ASTM D228-00B

(Test Method)Standard Test Methods for Sampling, Testing, and Analysis of Asphalt Roll Roofing, Cap Sheets, and Shingles Used in Roofing and Waterproofing

Standard Test Methods for Sampling, Testing, and Analysis of Asphalt Roll Roofing, Cap Sheets, and Shingles Used in Roofing and Waterproofing

SCOPE

1.1 These test methods include procedures for sampling, examination, physical testing, and analyses of asphalt-containing materials used in roofing and waterproofing. These materials include but are not limited to roll roofing, cap sheets, and shingles. Any of these materials are allowed to be partially or fully coated, surfaced, and/or laminated.

1.2 The values stated in SI units are to be regarded as the standard. The values given in parentheses are for information only.

1.3 The test methods and procedures in this standard appear in the following order:SectionContent5 Types of Roofing6 Sampling7 Mass and Area Determination8 Selection of Representative Specimens9 Moisture10 Pliability11 Weight Loss and Behavior on Heating12 Preparation and Selection of Small Test Specimens for Analyses13 Analysis of Glass Felt Products14 Analysis of Roofing Products with Organic or Asbestos Felts15 Ash of Desaturated Felt16 Calculation17 Adjusting Back Coating Fine Mineral Matter and Back Surfacing18 Report19 Precision and Bias

1.4 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or discontinued.

Contact ASTM International (www.astm.org) for the latest information.

Designation: D 228 – 00b

Standard Test Methods for

Asphalt Roll Roofing, Cap Sheets, and Shingles

This standard is issued under the fixed designation D 228; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

1. Scope Surfaced with Mineral Granules

D 4601 Specification for Asphalt-Coated Glass Fiber Base

1.1 These test methods cover the procedures for the physical

Sheet Used in Roofing

testing and analyses of roofing and shingles composed of

D 4897 Specification for Asphalt-Coated Glass-Fiber Vent-

asphalt saturated or glass fiber felt coated to various extents

ing Base Sheet Used in Roofing

with asphalt and having the coated portion surfaced with

D 6380 Specification for Asphalt Roll Roofing (Organic

powders, laminates or granules.

Felt)

1.2 The values stated in SI units are to be regarded as the

standard. The values given in parentheses are for information

3. Terminology

only.

3.1 For definitions of terms used in this test method, see

1.3 This standard does not purport to address all of the

Terminology D 1079.

safety concerns, if any, associated with its use. It is the

responsibility of the user of this standard to establish appro-

4. Significance and Use

priate safety and health practices and determine the applica-

4.1 These test methods cover the sampling, physical testing,

bility of regulatory limitations prior to use.

and compositional analyses of asphalt roofing products fabri-

cated with asphalt coatings. Other components may include,

2. Referenced Documents

but are not limited to, felts, mats, films, foils, mineral stabiliz-

2.1 ASTM Standards:

ers, papers, and mineral surfacing.

D 95 Test Method for Water in Petroleum Products and

2 4.2 Five random samples are required from lots equal to or

Bituminous Materials by Distillation

less than 1000 packages. The number of samples required for

D 224 Specification for Smooth-Surfaced Asphalt Roll

3 lots greater than 1000 packages is dependent on the variation in

Roofing (Organic Felt)

the unit mass within the lot and is determined by the two-step

D 225 Specification for Asphalt Shingles (Organic Felt)

3 sampling plan in 6.5.

Surfaced with Mineral Granules

4.3 The results of a visual examination, physical testing and

D 249 Specification for Asphalt Roll Roofing (Organic Felt)

compositional analysis are required for each sample. The

Surfaced with Mineral Granules

analytical data are further used to compute the probable

D 371 Specification for Asphalt Roll Roofing (Organic Felt)

minimum and the probable range for the average mass of each

Surfaced with Mineral Granules; Wide Selvage

of the components.

D 1079 Terminology Relating to Roofing, Waterproofing,

and Bituminous Materials

5. Types of Roofing

D 2178 Specification for Asphalt Glass Felt Used in Roof-

3 5.1 Asphalt coated roll roofing and shingles are divided into

ing and Waterproofing

the following types for the purposes of this test method (see

D 2626 Specification for Asphalt-Saturated and Coated Or-

3 Fig. 1).

ganic Felt Base Sheet Used in Roofing

5.1.1 Type 1—A single thickness of glass felt, coated with

D 3018 Specification for Class A Asphalt Shingles Surfaced

3 asphalt and mineral surfacing such as in Specifications D 2178,

with Mineral Granules

D 3462, D 3909, D 4601 and D 4897. The backing material

D 3462 Specification for Asphalt Shingles Made from Glass

3 (designated “Fine Mineral Surfacing” in Fig. 1) shall be

Felt and Surfaced with Mineral Granules

permitted to be any suitable material that prevents these

D 3909 Specification for Asphalt Roll Roofing (Glass Felt)

products from sticking together while packaged.

