ASTM D6684-01

(Specification)Standard Specification for Materials and Manufacture of Articulating Concrete Block (ACB) Revetment Systems

Standard Specification for Materials and Manufacture of Articulating Concrete Block (ACB) Revetment Systems

SCOPE

1.1 The purpose of this Standard is to provide specifications for articulating concrete block (ACB) revetment system structural components, material composition and physical properties, manufacturing methods and testing requirements.

1.2 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory requirements prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: D 6684 – 01

Standard Specification for

Materials and Manufacture of Articulating Concrete Block

(ACB) Revetment Systems

This standard is issued under the fixed designation D 6684; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

1. Scope D 4533 Test Method for Trapezoid Tearing Strength of

Geotextiles

1.1 The purpose of this Standard is to provide specifications

D 4632 Test Method for Grab Breaking Load and Elonga-

for articulating concrete block (ACB) revetment system struc-

tion of Geotextiles

tural components, material composition and physical proper-

D 4833 Test Method for Index Puncture Resistance of

ties, manufacturing methods and testing requirements.

Geotextiles, Geomembranes, and Related Products

1.2 This standard does not purport to address all of the

2.2 Other Documents:

safety concerns, if any, associated with its use. It is the

American Association of State Highway Transportation

responsibility of the user of this standard to establish appro-

Officials (AASHTO), 1995, “Standard Specification for

priate safety and health practices and determine the applica-

Geotextiles,” AASHTO Designation M 288, February.

bility of regulatory requirements prior to use.

Koerner, R.M., 1998, “Designing With Geotextiles,” 4th

2. Referenced Documents Edition, Prentice-Hall Publishers, Englewood Cliffs, N.J.

p. 761.

2.1 ASTM Standards:

C 33 Specification for Concrete Aggregates

3. Terminology

C 39 Test Method for Compressive Strength of Cylindrical

3.1 Definitions:

Concrete Specimens

3.1.1 articulating concrete block (ACB) revetment system,

C 42 Test Method for Obtaining and Testing Drilled Cores

n—a matrix of interconnected concrete block units sufficient

and Sawed Beams of Concrete

for erosion protection. Units are connected by geometric

C 67 Test Methods for Sampling and Testing Brick and

interlock and/or cables, geotextiles, or geogrids, and typically

Structural Clay Tile

include a geotextile underlay for subsoil retention.

C 140 Test Methods of Sampling and Testing Concrete

Masonry Units and Related Units

4. Significance and Use

C 150 Specification for Portland Cement

4.1 An articulating concrete block system is comprised of a

C 207 Specification for Hydrated Lime for Masonry Pur-

4 matrix of individual concrete blocks placed together to form an

poses

erosion-resistant revetment with specific hydraulic perfor-

C 331 Specification for Lightweight Aggregates for Con-

2 mance characteristics. The system includes a filter layer

crete Masonry Units

4 compatible with the subsoil which allows infiltration and

C 595 Specification for Blended Hydraulic Cements

exfiltration to occur while providing particle retention. The

C 618 Specification for Coal Fly Ash and Raw or Calcined

filter layer may be comprised of a geotextile, properly graded

Natural Pozzolan for use as a Mineral Admixture in

2 granular media, or both. The blocks within the matrix shall be

Concrete

dense and durable, and the matrix shall be flexible and porous.

C 666 Test Method for Resistance of Concrete to Rapid

2 4.2 Articulating concrete block systems are used to provide

Freezing and Thawing

erosion protection to underlying soil materials from the forces

C 1262 Test Method for Evaluating the Freeze-Thaw Dura-

of flowing water. The term “articulating,” as used in this

bility of Manufactured Concrete Masonry Units and Re-

Standard, implies the ability of individual blocks of the system

lated Concrete Units

to conform to changes in subgrade while remaining intercon-

nected by virtue of geometric interlock and/or additional

This specification is under the jurisdiction of ASTM Committee D18 on Soil system components such as cables, ropes, geotextiles, or

and Rock and is the direct responsibility of Subcommittee D18.25 on Erosion and

geogrids.

Sediment Control Technology.

Current edition approved June 10, 2001. Published August 2001.

Annual Book of ASTM Standards, Vol 04.02.

Annual Book of ASTM Standards, Vol 04.05.

4 5

Annual Book of ASTM Standards, Vol 04.01. Annual Book of ASTM Standards, Vol 04.13.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

D6684–01

4.3 The definition of articulating concrete block systems 5.5.1 For cabled systems, the revetment cable or rope and

does not distinguish between interlocking and non-interlocking fittings shall be designed to provide adequate strength and

block geometries, between cable-tied and non- cable-tied durability characteristics to facilitate lifting and placing of

systems, between vegetated and non-vegetated systems or large mattresses.

between methods of manufacturing or placement. Furthermore,

5.5.2 Fittings such as sleeves, clamps and stops shall be as

the definition does not restrict or limit the block size, shape,

required by the manufacturer. Selection of cable or rope and

strength, or longevity; however, guidelines and recommenda-

fittings shall be made in a manner that insures a safe design

tions regarding these factors are incorporated into this Stan-

factor for mats being lifted from one or both ends. Consider-

dard. Block systems are available in either open-cell or

ation shall be taken for the bending of the cables or ropes

closed-cell configurations.

around hooks or pins during lifting. Revetment cable or rope,

splice fittings, sleeves and stops shall be selected so that the

5. Materials and Manufacture

cable or rope and all connections result in a minimum

factor-of-safety of 5.0 with respect to lifting.

