ASTM B882-05

(Specification)Specification for Pre-Patinated Copper for Architectural Applications

Specification for Pre-Patinated Copper for Architectural Applications

ABSTRACT

This specification establishes of the requirements for pre-patinated (artificially aged) copper sheets and strips in ounce-weight thicknesses supplied in flat lengths for roofing, flashing, and other architectural applications. Materials made to this specification are not intended to be used for electrical applications. The pre-patinated surface shall not be the result of coating applications such as painting, but rather the result of chemical treatment that artificially ages the base metal to form green- to turquoise-colored protective layer. Products shall be produced in tempers H00 (eighth hard, cold-rolled), H01 (quarter hard, cold-rolled high yield), and H02 (half hard). Products shall be tested to examine their conformance to dimensional (mass, thickness, weight, width, length, and straightness), mechanical (tensile and yield strengths, and Rockwell hardness), and chemical composition requirements. Products shall also undergo color fade resistance and resistance to flaking tests.

SCOPE

1.1 This specification covers the establishment of the requirements for pre-patinated (artificially aged) copper sheet and strip in ounce-weight thicknesses supplied in flat lengths for roofing, flashing, and other architectural applications.

1.2 The pre-patinated surface is the result of chemical reaction with the copper and shall be applied on one side of the product.

1.2.1 The pre-patinated surface formed is comparable in color and ability to be bent or formed to the surface formed in naturally occurring patinated copper.

1.3 The pre-patinated surface is not the result of coating applications such as painting.

1.4 Materials made to this specification are not intended to be used for electrical applications.

1.5 The values stated in inch-pound units are to be regarded as standard. The values given in parentheses are mathematical conversions to SI units that are provided for information only and are not considered standard.Note 1

A companion specification for copper sheet and strip for building construction is Specification B 370.

The following precautionary statement pertains only to the test method portion, Section , of this specification: This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: B882 – 05

Standard Specification for

1

Pre-Patinated Copper for Architectural Applications

This standard is issued under the fixed designation B882; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope* B248 Specification for General Requirements for Wrought

Copper and Copper-Alloy Plate, Sheet, Strip, and Rolled

1.1 This specification covers the establishment of the re-

Bar

quirements for pre-patinated (artificially aged) copper sheet

B370 Specification for Copper Sheet and Strip for Building

and strip in ounce-weight thicknesses supplied in flat lengths

Construction

for roofing, flashing, and other architectural applications.

B571 Practice for Qualitative Adhesion Testing of Metallic

1.2 The pre-patinated surface is the result of chemical

Coatings

reaction with the copper and shall be applied on one side of the

B601 Classification for Temper Designations for Copper

product.

and Copper Alloys—Wrought and Cast

1.2.1 The pre-patinated surface formed is comparable in

B846 Terminology for Copper and Copper Alloys

color and ability to be bent or formed to the surface formed in

E8 Test Methods for Tension Testing of Metallic Materials

naturally occurring patinated copper.

E478 TestMethodsforChemicalAnalysisofCopperAlloys

1.3 The pre-patinated surface is not the result of coating

G23 Practice for Operating Light-Exposure Apparatus

applications such as painting.

(Carbon-Arc Type) With and Without Water for Exposure

1.4 Materials made to this specification are not intended to

3

of Nonmetallic Materials (Discontinued 2001)

be used for electrical applications.

1.5 The values stated in inch-pound units are to be regarded

3. Terminology

as standard. The values given in parentheses are mathematical

3.1 Definitions:

conversions to SI units that are provided for information only

3.1.1 For definitions of terms related to copper and copper

and are not considered standard.

alloys, refer to Terminology B846.

NOTE 1—A companion specification for copper sheet and strip for

3.2 Definitions of Terms Specific to This Standard:

building construction is Specification B370.

