ASTM D7108-12

(Guide)Standard Guide for Establishing Qualifications for a Nuclear Coatings Specialist

Standard Guide for Establishing Qualifications for a Nuclear Coatings Specialist

SIGNIFICANCE AND USE

4.1 This guide applies to personnel technically responsible for the safety-related coatings program.

4.2 It is the responsibility of each nuclear facility or organization participating in a safety-related coatings program to ensure that only those personnel within their respective organizations who meet the requirements of this guide are designated as Nuclear Coatings Specialists.

SCOPE

1.1 This guide delineates recommendations for development of procedures and criteria for designation of an individual as a Nuclear Coatings Specialist involved in coating work in nuclear facilities. The Nuclear Coatings Specialist is responsible for the technical aspects of the safety-related coatings program in a nuclear facility or organization, which includes establishing processes and quality control requirements.

1.2 This guide details the guidance provided in Guide D5144, and EPRI Report 1019157.

1.3 It is the intent of this guide to provide several alternatives for designation of personnel as Nuclear Coatings Specialists.

1.4 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory requirements prior to use.

General Information

Relations

Buy Standard

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation:D7108 −12

Standard Guide for

Establishing Qualifications for a Nuclear Coatings

1

Specialist

This standard is issued under the fixed designation D7108; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

4

1. Scope 2.3 Electric Power Research Institute (EPRI):

EPRI Report 1019157 Guidance on Nuclear Safety-Related

1.1 This guide delineates recommendations for develop-

Coatings, Revision 2 (formerlyTR-109937 and 1003102),

mentofproceduresandcriteriafordesignationofanindividual

December 2009

as a Nuclear Coatings Specialist involved in coating work in

5

2.4 Code of Federal Regulations (CFR):

nuclear facilities. The Nuclear Coatings Specialist is respon-

sible for the technical aspects of the safety-related coatings 10CFR21 Reporting of Defects and Nonconformance

10CFR50.59 Changes, Tests and Experiments

program in a nuclear facility or organization, which includes

establishing processes and quality control requirements.

3. Terminology

1.2 This guide details the guidance provided in Guide

3.1 Definitions—Definitions for use with this standard are

D5144, and EPRI Report 1019157.

shown in Terminology D4538 or other applicable standards.

1.3 It is the intent of this guide to provide several alterna-

3.2 Definitions of Terms Specific to This Standard:

tives for designation of personnel as Nuclear Coatings Special-

3.2.1 safety-related coatings program, n—the systematic

ists.

and planned activities conducted at a nuclear power plant to

1.4 This standard does not purport to address all of the

ensure that the safety-related coatings and linings perform all

safety concerns, if any, associated with its use. It is the

of their design functions.

responsibility of the user of this standard to establish appro-

priate safety and health practices and determine the applica-

4. Significance and Use

bility of regulatory requirements prior to use.

4.1 This guide applies to personnel technically responsible

2. Referenced Documents

for the safety-related coatings program.

2

2.1 ASTM Standards: 4.2 It is the responsibility of each nuclear facility or

D4537 Guide for Establishing Procedures to Qualify and organization participating in a safety-related coatings program

Certify Personnel Performing Coating and Lining Work to ensure that only those personnel within their respective

Inspection in Nuclear Facilities organizations who meet the requirements of this guide are

D4538 Terminology Relating to Protective Coating and

designated as Nuclear Coatings Specialists.

Lining Work for Power Generation Facilities

D5144 Guide for Use of Protective Coating Standards in

5. General Duties and Responsibilities of a Nuclear

Nuclear Power Plants Coatings Specialist

3

2.2 ANSI/ASME Codes and Standards:

5.1 The duties of a Nuclear Coatings Specialist should be

ANSI/ASME N45.2.6 Qualifications of Inspection, Exami-

detailed in the facility safety-related coatings program and

nation and Testing Personnel for Nuclear Power Plants

typically may include, but are not limited to:

5.1.1 Developing and managing the safety-related coatings

1

This guide is under the jurisdiction of ASTM Committee D33 on Protective

program,

Coating and Lining Work for Power Generation Facilities and is the direct

5.1.2 Developing and maintaining coatings and linings in-

responsibility of Subcommittee D33.04 on Quality Systems and Inspection.

spection criteria,

Current edition approved Nov. 15, 2012. Published February 2013. Originally

approved in 2005. Last previous edition approved in 2005 as D7108 – 05. DOI:

10.1520/D7108-12.

