ASTM B106-08

(Test Method)Standard Test Methods for Flexivity of Thermostat Metals

Standard Test Methods for Flexivity of Thermostat Metals

SIGNIFICANCE AND USE

These test methods are used for determining response to temperature change or flexivity of thermostat metal. The flexivity is calculated from the temperatures, dimensions of specimen, and the relative movement of the specimen. The simple beam method (Method A) is the method for certification. Any use of the spiral coil method (Method B) is to be mutually agreed upon between the user and supplier.

SCOPE

1.1 These test methods cover the determination of flexivity (a measure of thermal deflection rate or deflection temperature characteristics) of thermostat metals.

1.1.1 Test Method A—Tested in the form of flat strip

0.015 in. (0.38 mm) or over in thickness.

1.1.2 Test Method B—Tested in the form of spiral coils less than 0.012 in. in thickness.

1.2 The values stated in inch-pound units are to be regarded as standard. The values given in parentheses are mathematical conversions to SI units that are provided for information only and are not considered standard.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to become familiar with all hazards including those identified in the appropriate Material Safety Data Sheet (MSDS) for this product/material as provided by the manufacturer, to establish appropriate safety and health practices, and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Buy Standard

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: B106 − 08

StandardTest Methods for

1

Flexivity of Thermostat Metals

This standard is issued under the fixed designation B106; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope 3.1.2 flexivity (F), n—the change of curvature of the longi-

tudinalcenterlineofthespecimenperunittemperaturechange

1.1 These test methods cover the determination of flexivity

for unit thickness, given by the following equation:

(a measure of thermal deflection rate or deflection temperature

characteristics) of thermostat metals. 1/R 2 1/R

~ ! ~ !

2 1

F 5 t (1)

1.1.1 Test Method A—Tested in the form of flat strip T 2 T

2 1

0.015 in. (0.38 mm) or over in thickness.

To determine the flexivity between any two temperatures,

1.1.2 Test Method B—Tested in the form of spiral coils less

T and T , it is necessary to measure the curvature 1/ R and

1 2 1

than 0.012 in. in thickness.

1/R at temperature T and T , respectively. To find the cur-

2 1 2

1.2 The values stated in inch-pound units are to be regarded

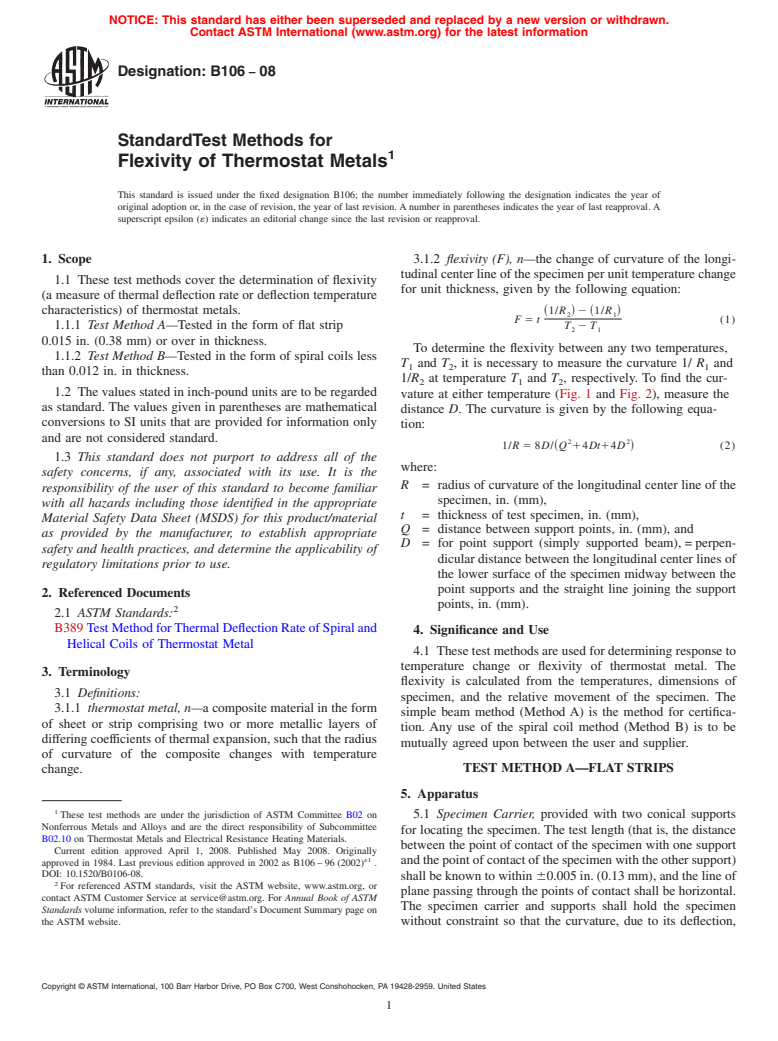

vature at either temperature (Fig. 1 and Fig. 2), measure the

as standard. The values given in parentheses are mathematical

distance D. The curvature is given by the following equa-

conversions to SI units that are provided for information only

tion:

and are not considered standard.