5.1 Materials Specifications: Cementitious Materials—

5.5.3 For those systems performance tested with, and that

Materials shall conform to the following applicable ASTM

rely on cables, ropes, or other non-concrete components to

standards:

maintain the block-to-block interconnection, the cables, ropes,

Portland Cements C 150

Blended Cements C 595 and/or non-concrete components shall also meet the design life

Hydrated Lime Types C 207

of the project.

Pozzolans C 618

5.6 Block Production:

5.2 Aggregates shall conform to the following ASTM speci-

5.6.1 Articulating concrete blocks may be produced at a

fications, except that grading requirements shall not necessarily

block plant or onsite using either wet-cast or dry-cast produc-

apply:

tion techniques, provided that the composition and physical

Normal Weight C 33

characteristics of the furnished units meet the requirements of

Light Weight C 331

5.1-5.3.

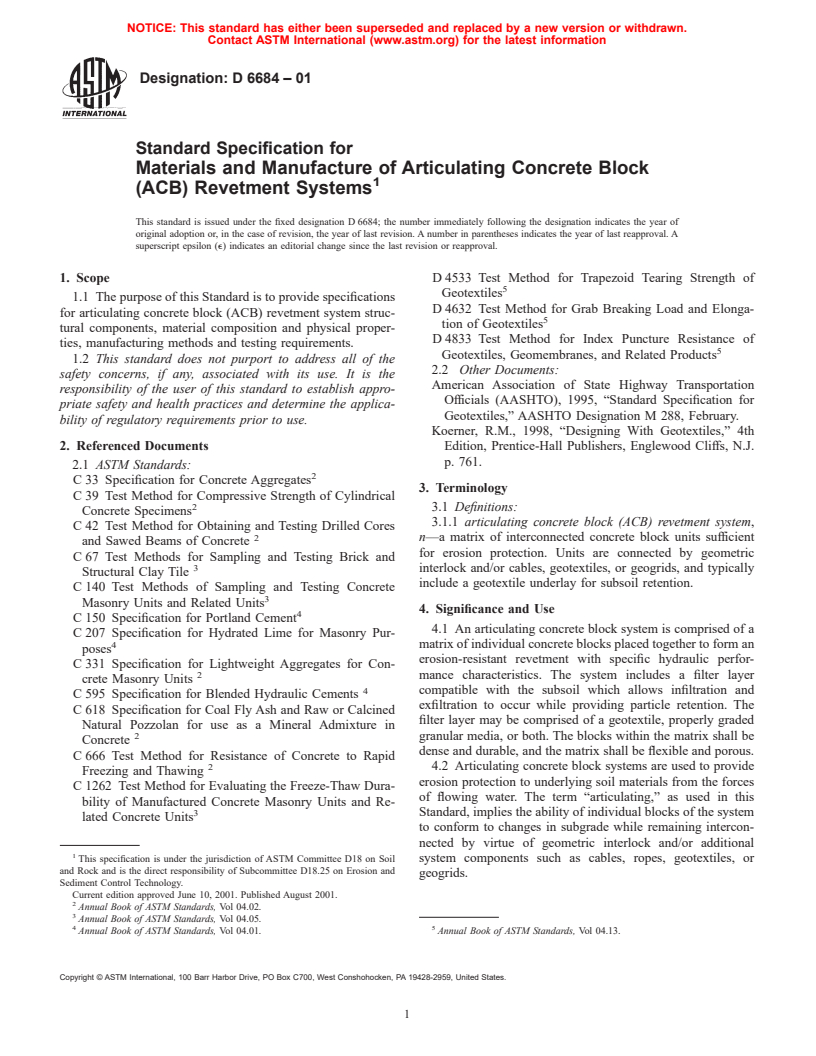

5.3 Physical Properties—At the time of delivery to the

5.7 Matrix Assembly:

work site, the units shall conform to the physical requirements

5.7.1 Non-Cabled System—Non-cabled articulating con-

prescribed in Table 1.

crete block systems are typically palletized, cured, and shipped

5.3.1 In addition to Table 1, when freeze-thaw durability to the job site. Non-cabled systems may also be assembled on,

testing is required, such testing shall be performed in accor-

and/or glued to, a high-strength geotextile fabric which is used

dance with Test Methods C 67, C 666, or C 1262, at the to carry the articulated block mattress.

direction of the Owner. The number of freeze-thaw cycles and

5.7.2 Cabled System—Cabled articulating concrete block

the corresponding weight loss criterion for pass-fail determi-

revetment systems can be assembled into mattresses, typically

nation shall be specified by the Owner along with the test

up to 480 square feet (45 square meters). Whole mat produc-

method.

tion can occur at the bloc

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.