ASTM D6301-21

(Practice)Standard Practice for Collection of On-Line Composite Samples of Suspended Solids and Ionic Solids in Process Water

Standard Practice for Collection of On-Line Composite Samples of Suspended Solids and Ionic Solids in Process Water

SIGNIFICANCE AND USE

5.1 The transport of any suspended solids or corrosion products from the preboiler cycle has been shown to be detrimental to all types of steam generating equipment. Corrosion product transport as low as 10 ppb can have significant impact on steam generators performance.

5.2 Deposited corrosion products on pressurized water reactor (PWR) steam generator tubes can reduce heat transfer, and, if the deposit is sufficiently thick, can provide a local area for impurities in the bulk water to concentrate, resulting in a corrosive environment. In boiling water reactor (BWR) plants, the transport of corrosion products can cause fuel failure, out of core radiation problems from activation reactions, and other material related problems.

5.3 In fossil plants, the transport of corrosion products can reduce heat transfer in the boilers leading to tube failures from overheating. The removal of these corrosion products by chemical cleaning is expensive and potentially harmful to the boiler tubes.

5.4 Normally, grab samples are not sensitive enough to detect changes in the level of corrosion product transport. Also, system transients may be missed by only taking grab samples. An integrated sample over time will increase the sensitivity for detecting the corrosion products and provide a better understanding of the total corrosion product transport to steam generators.

SCOPE

1.1 This practice is applicable for sampling condensed steam or water, such as boiler feedwater, for the collection of suspended solids and (optional) ionic solids using a 0.45-μm membrane filter (suspended solids) and ion exchange media (ionic solids). As the major suspended component found in most boiler feedwaters is some form of corrosion product from the preboiler system, the device used for this practice is commonly called a corrosion product sampler.

1.2 The values stated in SI units are to be regarded as standard. No other units of measurement are included in this standard.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety, health, and environmental practices and determine the applicability of regulatory limitations prior to use.

1.4 This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

General Information

Buy Standard

Standards Content (Sample)

This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the

Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

Designation:D6301 −21

Standard Practice for

Collection of On-Line Composite Samples of Suspended

1

Solids and Ionic Solids in Process Water

This standard is issued under the fixed designation D6301; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope Furnace Atomic Absorption, Plasma Emission

Spectroscopy, or Plasma Mass Spectrometry

1.1 This practice is applicable for sampling condensed

D2332 Practice for Analysis of Water-Formed Deposits by

steam or water, such as boiler feedwater, for the collection of

Wavelength-Dispersive X-Ray Fluorescence

suspended solids and (optional) ionic solids using a 0.45-µm

D2777 Practice for Determination of Precision and Bias of

membrane filter (suspended solids) and ion exchange media

Applicable Test Methods of Committee D19 on Water

(ionic solids). As the major suspended component found in

D3370 Practices for Sampling Water from Flowing Process

most boiler feedwaters is some form of corrosion product from

Streams

the preboiler system, the device used for this practice is

D3864 Guide for On-Line Monitoring Systems for Water

commonly called a corrosion product sampler.

Analysis

1.2 The values stated in SI units are to be regarded as

standard. No other units of measurement are included in this 3. Terminology

standard.

3.1 Definitions:

1.3 This standard does not purport to address all of the

3.1.1 For definitions of terms used in this standard, refer to

safety concerns, if any, associated with its use. It is the

Terminology D1129.

