ASTM B637-06(2011)

(Specification)Standard Specification for Precipitation-Hardening Nickel Alloy Bars, Forgings, and Forging Stock for High-Temperature Service

Standard Specification for Precipitation-Hardening Nickel Alloy Bars, Forgings, and Forging Stock for High-Temperature Service

ABSTRACT

This specification covers hot- and cold-worked precipitation-hardenable nickel alloy rod, bar, forgings, and forging stock for high-temperature service. Chemical analysis shall be performed on the alloy and shall conform to the chemical composition requirement in carbon, manganese, silicon, phosphorus, sulfur, chromium, cobalt, molybdenum, columbium, tantalum, titanium, aluminum, zirconium, boron, iron, copper, and nickel. The material shall follow recommended annealing treatment, solution treatment, stabilizing treatment, and precipitation hardening treatment. Tension testing, hardness testing and stress-rupture testing shall be performed on the material and shall comply to the required tensile strength, yield strength, elongation, reduction in area, and Brinell hardness.

SCOPE

1.1 This specification covers hot- and cold-worked precipitation-hardenable nickel alloy rod, bar, forgings, and forging stock for high-temperature service (Table 1).

1.2 The values stated in inch-pound units are to be regarded as standard. The values given in parentheses are mathematical conversions to SI units that are provided for information only and are not considered standard.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to become familiar with all hazards including those identified in the appropriate Material Safety Data Sheet (MSDS) for this product/material as provided by the manufacturer, to establish appropriate safety and health practices, and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: B637 – 06 (Reapproved 2011)

Standard Specification for

Precipitation-Hardening Nickel Alloy Bars, Forgings, and

Forging Stock for High-Temperature Service

This standard is issued under the fixed designation B637; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the Department of Defense.

1. Scope Check Analysis Limits for Nickel, Nickel Alloys and

2 Cobalt Alloys

1.1 This specification covers hot- and cold-worked

E8 Test Methods for Tension Testing of Metallic Materials

precipitation-hardenable nickel alloy rod, bar, forgings, and

E29 Practice for Using Significant Digits in Test Data to

forging stock for high-temperature service (Table 1).

Determine Conformance with Specifications

1.2 The values stated in inch-pound units are to be regarded

E139 Test Methods for Conducting Creep, Creep-Rupture,

as standard. The values given in parentheses are mathematical

and Stress-Rupture Tests of Metallic Materials

conversions to SI units that are provided for information only

E1473 Test Methods for Chemical Analysis of Nickel,

and are not considered standard.

Cobalt, and High-Temperature Alloys

1.3 This standard does not purport to address all of the

safety concerns, if any, associated with its use. It is the

3. Terminology

responsibility of the user of this standard to become familiar

3.1 Definitions:

with all hazards including those identified in the appropriate

3.1.1 bar, n—material of rectangular (flats), hexagonal,

Material Safety Data Sheet (MSDS) for this product/material

octagonal, or square solid section in straight lengths.

as provided by the manufacturer, to establish appropriate

3.1.2 rod, n—material of round solid section furnished in

safety and health practices, and determine the applicability of

straight lengths.

regulatory limitations prior to use.

4. Ordering Information

2. Referenced Documents

3 4.1 It is the responsibility of the purchaser to specify all

2.1 ASTM Standards:

requirements that are necessary for material ordered under this

B880 Specification for General Requirements for Chemical

specification. Examples of such requirements include, but are

not limited to, the following:

