ASTM D7194-19(2024)

(Specification)Standard Specification for Aerospace Parts Machined from Polychlorotrifluoroethylene (PCTFE)

Standard Specification for Aerospace Parts Machined from Polychlorotrifluoroethylene (PCTFE)

ABSTRACT

This specification establishes the requirements for parts intended for aerospace use and machined from polychlorotrifluoroethylene (PCTFE) homopolymers. This specification, however, does not cover parts machined from PCTFE copolymer, PCTFE film or tape, or modified PCTFE. Material covered by this specification is on four types, differentiated based on intended uses and exposures: Types I (high service pressure) and II (low service pressure) for use in air and oxygen media, Type II for use in inert and reactive media, and Type IV for use in other media. The parts shall be manufactured from virgin, unplasticized, pure PCTFE homopolymer, and the use of recycled polymer or regrind shall be prohibited. The base material shall be free of defects and contaminants. The finished parts shall be white or gray in color with a natural translucent appearance, and shall be free of voids, scratches, fissures, inclusions, or entrapped air bubbles. Tests for specific gravity, melting point, tensile strength and elongation, deformation under load, zero strength time, mechanical impact (in ambient liquid oxygen and pressurized liquid and gaseous oxygen environments), and dimensional stability shall be performed and shall conform to the requirements specified.

SCOPE

1.1 This specification is intended to be a means of calling out finished machined parts ready for aerospace use. Such parts may also find use in selected commercial applications where there are clear benefits derived from the use of parts with high molecular weight, good molecular weight retention during processing, dimensional stability, controlled crystallinity, and tightly controlled engineering tolerances.

1.2 This specification establishes requirements for parts machined from virgin, unplasticized, 100 % polychlorotrifluoroethylene (PCTFE) homopolymers.

1.3 This specification does not cover parts machined from PCTFE copolymers, PCTFE film or tape less than 0.25-mm (0.010-in.) thick, or modified PCTFE (containing pigments or plasticizers).

1.4 This specification does not allow parts containing recycled material.

1.5 The specification does not cover PCTFE parts intended for general use applications, in which control of dimensional stability, molecular weight, and crystallinity are not as important. For machined PCTFE parts intended for general use, use Specification D7211.

1.6 This specification classifies parts into three classes based upon intended uses and exposures: oxygen-containing media, reactive media, and inert media.

1.7 Application—PCTFE components covered by this specification are virgin, 100 % PCTFE resin, free of plasticizers and other additives. The components are combustion resistant in oxygen, dimensionally stable, and meet other specific physical characteristics appropriate for their end use. They are used in valves, regulators, and other devices in oxygen, air, helium, nitrogen, hydrogen, ammonia, and other aerospace media systems. The components typically are used as valve seats, o-rings, seals, and gaskets. They are removed and replaced during normal maintenance procedures. The components provide reliable sealing surfaces resulting in proper closure of valves and related devices and no leakage from the system into the environment. They will experience static mechanical loading, cyclic mechanical loading, temperatures ranging from cryogenic to 71°C (160°F), and pressures up to 68.9 MPa (10,000, psig) for oxygen and air media, and 103.4 MPa (15,000 psig) for inert media.

1.8 The values stated in SI units are to be regarded as standard. The values in parentheses are for information only.

1.9 The following precautionary caveat pertains only to the test methods portion, Section 13, of this specification: This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety, health, and environmental pra...

General Information

Relations

Standards Content (Sample)

This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the

Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

Designation: D7194 − 19 (Reapproved 2024)

Standard Specification for

Aerospace Parts Machined from Polychlorotrifluoroethylene

(PCTFE)

This standard is issued under the fixed designation D7194; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope during normal maintenance procedures. The components pro-

vide reliable sealing surfaces resulting in proper closure of

1.1 This specification is intended to be a means of calling

valves and related devices and no leakage from the system into

out finished machined parts ready for aerospace use. Such parts

the environment. They will experience static mechanical

may also find use in selected commercial applications where

loading, cyclic mechanical loading, temperatures ranging from

there are clear benefits derived from the use of parts with high

cryogenic to 71°C (160°F), and pressures up to 68.9 MPa

molecular weight, good molecular weight retention during

(10,000, psig) for oxygen and air media, and 103.4 MPa

processing, dimensional stability, controlled crystallinity, and

(15,000 psig) for inert media.

tightly controlled engineering tolerances.

