ASTM D7299-06

(Practice)Standard Practice for Verifying Performance of a Vertical Inclinometer Probe

Standard Practice for Verifying Performance of a Vertical Inclinometer Probe

SIGNIFICANCE AND USE

Inclinometer monitoring programs often run several years or more. During this time, hundreds of surveys can be collected. Each new survey is processed by comparing it to a baseline survey.

Over a period of years, normal wear and tear can gradually degrade the probe’s ability to produce new surveys that are directly comparable to the baseline survey. This may go unnoticed for some time, because the quality of readings may degrade in very small increments.

When function tests are incorporated into an inclinometer monitoring program, the degradation of reading quality can be avoided. Probes that pass the tests can be used with confidence. Probes that fail the tests should be returned to the probe manufacturer for servicing. It should be noted that manufacturers calibrate inclinometer probes using high-precision, electronically-controlled equipment in temperature-controlled environments. Ordinary users do not have access to such equipment, so the pass/fail criteria suggested for these tests accommodate typical results produced by less precise equipment in a less controlled environment.

The quality of the result produced by this standard is dependent on the competence of the personnel performing it and the suitability of the equipment and facilities used. Agencies that meet the criteria of Practice D 3740 are generally considered capable of competent and objective testing/sampling/inspection/etc. Users of this standard are cautioned that compliance with Practice D 3740 does not in itself assure reliable results. Reliable results depend on many factors; Practice D 3740 provides a means of evaluating some of those factors.

SCOPE

1.1 This practice describes three function tests that together can be used to verify that a vertical inclinometer probe is working properly.

1.2 This practice does not address calibration routines, electronic diagnostics, or repair of the probe, nor does it address inspection of the probes mechanical parts.

1.3 This practice is not intended to replace manufacturers recommendations for servicing and calibration of inclinometer equipment, nor is it intended to replace maintenance and calibration schedules established by users as part of their quality programs.

1.4 This practice offers a set of instructions for performing one or more specific operations. This document cannot replace education or experience and should be used in conjunction with professional judgment. Not all aspects of this practice may be applicable in all circumstances. This ASTM standard is not intended to represent or replace the standard of care by which the adequacy of a given professional service must be judged, nor should this document be applied without consideration of a projects many unique aspects. The word "standard" in the title of this document means only that the document has been approved through the ASTM consensus process.

1.5 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: D7299 − 06

StandardPractice for

Verifying Performance of a Vertical Inclinometer Probe

This standard is issued under the fixed designation D7299; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope D3740 Practice for Minimum Requirements for Agencies

Engaged in Testing and/or Inspection of Soil and Rock as

1.1 This practice describes three function tests that together

Used in Engineering Design and Construction

can be used to verify that a vertical inclinometer probe is

working properly.

3. Terminology

1.2 This practice does not address calibration routines,

3.1 Definitions:

electronic diagnostics, or repair of the probe, nor does it

3.1.1 Terms not defined below may appear in Terminology

address inspection of the probe’s mechanical parts.

D653.

1.3 This practice is not intended to replace manufacturers’

3.1.2 inclinometer casing, n—A special-purpose pipe, typi-

recommendations for servicing and calibration of inclinometer

cally installed in boreholes, with internal guide grooves that

equipment, nor is it intended to replace maintenance and

control the orientation of the inclinometer probe and that

calibration schedules established by users as part of their

provide a flat surface for repeatable tilt measurements.

quality programs.

3.1.3 survey, n—A set of readings obtained with the incli-

1.4 This practice offers a set of instructions for performing

nometer probe and readout.

one or more specific operations. This document cannot replace

3.1.4 vertical inclinometer probe, n—A wheeled device

education or experience and should be used in conjunction

used to measure the tilt of inclinometer casing that is installed

with professional judgment. Not all aspects of this practice may

in a vertical borehole. The wheels of the device track the

be applicable in all circumstances. This ASTM standard is not

grooves of the inclinometer casing and also keep the body of

intended to represent or replace the standard of care by which

the probe centralized within the casing.Typically there are two

the adequacy of a given professional service must be judged,

sensors inside the device, each capable of reporting positive

nor should this document be applied without consideration of

and negative values. One sensor measures tilt in the plane of

a project’s many unique aspects. The word “standard” in the

the wheels and is commonly known as the A-axis sensor. The

title of this document means only that the document has been

othersensormeasurestiltintheplanenormaltothewheelsand

approved through the ASTM consensus process.

is commonly known as the B-axis sensor.

1.5 This standard does not purport to address all of the

3.1.5 zero offset, n—Non-zero values reported by theA-axis

safety concerns, if any, associated with its use. It is the

and B-axis sensors when the probe is held precisely vertical.

responsibility of the user of this standard to establish appro-

priate safety and health practices and determine the applica-

4. Significance and Use

bility of regulatory limitations prior to use.

4.1 Inclinometer monitoring programs often run several

2. Referenced Documents years or more. During this time, hundreds of surveys can be

collected. Each new survey is processed by comparing it to a

2.1 ASTM Standards:

baseline survey.