4.1.1 Alloy (Table 1).

This specification is under the jurisdiction of ASTM Committee B02 on

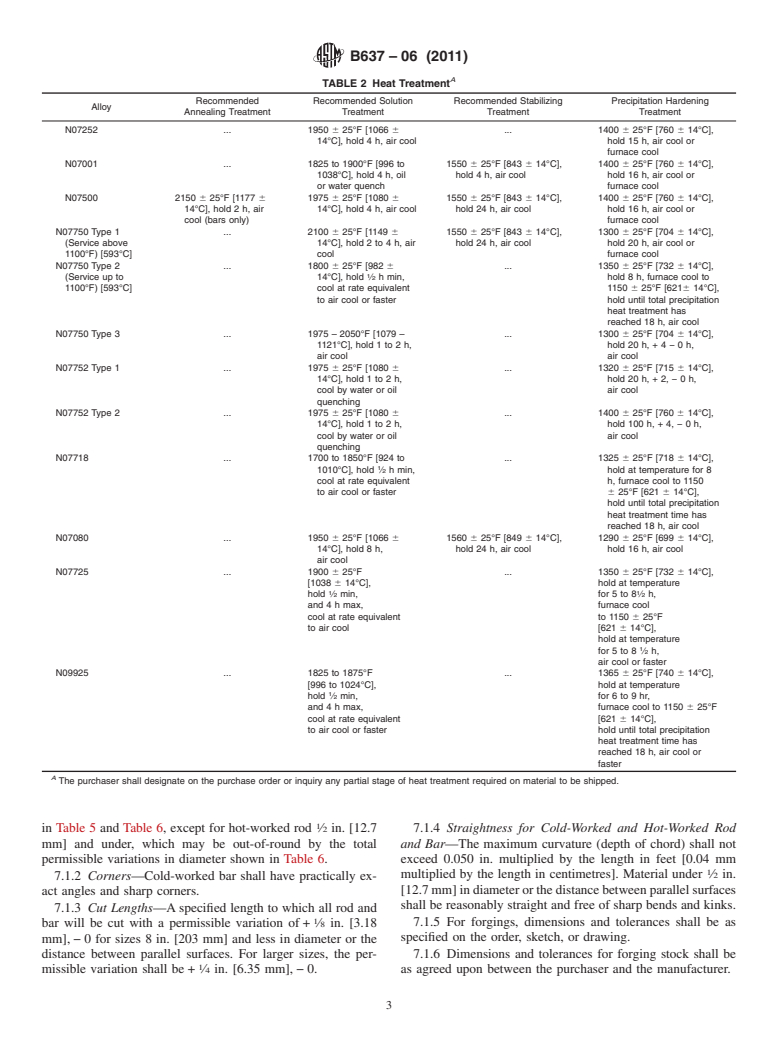

4.1.2 Condition (temper) (Table 2).

Nonferrous Metals and Alloys and is the direct responsibility of Subcommittee

B02.07 on Refined Nickel and Cobalt and Their Alloys. 4.1.3 Shape—Rod or bar (round, rectangle, square, hexa-

Current edition approved June 1, 2011. Published June 2011. Originally

gon, octagon).

´1

approved in 1970. Last previous edition addition approved in 2006 as B637–06 .

4.1.3.1 Forging (sketch or drawing).

DOI: 10.1520/B0637-06R11.

4.1.4 Dimensions, including length.

For ASME Boiler and Pressure Vessel Code applications, see related Specifi-

cation SB-637 in Section II of that Code.

4.1.5 Quantity (mass or number of pieces).

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

4.1.6 Forging Stock—Specifyifmaterialisstockforreforg-

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

ing.

Standards volume information, refer to the standard’s Document Summary page on

the ASTM website. 4.1.7 Finish.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

B637 – 06 (2011)

TABLE 1 Chemical Requirements

Element Composition Limits, %

UNS N07252 UNS N07001 UNS N07500 UNS N07750 UNS N07718

(Formerly (Formerly (Formerly (Formerly (Formerly

Grade 689) Grade 685) Grade 684) Grade 688) Grade 718)

Carbon 0.10–0.20 0.03–0.10 0.15 max 0.08 max 0.08 max

Manganese 0.50 max 1.00 max 0.75 max 1.00 max 0.35 max

Silicon 0.50 max 0.75 max 0.75 max 0.50 max 0.35 max

Phosphorus 0.015 max 0.030 max 0.015 max . 0.015 max

Sulfur 0.015 max 0.030 max 0.015 max 0.01 max 0.015 max

Chromium 18.00–20.00 18.00–21.00 15.00–20.00 14.00–17.00 17.0–21.0

A A

Cobalt 9.00–11.00 12.00–15.00 13.00–20.00 1.00 max 1.0 max

Molybdenum 9.00–10.50 3.50–5.00 3.00–5.00 . 2.80–3.30

Columbium . . . 0.70–1.20 4.75–5.50

(Nb) + tantalum

Titanium 2.25–2.75 2.75–3.25 2.50–3.25 2.25–2.75 0.65–1.15

Aluminum 0.75–1.25 1.20–1.60 2.50–3.25 0.40–1.00 0.20–0.80

Zirconium . 0.02–0.12 . . .