1.8 The values stated in SI units are to be regarded as

1.2 This specification establishes requirements for parts

standard. The values in parentheses are for information only.

machined from virgin, unplasticized, 100 % polychlorotrifluo-

1.9 The following precautionary caveat pertains only to the

roethylene (PCTFE) homopolymers.

test methods portion, Section 13, of this specification: This

1.3 This specification does not cover parts machined from

standard does not purport to address all of the safety concerns,

PCTFE copolymers, PCTFE film or tape less than 0.25-mm

if any, associated with its use. It is the responsibility of the user

(0.010-in.) thick, or modified PCTFE (containing pigments or

of this standard to establish appropriate safety, health, and

plasticizers).

environmental practices and determine the applicability of

1.4 This specification does not allow parts containing re-

regulatory limitations prior to use.

cycled material.

NOTE 1—There is no known ISO equivalent to this standard.

1.5 The specification does not cover PCTFE parts intended

1.10 This international standard was developed in accor-

for general use applications, in which control of dimensional

dance with internationally recognized principles on standard-

stability, molecular weight, and crystallinity are not as impor-

ization established in the Decision on Principles for the

tant. For machined PCTFE parts intended for general use, use

Development of International Standards, Guides and Recom-

Specification D7211.

mendations issued by the World Trade Organization Technical

1.6 This specification classifies parts into three classes

Barriers to Trade (TBT) Committee.

based upon intended uses and exposures: oxygen-containing

2. Referenced Documents

media, reactive media, and inert media.

2.1 ASTM Standards:

1.7 Application—PCTFE components covered by this speci-

D618 Practice for Conditioning Plastics for Testing

fication are virgin, 100 % PCTFE resin, free of plasticizers and

D638 Test Method for Tensile Properties of Plastics

other additives. The components are combustion resistant in

D792 Test Methods for Density and Specific Gravity (Rela-

oxygen, dimensionally stable, and meet other specific physical

tive Density) of Plastics by Displacement

characteristics appropriate for their end use. They are used in

D883 Terminology Relating to Plastics

valves, regulators, and other devices in oxygen, air, helium,

D1204 Test Method for Linear Dimensional Changes of

nitrogen, hydrogen, ammonia, and other aerospace media

Nonrigid Thermoplastic Sheeting or Film at Elevated

systems. The components typically are used as valve seats,

Temperature

o-rings, seals, and gaskets. They are removed and replaced

D1430 Classification System for Polychlorotrifluoroethylene

(PCTFE) Plastics

This specification is under the jurisdiction of ASTM Committee D20 on

Plastics and is the direct responsibility of Subcommittee D20.15 on Thermoplastic

Materials. For referenced ASTM standards, visit the ASTM website, www.astm.org, or

Current edition approved April 1, 2024. Published April 2024. Originally contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

approved in 2005. Last previous edition approved in 2019 as D7194 - 19. DOI: Standards volume information, refer to the standard’s Document Summary page on

10.1520/D7194-19R24. the ASTM website.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

D7194 − 19 (2024)

D1600 Terminology for Abbreviated Terms Relating to Plas- molecular weight retention during molding, whereby as-

tics (Withdrawn 2024) polymerized resin, typically powder or coarse granular

D1708 Test Method for Tensile Properties of Plastics by Use material, is thermoformed into semi-finished rod or sheet stock,

of Microtensile Specimens typically by extrusion or compression molding.

