ASTM D2805-11(2023)

(Test Method)Standard Test Method for Hiding Power of Paints by Reflectometry

Standard Test Method for Hiding Power of Paints by Reflectometry

SIGNIFICANCE AND USE

5.1 This is a precise instrumental method giving results having an absolute physical significance without reference to a comparison paint. It should be used when maximum precision and minimum subjectivity are required, as in testing specification coatings or evaluating the hiding efficiency of pigments.

5.2 Hiding power Test Method D344 is visual instead of instrumental, and gives results that are relative to a material standard instead of absolute. It is less precise than Test Method D2805 but more closely aligned with practical painting procedures.

SCOPE

1.1 This test method covers the determination, without reference to a material paint standard, of the hiding power of air dry coatings with Y tristimulus values greater than 15 %. With appropriate modification, it can also be used to test baking finishes.

1.2 The values stated in SI units are to be regarded as standard. No other units of measurement are included in this standard.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety, health, and environmental practices and determine the applicability of regulatory limitations prior to use.

1.4 This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

General Information

Relations

Standards Content (Sample)

This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the

Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

Designation: D2805 − 11 (Reapproved 2023)

Standard Test Method for

Hiding Power of Paints by Reflectometry

This standard is issued under the fixed designation D2805; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the U.S. Department of Defense.

INTRODUCTION

Using equations derived from Kubelka-Munk turbid media theory (1-4) (see Annex A1), the

reflectance of a coating can be predicted for any film thickness from measurements made at only one.

On this basis several rapid and accurate test methods (5, 6) have been developed for determining

hiding power. In the past such test methods have been considered difficult due to complexities,

apparent and actual, in the treatment of data. The present test method has been simplified in this

respect, primarily by adapting it fully for computer calculations.

Although the use of broad-band reflectometry makes this test method theoretically valid only for

nonchromatic (white or gray) colors, good agreement has been obtained with chromatic paints as well.

This is undoubtedly because the experimental measurements are made fairly close to the hiding power

end point so that the Kubelka-Munk extrapolation and thus any associated error is relatively small.

This test method is therefore recommended without restriction as to color.

1. Scope 2. Referenced Documents

1.1 This test method covers the determination, without 2.1 ASTM Standards:

reference to a material paint standard, of the hiding power of D344 Test Method for Relative Hiding Power of Paints by

air dry coatings with Y tristimulus values greater than 15 %. the Visual Evaluation of Brushouts (Withdrawn 2018)

With appropriate modification, it can also be used to test D1475 Test Method for Density of Liquid Coatings, Inks,

baking finishes. and Related Products

D3924 Specification for Standard Environment for Condi-

1.2 The values stated in SI units are to be regarded as

tioning and Testing Paint, Varnish, Lacquer, and Related

standard. No other units of measurement are included in this

Materials

standard.

E284 Terminology of Appearance

1.3 This standard does not purport to address all of the

E1247 Practice for Detecting Fluorescence in Object-Color

safety concerns, if any, associated with its use. It is the

Specimens by Spectrophotometry

responsibility of the user of this standard to establish appro-

E1331 Test Method for Reflectance Factor and Color by

priate safety, health, and environmental practices and deter-

Spectrophotometry Using Hemispherical Geometry

mine the applicability of regulatory limitations prior to use.

E1347 Test Method for Color and Color-Difference Mea-

1.4 This international standard was developed in accor-

surement by Tristimulus Colorimetry

dance with internationally recognized principles on standard-

E1349 Test Method for Reflectance Factor and Color by

ization established in the Decision on Principles for the

Spectrophotometry Using Bidirectional (45°:0° or 0°:45°)

Development of International Standards, Guides and Recom-

Geometry

mendations issued by the World Trade Organization Technical

3. Terminology

Barriers to Trade (TBT) Committee.

3.1 Definitions—For definitions used in this test method, see

Terminology E284.

This test method is under the jurisdiction of ASTM Committee D01 on Paint

and Related Coatings, Materials, and Applications and is the direct responsibility of

Subcommittee D01.26 on Optical Properties. For referenced ASTM standards, visit the ASTM website, www.astm.org, or

Current edition approved July 1, 2023. Published August 2023. Originally contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

approved in 1969. Last previous edition approved in 2018 as D2805 – 11 (2018). Standards volume information, refer to the standard’s Document Summary page on

DOI: 10.1520/D2805-11R23. the ASTM website.

