ASTM D1087-60

(Practice)Recommended Practice for Volume Calculations and Corrections in the Measurement of Petroleum and Petroleum Products (Withdrawn 1964)

Recommended Practice for Volume Calculations and Corrections in the Measurement of Petroleum and Petroleum Products (Withdrawn 1964)

General Information

Standards Content (Sample)

Recommended Practice/or

VOLUME CALCULATIONS AND CORRECTIONS

IN THE MEASUREMENT OF PETROLEUM

1

AND PETROLEUM PRODUCTS

ASTM Designation: D 1087 - 60

ADOPTED, 1960.1

This Recommended Practice of the American

Society for Testing Materials is issued under

the fixed designation D 1087; the final number

indicates the year of original adoption or, in

the case of revision, the year of last revision.

Scope

1. This recommended practice describes procedures for voltJ,me

calculations and corrections in the measurement of petroleum and its

·liquid products.

Terminology

2. (a) Measured Quantity is the volume of material in a tank for a

given gage at the temperature observed at the time of gaging.

(b) Gross Quantity at 60 F. is the measured quantity converted to

the equivalent volume at 60 F. after deducting any free water and

sediment (FW & S) which may be present.

(c) Net Quantity at 60 F. is the gross quantity at 60 F. corrected

for any deducti'bl.e suspended water and sediment (SW & S) which

may be present. (All SW & S is deductible, unless otherwise speci

fied by contract.)

NOTE.-ln crude oil measuring and testing, "FW & S" and "SW & S" are

frequently ref erred to as "BS & W," meaning respectively "Bottom" and "Basic"

Sediment and Water.

(d) Tables.-All references in this standard to tables followed by a

1

Under the standardization procedure of the Society, this recommended

practice is under the jurisdiction of the ASTM Committee D-2 on Petroleum

Products and Lubricants.

2

Prior to adoption, this recommended practice was published as tentative

from 1950 to 1960, being revised in 1952 and 1957.

In 1960, this recommended practice was adopted without revision. ·

1076

---------------------- Page: 1 ----------------------

VoLUME CALCULATIONS AND CORRECTION& (D 1087) 1077

number refer to the ASTM-IP Petroleum Measurement Tables

3

(American Edition) (ASTM Designation: D 1250; IP 200).

Use of Capacity Tables

3. Capacity tables showing quantities for either innage or outage

gages shall be based on accurate tank calibration data. The cali

brations should be checked periodically and whenever repairs or al

terations are made to a tank or compartment.

BASIC CALCULATIONS

Basic Calculations

4. (a) Measured Quantity.-Obtain the measured quantity for each

opening and closing gage directly from the capacity table. If the basis

of the table, innage or outage, is not the same as that of the gage,

convert the gage to the same basis as the table by deducting the

gage reading from the reference depth (gaging height).

(b) Free Water and Sediment Deduction.-Obtain the quantities of

free water and sediment, corresponding to each opening and closing

water gage from the capacity table and deduct them from the respec

tive opening and closing measured quantities.

(c) Gross Quantity at 60 F.-Calculate the gross quantity at 60 F.

by multiplying the measured quantity, corrected for any free water

and secli.ment, by the volume correction factor which corresponds to

3

its gravity. Obtain this factor from Table 6 of Standard D 1250 ; for

liquefied petroleum gases obtain this factor from Table 34. The de

livered or received gross quantity at 60 F. is the difference between

the gross quantities at 60 F. calculated from the opening and closing

gages.

(d) Net Quantity at 60 F.-Obtain the net quantity at 60 F. by

subtracting any suspended water and sediment which may be present

from the gross quantity at 60 F. When contracts make allowance for

some SW & S, the deductible quantity is the difference between

the total and the allowable quantities of SW & S.

(e) Tanks are usually calibrated in U.S. gallons or barrels. Convert

gallons to barrels by dividing by 42.