D2512 Test Method for Compatibility of Materials with

4.2 Given the relatively low glass transition temperature of

Liquid Oxygen (Impact Sensitivity Threshold and Pass-

PCTFE (T ≈ 55°C (130°F)), the second intention of this

g

Fail Techniques) (Withdrawn 2023)

specification is to ensure good dimensional stability of finished

D3045 Practice for Heat Aging of Plastics Without Load

articles subjected to temperature excursions during service that

D4591 Test Method for Determining Temperatures and

approach or exceed the T .

g

Heats of Transitions of Fluoropolymers by Differential

4.3 Because the crystallinity can vary widely in PCTFE,

Scanning Calorimetry

which in turn can affect the performance of a finished PCTFE

D7211 Specification for Parts Machined from Polychlorotri-

part in its intended application, nonmandatory guidance is

fluoroethylene (PCTFE) and Intended for General Use

given in Appendix X1. This guidance cites recommended

G86 Test Method for Determining Ignition Sensitivity of

ASTM Test Methods that measure the specific gravity

Materials to Mechanical Impact in Ambient Liquid Oxy-

(X1.1.4), melting point (X1.1.5), and tensile properties

gen and Pressurized Liquid and Gaseous Oxygen Envi-

(X1.1.6) of PCTFE. Control of these properties is used to

ronments

established consistency between different lots of finished parts

2.2 Federal Standards

where either the starting resin, molding method, thickness of

NASA-STD-6001B Flammability, Offgassing, and Compat-

the semifinished article, or machining method change.

ibility Requirements and Test Procedures—Mechanical

Impact for Materials in Ambient Pressure LOX (Test 13A) 4.4 Finished parts are categorized based on whether anneal-

and Mechanical Impact for Materials in Variable Pressure

ing of the finished parts is not performed (Method A), or is

GOX and LOX (Test 13B) performed (Methods B and C), depending on the dimensional

stability of a statistical sample of unannealed finished parts.

3. Terminology

5. Classification

3.1 Definitions:

3.1.1 Terms are defined in accordance with Terminologies

5.1 Part shape and size shall be defined by the applicable

D883 and D1600 unless otherwise indicated.

purchase order.

3.1.2 air media, n—liquid air, pressurized air, and breathing

5.2 The type of product shall be categorized by the intended

air.

use category:

3.1.3 cognizant engineering organization, n—the company,

5.2.1 Type I for use in air and oxygen media (see 3.1.2 and

agency, or other authority responsible for the system or

3.1.5) at service pressures above 11.4 MPa (1650 psi) that

component in which aerospace grade PCTFE is used. This, in

require batch testing.

addition to design personnel, may include personnel from

5.2.2 Type II for use in (1) air and oxygen media (at service

material and process engineering, or quality groups and others

pressures below 11.4 MPa (1650 psi), or at service pressures

as appropriate.

above 11.4 MPa (1650 psi) that do not require batch testing);

or (2) inert and reactive media up to the pressures specified in

3.1.4 inert media, n—gaseous helium (GHe) and gaseous

nitrogen (GN ) up to 103.4 MPa (15,000 psig). 3.1.4 and 3.1.7.

5.2.3 Type III for use in media other than air, oxygen, GHe,

3.1.5 oxygen media, n—liquid oxygen (LOX) and gaseous

GN , ammonia, GH and LH , at service pressures specified by

2 2 2

oxygen (GOX) up to 68.9 MPa (10,000 psig).

the cognizant engineering organization.

3.1.6 processing route, n—the method whereby a thermo-

plastic is taken above its melting point and processed into a

6. Ordering Information

semifinished article, typically sheet or rod stock. For PCTFE,

6.1 All parts covered by this specification shall be ordered

the common processing methods are extrusion and compres-

by Specification D7194, Type, as listed in Section 5, or as listed

sion molding.

on the purchase contract or order when Type is not specified

3.1.7 reactive media, n—ammonia (NH ) up to 3.5 MPa

explicitly.

