

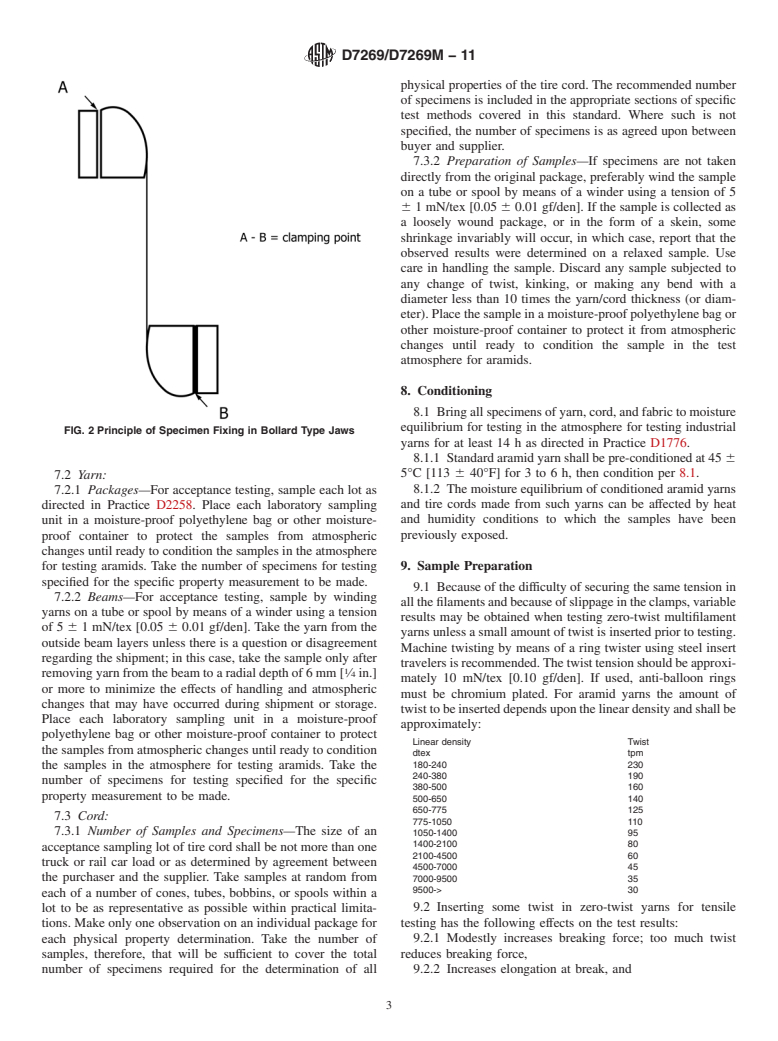

D7269/D7269M–11

3.1.2For definitions of terms related to force and deformation in textiles, refer to Terminology

3.1 Definitions:

3.1.1 slippage, n—with tensile testing, insufficient quality of clamping, resulting in movement of the test material through the

total clamping surface. This can be visualized by the movement of markers at the clamp exit, or by sudden changes in the

strain-modulus curves (1st derivative of the strain-stress curve).

3.1.2 zero twist, n—twistless, devoid of twist.

3.2 The following terms are relevant to this standard: industrial yarn, moisture equilibrium for testing, aramid, zero twist,

standard atmosphere for testing textiles.

3.3 For definitions of terms related to force and deformation in textiles, refer to Terminology D4848.

3.1.2.1The3.4 The following terms are relevant to this standard: breaking force, breakin

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.