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

4

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM Available from Electric Power Research Institute, 3420 Hillview Ave., Palo

Standards volume information, refer to the standard’s Document Summary page on Alto, CA 94304, http://www.epri.com.

5

the ASTM website. AvailablefromU.S.GovernmentPrintingOfficeSuperintendentofDocuments,

3

Available from American National Standards Institute (ANSI), 25 W. 43rd St., 732 N. Capitol St., NW, Mail Stop: SDE, Washington, DC 20401, http://

4th Floor, New York, NY 10036, http://www.ansi.org. www.access.gpo.gov.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

D7108−12

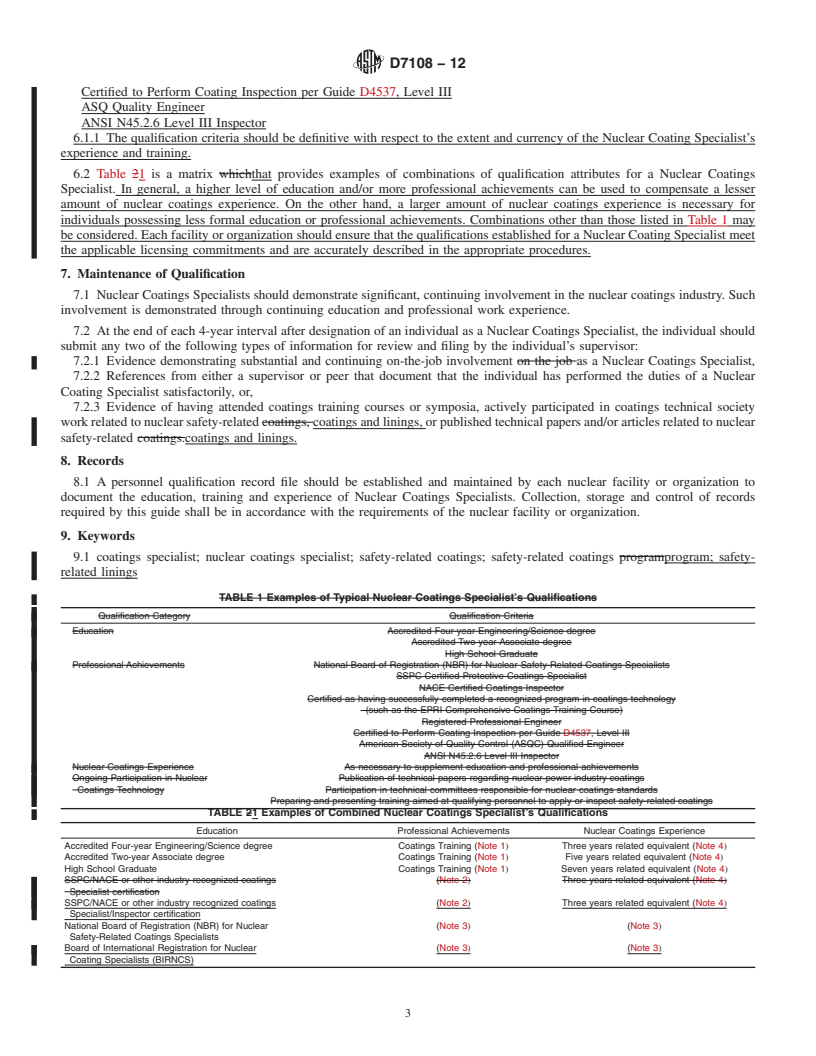

5.1.3 Resolving and dispositioning issues that arise during ingsSpecialists.Thecriteriaultimatelydevelopedandincluded

the performance of coating and lining work, in each facility’s or organization’s safety-related coatings

...

