ASTM E431-96(2022)

(Guide)Standard Guide to Interpretation of Radiographs of Semiconductors and Related Devices

Standard Guide to Interpretation of Radiographs of Semiconductors and Related Devices

SIGNIFICANCE AND USE

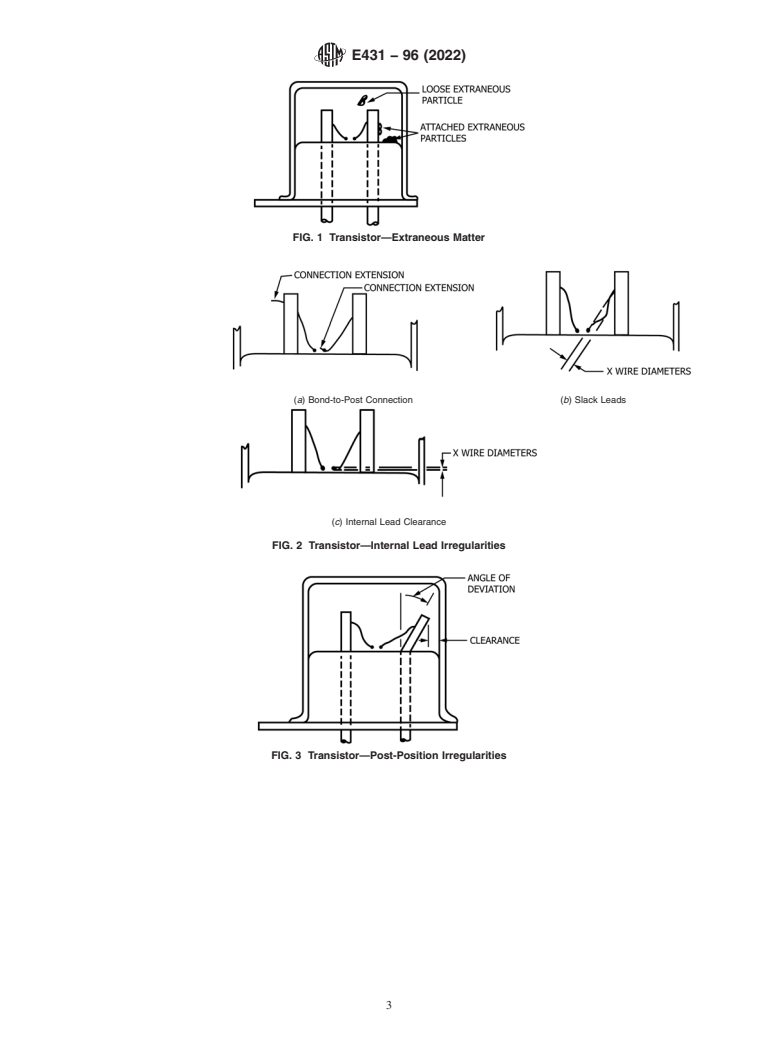

4.1 Illustrations provided in this guide are intended for use as references to aid in interpreting film or nonfilm images resulting from x-ray examinations (see Table 1) to ascertain quality of assembly and workmanship.

4.2 Required attributes of the design features or other construction details are not provided but are to be established as mutually agreed upon by manufacturers and users of these devices. Many devices share common assembly features; thus, these interpretations can be used for components not illustrated.

SCOPE

1.1 This guide provides illustrations of radiographs of semiconductors and related devices. Low powered transistors (through the TO-11 case configuration), diodes, low-power rectifiers, power devices, and integrated circuits are illustrated with common assembly features. Particular areas of construction are featured for these devices detailing critical points of design or assembly.

1.2 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety, health, and environmental practices and determine the applicability of regulatory limitations prior to use.

1.3 This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

General Information

Relations

Standards Content (Sample)

This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the

Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

Designation: E431 − 96 (Reapproved 2022)

Standard Guide to

Interpretation of Radiographs of Semiconductors and

Related Devices

This standard is issued under the fixed designation E431; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope 4. Significance and Use

1.1 This guide provides illustrations of radiographs of 4.1 Illustrations provided in this guide are intended for use

semiconductors and related devices. Low powered transistors

as references to aid in interpreting film or nonfilm images

(through the TO-11 case configuration), diodes, low-power resulting from x-ray examinations (see Table 1) to ascertain

rectifiers, power devices, and integrated circuits are illustrated

quality of assembly and workmanship.

with common assembly features. Particular areas of construc-

4.2 Required attributes of the design features or other

tion are featured for these devices detailing critical points of

construction details are not provided but are to be established

design or assembly.

as mutually agreed upon by manufacturers and users of these

1.2 This standard does not purport to address all of the

devices. Many devices share common assembly features; thus,

safety concerns, if any, associated with its use. It is the

these interpretations can be used for components not illus-

responsibility of the user of this standard to establish appro-

trated.

priate safety, health, and environmental practices and deter-

mine the applicability of regulatory limitations prior to use.

