ASTM B904-00(2021)

(Specification)Standard Specification for Autocatalytic Nickel over Autocatalytic Copper for Electromagnetic Interference Shielding

Standard Specification for Autocatalytic Nickel over Autocatalytic Copper for Electromagnetic Interference Shielding

ABSTRACT

This specification covers the requirements for multilayer coatings of autocatalytic nickel-phosphorus over autocatalytic copper intended for electromagnetic interference or electrostatic discharge shielding to parts fabricated from either polymeric or metallic substrates or parts. Coatings are classified into four types based on thickness and testing requirements, and into two grades based on alloy composition, specifically phosphorus. Surfaces shall be prepared by cleaning it of surface contaminants, conditioning, and activation; identifying of base material suitability; and mechanical roughening. Coatings shouldl be inspected for process qualification, appearance, blisters, unplated areas, adhesion, electrical continuity, and DC resistance. Coatings should also be tested for thickness, which may be performed either by Coulometric, X-ray, or Beta backscatter methods. The requirements for process qualification shall include coating composition, electrical integrity, adhesion, thermal shock resistance, thermal cycling, and shielding effectiveness.

SCOPE

1.1 This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

General Information

Relations

Standards Content (Sample)

This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the

Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

Designation:B904 −00 (Reapproved 2021)

Standard Specification for

Autocatalytic Nickel over Autocatalytic Copper for

Electromagnetic Interference Shielding

This standard is issued under the fixed designation B904; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope B504 Test Method for Measurement of Thickness of Metal-

This specification presents the requirements for multilayer lic Coatings by the Coulometric Method

coatings of autocatalytic nickel-phosphorus over autocata- B532 Specification for Appearance of Electroplated Plastic

lytic copper on metallic and polymeric substrates. The coat- Surfaces

ing system is intended to provide electromagnetic interfer- B533 Test Method for Peel Strength of Metal Electroplated

ence (EMI) protection properties or electrostatic discharge Plastics

(ESD) protection to parts fabricated from either polymeric or B553 Test Method for Thermal Cycling of Electroplated

metallic materials. Plastics (Withdrawn 1991)

B554 Practice for Measurement of Thickness of Metallic

1.1 This international standard was developed in accor-

Coatings on Nonmetallic Substrates (Withdrawn 1987)

dance with internationally recognized principles on standard-

B567 Test Method for Measurement of Coating Thickness

ization established in the Decision on Principles for the

by the Beta Backscatter Method

Development of International Standards, Guides and Recom-

B568 Test Method for Measurement of Coating Thickness

mendations issued by the World Trade Organization Technical

by X-Ray Spectrometry

Barriers to Trade (TBT) Committee.

B602 Test Method for Attribute Sampling of Metallic and

Inorganic Coatings

2. Referenced Documents

B697 Guide for Selection of Sampling Plans for Inspection

2.1 ASTM Standards:

of Electrodeposited Metallic and Inorganic Coatings

A919 Terminology Relating to Heat Treatment of Metals

B727 Practice for Preparation of Plastics Materials for Elec-

(Withdrawn 1999)

troplating

B183 Practice for Preparation of Low-Carbon Steel for

B733 Specification for Autocatalytic (Electroless) Nickel-

Electroplating

Phosphorus Coatings on Metal

B242 Guide for Preparation of High-Carbon Steel for Elec-

D3330/D3330M TestMethodforPeelAdhesionofPressure-

troplating

Sensitive Tape

B252 Guide for Preparation of Zinc Alloy Die Castings for

D3359 Test Methods for Rating Adhesion by Tape Test

Electroplating and Conversion Coatings

D4935 Test Method for Measuring the Electromagnetic

B253 Guide for Preparation of Aluminum Alloys for Elec-

Shielding Effectiveness of Planar Materials

troplating

2.2 Military Standard:

B320 Practice for Preparation of Iron Castings for Electro-

MIL-STD-461 Electromagnetic Emission and Susceptibility

plating

Requirements for the Control of Electromagnetic Interfer-

B322 Guide for Cleaning Metals Prior to Electroplating

ence

B374 Terminology Relating to Electroplating

3. Terminology

This specification is under the jurisdiction of ASTM Committee B08 on

3.1 Definitions—Many of the terms used in this specifica-

Metallic and Inorganic Coatings and is the direct responsibility of Subcommittee

tion can be found in Terminologies A919 or B374.

B08.03 on Engineering Coatings.