2 2

1/R 5 8D/ Q 14Dt14D (2)

~ !

1.3 This standard does not purport to address all of the

where:

safety concerns, if any, associated with its use. It is the

R = radius of curvature of the longitudinal center line of the

responsibility of the user of this standard to become familiar

specimen, in. (mm),

with all hazards including those identified in the appropriate

t = thickness of test specimen, in. (mm),

Material Safety Data Sheet (MSDS) for this product/material

Q = distance between support points, in. (mm), and

as provided by the manufacturer, to establish appropriate

D = for point support (simply supported beam),=perpen-

safety and health practices, and determine the applicability of

dicular distance between the longitudinal center lines of

regulatory limitations prior to use.

the lower surface of the specimen midway between the

point supports and the straight line joining the support

2. Referenced Documents

points, in. (mm).

2

2.1 ASTM Standards:

B389TestMethodforThermalDeflectionRateofSpiraland

4. Significance and Use

Helical Coils of Thermostat Metal

4.1 Thesetestmethodsareusedfordeterminingresponseto

temperature change or flexivity of thermostat metal. The

3. Terminology

flexivity is calculated from the temperatures, dimensions of

3.1 Definitions:

specimen, and the relative movement of the specimen. The

3.1.1 thermostat metal, n—a composite material in the form

simple beam method (Method A) is the method for certifica-

of sheet or strip comprising two or more metallic layers of

tion. Any use of the spiral coil method (Method B) is to be

differingcoefficientsofthermalexpansion,suchthattheradius

mutually agreed upon between the user and supplier.

of curvature of the composite changes with temperature

TEST METHOD A—FLAT STRIPS

change.

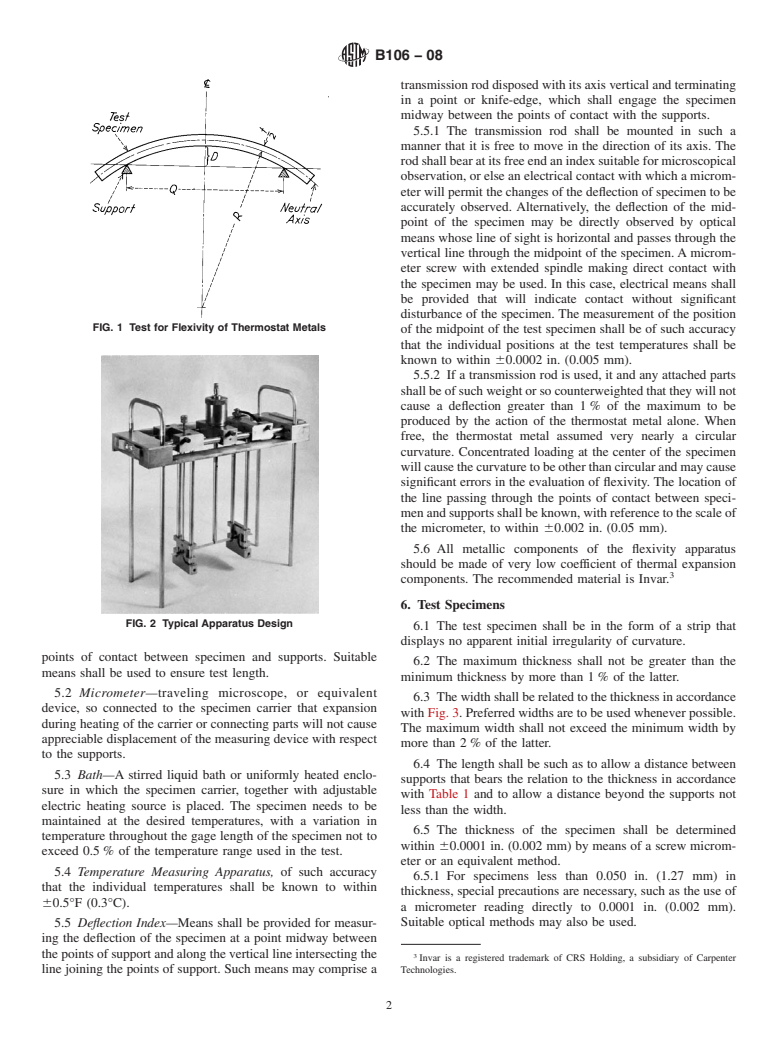

5. Apparatus

1

These test methods are under the jurisdiction of ASTM Committee B02 on

5.1 Specimen Carrier, provided with two conical supports

Nonferrous Metals and Alloys and are the direct responsibility of Subcommittee

for locating the specimen. The test length (that is, the distance

B02.10 on Thermostat Metals and Electrical Resistance Heating Materials.

between the point of contact of the specimen with one support

Current edition approved April 1, 2008. Published May 2008. Originally

´1

andthepointofcontactofthespecimenwiththeothersupport)

approved in 1984. Last previous edition approved in 2002 as B106–96(2002) .

