ASTM D3246-11

(Test Method)Standard Test Method for Sulfur in Petroleum Gas by Oxidative Microcoulometry

Standard Test Method for Sulfur in Petroleum Gas by Oxidative Microcoulometry

SIGNIFICANCE AND USE

Trace quantities of sulfur compounds in hydrocarbon products can be harmful to many catalytic chemical processes in which these products are used. Maximum permissible levels of total sulfur are normally included in specifications for such hydrocarbons. It is recommended that this test method be used to provide a basis for agreement between two laboratories when the determination of sulfur in hydrocarbon gases is important.

On liquefied petroleum gas, total volatile sulfur is measured on an injected gas sample. For such material a liquid sample must be used to measure total sulfur.

SCOPE

1.1 This test method covers determination of sulfur in the range from 1.5 to 100 mg/kg (ppm by mass) by weight in hydrocarbon products that are gaseous at normal room temperature and pressure.

Note 1— The test method has been tested cooperatively only on high-purity ethylene gas. Precision data have not been developed for other products.

1.2 The values stated in Si units are to be regarded as the standard. The values given n parentheses are for information only

1.3This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: D3246 − 11

StandardTest Method for

1

Sulfur in Petroleum Gas by Oxidative Microcoulometry

This standard is issued under the fixed designation D3246; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope* 2.2 Other Standards:

CompressedGasAssociationBookletsG-4andG-4-1onthe

1.1 This test method covers determination of sulfur in the

3

Use of Oxygen

range from 1.5 to 100 mg/kg (ppm by mass) by weight in

hydrocarbon products that are gaseous at normal room tem-

3. Summary of Test Method

perature and pressure.

3.1 Asample is injected into a combustion tube maintained

NOTE 1—The test method has been tested cooperatively only on

at about 800°C having a flowing stream of gas containing

high-purityethylenegas.Precisiondatahavenotbeendevelopedforother

about 80% oxygen and 20% inert gas (for example, nitrogen,

products.

argon, etc.). Oxidative pyrolysis converts the sulfur to sulfur

1.2 The values stated in SI units are to be regarded as

dioxide which then flows into a titration cell where it reacts

standard. No other units of measurement are included in this

with triiodide ion present in the electrolyte. The triiodide thus

standard.

consumed, is coulometrically replaced and the total current

1.3 This standard does not purport to address all of the

required to replace it is a measure of the sulfur present in the

safety concerns, if any, associated with its use. It is the

sample injected.

responsibility of the user of this standard to establish appro-

3.2 The reaction occurring in the titration cell as sulfur

priate safety and health practices and determine the applica-

dioxide enters is:

bility of regulatory limitations prior to use.

2 2 1

I 1SO 1H O→SO 13I 12H (1)

3 2 2 3

2. Referenced Documents

The triiodide ion consumed in the above reaction is gener-

2

2.1 ASTM Standards:

ated coulometrically thus:

D1265Practice for Sampling Liquefied Petroleum (LP)

2 2 2

3I →I 12e (2)

3

Gases, Manual Method

3.3 Thesemicroequivalentsoftriiodide(iodine)areequalto

D1193Specification for Reagent Water

the number of microequivalents of titratable sample ion enter-

D3120Test Method for Trace Quantities of Sulfur in Light

ing the titration cell.

Liquid Petroleum Hydrocarbons by Oxidative Microcou-

lometry

3.4 A liquid blend containing a known amount of sulfur is

D6299Practice for Applying Statistical Quality Assurance

used for calibration.

and Control Charting Techniques to Evaluate Analytical

4. Significance and Use

Measurement System Performance

F307Practice for Sampling Pressurized Gas for GasAnaly-

4.1 Trace quantities of sulfur compounds in hydrocarbon

sis

products can be harmful to many catalytic chemical processes

inwhichtheseproductsareused.Maximumpermissiblelevels

1

of total sulfur are normally included in specifications for such

This test method is under the jurisdiction of ASTM Committee D02 on

Petroleum Products and Lubricants and is the direct responsibility of Subcommittee

hydrocarbons. It is recommended that this test method be used

D02.03 on Elemental Analysis.

to provide a basis for agreement between two laboratories

CurrenteditionapprovedJune1,2011.PublishedJuly2011.Originallyapproved

when the determination of sulfur in hydrocarbon gases is

in 1973. Last previous edition approved in 2005 as D3246–05. DOI: 10.1520/

D3246-11. important.

