ASTM F17-98

(Terminology)Standard Terminology Relating to Flexible Barrier Materials

Standard Terminology Relating to Flexible Barrier Materials

General Information

Relations

Standards Content (Sample)

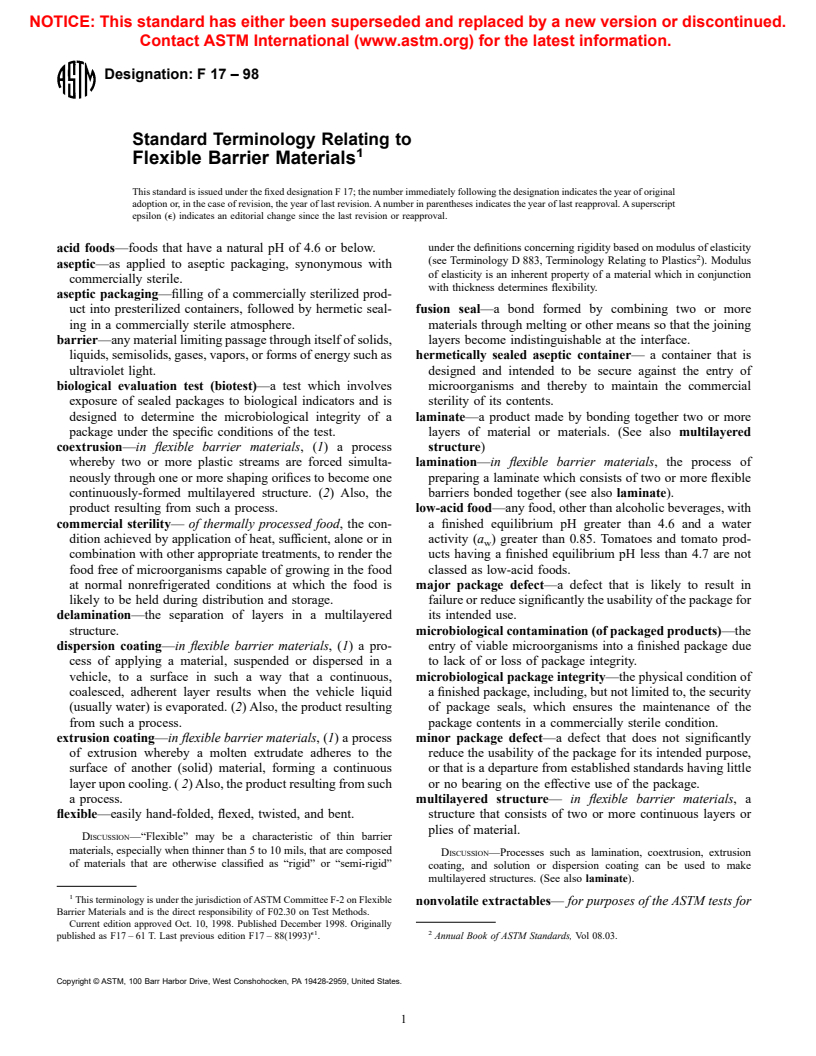

NOTICE: This standard has either been superseded and replaced by a new version or discontinued.

Contact ASTM International (www.astm.org) for the latest information.

Designation: F 17 – 98

Standard Terminology Relating to

1

Flexible Barrier Materials

This standard is issued under the fixed designation F 17; the number immediately following the designation indicates the year of original

adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A superscript

epsilon (e) indicates an editorial change since the last revision or reapproval.

under the definitions concerning rigidity based on modulus of elasticity

acid foods—foods that have a natural pH of 4.6 or below.

2

(see Terminology D 883, Terminology Relating to Plastics ). Modulus

aseptic—as applied to aseptic packaging, synonymous with

of elasticity is an inherent property of a material which in conjunction

commercially sterile.

with thickness determines flexibility.

aseptic packaging—filling of a commercially sterilized prod-

uct into presterilized containers, followed by hermetic seal- fusion seal—a bond formed by combining two or more

ing in a commercially sterile atmosphere. materials through melting or other means so that the joining

barrier—any material limiting passage through itself of solids, layers become indistinguishable at the interface.

liquids, semisolids, gases, vapors, or forms of energy such as hermetically sealed aseptic container— a container that is

ultraviolet light. designed and intended to be secure against the entry of

biological evaluation test (biotest)—a test which involves microorganisms and thereby to maintain the commercial

exposure of sealed packages to biological indicators and is sterility of its contents.

designed to determine the microbiological integrity of a laminate—a product made by bonding together two or more

package under the specific conditions of the test. layers of material or materials. (See also multilayered

coextrusion—in flexible barrier materials,(1) a process structure)

whereby two or more plastic streams are forced simulta- lamination—in flexible barrier materials, the process of

neously through one or more shaping orifices to become one preparing a laminate which consists of two or more flexible

continuously-formed multilayered structure. (2) Also, the barriers bonded together (see also laminate).

product resulting from such a process. low-acid food—any food, other than alcoholic beverages, with

commercial sterility— of thermally processed food, the con- a finished equilibrium pH greater than 4.6 and a water

dition achieved by application of heat, sufficient, alone or in activity (a ) greater than 0.85. Tomatoes and tomato prod-

w

combination with other appropriate treatments, to render the ucts having a finished equilibrium pH less than 4.7 are not

food free of microorganisms capable of growing in the food classed as low-acid foods.

at normal nonrefrigerated conditions at which the food is major package defect—a defect that is likely to result in

likely to be held during distribution and storage. failure or reduce significantly the usability of the package for

delamination—the separation of layers in a multilayered its intended use.

structure. microbiological contamination (of packaged products)—the

dispersion coating—in flexible barrier materials,(1) a pro- entry of viable microorganisms into a finished package due

cess of applying a material, suspended or dispersed in a to lack of or loss of package integrity.

vehicle, to a surface in such a way that a continuous, microbiological package integrity—the physical condition of

coalesced, adherent layer results when the vehicle liquid a finished package, including, but not limited to, the security

(usually water) is evaporated. (2) Also, the product resulting of package seals, which ensures the maintenance of the

from such a process. package contents in a commercially sterile condition.

extrusion coating—in flexible barrier materials,(1) a process minor package defect—a defect that does not significantly

of extrusion whereby a molten extrudate adheres to the reduce the usability of the package for its intended purpose,

surface of another (solid) material, forming a continuous or that is a departure from established standards having little

layer upon cooling. ( 2) Also, the product resulting from such or no bearing on the effective use of the package.

a process. multilayered structure— in flexible barrier materials,a

flexible—easily hand-folded, flexed, twisted, and bent. structure that consists of two or more continuous layers or

plies of material.

DISCUSSION—“Flexible” may be a characteristic of thin barrier

materials, especially when thinner than 5 to 10 mils, that are composed

DISCUSSION—Processes such as lamination, coextrusion, extrusion

of materials that are otherwise classified as “rigid” or “semi-rigid”

coating, and solution or dispersion coating can be used to make

multilayered structures. (See

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.