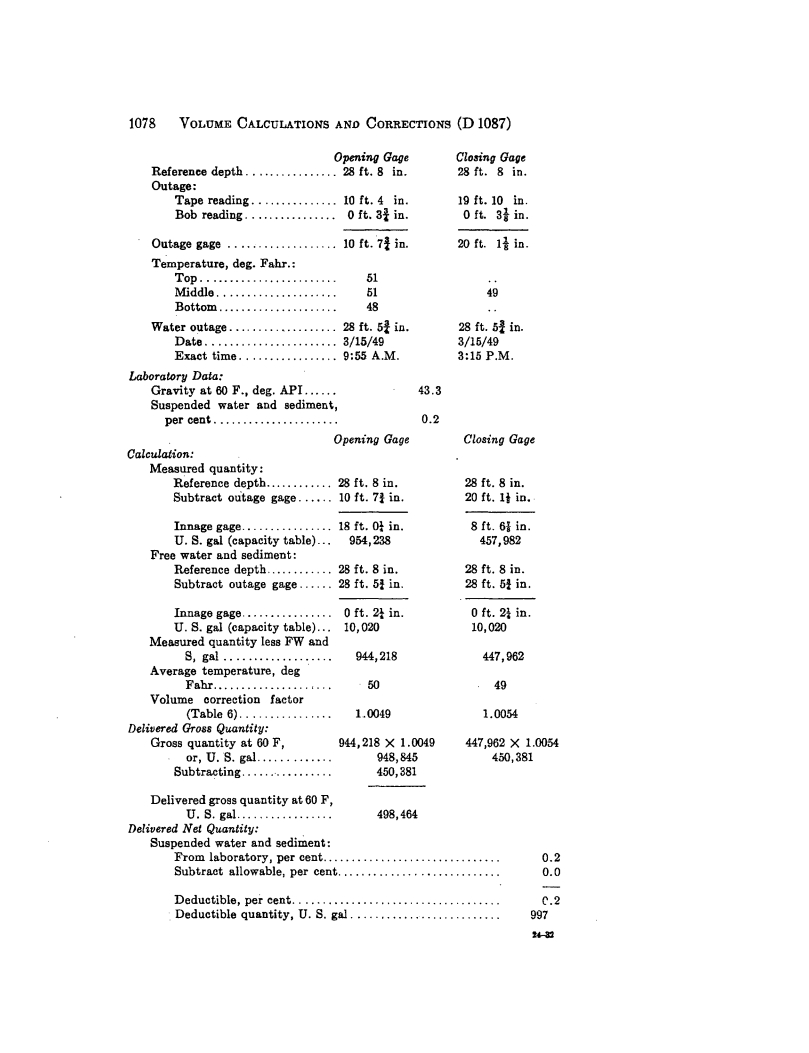

(j) Example.-The following data and calculations illustrate the

recommended procedure for calculating the gross and net quantities

of product at 60 F. measured in or delivered from a tank:

Gaging Data:

Tank number. . . . . . . . . . . . . . . . . . 307

Product . West Texas crude oil

Vessel . Barge No. 16

a Published j oiL.tly by, and available from, the American Society for Testing

Materials, 1916 Race St., Philadelphia 3, and the Institute of Petroleum, 26

Portland Place, London W-1. Companion volumes-the British Edition and

the Metric Edition-are also available. ·

---------------------- Page: 2 ----------------------

1078 VOLUME CALCULATIONS AND CORRECTIONS (D 1087)

Opening Gage Cloaing Gage

Reference depth . 28 ft. 8 in. 28 ft. 8 in.

Outage:

Tape reading . 10 ft. 4 in. 19 ft. 10 in.

Bob reading. . . . . . . . . . . . . . . . 0 ft. 3f in. 0 ft. 3} in.

Outage gage . 10 ft. 7i in. 20 ft. lt in.

Temperature, deg. Fa.hr.:

Top . . 51

Middle . . 51 49

Bottom . . 48

Water outage . 28 ft. 5! in. 28 ft. 5} in.

Date. . . . . . . . . . .

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.