ASTM E3325-21

(Practice)Standard Practice for Sampling of Solar Photovoltaic Modules for Toxicity Testing

Standard Practice for Sampling of Solar Photovoltaic Modules for Toxicity Testing

SIGNIFICANCE AND USE

6.1 The primary goal of this practice is to extract representative samples from PV modules for TCLP toxicity testing purposes in order to receive unbiased, comparable and repeatable toxicity test results from independent TCLP testing laboratories.

6.2 Solar photovoltaic (PV) modules in the United States and the world reaching end-of-life due to failure, underperformance or breakage due to extreme weather have to be recycled or otherwise safely disposed of following the Resource Conservation and Recovery Act (RCRA) regulation [United States, Resource Conservation and Recovery Act. Pub.L. 94–580, October 1976]. For end-of-life PV modules, the U.S. Environmental Protection Agency (EPA) Method 1311 (TCLP) is used for waste characterization based on leaching potential under simulated landfill conditions.

6.3 Commercial PV modules contain compounds and alloys of various metals (for example, Ag, Al, Cd, Cu, Ga, In, Ni, Pb, Se, Sn, Te, Zn) which are used in semiconductor compounds and electrical contacts.5 Modules that pass the EPA Method 1311 TCLP test, and state protocols (if applicable), can be disposed of in a regular landfill. Otherwise, they are classified as hazardous waste and must go through a more onerous and expensive disposal process. Currently, there is no national or international standard, nor a standardized protocol available for removal of test samples from PV modules for toxicity testing per the EPA Method 1311 standard.

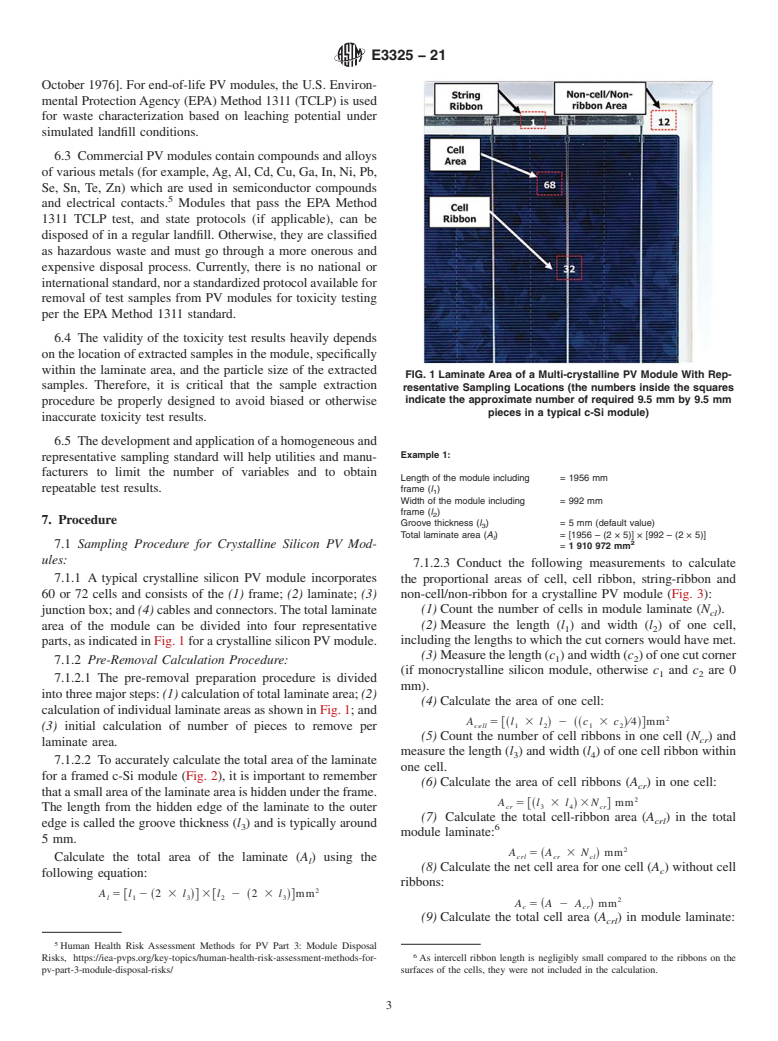

6.4 The validity of the toxicity test results heavily depends on the location of extracted samples in the module, specifically within the laminate area, and the particle size of the extracted samples. Therefore, it is critical that the sample extraction procedure be properly designed to avoid biased or otherwise inaccurate toxicity test results.

6.5 The development and application of a homogeneous and representative sampling standard will help utilities and manufacturers to limit the number of variables and to obtain repeatable...

SCOPE

1.1 The purpose of this practice is to describe a representative and repeatable sample preparation methodology to conduct toxicity testing on solar photovoltaic (PV) modules for use with EPA Test Method 1311: Toxicity Characteristic Leaching Procedure (TCLP).

1.2 This practice refers to the extraction and preparation of PV module samples by EPA Method 1311, the testing for eight (8) distinct metals – mercury (by Method 7470A), arsenic, barium, cadmium, chromium, lead, selenium and silver (by Method 6010C) as well as the analysis and interpretation of the test results on a module level.