D653 Terminology Relating to Soil, Rock, and Contained

Fluids 4.2 Over a period of years, normal wear and tear can

gradually degrade the probe’s ability to produce new surveys

that are directly comparable to the baseline survey. This may

go unnoticed for some time, because the quality of readings

This practice is under the jurisdiction of ASTM Committee D18 on Soil and

Rock and is the direct responsibility of Subcommittee D18.23 on Field Instrumen-

may degrade in very small increments.

tation.

4.3 When function tests are incorporated into an inclinom-

Current edition approved Nov. 1, 2006. Published December 2006. DOI:

10.1520/D7299-06.

eter monitoring program, the degradation of reading quality

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

can be avoided. Probes that pass the tests can be used with

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

confidence. Probes that fail the tests should be returned to the

Standardsvolume information, refer to the standard’s Document Summary page on

the ASTM website. probe manufacturer for servicing. It should be noted that

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

D7299 − 06

manufacturers calibrate inclinometer probes using high- vernier plate that permits direct reading to within 5 s. The

precision, electronically-controlled equipment in temperature- vernier scale is used to make the various test measurements.

controlled environments. Ordinary users do not have access to

5.2.2 MakethepedestalfromasteelI-beamora6-inch(150

such equipment, so the pass/fail criteria suggested for these

mm) diameter steel pipe cut to a convenient height. Steel is a

tests accommodate typical results produced by less precise

commonly available material but other metals may be also be

equipment in a less controlled environment.

suitable. Make plates for the top and bottom of the pedestal

using 0.5-in. (12.5 mm) thick steel. Mill the top plate flat for

4.4 The quality of the result produced by this standard is

proper mounting of the rotary table. Drill bolt holes in the base

dependent on the competence of the personnel performing it

plate, as shown in Fig. 1. Weld the steel plates to the two ends

and the suitability of the equipment and facilities used.

of the beam or pipe. Choose a location for the stand and set

Agencies that meet the criteria of Practice D3740 are generally

bolts into stable flooring, such as a concrete floor slab. Ideally,

considered capable of competent and objective testing/

the location will be free from vibration. Place the test stand

sampling/inspection/etc. Users of this standard are cautioned

onto the bolts. Place steel shims under the bottom plate so that

that compliance with Practice D3740 does not in itself assure

the top plate is completely horizontal, as indicated by a

reliable results. Reliable results depend on many factors;

machinist’s bubble level. Tighten nuts on the floor bolts.

Practice D3740 provides a means of evaluating some of those

5.2.3 Mount the rotary table to the top plate as shown in

factors.

Figure 1. Place steel shims as necessary to make the plane of

5. Apparatus the table vertical. Make a probe holder from 2-in. (50 mm)

square-section 6061 T6 aluminum tubing. The square section

5.1 Two pieces of equipment are suggested: a rotary table

tubing holds the wheels tightly, in a fixed, repeatable position.

test stand and a test casing. All the tests could be performed

Inclinometer casing is not a suitable substitute for the tubing,

usingonlytherotarytableteststand,butoperationoftherotary

since casing grooves are purposely made wider to facilitate

table requires a trained operator working slowly and deliber-

passage of the probe through deformed casing. Mount the

ately. The test casing, on the other hand, provides a simple test

probe holder to the rotary table using two V-blocks, fitting the

thatcanbeusedfrequentlybyanyinclinometeruserafterafew

holder so that it provides two possible positions for the probe,

minutes of training.

one parallel to the rotary table, and the other perpendicular to

5.2 Rotary Table Test Stand—

the table.