Current edition approved April 1, 2021. Published May 2021. Originally

3.2 Definitions of Terms Specific to This Standard:

approvedin2000.Lastpreviouseditionapprovedin2014asB904 – 00(2014).DOI:

3.2.1 significant surfaces, n—these surfaces are classified as

10.1520/B0904-00R21.

primary, secondary, nonsignificant, and coating-free surfaces.

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

Standards volume information, refer to the standard’s Document Summary page on

the ASTM website.

3 4

The last approved version of this historical standard is referenced on AvailablefromStandardizationDocumentsOrderDesk,Bldg.4SectionD,700

www.astm.org. Robbins Ave. Philadelphia, PA 19111–5094, Attn: NPODS.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

B904−00 (2021)

3.2.1.1 coating-free areas, adj—areas specified on part 4.3.3 Grade 1 coatings have a phosphorus content between

drawings or suitably marked samples. 3 and 5 %.

3.2.1.2 nonsignificant surfaces, adj—all holes, recesses, and

NOTE 2—Low phosphorus coatings exhibit low electrical contact

other areas where a controlled deposit cannot be obtained impedance. High phosphorus contents exhibit somewhat higher contact

impedance, however, the coating is more corrosion resistant.

under normal coating conditions and that cannot be touched

with a 20-mm diameter ball shall be considered nonsignificant

4.3.4 Grade 2 coatings have a phosphorus content between

surfacesunlessotherwisespecifiedonpartdrawingsorsuitably

6 and 11 %.

marked samples.

NOTE 3—The adhesion and resistance to blistering are improved on

3.2.1.3 primary significant surface, adj—all mating surfaces

some polymeric substrates by an initial flash deposit of autocatalytic

nickel.

and those other surfaces specified on part drawings or suitably

marked samples.

5. Ordering Information

3.2.1.4 secondary significant surfaces, adj—all surfaces,

5.1 To avoid misunderstanding between contractual parties,

other than primary significant surfaces, that can be touched

purchase orders or contracts for autocatalytic nickel over

with a 20-mm diameter ball shall be considered secondary

autocatalytic copper coatings under this specification should

significantsurfacesunlessotherwisespecifiedonpartdrawings

include the designation, issue date, and the following informa-

or suitably marked samples.

tion:

4. Classification 5.1.1 Type of substrate.

5.1.1.1 Metallic substrates should state the composition and

4.1 This classification system provides for the following:

metallurgical condition. Assemblies of dissimilar materials

4.1.1 Types of coating based on thickness and testing

should be identified.

requirements, and

5.1.1.2 Polymeric substrates should state the polymer type

4.1.2 Grades of coating based on alloy composition.

and should be of a plating grade.

4.2 Coating Type:

5.1.2 Classification of the deposit by type and grade.

4.2.1 The coating type indicates the type of application and

5.1.3 Primary significant surfaces and coating-free surfaces

tests to be used in determining the acceptance of the coating.

must be indicated on drawings.

4.2.2 Coating Type Definitions:

5.1.4 Any special requirements.

4.2.2.1 Type 1—Coatings intended to shield devices for

5.1.5 Testmethodsforcoatingadhesion,thickness,porosity.

FCC/VDE Class B service.

5.1.6 Sampling program.

4.2.2.2 Type 2—Coatings intended to shield devices for

FCC/VDE Class B service in harsh environments.

6. Surface Preparation

4.2.2.3 Type 3—Coatings intended to shield devices for

6.1 Surface Contamination—Surfaces of polymeric parts

MIL-STD-461 requirements.

must be free of all mold release agents, dirt, oil, grease, and

4.2.2.4 Type 4—Coatings intended to shield devices for

contamination detrimental to the final finish. Surfaces of

FCC/VDE Class A requirements.

metallic parts must be free of all scale, oxidation, and contami-

4.2.3 The description of Types 1, 2, 3, and 4 is summarized

nation detrimental to the final finish. A clean surface is

in Table 1.

essential to the adhesion and electrical conductivity require-

4.3 Coating Grade:

ments of the subsequent coated part.

4.3.1 The coating grade is based upon phosphorus content.

6.2 Cleaning, Conditioning, and Activating—Any adequate

NOTE 1—The coating grade indicates the relative contact impedance

method of cleaning, conditioning, and activating is acceptable

and the relative corrosion resistance of the nickel-phosphorus coating and

provided the coated parts meet the inspection requirements and

tests to be used in determining the acceptance of the coating

are free of distortion. Examples of adequate methods of

4.3.2 Coating Grade Definitions:

cleaning can be found in 10.2.