responsibility of the user of this standard to establish appro-

3.2 Definitions of Terms Specific to This Standard:

priate safety, health, and environmental practices and deter-

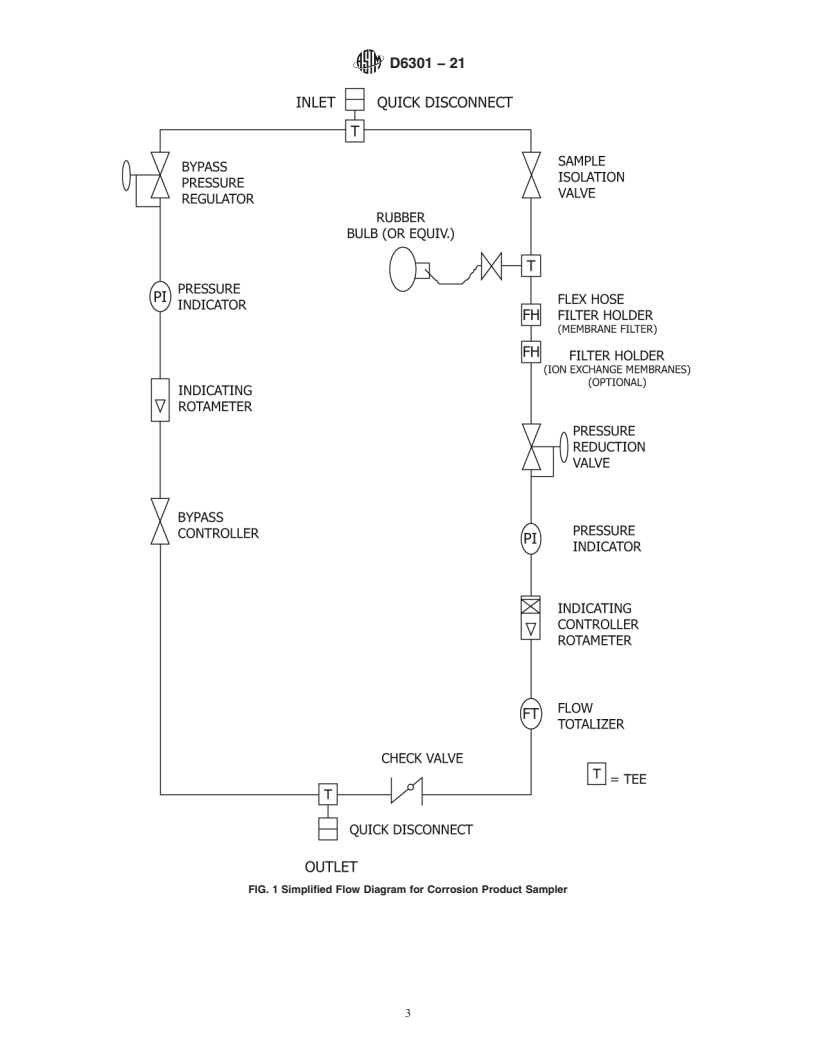

3.2.1 corrosion product sampler, n—a device used to collect

mine the applicability of regulatory limitations prior to use.

integrated samples of suspended solids and (as an option) ionic

1.4 This international standard was developed in accor-

solids.

dance with internationally recognized principles on standard-

3.2.1.1 Discussion—It consists of a flow totalizer that accu-

ization established in the Decision on Principles for the

rately measures the amount of sample passing through the

Development of International Standards, Guides and Recom-

device and a 0.45-µm pore size membrane filter. Adding a

mendations issued by the World Trade Organization Technical

second filter for ion exchange resin impregnated membranes

Barriers to Trade (TBT) Committee.

allows for collecting ionic solids.

3.2.2 ionic solids, n—includes all matter that will pass

2. Referenced Documents

through a 0.45-µm pore size filter and may be captured on

2

2.1 ASTM Standards:

anion, or cation ion exchange membranes, or both.

D1066 Practice for Sampling Steam

3.2.3 suspended solids, n—includes all matter that is re-

D1129 Terminology Relating to Water

moved by a 0.45-µm pore size filter.

D1193 Specification for Reagent Water

D1971 Practices for Digestion of Water Samples for Deter-

4. Summary of Practice

minationofMetalsbyFlameAtomicAbsorption,Graphite

4.1 A typical sampling apparatus, or corrosion product

sampler, is used to obtain integrated, representative samples of

1 suspended solids and ionic solids using a 0.45-µm membrane

This practice is under the jurisdiction ofASTM Committee D19 on Water and

is the direct responsibility of Subcommittee D19.03 on Sampling Water and

filter and ion exchange membranes. The sampling is accom-

Water-Formed Deposits, Analysis of Water for Power Generation and Process Use,

plished at system operating pressure or after pressure

On-Line Water Analysis, and Surveillance of Water.

reduction, and sample temperature of ≤50°C. The practice

Current edition approved Dec. 1, 2021. Published December 2021. Originally

utilizesamodifiedstainlesssteelhighpressurefilterhousingto

approved in 1998. Last previous edition approved in 2013 as D6301 – 13. DOI:

10.1520/D6301-21.

accommodate a 47-mm diameter filter (for suspended solids)

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

and if desired, ion exchange membranes (for ionic solids). The

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

sample collection system (corrosion product sampler) is de-

Standards volume information, refer to the standard’s Document Summary page on

the ASTM website. signed and operated specifically for quantitative collection of

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohock

...