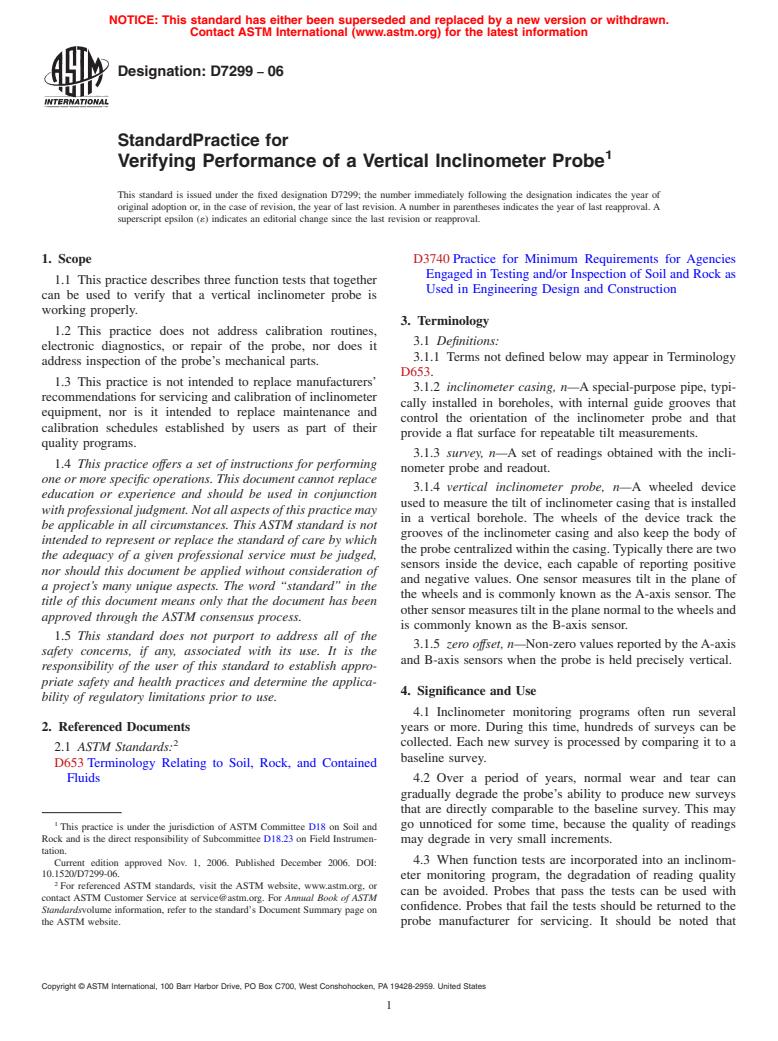

5.2.1 The rotary table test stand (Fig. 1) consists of a rotary

5.2.4 Devise a means of applying a constant torque to the

table mounted on a pedestal. The rotary table is a device that is

table to compensate for backlash in the gears and improve the

commonly used in precision machining operations. In machine

precision with which the table can be rotated. Fig. 1 shows a

shops, rotary tables are usually mounted horizontally. In this

weight suspended from a wire rope that is attached to the table.

case, the table is mounted vertically, so that it can move the

Wrap the wire rope over the top of the table so that the weight

probe through its specified tilt range. A suitable rotary table

assists rotation toward positive angles (typically clockwise) as

will offer a placement accuracy of 30 seconds of arc or better

read from the scales on the rotary table.

throughoutitsrange.Itshouldprovideanadjustabledialonthe

hand wheel that reads directly to each minute of arc, and a 5.3 Test Casing

FIG. 1 Rotary Table Test Stand

D7299 − 06

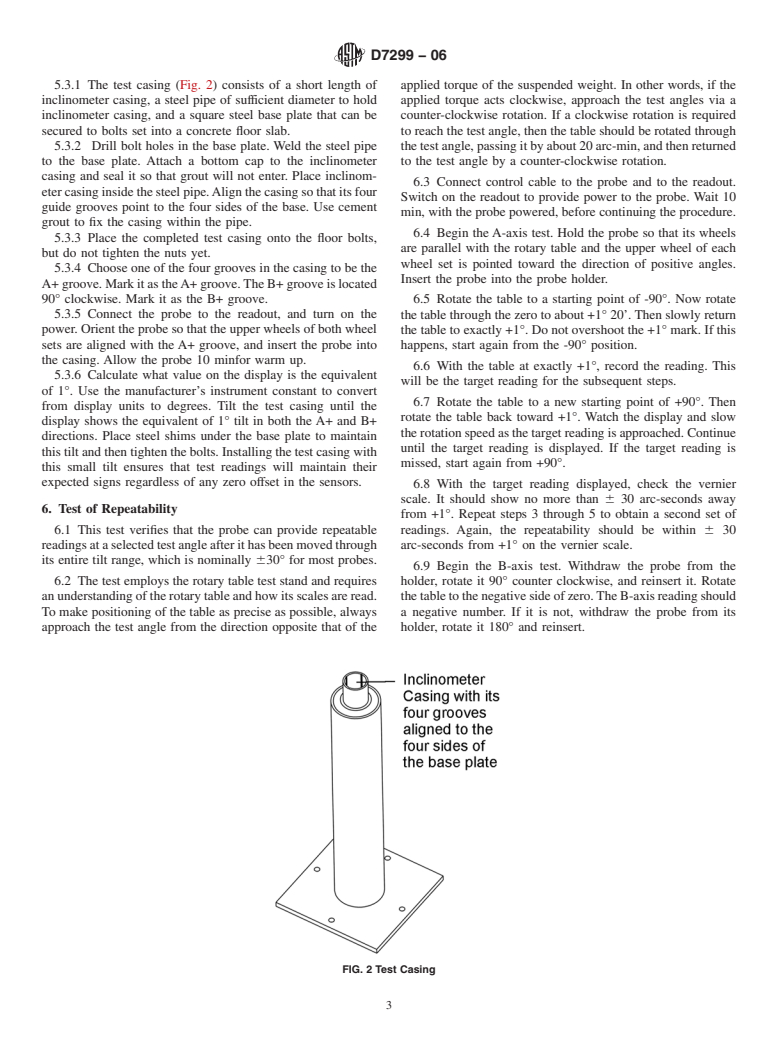

5.3.1 The test casing (Fig. 2) consists of a short length of applied torque of the suspended weight. In other words, if the

inclinometer casing, a steel pipe of suffici

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.