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

3

Standards volume information, refer to the standard’s Document Summary page on Available from Compressed Gas Association, 1235 Jefferson Davis Hwy.,

the ASTM website. Arlington, VA 22202.

*A Summary of Changes section appears at the end of this standard

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

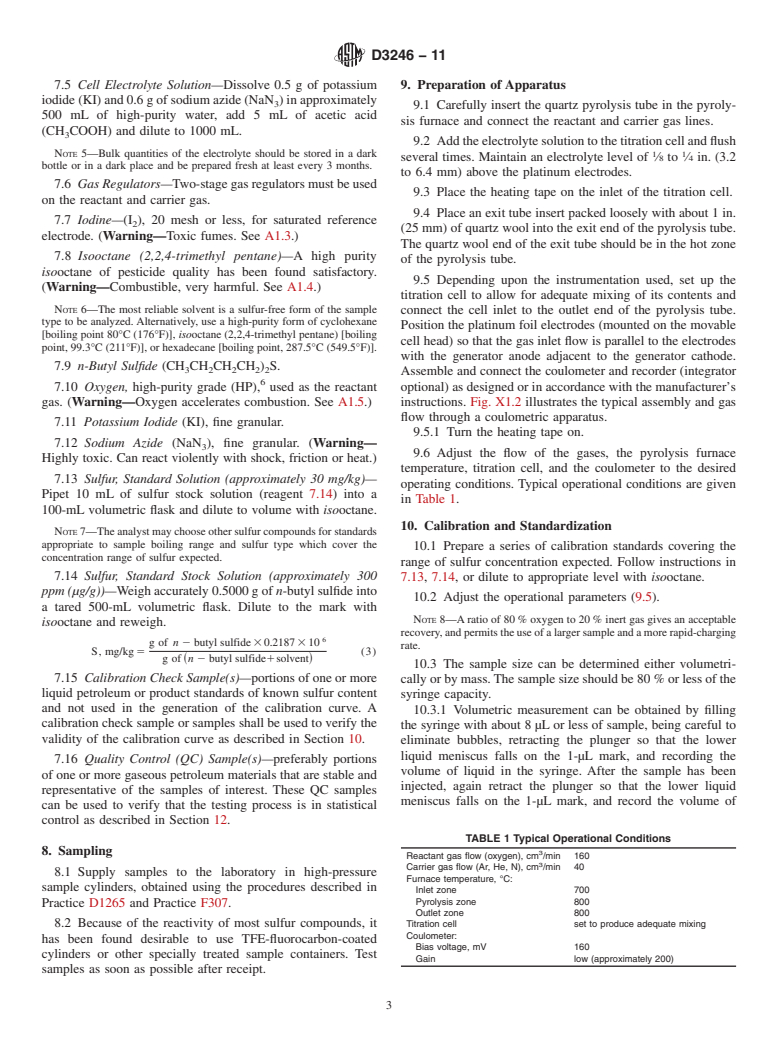

D3246 − 11

4.2 On liquefied petroleum gas, total volatile sulfur is means. (Warning—Excessive speed will decouple the stirring

measuredonaninjectedgassample.Forsuchmaterialaliquid bar,causingittoriseinthecellanddamagetheelectrodes.The

sample must be used to measure total sulfur. creation of a slight vortex is adequate.)

6.4 Microcoulometer, having variable attenuation gain con-

5. Interferences

trol, and capable of measuring the potential of the sensing-

5.1 This test method is applicable in the presence of total

reference electrode pair, and comparing this potential with a

halideconcentrationsofupto10timesthesulfurlevelandtotal

biaspotential,amplifyingthepotentialdifference,andapplying

nitrogen content

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.