5.1.2 Type 2—A single thickness of asphalt saturated felt

These test methods are under the jurisdiction of ASTM Committee D08 on coated with asphalt and mineral surfacing such as in Specifi-

Roofing, Waterproofing, and Bituminous Materials and are the direct responsibility

cations D 224, D 225, D 249, D 2626, and some of the prod-

of Subcommittee D08.02 on Prepared Roofing, Shingles, and Siding Materials.

ucts in Specification D 6380. The backing material (designated

Current edition approved Dec. 12, 2000. Published February 2001. Originally

“Fine Mineral Surfacing” in Fig. 1) shall be permitted to be any

published as D 228 – 25. Last previous edition D 228 – 00a.

Annual Book of ASTM Standards, Vol 05.01.

suitable material that prevents these products from sticking

Annual Book of ASTM Standards, Vol 04.04.

Copyright © ASTM, 100 Barr Harbor Drive, West Conshohocken, PA 19428-2959, United States.

D 228

FIG. 1 Types of Asphalt-Coated Roll Roofing and Shingles

together while packaged. 6.5 Calculate the required number of samples based on the

5.1.3 Type 3—Similar to Type 2, but asphalt coated and standard deviation (s) of the preliminary sampling by:

surfaced with mineral granules for part of one side of the

2 2

t s

saturated felt such as in Specification D 371.

n 5 (1)

d

6. Sampling

where:

6.1 The rolls or bundles selected in accordance with this

n = total number of samples required (n − 5 more rolls or

section constitute the representative sample used in Sections 7

packages must be selected at random as samples),

and 8. See Fig. 2.

t = test statistic for number of samples in the preliminary

6.2 The lot is defined as a shipment or fraction thereof

test series for 4° and a 95 % confidence that the

representing a product of the same kind, class, and mass.

calculated average mass will not exceed d (t = 2.776),

6.3 Select five rolls or packages from the lot at random.

and

2 2

2 2

Determine the average net mass per g/m (lb/100 ft ) and the

d = 100 g/m (2 lb/100 ft ) (the mean mass obtained from

standard deviation in accordance with 7.1 to 7.8. the analysis should be within6 100 g/m of the true

6.4 If the lot is 1000 or fewer rolls or packages proceed to

value, with 95 % confidence).

Section 7. If the lot is 1001 or greater in number, follow the

second part of the sampling plan in 6.5.

