ASTM C482-20

(Test Method)Standard Test Method for Bond Strength of Ceramic Tile to Portland Cement Paste

Standard Test Method for Bond Strength of Ceramic Tile to Portland Cement Paste

SIGNIFICANCE AND USE

5.1 This test method provides a means of determining whether or not tile of the types indicated in 1.1 can be bonded with adequate strength to portland cement paste. Tile specifications can refer to this test method in order to establish minimum bond strength limits appropriate to the service conditions that are anticipated.

5.2 Separation between bond coat and setting bed, or breakage of the setting bed itself shall not be considered failures of tile bond.

SCOPE

1.1 This test method covers the determination of the ability of ceramic tile, ceramic mosaic tile, quarry tile, porcelain tile, and paver tile to be bonded to portland cement paste. Tiles may be glazed or unglazed. This test method includes both face-mounted and back-mounted tile.

1.2 The values stated in inch-pound units are to be regarded as standard. The values given in parentheses are mathematical conversions to SI units that are provided for information only and are not considered standard.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety, health, and environmental practices and determine the applicability of regulatory limitations prior to use.

1.4 This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

General Information

Relations

Buy Standard

Standards Content (Sample)

This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the

Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

Designation: C482 − 20

Standard Test Method for

1

Bond Strength of Ceramic Tile to Portland Cement Paste

This standard is issued under the fixed designation C482; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope 3.1.1 For definitions of the types of tile listed in 1.1, refer to

Terminology C242.

1.1 This test method covers the determination of the ability

of ceramic tile, ceramic mosaic tile, quarry tile, porcelain tile,

4. Summary of Test Method

and paver tile to be bonded to portland cement paste.Tiles may

be glazed or unglazed. This test method includes both face-

4.1 This test method consists of bonding tile under con-

mounted and back-mounted tile.

trolled conditions to a pure portland cement paste bond coat,

1.2 The values stated in inch-pound units are to be regarded supported by a cement mortar bed.

as standard. The values given in parentheses are mathematical

4.2 After proper cure of the test assembly, a load is applied

conversions to SI units that are provided for information only

to one edge of the tile and the load increased at a definite rate

and are not considered standard.

until the bond between tile and bond coat is broken.

1.3 This standard does not purport to address all of the

safety concerns, if any, associated with its use. It is the 4.3 Because the laboratory method of applying shear stress

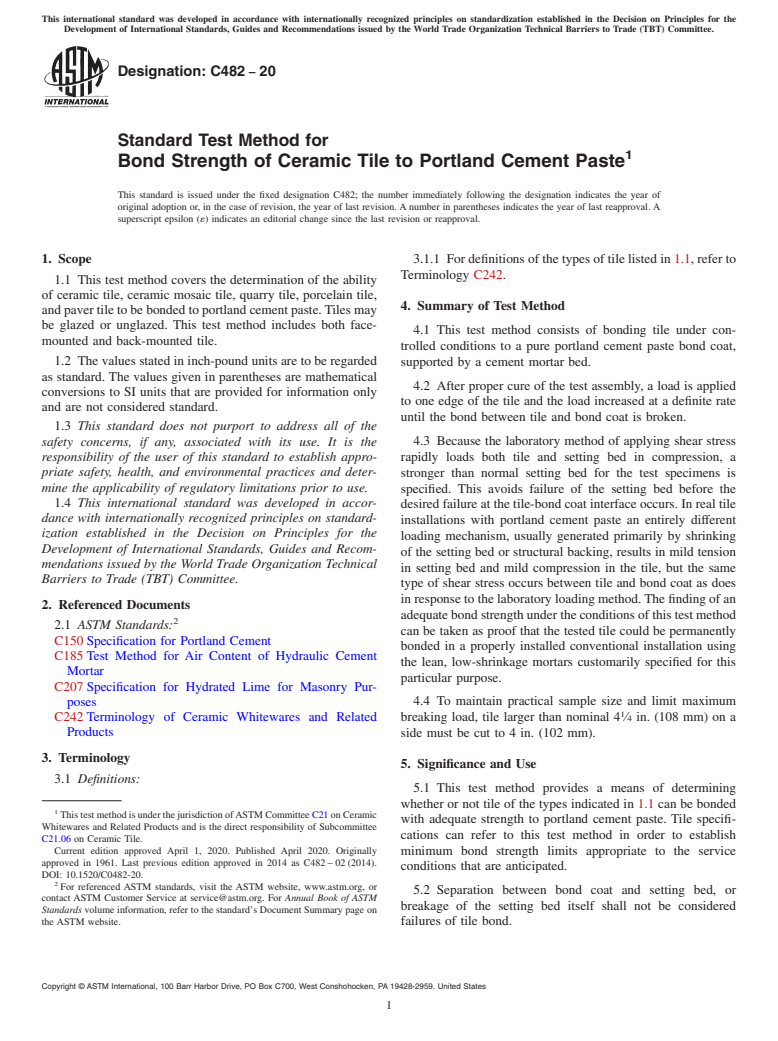

responsibility of the user of this standard to establish appro- rapidly loads both tile and setting bed in compression, a