Boron 0.003–0.01 0.003–0.01 0.003–0.01 . 0.006 max

B

Iron 5.00 max 2.00 max 4.00 max 5.00–9.00 remainder

Copper . 0.50 max 0.15 max 0.50 max 0.30 max

B B B

Nickel remainder remainder remainder 70.00 min 50.0–55.0

UNS N07080

(Formerly UNS N07752 UNS N09925 UNS N07725

Grade 80A)

Carbon 0.10 max 0.020–0.060 0.03 max 0.03 max

Manganese 1.00 max 1.00 max 1.0 max 0.35 max

Silicon 1.00 max 0.50 max 0.5 max 0.20 max

Phosphorus . 0.008 max 0.03 max 0.015 max

Sulfur 0.015 max 0.003 max 0.03 max 0.010 max

Chromium 18.00–21.00 14.50–17.00 19.5–22.5† 19.00–22.50†

Cobalt . 0.050 max . .

Molybdenum . . 2.5–3.5 7.00–9.50

Columbium . 0.70–1.20 0.5 max (Nb only) 2.75–4.00

(Nb) + tantalum

Titanium 1.80–2.70 2.25–2.75 1.9–2.40 1.00–1.70

Aluminum 0.50–1.80 0.40–1.00 0.1–0.5 0.35 max

Boron . 0.007 max . .

B

Iron 3.00 max 5.00–9.00 22.0 min remainder

Copper . 0.50 max 1.5–3.0 .

Zirconium . 0.050 max . .

Vanadium . 70.0 min . .

B

Nickel remainder 70.0 min 42.0–46.0 55.0–59.0

A

If determined.

B

The element shall be determined arithmetically by difference.

† Chromium content was corrected editorially.

4.1.8 Certification—State if certification is required (Sec- 6.2 Thesolutiontreatedmaterialshallbecapableofmeeting

tion 15). themechanicalpropertyrequirementsofTable3,andthestress

4.1.9 Samples for Product (Check) Analysis—Whether rupture requirements of Table 4 (except alloys UNS N09925

samples for product (check) analysis shall be furnished (9.2). and N07725), following the precipitation hardening treatment

4.1.10 Purchaser Inspection—If the purchaser wishes to described in Table 2.

witness tests or inspection of material at the place of manu- 6.3 When the material is to be supplied in the solution

facture, the purchase order must so state indicating which tests treated plus aged condition, the requirements of Table 3 and

or inspections are to be witnessed (Section 13). Table 4 (except alloys UNS N09925 and N07725) shall apply,

with the precipitation hardening treatment of Table 2,oras

5. Chemical Composition

agreed upon between the purchaser and the manufacturer as

5.1 The material shall conform to the requirements as to part of the purchase contract.

chemical composition prescribed in Table 1.

7. Dimensions and Permissible Variations

5.2 If a product (check) analysis is performed by the

purchaser, the material shall conform to the product (check) 7.1 Diameter, Thickness, or Width—The permissible varia-

analysis variations prescribed in Specification B880. tionsfromthespecifieddimensionsofcold-workedrodandbar

shallbeasprescribedinTable5,andofhot-workedrodandbar

6. Mechanical Properties

as prescribed in Table 6.

6.1 Unless otherwise specified, the material shall be sup- 7.1.1 Out of Round—Cold-worked and hot-worked rod, all

plied in the solution treated condition, suitable for subsequent sizes, in straight lengths, shall not be out-of-round by more

age hardening. thanonehalfthetotalpermissiblevariationsindiametershown

B637 – 06 (2011)

A

TABLE 2 Heat Treatment

Recommended Recommended Solution Recommended Stabilizing Precipitation Hardening

Alloy

Annealing Treatment Treatment Treatment Treatment

N07252 . 1950 6 25°F [1066 6 . 1400 6 25°F [760 6 14°C],

14°C], hold 4 h, air cool hold 15 h, air cool or

furnace cool

N07001 . 1825 to 1900°F [996 to 1550 6 25°F [843 6 14°C], 1400 6 25°F [760 6 14°C],