The boldface numbers in parentheses refer to the list of references at the end of The last approved version of this historical standard is referenced on

this standard. www.astm.org.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

D2805 − 11 (2023)

3.2 Definitions of Terms Specific to This Standard: 4.4 As an optional procedure the contrast ratio C at a

specified spreading rate H is calculated from R and S.

3.2.1 contrast ratio, n—the ratio of the reflectance of a film

C ∞

on a black substrate to that of an identical film on a white

5. Significance and Use

substrate.

5.1 This is a precise instrumental method giving results

3.2.1.1 C , n—the contrast ratio with a white substrate of

W

having an absolute physical significance without reference to a

reflectance W.

comparison paint. It should be used when maximum precision

Thus:C 5 R /R

W 0 W

and minimum subjectivity are required, as in testing specifica-

3.2.1.2 C, n—the contrast ratio with a white substrate for tion coatings or evaluating the hiding efficiency of pigments.

which W = 0.80.

5.2 Hiding power Test Method D344 is visual instead of

Thus:C 5 R /R instrumental, and gives results that are relative to a material

0 0.80

standard instead of absolute. It is less precise than Test Method

3.2.2 reflectance, n—the daylight luminous diffuse reflec-

D2805 but more closely aligned with practical painting proce-

tance factor (specular reflection excluded). Also referred to in

dures.

this test method as the Y-tristimulus value. This value may be

expressed as a percent or a decimal fraction, the latter being

6. Apparatus and Materials

preferred and usually required for mathematical calculations.

6.1 Substrates:

3.2.2.1 reflectivity, R , n—the reflectance of film thick

∞

6.1.1 Black Glass Panels, minimum size 200 mm by 200

enough to have the same reflectance over both a black and a

mm, and approximately 6 mm thick.

white substrate.

6.1.2 Black and White Paper Charts—The surface shall be

3.2.2.2 R , n—the reflectance of a film on a black surface

smooth and level, and impervious to paint liquids. The black

with a reflectance of 1 % or less, which is effectively zero for

area shall have a maximum reflectance of 1 % and the white

the purpose of this test.

area a minimum reflectance of 78 %. The white area shall be

non-fluorescent, as observed visually under ultra-violet

3.2.2.3 W, n—the reflectance of a white substrate.

illumination, or determined in accordance with Practice E1247.

3.2.2.4 R , n—the reflectance of a film applied on a white

W

6.2 Balance, accurate to 0.1 mg.

substrate of reflectance W.

6.3 Glass Slides—Round or square plates of thickness

3.2.2.5 R , n—the reflectance of a film applied on a

0.80

similar to that used for microscope specimen slides, with a

substrate having a reflectance of 80 %, which is the standard

minimum area of 40 cm .

white-substrate reflectance in paint technology.

6.4 Reflectance-Measuring Instrument —One that allows

3.2.3 scattering coeffıcient, S, n—the ability of a material to

only diffusely reflected, radiant flux to be incident upon the

internally scatter and thereby reflect light; expressed in this test

measuring element. It shall employ a photometric system,

method in the same units as spreading rate.

including source, filters, and receptor, that provides a response

3.2.4 spreading rate, H, n—film area per unit volume of

closely similar to the product of the spectral luminous effi-

coating, in this test method expressed in square metres per litre

ciency function of the CIE standard observer and source C. It

(m /L).

shall provide readings to at least the third decimal place and

3.2.4.1 spreading rate, H , n—an experimentally deter- permit estimation to the fourth.