priate safety, health, and environmental practices and deter-

stronger than normal setting bed for the test specimens is

mine the applicability of regulatory limitations prior to use. specified. This avoids failure of the setting bed before the

1.4 This international standard was developed in accor-

desired failure at the tile-bond coat interface occurs. In real tile

dance with internationally recognized principles on standard-

installations with portland cement paste an entirely different

ization established in the Decision on Principles for the

loading mechanism, usually generated primarily by shrinking

Development of International Standards, Guides and Recom-

of the setting bed or structural backing, results in mild tension

mendations issued by the World Trade Organization Technical

in setting bed and mild compression in the tile, but the same

Barriers to Trade (TBT) Committee.

type of shear stress occurs between tile and bond coat as does

in response to the laboratory loading method.The finding of an

2. Referenced Documents

adequate bond strength under the conditions of this test method

2

2.1 ASTM Standards:

can be taken as proof that the tested tile could be permanently

C150 Specification for Portland Cement

bonded in a properly installed conventional installation using

C185 Test Method for Air Content of Hydraulic Cement

the lean, low-shrinkage mortars customarily specified for this

Mortar

particular purpose.

C207 Specification for Hydrated Lime for Masonry Pur-

4.4 To maintain practical sample size and limit maximum

poses

1

C242 Terminology of Ceramic Whitewares and Related breaking load, tile larger than nominal 4 ⁄4 in. (108 mm) on a

Products

side must be cut to 4 in. (102 mm).

3. Terminology

5. Significance and Use

3.1 Definitions:

5.1 This test method provides a means of determining

whether or not tile of the types indicated in 1.1 can be bonded

1

This test method is under the jurisdiction ofASTM Committee C21 on Ceramic

with adequate strength to portland cement paste. Tile specifi-

Whitewares and Related Products and is the direct responsibility of Subcommittee

cations can refer to this test method in order to establish

C21.06 on Ceramic Tile.

Current edition approved April 1, 2020. Published April 2020. Originally

minimum bond strength limits appropriate to the service

approved in 1961. Last previous edition approved in 2014 as C482 – 02 (2014).

conditions that are anticipated.

DOI: 10.1520/C0482-20.

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

5.2 Separation between bond coat and setting bed, or

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

breakage of the setting bed itself shall not be considered

Standards volume information, refer to the standard’s Document Summary page on

the ASTM website. failures of tile bond.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

-------------

...

This document is not an ASTM standard and is intended only to provide the user of an ASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

Designation: C482 − 02 (Reapproved 2014) C482 − 20

Standard Test Method for

1

Bond Strength of Ceramic Tile to Portland Cement Paste

This standard is issued under the fixed designation C482; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope

1.1 This test method covers the determination of the ability of glazed ceramic wall tile, ceramic mosaic tile, quarry tile, and

pavers porcelain tile, and paver tile to be bonded to portland cement paste. Tiles may be glazed or unglazed. This test method

includes both face-mounted and back-mounted tile.

1.2 The values stated in inch-pound units are to be regarded as standard. The values given in parentheses are mathematical

conversions to SI units that are provided for information only and are not considered standard.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility

of the user of this standard to establish appropriate safety safety, health, and healthenvironmental practices and determine the

applicability of regulatory limitations prior to use.

1.4 This international standard was developed in accordance with internationally recognized principles on standardization

established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued

by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

2. Referenced Documents

2

2.1 ASTM Standards:

C150 Specification for Portland Cement

C185 Test Method for Air Content of Hydraulic Cement Mortar

C207 Specification for Hydrated Lime for Masonry Purposes

C242 Terminology of Ceramic Whitewares and Related Products

3. Terminology

3.1 Definitions:

3.1.1 For definitions of the types of tile listed in 1.1, refer to Terminology C242.

4. Summary of Test Method

4.1 This test method consists of bonding tile under controlled conditions to a pure portland cement paste bond coat, supported

by a cement mortar bed.

4.2 After proper cure of the test assembly, a load is applied to one edge of the tile and the load increased at a definite rate until

the bond between tile and bond coat is broken.