DOI: 10.1520/B0106-08.

shallbeknowntowithin 60.005in.(0.13mm),andthelineof

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

plane passing through the points of contact shall be horizontal.

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

The specimen carrier and supports shall hold the specimen

Standards volume information, refer to the standard’s Document Summary page on

the ASTM website. without constraint so that the curvature, due to its deflection,

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

B106 − 08

willfollowaverticalplanepassingthroughthelinejoiningthe

1

---------------------- Page: 2 ----------------------

B106 − 08

transmissionroddisposedwithitsaxisverticalandterminating

in a point or knife-edge, which shall en

...

This document is not anASTM standard and is intended only to provide the user of anASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

e1

Designation:B106–96(Reapproved 2002) Designation:B106–08

Standard Test Methods for

1

Flexivity of Thermostat Metals

This standard is issued under the fixed designation B106; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

1

e NOTE—Paragraph 1.3 was corrected editorially in June 2002.

1. Scope

1.1 These test methods cover the determination of flexivity (a measure of thermal deflection rate or deflection temperature

characteristics) of thermostat metals.

1.1.1 Test Method A—Tested in the form of flat strip 0.012

0.015 in. (0.30(0.38 mm) or over in thickness.

1.1.2 Test Method B—Tested in the form of spiral coils less than 0.012 in. in thickness.

1.2The values stated in inch-pound units are to be regarded as the standard. The values given in parentheses are provided for

information purposes only. 1.2

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility

of the user of this standard to become familiar with all hazards including those identified in the appropriate Material Safety Data

Sheet (MSDS) for this product/material as provided by the manufacturer, to establish appropriate safety and health practices, and

determine the applicability of regulatory limitations prior to use.

2. Referenced Documents

2

2.1 ASTM Standards:

B389 Test Method for Thermal Deflection Rate of Spiral and Helical Coils of Thermostat MetalMetal

3. Terminology

3.1 Definitions:

3.1.1 thermostat metalthermostat metal, n—a composite material in the form of sheet or strip comprising two or more metallic

layers of differing coefficients of thermal expansion, such that the radius of curvature of the composite changes with temperature

change.

3.1.2 flexivity (F)flexivity (F), n—the change of curvature of the longitudinal center line of the specimen per unit temperature

change for unit thickness, given by the following equation:

F5t 1/R

~

~1/R !2~1/R !

2 1

F 5 t (1)

T 2T

2 1

~1/R ! 2 ~1/R !

2 1

F 5 t (1)

T 2 T

2 1

To determine the flexivity between any two temperatures, T and T , it is necessary to measure the curvature 1/ R and 1/R

1 2 1 2

at temperature T and T , respectively.To find the curvature at either temperature (Fig. 1 and Fig. 2), measure the distance D.The

1 2

curvature is given by the following equation:

2 2

1/R58D/ Q 14Dt14D ! (2)

~

2 2

1/R 58D/~Q 14Dt 14D ! (2)

1

These test methods are under the jurisdiction of ASTM Committee B02 on Nonferrous Metals and Alloys and isare the direct responsibility of Subcommittee B02.10

on Thermostat Metals and Electrical Resistance Heating Materials.

CurrenteditionapprovedJan.10,1996.April1,2008.PublishedApril1996.May2008.OriginallypublishedasB106–84.approvedin1984.Lastpreviouseditionapproved

e1

in 2002 as B106–96(2002) .

2

Annual Book of ASTM Standards, Vol 02.04.

2

The boldface numbers in parentheses refer to a list of references at the end of this standard.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

1

---------------------- Page: 1 ----------------------

B106–08

FIG. 1 Test for Flexivity of Thermostat Metals

FIG. 2 Typical Apparatus Design

where:

R = radius of curvature of the longitudinal center line of the specimen, in. (mm),

t = thickness of test specimen, in. (mm),

Q = distance between support points, in. (mm), and

D = for point support (simply supported beam),=perpendicular distance between the longitudinal center lines of the lower

surface of the specimen midway between the point supports and the straight line joining the support points, in. (mm).

4. Significance and Use

4.1 These test methods are used for determining response to temperature change or flexivity of thermostat metal. The flexivity

iscalculatedfromthetemperatures,dimensionsofspecimen,andtherelativemovementofthespecimen.Thesimplebeammethod

(MethodA) is the method for certification.Any use of the spiral coil method (Method B) is to be mutually agreed upon between

the user and supplier.

TEST METHOD A—FLAT STRIPS

5. Apparatus

5.1 Specimen Carrier, provided with two conical supports for locating the specimen. The test length (that is, the distance

between the point of contact of the specimen with one support and the point of contact of the specimen with the other support)

shall be known to within 60.005 in. (0.

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.