ASTM E749-01

(Practice)Standard Practice for Acoustic Emission Monitoring During Continuous Welding

Standard Practice for Acoustic Emission Monitoring During Continuous Welding

SCOPE

1.1 This practice provides recommended guidelines for acoustic emission (AE) monitoring of weldments during and immediately following their fabrication by continuous welding processes. The technique is in a developmental stage and is not used routinely on production welding. Depending on the results of ongoing research and preproduction weld monitoring experience, these procedures are subject to change before routine implementation on production welds.

1.2 The procedure described in this practice is applicable to the detection and location of AE sources in weldments and in their heat-affected zone during fabrication, particularly in those cases where the time duration of welding is such that fusion and solidification take place while welding is still in progress.

1.3 The effectiveness of acoustic emission to detect discontinuities in the weldment and the heat-affected zone is dependent on the design of the AE system, the calibration procedure, the weld process, and the material type. Materials that have been monitored include low-carbon steels, low-alloy steels, stainless steels, and some aluminum alloys. The system performance must be verified for each application by demonstrating that the defects of concern can be detected with the desired reliability.

1.4 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: E 749 – 01

Standard Practice for

1

Acoustic Emission Monitoring During Continuous Welding

This standard is issued under the fixed designation E 749; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

3

1. Scope 2.2 ASNT Standards:

SNT-TC-1A Recommended Practice for Nondestructive

1.1 This practice provides recommended guidelines for

Testing Personnel Qualification and Certification

acoustic emission (AE) monitoring of weldments during and

ANSI/ASNT CP-189 Standard for Qualification and Certi-

immediately following their fabrication by continuous welding

fication of Nondestructive Testing Personnel

processes.The technique is in a developmental stage and is not

2.3 Military Standard:

used routinely on production welding. Depending on the

MIL-STD-410 Nondestructive Testing Personnel Qualifica-

results of ongoing research and preproduction weld monitoring

4

tion and Certification

experience, these procedures are subject to change before

routine implementation on production welds.

3. Terminology

1.2 The procedure described in this practice is applicable to

3.1 Definitions—Fordefinitionsoftermsrelatingtoacoustic

the detection and location of AE sources in weldments and in

emission testing, see Section B of Terminology E 1316.

theirheat-affectedzoneduringfabrication,particularlyinthose

cases where the time duration of welding is such that fusion

4. Significance and Use

and solidification take place while welding is still in progress.

4.1 Detection and location of AE sources in weldments

1.3 The effectiveness of acoustic emission to detect discon-

during fabrication may provide information related to the

tinuities in the weldment and the heat-affected zone is depen-

integrity of the weld. Such information may be used to direct

dentonthedesignoftheAEsystem,theAEsystemverification

repair procedures on the weld or as a guide for application of

procedure, the weld process, and the material type. Materials

other nondestructive evaluation (NDE) methods. A major

that have been monitored include low-carbon steels, low-alloy

attribute of applying AE for in-process monitoring of welds is

steels, stainless steels, and some aluminum alloys. The system

the ability of the method to provide immediate real-time

performance must be verified for each application by demon-

information on weld integrity. This feature makes the method

strating that the defects of concern can be detected with the

useful to lower weld costs by repairing defects at the most

desired reliability.