4.3 Because the laboratory method of applying shear stress rapidly loads both tile and setting bed in compression, a stronger

than normal setting bed for the test specimens is specified. This avoids failure of the setting bed before the desired failure at the

tile-bond coat interface occurs. In real tile installations with portland cement paste an entirely different loading mechanism, usually

generated primarily by shrinking of the setting bed or structural backing, results in mild tension in setting bed and mild

compression in the tile, but the same type of shear stress occurs between tile and bond coat as does in response to the laboratory

loading method. The finding of an adequate bond strength under the conditions of this test method can be taken as proof that the

tested tile could be permanently bonded in a properly installed conventional installation using the lean, low-shrinkage mortars

customarily specified for this particular purpose.

1

This test method is under the jurisdiction of ASTM Committee C21 on Ceramic Whitewares and Related Products and is the direct responsibility of Subcommittee C21.06

on Ceramic Tile.

Current edition approved Dec. 1, 2014April 1, 2020. Published December 2014April 2020. Originally approved in 1961. Last previous edition approved in 20092014 as

C482 – 02 (2009).(2014). DOI: 10.1520/C0482-02R14.10.1520/C0482-20.

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM Standards

volume information, refer to the standard’s Document Summary page on the ASTM website.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

C482 − 20

1

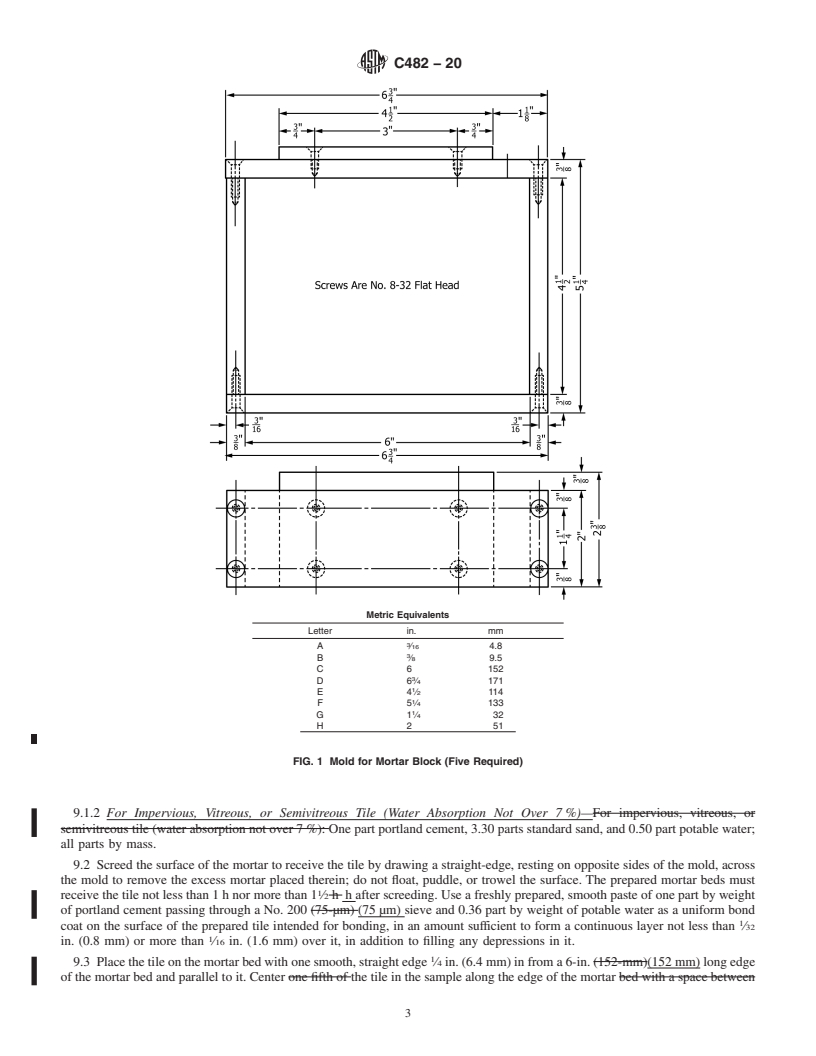

4.4 To maintain practical sample size and limit maximum breaking load, tile larger than nominal 4 ⁄4 in. (108 mm) on a side

must be cut to 4 in. (102 mm).

5. Significance and Use

5.1 This test method provides a means of determining whether or not tile of the types indicated in 1.1 can be bonded with

adequate strength to portland cement paste. Tile specificati

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.