D 228

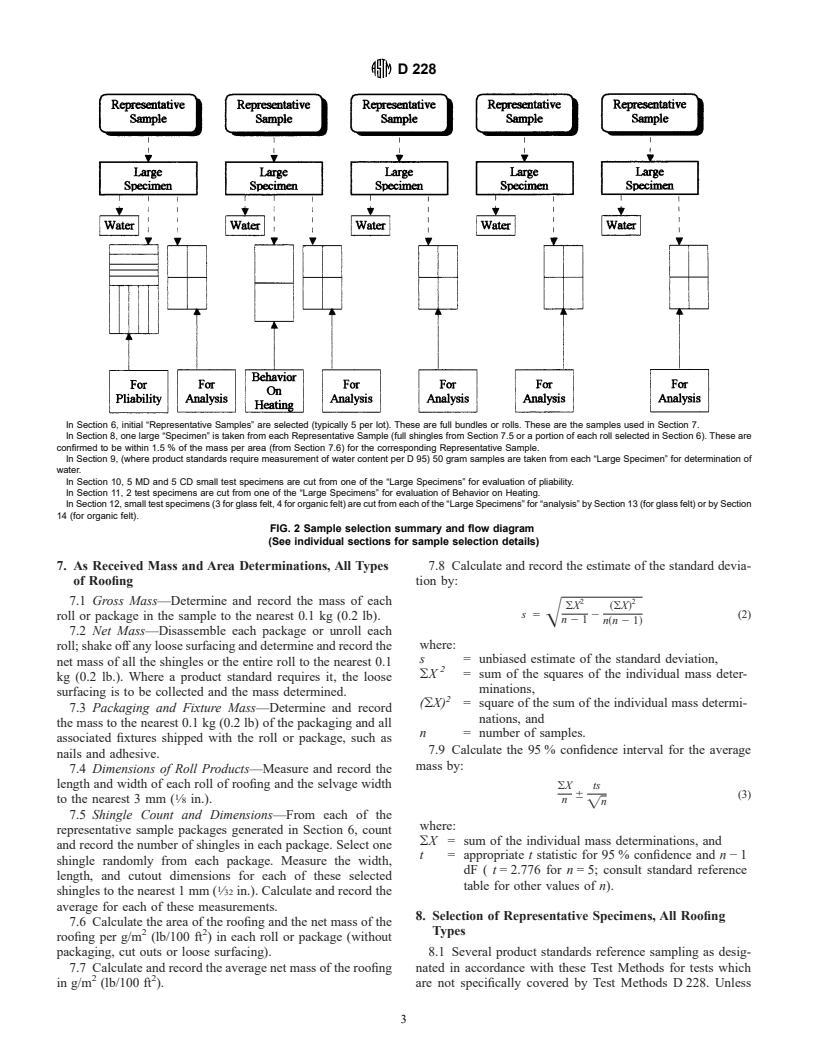

In Section 6, initial “Representative Samples” are selected (typically 5 per lot). These are full bundles or rolls. These are the samples used in Section 7.

In Section 8, one large “Specimen” is taken from each Representative Sample (full shingles from Section 7.5 or a portion of each roll selected in Section 6). These are

confirmed to be within 1.5 % of the mass per area (from Section 7.6) for the corresponding Representative Sample.

In Section 9, (where product standards require measurement of water content per D 95) 50 gram samples are taken from each “Large Specimen” for determination of

water.

In Section 10, 5 MD and 5 CD small test specimens are cut from one of the “Large Specimens” for evaluation of pliability.

In Section 11, 2 test specimens are cut from one of the “Large Specimens” for evaluation of Behavior on Heating.

In Section 12, small test specimens (3 for glass felt, 4 for organic felt) are cut from each of the “Large Specimens” for “analysis” by Section 13 (for glass felt) or by Section

14 (for organic felt).

FIG. 2 Sample selection summary and flow diagram

(See individual sections for sample selection details)

7. As Received Mass and Area Determinations, All Types 7.8 Calculate and record the estimate of the standard devia-

of Roofing tion by:

2 2

7.1 Gross Mass—Determine and record the mass of each

(X ~(X!

s 5 2 (2)

roll or package in the sample to the nearest 0.1 kg (0.2 lb). ˛

n 2 1 n~n 2 1!

7.2 Net Mass—Disassemble each package or unroll each

where:

roll; shake off any loose surfacing and determine and record the

s = unbiased estimate of the standard deviation,

net mass of all the shingles or the entire roll to the nearest 0.1

(X = sum of the squares of the individual mass deter-

kg (0.2 lb.). Where a product standard requires it, the loose

minations,

surfacing is to be collected and the mass determined.

((X) = square of the sum of the individual mass determi-

7.3 Packaging and Fixture Mass—Determine and record

nations, and

the mass to the nearest 0.1 kg (0.2 lb) of the packaging and all

n = number of samples.

associated fixtures shipped with the roll or package, such as

7.9 Calculate the 95 % confidence interval for the average

nails and adhesive.

mass by:

7.4 Dimensions of Roll Products—Measure and record the

length and width of each roll of roofing and the selvage width (X ts

6 (3)

to the nearest 3 mm ( ⁄8 in.). n

n

=

7.5 Shingle Count and Dimensions—From each of the

where:

representative sample packages generated in Section 6, count

(X = sum of the individual mass determinations, and

and record the number of shingles in each package. Select one

t = appropriate t statistic for 95 % confidence and n−1

shingle randomly from each package. Measure the width,

dF ( t = 2.776 for n = 5; consult standard reference

length, and cutout dimensions for each of these selected

table for other values of n).

shingles to the nearest 1 mm ( ⁄32 in.). Calculate and record the

average for each of these measurements.