X

mined value of H. 6 2

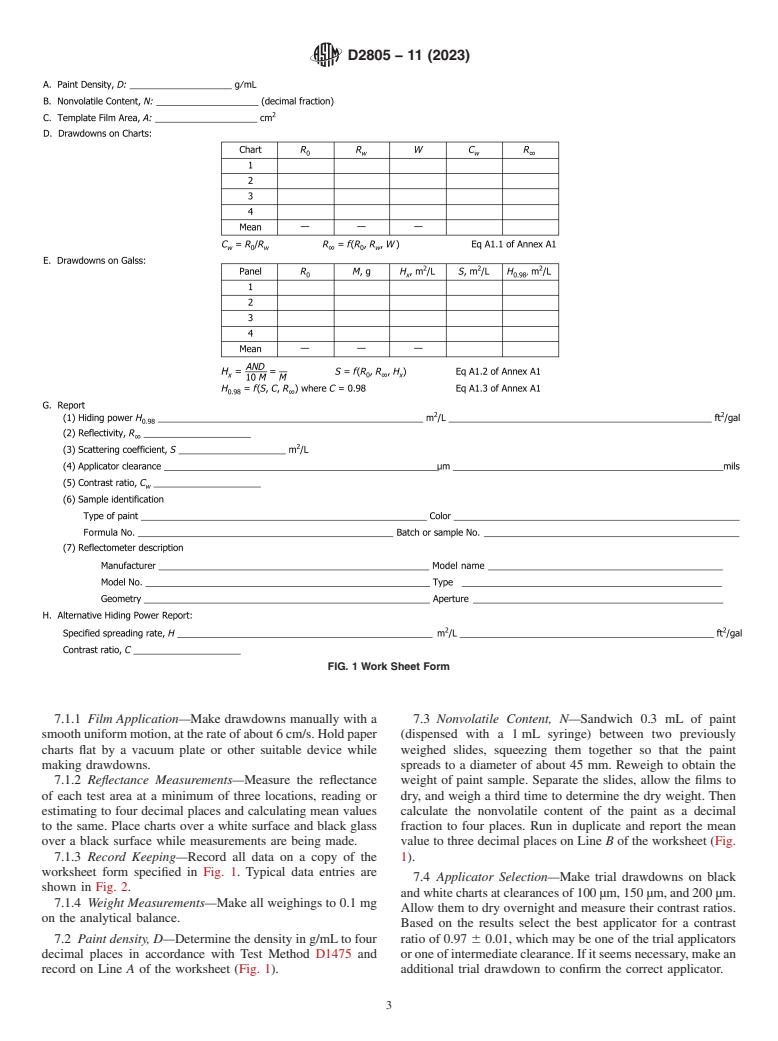

6.5 Template, with a film area approximately 100 cm

3.2.4.2 spreading rate, H , n—value of H at a specified determined to the nearest tenth. Record the exact value on Line

C

C of the worksheet shown in Fig. 1.

contrast ratio C.

3.2.4.3 hiding power, H , n—the spreading rate at the 6.6 Doctor Blade Film Applicators, width 150 mm, clear-

0.98

ances 50 μm, 75 μm, 100 μm, 125 μm, 150 μm, 175 μm, and

contrast ratio C = 0.98.

200 μm.

NOTE 1—It should be emphasized that a contrast ratio of 0.98 does not

6.7 Computer and Software, for solving the relevant

represent visually complete hiding, nor does it indicate that the same

contrast ratio holds at every wavelength.

Kubelka-Munk equations.

7. Procedure

4. Summary of Test Method

7.1 General Instructions:

4.1 The reflectivity R of the coating is determined from

∞

reflectance measurements on black and white hiding power

charts.

Conforming with Test Methods E1331, E1347, or E1349. Other methods for

measuring the CIE-Y tristimulus value (specular reflection excluded) are permis-

4.2 The scattering coefficient S of the coating is determined

sible.

from R , and the reflectance R and spreading rate H of a film

∞ 0 X

The sole source of supply of the template known to the committee at this time

applied on black glass.

is Paul Gardner Co., 316 N. E. First St., Pompano Beach, FL 33061. If you are aware

of alternative suppliers, please provide this information to ASTM International

4.3 The hiding power, H of the coating is calculated

0.98 Headquarters. Your comments will receive careful consideration at a meeting of the

from the reflectivity R and the scattering coefficient S. responsible technical committee, which you may attend.

∞

D2805 − 11 (2023)

FIG. 1 Work Sheet Form

7.1.1 Film Application—Make drawdowns manually with a 7.3 Nonvolatile Content, N—Sandwich 0.3 mL of paint

smooth uniform motion, at the rate of about 6 cm/s. Hold paper (dispensed with a 1 mL syringe) between two previously

charts flat by a vacuum plate or other suitable device while weighed slides, squeezing them together so that the paint

making drawdowns. spreads to a diameter of about 45 mm. Reweigh to obtain the

7.1.2 Reflectance Measurements—Measure the reflectance weight

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.