convenient point in the production process. The AE activity

1.4 This standard does not purport to address all of the

from discontinuities in the weldment is stimulated by the

safety concerns, if any, associated with its use. It is the

thermal stresses from the welding process. The AE activity

responsibility of the user of this standard to establish appro-

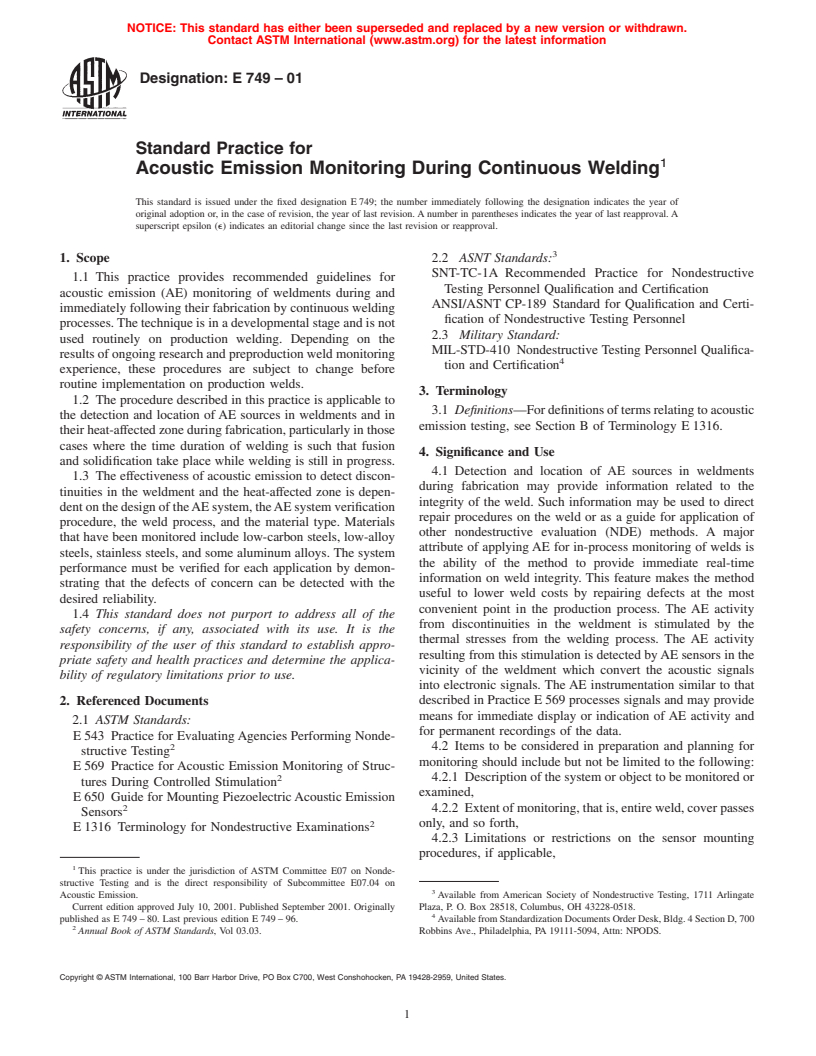

resulting from this stimulation is detected byAE sensors in the

priate safety and health practices and determine the applica-

vicinity of the weldment which convert the acoustic signals

bility of regulatory limitations prior to use.

into electronic signals. The AE instrumentation similar to that

2. Referenced Documents described in Practice E 569 processes signals and may provide

means for immediate display or indication of AE activity and

2.1 ASTM Standards:

for permanent recordings of the data.

E 543 Practice for EvaluatingAgencies Performing Nonde-

2 4.2 Items to be considered in preparation and planning for

structive Testing

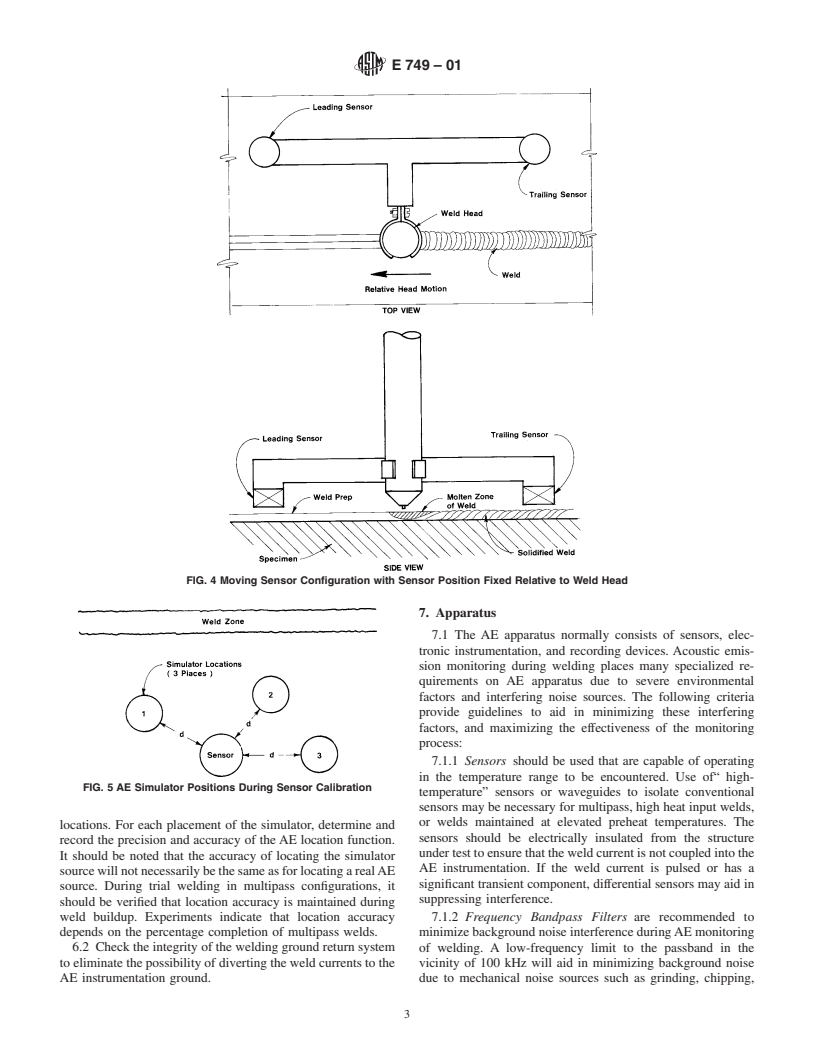

monitoring should include but not be limited to the following:

E 569 Practice for Acoustic Emission Monitoring of Struc-

2 4.2.1 Description of the system or object to be monitored or

tures During Controlled Stimulation

examined,

E 650 Guide for Mounting PiezoelectricAcoustic Emission

2 4.2.2 Extent of monitoring, that is, entire weld, cover passes

Sensors

2

only, and so forth,

E 1316 Terminology for Nondestructive Examinations

4.2.3 Limitations or restrictions on the sensor mounting

procedures, if applicable,

1

This practice is under the jurisdiction of ASTM Committee E07 on Nonde-

structive Testing and is the direct responsibility of Subcommittee E07.04 on

3

Acoustic Emission. Available from American Society of Nondestructive Testing, 1711 Arlingate

Current edition approved July 10, 2001. Published September 2001. Originally Plaza, P. O. Box 28518, Columbus, OH 43228-0518.

4

published as E 749 – 80. Last previous edition E 749 – 96. AvailablefromStandardizationDocumentsOrderDesk,Bldg.4SectionD,700

2

Annual Book of ASTM Standards, Vol 03.03. Robbins Ave., Philadelphia, PA 19111-509

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.