This document is not an ASTM standard and is intended only to provide the user of an ASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

Designation: D7108 − 05 D7108 − 12

Standard Guide for

Establishing Qualifications for a Nuclear Coatings

1

Specialist

This standard is issued under the fixed designation D7108; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope

1.1 This guide delineates recommendations for development of procedures and criteria for designation of personnel an

individual as a Nuclear Coatings Specialist involved in coating work in nuclear facilities. The Nuclear Coatings Specialist is

responsible for the technical aspects of the safety-related coatings program in a nuclear facility or organization.organization, which

includes establishing processes and quality control requirements.

1.2 This guide details the guidance provided in Guide D5144, USNRC Regulatory Guide 1.54 Revision 1, and EPRI Report

1003102.1019157.

1.3 It is the intent of this guide to provide several alternatives for designation of personnel as Nuclear Coatings Specialists.

1.4 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility

of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory

requirements prior to use.

2. Referenced Documents

2

2.1 ASTM Standards:

D4537 Guide for Establishing Procedures to Qualify and Certify Personnel Performing Coating and Lining Work Inspection in

Nuclear Facilities

D4538 Terminology Relating to Protective Coating and Lining Work for Power Generation Facilities

D5144 Guide for Use of Protective Coating Standards in Nuclear Power Plants

3

2.2 Other Documents:ANSI/ASME Codes and Standards:

ANSIANSI/ASME N45.2.6 Qualifications of Inspection, Examination and Testing Personnel for Nuclear Power Plants

USNRC Regulatory Guide 1.54 Revision 1, Service Level I, II and III Protective Coatings Applied to Nuclear Power Plants,

July 2000

EPRI Report 1003102 Guidance on Nuclear Safety-Related Coatings, Revision 1 (formerly TR-109937), November 2001

10CFR21 Reporting of Defects and Nonconformance

10CFR50.59 Changes, Tests and Experiments

4

2.3 Electric Power Research Institute (EPRI):

EPRI Report 1019157 Guidance on Nuclear Safety-Related Coatings, Revision 2 (formerly TR-109937 and 1003102),

December 2009

5

2.4 Code of Federal Regulations (CFR):

10CFR21 Reporting of Defects and Nonconformance

10CFR50.59 Changes, Tests and Experiments

1

This guide is under the jurisdiction of ASTM Committee D33 on Protective Coating and Lining Work for Power Generation Facilities and is the direct responsibility

of Subcommittee D33.04 on Quality Systems and Inspection.

Current edition approved Sept. 1, 2005Nov. 15, 2012. Published September 2005February 2013. Originally approved in 2005. Last previous edition approved in 2005 as

D7108 – 05. DOI: 10.1520/D7108-05.10.1520/D7108-12.

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM Standards

volume information, refer to the standard’s Document Summary page on the ASTM website.

3

Available from American National Standards Institute (ANSI), 25 W. 43rd St., 4th Floor, New York, NY 10036, http://www.ansi.org.

4

Available from Electric Power Research Institute, 3420 Hillview Ave., Palo Alto, CA 94304, http://www.epri.com.

5

Available from U.S. Government Printing Office Superintendent of Documents, 732 N. Capitol St., NW, Mail Stop: SDE, Washington, DC 20401.20401,

http://www.access.gpo.gov.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

D7108 − 12

3. Terminology

3.1 Definitions—Definitions for use with this standard are shown in Terminology D4538 or other applicable standards.

3.2 Definitions of Terms Specific to This Standard:

3.2.1 safety-related coatings program, n—the systematic and planned activities conducted at a nuclear power plant to ensure that

the safety-related coatings and linings perform all of their design functions.

4. Significance and Use

4.1 This guide applies to personnel technically responsible for the safety-related coatings program.

4.2 It is the responsibility of each nuclear facility or organization participating in a safety-related coatings prog

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.