1038°C], hold 4 h, oil hold 4 h, air cool hold 16 h, air cool or

or water quench furnace cool

N07500 2150 6 25°F [1177 6 1975 6 25°F [1080 6 1550 6 25°F [843 6 14°C], 1400 6 25°F [760 6 14°C],

14°C], hold 2 h, air 14°C], hold 4 h, air cool hold 24 h, air cool hold 16 h, air cool or

cool (bars only) furnace cool

N07750 Type 1 . 2100 6 25°F [1149 6 1550 6 25°F [843 6 14°C], 1300 6 25°F [704 6 14°C],

(Service above 14°C], hold 2 to 4 h, air hold 24 h, air cool hold 20 h, air cool or

1100°F) [593°C] cool furnace cool

N07750 Type 2 . 1800 6 25°F [982 6 . 1350 6 25°F [732 6 14°C],

(Service up to 14°C], hold ⁄2 h min, hold 8 h, furnace cool to

1100°F) [593°C] cool at rate equivalent 1150 6 25°F [6216 14°C],

to air cool or faster hold until total precipitation

heat treatment has

reached 18 h, air cool

N07750 Type 3 . 1975 – 2050°F [1079 – . 1300 6 25°F [704 6 14°C],

1121°C], hold 1 to 2 h, hold20h,+4−0h,

air cool air cool

N07752 Type 1 . 1975 6 25°F [1080 6 . 1320 6 25°F [715 6 14°C],

14°C], hold 1 to 2 h, hold20h,+2, −0h,

cool by water or oil air cool

quenching

N07752 Type 2 . 1975 6 25°F [1080 6 . 1400 6 25°F [760 6 14°C],

14°C], hold 1 to 2 h, hold 100 h, + 4, − 0 h,

cool by water or oil air cool

quenching

N07718 . 1700 to 1850°F [924 to . 1325 6 25°F [718 6 14°C],

1010°C], hold ⁄2 h min, hold at temperature for 8

cool at rate equivalent h, furnace cool to 1150

to air cool or faster 6 25°F [621 6 14°C],

hold until total precipitation

heat treatment time has

reached 18 h, air cool

N07080 . 1950 6 25°F [1066 6 1560 6 25°F [849 6 14°C], 1290 6 25°F [699 6 14°C],

14°C], hold 8 h, hold 24 h, air cool hold 16 h, air cool

air cool

N07725 . 1900 6 25°F . 1350 6 25°F [732 6 14°C],

[1038 6 14°C], hold at temperature

1 1

hold ⁄2 min, for 5 to 8 ⁄2 h,

and 4 h max, furnace cool

cool at rate equivalent to 1150 6 25°F

to air cool [621 6 14°C],

hold at temperature

for 5 to 8 ⁄2 h,

air cool or faster

N09925 . 1825 to 1875°F . 1365 6 25°F [740 6 14°C],

[996 to 1024°C], hold at temperature

hold ⁄2 min, for 6 to 9 hr,

and 4 h max, furnace cool to 1150 6 25°F

cool at rate equivalent [621 6 14°C],

to air cool or faster hold until total precipitation

heat treatment time has

reached 18 h, air cool or

faster

A

The purchaser shall designate on the purchase order or inquiry any partial stage of heat treatment required on material to be shipped.

in Table 5 and Table 6, except for hot-worked rod ⁄2 in. [12.7 7.1.4 Straightness for Cold-Worked and Hot-Worked Rod

mm] and under, which may be out-of-round by the total and Bar—The maximum curvature (depth of chord) shall not

permissible variations in diameter shown in Table 6. exceed 0.050 in. multiplied by the length in feet [0.04 mm

multiplied by the length in centimetres]. Material under ⁄2 in.

7.1.2 Corners—Cold-worked bar shall have practically ex-

[12.7mm]indiameterorthedistancebetweenparallelsurfaces

act angles and sharp corners.

shall be reasonably straight and free of sharp bends and kinks.

7.1.3 Cut Lengths—Aspecified length to which all rod and

7.1.5 For forgings, dimensions and tolerances shall be as

bar will be cut with a permissible variation of+ ⁄8 in. [3.18

specified on the order, sketch, or drawing.

mm],−0 for sizes 8 in. [203 mm] and less in diameter or the

distance between parallel surfaces. For larger sizes, the per- 7.1.6 Dimensions and tolerances for forging stock shall be

missible variation shall be+ ⁄4 in. [6.35 mm],−0. as agreed upon between the purchaser and the manufacturer.