1.3 This practice applies to only (1) standard crystalline silicon (c-Si) modules, multi and mono-crystalline silicon with aluminum back surface field (Al-BSF) cell technology and (2) cadmium telluride (CdTe) PV modules.

1.4 Other and newer PV technologies and module architectures, for example, passivated emitter and rear cell (PERC), interdigitated back contact (IBC), hetero-junction technology (HJT), multiwire, half cut, shingled etc., have not been evaluated with this practice, although the concept and practice can be easily extended and applied to other technologies following the conceptual approach presented in this document.

1.5 The sample extraction/removal methodology applied in this practice is the waterjet cutting sampling method. Sample extraction with mechanical cutting has been extensively evaluated but the variability of TCLP test results based on the mechanical cut samples tend to be much higher (30 %) than that of the waterjet cut samples (8 %).2 Therefore, the mechanical cut method is not presented in this practice.

1.6 Only the laminate area of the PV module is considered for TCLP testing, as other possible module parts, such as aluminum frame, junction box and cables contain recyclable materials that are already well-documented and are not specific to the PV modules.

1.7 The material gravimetric density...

General Information

Standards Content (Sample)

This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the

Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

Designation: E3325 − 21 An American National Standard

Standard Practice for

Sampling of Solar Photovoltaic Modules for Toxicity

1

Testing

This standard is issued under the fixed designation E3325; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope aluminum frame, junction box and cables contain recyclable

materialsthatarealreadywell-documentedandarenotspecific

1.1 The purpose of this practice is to describe a representa-

to the PV modules.

tiveandrepeatablesamplepreparationmethodologytoconduct

3

toxicity testing on solar photovoltaic (PV) modules for use

1.7 Thematerialgravimetricdensity(g/cm )throughoutthe

with EPATest Method 1311: Toxicity Characteristic Leaching laminate area is considered constant.

Procedure (TCLP).

1.8 This practice was developed to be consistent with three

1.2 This practice refers to the extraction and preparation of fundamental requirements:

PVmodule samples by EPAMethod 1311, the testing for eight

1.8.1 Sample pieces with particle size not to exceed the

(8) distinct metals – mercury (by Method 7470A), arsenic,

allowed size limit of EPA 1311 standard which is 9.5 mm,

barium, cadmium, chromium, lead, selenium and silver (by

1.8.2 The particle size used in this practice as sample piece

Method6010C)aswellastheanalysisandinterpretationofthe

is consistent with the median particle size expected in landfill

2

test results on a module level.

disposal , and

1.8.3 An assumption that each laminate sample piece will

1.3 This practice applies to only (1) standard crystalline

result in 100 % glass coverage area, due to the presence of

silicon (c-Si) modules, multi and mono-crystalline silicon with

bonding encapsulant layers once it is broken in the landfill.

aluminum back surface field (Al-BSF) cell technology and (2)

cadmium telluride (CdTe) PV modules.

1.9 The values stated in SI units are to be regarded as

standard. No other units of measurement are included in this

1.4 Other and newer PV technologies and module

standard.

architectures, for example, passivated emitter and rear cell

(PERC), interdigitated back contact (IBC), hetero-junction

1.10 This standard does not purport to address all of the

technology (HJT), multiwire, half cut, shingled etc., have not

safety concerns, if any, associated with its use. It is the

been evaluated with this practice, although the concept and

responsibility of the user of this standard to establish appro-

practice can be easily extended and applied to other technolo-

priate safety, health, and environmental practices and deter-

gies following the conceptual approach presented in this

mine the applicability of regulatory limitations prior to use.

document.

1.11 This international standard was developed in accor-

dance with internationally recognized principles on standard-

1.5 The sample extraction/removal methodology applied in

ization established in the Decision on Principles for the

this practice is the waterjet cutting sampling method. Sample

Development of International Standards, Guides and Recom-

extraction with mechanical cutting has been extensively evalu-

mendations issued by the World Trade Organization Technical

ated but the variability of TCLP test results based on the

Barriers to Trade (TBT) Committee.

mechanical cut samples tend to be much higher (30 %) than

2

that of the waterjet cut samples (8 %). Therefore, the

2. Referenced Documents

mechanical cut method is not presented in this practice.

3

1.6 Only the laminate area of the PV module is considered

2.1 ASTM Standard:

for TCLP testing, as other possible module parts, such as

D4538Terminology Relating to Protective Coating and

Lining Work for Power Generation Facilities

E772Terminology of Solar Energy Conversion

1

This practice is under the jurisdiction of ASTM Committee E44 on Solar,

GeothermalandOtherAlternativeEnergySourcesandisthedirectresponsibilityof

Subcommittee E44.09 on Photovoltaic Electric Power Conversion.

Current edition approved Nov. 1, 2021. Published December 2021. DOI:

3

10.1520/E3325-21. For referenced ASTM standards, visit the ASTM website, www.astm.org, or

2

TamizhMani, G., Libby, C., Shaw, S., Krishnamurthy, R., Leslie, J.,Yadav, R., contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

Tatapudi S., and Bicer, B. “Evaluating PV Module Sample Removal Methods for Standards volume information, refer to the standard’s Document Summary page on

TCLP Testing,” IEEE Photovoltaic Specialists Conferenc

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.