(500 psig), gaseous hydrogen (GH ) up to 46.2 MPa (6700

psig), and liquid hydrogen (LH ) up to 2.8 MPa (400 psig). 7. Apparatus

7.1 Oven—A convection oven capable of maintaining a

4. Significance and Use

temperature of 100 to 200 6 2°C.

4.1 Given the thermal instability of PCTFE in the melt, the

primary intention of this specification is to ensure adequate

8. Materials and Manufacture

8.1 Parts shall be made from as-polymerized resin meeting

The last approved version of this historical standard is referenced on

all requirements of Classification System D1430. Type I, II and

www.astm.org.

III parts shall be fabricated from as-polymerized resin classi-

Available from U.S. Government Printing Office, Superintendent of

fied as meeting Classification System D1430, Group 01, Class

Documents, 732 N. Capitol St., NW, Washington, DC 20401-0001, http://

www.access.gpo.gov. 1, Grade 3.

D7194 − 19 (2024)

8.2 Parts shall be made from virgin, unplasticized, 100 % ity of PCTFE semi-finished articles and parts machined there-

polychlorotrifluoroethylene (PCTFE) homopolymer. from subject to this specification, refer to Nonmandatory

Appendix X1.

8.3 No recycled polymer or regrind shall be permitted.

8.4 The base material shall be free of all defects or con-

11. Specific Requirements

taminants that would be detrimental to final fabrication or

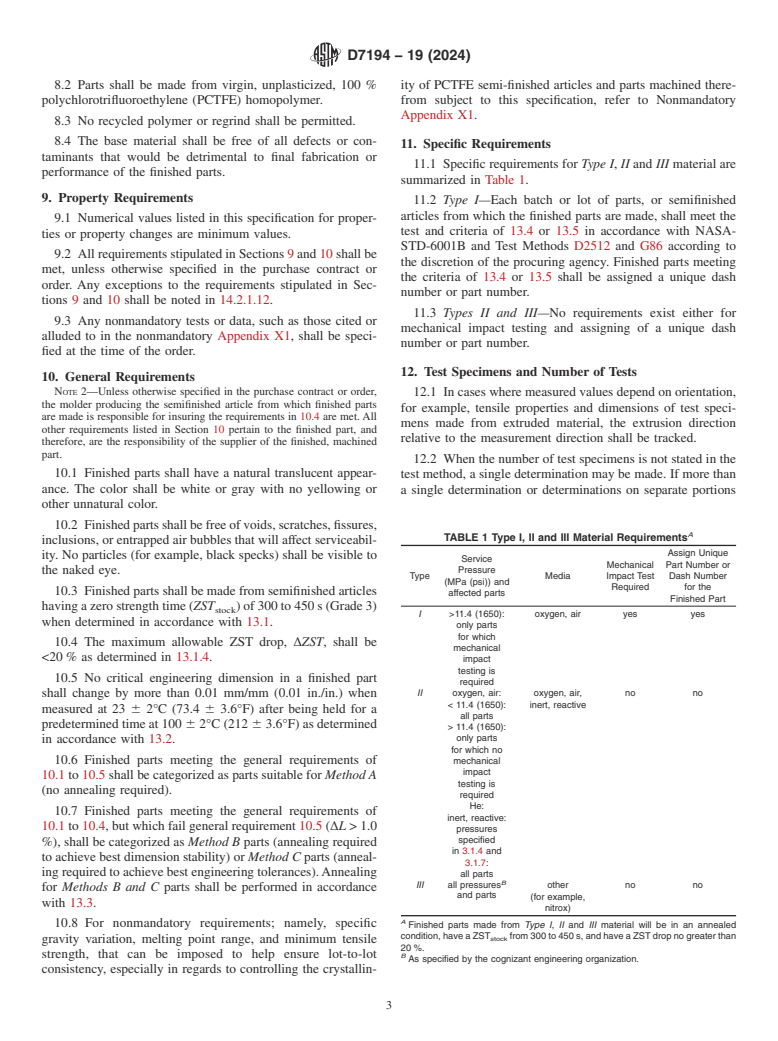

11.1 Specific requirements for Type I, II and III material are

performance of the finished parts.

summarized in Table 1.