B637 – 06 (2011)

A

TABLE 3 Tensile and Hardness Requirements

Yield Elongation in

Tensile

Strength 2 in. [50 Reduction

Strength, Brinell

Alloy Heat Treatment (0.2 % mm] of Area,

min, psi Hardness

offset), min, or 4D, min, %

[MPa]

psi [MPa] min, %

N07252 solution + precipitation harden 160 000 90 000 20 18 310 min

[1100] [620]

B B

N07001 solution + stabilize + precipitation harden 160 000 110 000 15 18 310 min

[1100] [760]

N07500 (rod and anneal + solution + stabilize + precipitation harden 175 000 105 000 15 15 310 min

bar) [120] [725]

N07500 (forgings) solution + stabilize + precipitation harden 170 000 100 000 20 18 310 min

[1170] [690]

N07750 Type 1 solution at 2100°F [1149°C] + 140 000 90 000 8 . 262 min

stabilize + precipitation harden [965] [620]

C

N07750 Type 2 solution at 1800°F [982°C] + precipitation harden 170 000 115 000 18 18 302 to 363

[1170] [790]

D

N07750 Type 2 solution at 1800°F [982°C] + precipitation harden 170 000 115 000 15 15 302 to 363

E E

[1170] [790] (10) (12)

N07750 Type 3 solution anneal at 2000°F [1093°C] + precipitation 160 000 100 000 20 20 267–363,

harden [1103], min [689], min Bm

185 000 130 000 27–40, Rc

[1276], max [896], max

N07752 Type 1 solution anneal at 1975°F [1080°C] + precipitation 160 000 100 000 20 20 267 to 363,

harden [1103], min [689], min Ba

185 000 130 000 27 to 40, Rc

[1276], max [896], max

N07752 Type 2 solution anneal at 1975°F (1080°C) + precipitation 140 000 85 0000 20 20 .

harden [965] [585]

N07718 solution + precipitation harden 185 000 150 000 12 15 331 min

E E

[1275] [1034] (6) (8)

N07080 solution + stabilize + precipitation harden 135 000 90 000 20 . .

[930] [620]

N07725 solution + precipitation harden 150 000 120 000 20 35 43, Rc max

[1034] [827]

F

N09925 solution + precipitation harden 140 000 105 000 18 25 38, Rc max

[965] [724]

G

N09925 solution + precipitation harden 140 000 110 000 18 25 38, Rc max

[965] [758]

A

The supplier shall demonstrate that the material will meet fully heat-treated properties after full heat treatment in accordance with Table 2.

B

Forgings.

C

Up to 2.50 in. [63.5 mm], exclusive.

D

2.50 to 4.00 in. [63.5 to 101.6 mm], exclusive.

E 2 2

These values apply for tension specimens machined tangentially from near the center of large disk forgings over 50 in. [3225.8 mm ] in cross section or radially from

rings 3 in. [76.2 mm] or more in thickness.

F

Cold worked, solution annealed and aged, 0.625 in. [15.9 mm] to 3 in. [76.2 mm], inclusive.

G

Hot worked, solution annealed and aged, 1 in. [25.4 mm] or over.

A

TABLE 4 Stress-Rupture Requirements

Test

Stress, psi Minimum Elongation in 2 in. or 50

Alloy Heat Treatment Temperature,

B

[MPa] Hours mm (or 4D), min, %

°F [°C]

N07252 solution + precipitation harden 1500 30 000 100 10

[816] [205]

N07001 solution + stabilize + precipitation harden 1500 33 000 100 5

[816] [230]

N07500 (rod and bar) anneal + solution + stabilize + precipitation harden 1500 38 000 100 5

[816] [260]

N07500 (forgings) solution + stabilize + precipitation harden 1500 38 000 100 5

[816] [260]

N07750 Type 1 solution at 2100°F [1149°C] + stabilize + precipitation 1350 45 000 100 5 (3 if hours exceed

harden [732] [310] 136)

N07718 solution + precipitation harden 1200 100 000 23 5

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.