5. Use of Illustrations

1.3 This international standard was developed in accor-

5.1 The illustrations in this guide are for use in interpreting

dance with internationally recognized principles on standard-

radiographs of semiconductors and related devices. They

ization established in the Decision on Principles for the

provide reference points and information on the critical areas

Development of International Standards, Guides and Recom-

of such devices. These points must be clearly resolved in the

mendations issued by the World Trade Organization Technical

radiographs being interpreted. The radiographs to be inter-

Barriers to Trade (TBT) Committee.

preted must comply with the requirements of Practice E801 to

2. Referenced Documents ensure suitable image quality with minimal distortion. Addi-

tional information on the application of radiographic tech-

2.1 ASTM Standards:

niques to semiconductors and electronic components may be

E801 Practice for Controlling Quality of Radiographic Ex-

found in Test Method E1161.

amination of Electronic Devices

E1161 Practice for Radiographic Examination of Semicon-

5.2 The illustrations in this guide may also be used to

ductors and Electronic Components

interpret the radioscopic images of semiconductors and related

E1255 Practice for Radioscopy

devices when using radioscopic techniques. The radioscopic

E1316 Terminology for Nondestructive Examinations

images to be interpreted must comply with the requirements of

Practice E801 to ensure suitable image quality with minimal

3. Terminology

distortion. Additional information on the application of radio-

3.1 Definitions of terms used in these reference illustrations

scopic techniques may be found in Test Method E1161 and

may be found in Terminology E1316, Section D.

Practice E1255.

This guide is under the jurisdiction of ASTM Committee E07 on Nondestruc-

6. Description

tive Testing and is the direct responsibility of Subcommittee E07.02 on Reference

Radiological Images.

6.1 Description of irregularities and applicable figures are

Current edition approved Oct. 1, 2022. Published October 2022. Originally

shown in Table 1.

approved in 1971. Last previous edition approved in 2016 as E431 – 96(2016). DOI:

10.1520/E0431-96R22.

7. Keywords

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

7.1 electronic devices; nondestructive testing; radiographs;

Standards volume information, refer to the standard’s Document Summary page on

radiography; reference illustrations; semiconductors; x-ray

the ASTM website.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

E431 − 96 (2022)

TABLE 1 Irregularity Description and Figure References

Figure

Item and Irregularity Expressed as

Reference

Transistors, low-power (TO-11 and smaller packages)

Extraneous matter Any material contained in the semiconductor device that is not necessary for its manufacture or 1

operation.

Internal lead irregularities, bond-to-post connection Leads extending beyond attachment points at either end. Allowable extension should be stated in 2(a)

wire diameters.

Slack leads deviate from a straight line between attachment points. Allowable deviation should 2(b)

be stated in wire diameters.

Internal lead clearance is the distance between the edge of the chip and lead wire. Allowable 2(c)

clearance should be stated in wire diameters.

Post-position irregularities Allowable deviations of the post from its intended (design) position may be specified as minimum 3

angle made by the post and header, or as clearance between post and post or post and case

expressed in terms of post diameter.

Getter-position irregularities In crimp-type devices, deviations of the getter ring from its intended (design) position are stated 4(a)

relative to the crimp. In noncrimp-type devices, deviations of the getter ring from its intended 4(b)

(design) position are stated as the angle between the actual and intended positions.

Mounting paste Mounting-paste buildup or expulsion, or both, is an excessive amount of material used to mount 5

the semiconductor element on the header. Allowable excess should be measured relative to

the surfaces, clearances, and shape of the deposit.

Post-connection solder or gold paste Post-connection solder or gold-paste buildup is an excessive amount of such material at the 6

termination. Excess is measured relative to the diameter at the attachment point and by the

deposit shape.

Diodes and low-power rectifiers (whisker-type)

Extraneous matter Any material contained in the cav

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.