3.2.1 pre-patinated copper—copper that has been artifi-

1.6 The following precautionary statement pertains only to

cially aged under controlled and monitored conditions to

the test method portion, Section 12, of this specification: This

produce a protective surface that is within the range of colors

standard does not purport to address all of the safety concerns,

from green to turquoise.

if any, associated with its use. It is the responsibility of the user

4. Ordering Information

of this standard to establish appropriate safety and health

practices and determine the applicability of regulatory limita-

4.1 Orders for product produced to this specification should

tions prior to use. include the following information:

4.1.1 ASTM designation and year of issue,

2. Referenced Documents

4.1.2 Ounce weight thickness of the base copper sheet (see

2

2.1 ASTM Standards:

Table 1),

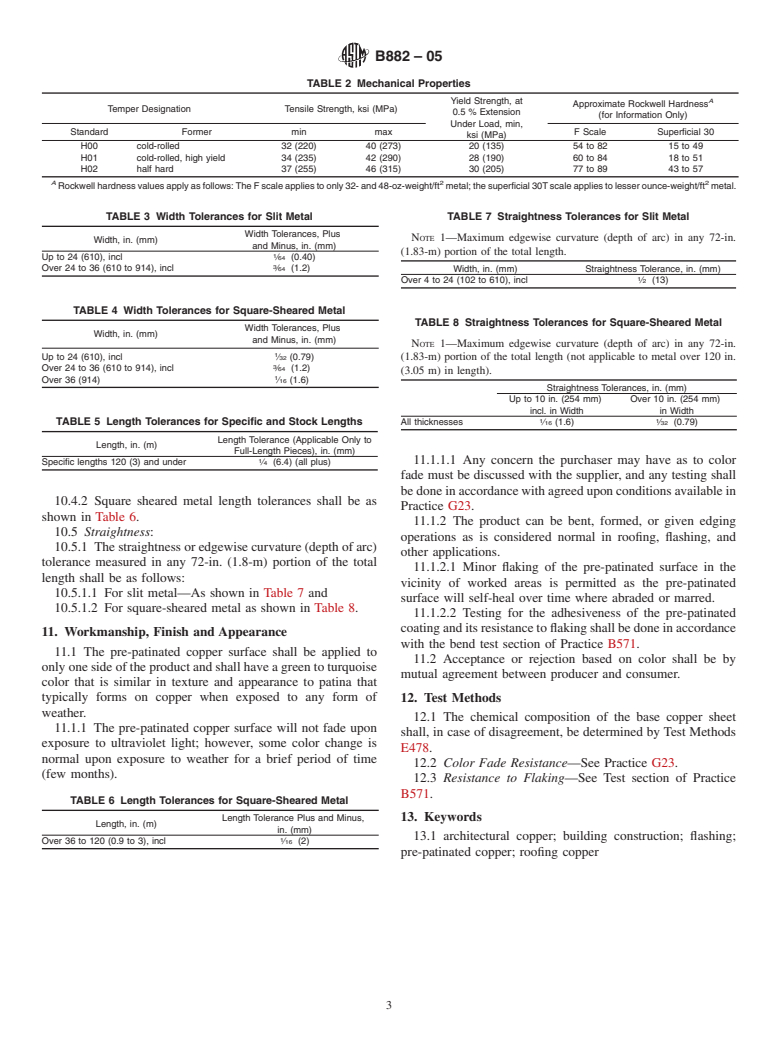

4.1.3 Temper (see Table 2),

4.1.4 Dimensions—Width and length of sheets, and

4.1.5 Quantity—Total weight or number of sheets of each

1

ThisspecificationisunderthejurisdictionofASTMCommitteeB05onCopper

size.

andCopperAlloysandisthedirectresponsibilityofSubcommitteeB05.01onPlate,

Sheet, and Strip. 4.2 The following requirements are optional and shall be

Current edition approved Oct. 1, 2005. Published October 2005. Originally

included in the purchase order or contract when required:

approved in 1997. Last previous edition approved in 2000 as B882 – 00. DOI:

4.2.1 Certification,

10.1520/B0882-05.

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

3

Standards volume information, refer to the standard’s Document Summary page on Withdrawn. The last approved version of this historical standard is referenced

the ASTM website. on www.astm.org.

*ASummary of Changes section appears at the end of this standard.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

1

---------------------- Page: 1 ----------------------

B882 – 05

TABLE 1 Thickness and Weight Tolerances of Sheet and Strip

7.3 The artificial patina is composed of metallic salts which

Theoretical are also found in naturally occurring patinas.

Tolerances, Plus and Minus,

2 A

Ounce-Weight/ft Thickness,

in. (mm)

in. (mm)

8. Temper

6 0.0081 (0.206) 0.001 (0.026)

8.1 The nonpatinated base copper sheet, referred to in 6.1 of

8 0.0108 (0.274) 0.0011 (0.028)

10 0.0135 (0.343) 0.0011 (0.028)

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.