6.2.1 BaseMaterialSuitability—Thepartstobecoatedshall

be inspected by the coater prior to any processing to determine

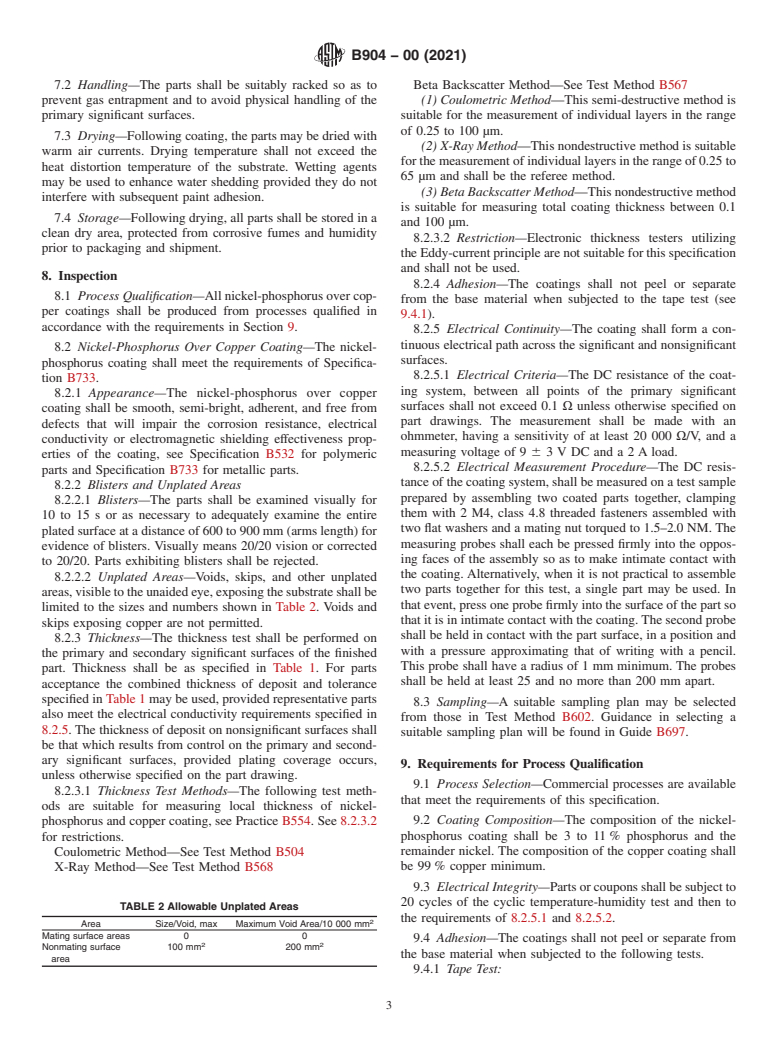

TABLE 1 Autocatalytic Nickel-Phosphorus Over Autocatalytic

their suitability for coating. Unsuitable parts shall be returned

Copper Coating Descriptions Summary

to the fabricator or molder.

Type Thickness Shielding Application

Autocatalytic Autocatalytic Effectiveness

6.3 Mechanical Roughening—Mechanical roughening of

Copper Nickel- (Typical) in

polymersurfaces,topromoteadhesion,mayonlybeusedwhen

Phosphorus accordance with

Test Method

specified on the part drawing.

D4935

1 1 µm min 0.25 µm min 80-100 dB FCC/VDE

7. In-Process Storage and Handling

Class B

2 1 µm min 1.5 µm min 80-100 dB Harsh Envi-

7.1 Following cleaning, conditioning, and activating, all

ronment

3 2.5 µm min 0.25 µm min 90-110 dB MIL-STD- parts shall be immediately coated with copper and then

461B

nickel-phosphorus to the thickness specified in Table 1. The

4 Optional/Not re- 1.0 µm min 50-70 dB FCC/VDE

parts processing cycle shall be a continuous operation without

quired Class A

any interruption.

B904−00 (2021)

7.2 Handling—The parts shall be suitably racked so as to Beta Backscatter Method—See Test Method B567

prevent gas entrapment and to avoid physical handling of the (1) Coulometric Method—This semi-destructive method is

primary significant surfaces. suitable for the measurement of individual layers in the range

of 0.25 to 100 µm.

7.3 Drying—Following coating, the parts may be dried with

(2) X-Ray M

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.