This document is not an ASTM standard and is intended only to provide the user of an ASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

Designation: D6301 − 13 D6301 − 21

Standard Practice for

Collection of On-Line Composite Samples of Suspended

1

Solids and Ionic Solids in Process Water

This standard is issued under the fixed designation D6301; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope

1.1 This practice is applicable for sampling condensed steam or water, such as boiler feedwater, for the collection of suspended

solids and (optional) ionic solids using a 0.45-μm membrane filter (suspended solids) and ion exchange media (ionic solids). As

the major suspended component found in most boiler feedwaters is some form of corrosion product from the preboiler system, the

device used for this practice is commonly called a corrosion product sampler.

1.2 The values stated in SI units are to be regarded as standard. No other units of measurement are included in this standard.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility

of the user of this standard to establish appropriate safety safety, health, and healthenvironmental practices and determine the

applicability of regulatory limitations prior to use.

1.4 This international standard was developed in accordance with internationally recognized principles on standardization

established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued

by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

2. Referenced Documents

2

2.1 ASTM Standards:

D1066 Practice for Sampling Steam

D1129 Terminology Relating to Water

D1193 Specification for Reagent Water

D1971 Practices for Digestion of Water Samples for Determination of Metals by Flame Atomic Absorption, Graphite Furnace

Atomic Absorption, Plasma Emission Spectroscopy, or Plasma Mass Spectrometry

D2332 Practice for Analysis of Water-Formed Deposits by Wavelength-Dispersive X-Ray Fluorescence

D2777 Practice for Determination of Precision and Bias of Applicable Test Methods of Committee D19 on Water

D3370 Practices for Sampling Water from Flowing Process Streams

D3864 Guide for On-Line Monitoring Systems for Water Analysis

3. Terminology

3.1 Definitions—Definitions: For definitions of terms used in this practice, refer to Terminology D1129.

1

This practice is under the jurisdiction of ASTM Committee D19 on Water and is the direct responsibility of Subcommittee D19.03 on Sampling Water and Water-Formed

Deposits, Analysis of Water for Power Generation and Process Use, On-Line Water Analysis, and Surveillance of Water.

Current edition approved July 15, 2013Dec. 1, 2021. Published August 2013December 2021. Originally approved in 1998. Last previous edition approved in 20082013

as D6301 – 08.D6301 – 13. DOI: 10.1520/D6301-13.10.1520/D6301-21.

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM Standards

volume information, refer to the standard’s Document Summary page on the ASTM website.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

D6301 − 21

3.1.1 For definitions of terms used in this standard, refer to Terminology D1129.

3.2 Definitions of Terms Specific to This Standard:

3.2.1 corrosion product sampler, n—a device used to collect integrated samples of suspended solids and (as an option) ionic solids.

3.2.1.1 Discussion—

It consists of a flow totalizer that accurately measures the amount of sample passing through the device and a 0.45-μm pore size

membrane filter. Adding a second filter for ion exchange resin impregnated membranes allows for collecting ionic solids.

3.2.2 ionic solids, n—includes all matter that will pass through a 0.45-μm pore size filter and may be captured on anion, or cation

ion exchange membranes, or both.

3.2.3 suspended solids, n—includes all matter that is removed by a 0.45-μm pore size filter.

4. Summary of Practice

4.1 A typical sampling apparatus, or corrosion product sampler, is used to obtain integrated, representative samples of suspended

solids and ionic solids using a 0.45-μm membrane filter and ion exchange membranes. The sampling is accomplished at system

operating

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.