8. Selection of Representative Specimens, All Roofing

7.6 Calculate the area of the roofing and the net mass of the

2 2 Types

roofing per g/m (lb/100 ft ) in each roll or package (without

packaging, cut outs or loose surfacing). 8.1 Several product standards reference sampling as desig-

7.7 Calculate and record the average net mass of the roofing nated in accordance with these Test Methods for tests which

2 2

in g/m (lb/100 ft ). are not specifically covered by Test Methods D 228. Unless

D 228

otherwise specified in these test methods, the samples or ( ⁄8 in.), as measured while bent over the block, is considered

specimens for testing shall all be selected from the represen- a failure. For coated products, failure is defined as cracking of

tative sample (roll or package selected in Section 6) which has the filled coating asphalt which exposes the reinforcement of

the individual net mass per unit area closest to the average net the specimen. The cracking shall be visible to the naked eye

mass per unit area for the combined representative samples as when the specimen is viewed in the bent condition on the

determined in Section 7. If more than one roll or package needs mandrel block. Separation of granules or other superficial

to be selected to provide sufficient specimens for all the tests fissures which do not extend through the filled coating asphalt

dictated within the product standard, any additional specimens surface to the reinforcement do not constitute cracking. Frac-

shall be selected from the representative sample that has the net ture through the specimen is considered a failure. Report the

mass per unit area that is next closest to the average net mass number of specimens failing.

per unit area of the combined representative samples.

ASPHALT ROLL ROOFING, CAP SHEETS, AND

NOTE 1—It is the intent of these test methods that whenever not

SHINGLES

specifically directed to select specimens in some other manner, specimens

shall be selected from the representative sample which is the closest in

11. Weight Loss and Behavior on Heating

mass per unit area to the average mass per unit area of the combined

representative samples. 11.1 Cut two test specimens, each approximately 100 by

100 mm (4 by 4 n.) from a large specimen selected in

8.2 For roll products, select a specimen of roofing, the full

accordance with Section 8. Condition the smaller specimens

sheet width and at least 1m (3 ft) in length from each roll,

for 24 h in a desiccator, weigh to the nearest 0.1 g, and then by

starting a minimum of three wraps into the roll. For shingle

means of a thin wire fastened through holes punctured near one

products, the shingles from 7.5 shall be used.

edge, suspend them vertically in the center of an air oven

8.3 Determine the mass of each specimen and calculate the

2 2

maintained at 80 6 3°C (176 6 5°F) with the cross machine

mass in g/m (lb/100 ft ).

direction vertical. The internal dimensions of the oven shall be

8.4 Discard all specimens that differ by more than 1.5 %

not less than 305 by 305 by 305 mm (12 by 12 by 12 in.). The

from the net mass determined in 7.6, select replacements, and

oven shall be electrically heated with forced draft. Insert a

determine the mass as in 8.3.

thermometer in the center of the oven to such a depth that its

8.5 Continue this process until five representative speci-

bulb is in line with the center of the specimens. Maintain the

mens are obtained, no more than one from each package or roll,

specimens at the prescribed temperature for 2 h 6 5 min, then

that reflect that roll or package’s average net weight as

cool in a desiccator and weigh each specimen. Calculate the

determined in 7.6.

average loss of volatile matter as percentage of the final

8.6 If fewer than five specimens are available, use all the

specimen mass. Record any change in appearance of the

available specimens and adjust the final calculations to reflect

specimen such as blistering, absorption of the asphalt coatings,

the lower number of samples tested.

or sliding of coating or granular surfacing. Record the extent of

the latter to the nearest 1.6 mm ( ⁄16 in.).

ALL ROOFING TYPES

9. Moisture METHODS OF ANALYSIS

9.1 Determine the water in each sample in accordance with

12. Preparation and Selection of Small Specimens for

Test Method D 95; use 50 g (0.11 lb) of product for each

Analyses

determination, cut up to fit in the flask. Report the water

12.1 Materials of Uniform Composition—Each of the 5

content as a percent of the dry (water free) product mass.

large specimens selected in Section 8 is to have small speci-

ASPHALT ROLL ROOFING AND CAP SHEETS

mens cut for composition analysis. Cut 50 by 100 6 1-mm (2

by 4 6 ⁄32-in.) small specimens from each of the large

10. Pliability

specimens. Compare the equivalent mass per unit area of the

10.1 From a large specimen selected in Section 8, cut ten small specimens to the mass per unit area previously generated

for the large specimens (Section 8). For products that contain

small test specimens 25.4 mm (1 in.) in width by 203 mm (8

in.) in length, five in the direction of and five across the length organic felt, 4 small specimens must be cut from each large

of the roll. Immerse in water at 25°C (77°F) for 25 to 30 min; specimen that are within 1.5 % of the equivalent mass per unit

then remove and immediately bend each specimen, with the area of the large specimen. For products that contain only glass

weather side up, at a uniform speed through 90° in approxi- felt, 3 small specimens must be cut from each of the

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.