9. Property Requirements

11.2 Type I—Each batch or lot of parts, or semifinished

articles from which the finished parts are made, shall meet the

9.1 Numerical values listed in this specification for proper-

test and criteria of 13.4 or 13.5 in accordance with NASA-

ties or property changes are minimum values.

STD-6001B and Test Methods D2512 and G86 according to

9.2 All requirements stipulated in Sections 9 and 10 shall be

the discretion of the procuring agency. Finished parts meeting

met, unless otherwise specified in the purchase contract or

the criteria of 13.4 or 13.5 shall be assigned a unique dash

order. Any exceptions to the requirements stipulated in Sec-

number or part number.

tions 9 and 10 shall be noted in 14.2.1.12.

11.3 Types II and III—No requirements exist either for

9.3 Any nonmandatory tests or data, such as those cited or

mechanical impact testing and assigning of a unique dash

alluded to in the nonmandatory Appendix X1, shall be speci-

number or part number.

fied at the time of the order.

12. Test Specimens and Number of Tests

10. General Requirements

NOTE 2—Unless otherwise specified in the purchase contract or order,

12.1 In cases where measured values depend on orientation,

the molder producing the semifinished article from which finished parts

for example, tensile properties and dimensions of test speci-

are made is responsible for insuring the requirements in 10.4 are met. All

mens made from extruded material, the extrusion direction

other requirements listed in Section 10 pertain to the finished part, and

relative to the measurement direction shall be tracked.

therefore, are the responsibility of the supplier of the finished, machined

part.

12.2 When the number of test specimens is not stated in the

10.1 Finished parts shall have a natural translucent appear-

test method, a single determination may be made. If more than

ance. The color shall be white or gray with no yellowing or

a single determination or determinations on separate portions

other unnatural color.

10.2 Finished parts shall be free of voids, scratches, fissures,

A

TABLE 1 Type I, II and III Material Requirements

inclusions, or entrapped air bubbles that will affect serviceabil-

Assign Unique

ity. No particles (for example, black specks) shall be visible to

Service

Mechanical Part Number or

Pressure

the naked eye.

Type Media Impact Test Dash Number

(MPa (psi)) and

Required for the

10.3 Finished parts shall be made from semifinished articles

affected parts

Finished Part

having a zero strength time (ZST ) of 300 to 450 s (Grade 3)

stock

I >11.4 (1650): oxygen, air yes yes

when determined in accordance with 13.1.

only parts

for which

10.4 The maximum allowable ZST drop, ∆ZST, shall be

mechanical

<20 % as determined in 13.1.4.

impact

testing is

10.5 No critical engineering dimension in a finished part

required

II oxygen, air: oxygen, air, no no

shall change by more than 0.01 mm/mm (0.01 in./in.) when

< 11.4 (1650): inert, reactive

measured at 23 6 2°C (73.4 6 3.6°F) after being held for a

all parts

predetermined time at 100 6 2°C (212 6 3.6°F) as determined

> 11.4 (1650):

only parts

in accordance with 13.2.

for which no

10.6 Finished parts meeting the general requirements of mechanical

impact

10.1 to 10.5 shall be categorized as parts suitable for Method A

testing is

(no annealing required).

required

He:

10.7 Finished parts meeting the general requirements of

inert, reactive:

10.1 to 10.4, but which fail general requirement 10.5 (∆L > 1.0

pressures

specified

%), shall be categorized as Method B parts (annealing required

in 3.1.4 and

to achieve best dimension stability) or Method C parts (anneal-

3.1.7:

ing required to achieve best engineering tolerances). Annealing

all parts

B

III all pressures other no no

for Methods B and C parts shall be performed in accordance

and parts

(for example,

with 13.3.

nitrox)

A

10.8 For nonmandatory requirements; namely, specific Finished parts made from Type

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.