ASTM D6227-18(2023)

(Specification)Standard Specification for Unleaded Aviation Gasoline Containing a Non-hydrocarbon Component

Standard Specification for Unleaded Aviation Gasoline Containing a Non-hydrocarbon Component

ABSTRACT

This specification covers Grade 82 unleaded aviation gasoline for use only in engines and associated aircraft that are specifically approved by the engine and aircraft manufacturers, and certified by the National Certifying Agencies to use this fuel. Aviation gasoline shall consist of blends of refined hydrocarbons derived from crude petroleum, natural gasoline or blends thereof, with specific aliphatic ethers, synthetic hydrocarbons, or aromatic hydrocarbons, and when applicable, methyl tertiarybutyl ether (MTBE). They may also contain antioxidants (oxidation inhibitors), metal deactivators, corrosion inhibitors, and fuel system icing inhibitors. The gasoline shall be tested and conform accordingly to the following property requirements: lean mixture knock value and motor method octane number; color; blue and red dye content; distillation temperature at % evaporated, end point, and residue content; distillation recovery; distillation loss; net heat of combustion; freezing point; vapor pressure; lead content; copper strip corrosion; sulfur content; potential gum; and alcohols and ether content (aliphatic ethers, methanol, and ethanol).

SCOPE

1.1 This specification covers Grades UL82 and UL87 unleaded aviation gasolines, which are defined by this specification and are only for use in engines and associated aircraft that are specifically approved by the engine and aircraft manufacturers, and certified by the National Certifying Agencies to use these fuels. Components containing hetro-atoms (oxygenates) may be present within the limits specified.

1.2 A fuel may be certified to meet this specification by a producer as Grade UL82 or UL87 aviation gasoline only if blended from component(s) approved for use in these grades of aviation gasoline by the refiner(s) of such components, because only the refiner(s) can attest to the component source and processing, absence of contamination, and the additives used and their concentrations. Consequently, reclassifying of any other product to Grade UL82 or Grade UL87 aviation gasoline does not meet this specification.

1.3 Appendix X1 contains an explanation for the rationale of the specification. Appendix X2 details the reasons for the individual specification requirements.

1.4 The values stated in SI units are to be regarded as standard. The values given in parentheses after SI units are provided for information only and are not considered standard.

1.5 This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

General Information

Relations

Buy Standard

Standards Content (Sample)

This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the

Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

Designation: D6227 − 18 (Reapproved 2023)

Standard Specification for

Unleaded Aviation Gasoline Containing a Non-hydrocarbon

Component

This standard is issued under the fixed designation D6227; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope 2. Referenced Documents

1.1 This specification covers Grades UL82 and UL87 un- 2.1 ASTM Standards:

D86 Test Method for Distillation of Petroleum Products and

leaded aviation gasolines, which are defined by this specifica-

Liquid Fuels at Atmospheric Pressure

tion and are only for use in engines and associated aircraft that

D130 Test Method for Corrosiveness to Copper from Petro-

are specifically approved by the engine and aircraft

leum Products by Copper Strip Test

manufacturers, and certified by the National Certifying Agen-

D357 Method of Test for Knock Characteristics of Motor

cies to use these fuels. Components containing hetro-atoms

Fuels Below 100 Octane Number by the Motor Method;

(oxygenates) may be present within the limits specified.

Replaced by D 2700 (Withdrawn 1969)

1.2 A fuel may be certified to meet this specification by a

D381 Test Method for Gum Content in Fuels by Jet Evapo-

producer as Grade UL82 or UL87 aviation gasoline only if

ration

blended from component(s) approved for use in these grades of

D873 Test Method for Oxidation Stability of Aviation Fuels

aviation gasoline by the refiner(s) of such components, because

(Potential Residue Method)

only the refiner(s) can attest to the component source and

D909 Test Method for Supercharge Rating of Spark-Ignition

processing, absence of contamination, and the additives used

Aviation Gasoline

and their concentrations. Consequently, reclassifying of any

D910 Specification for Leaded Aviation Gasolines

other product to Grade UL82 or Grade UL87 aviation gasoline

D1266 Test Method for Sulfur in Petroleum Products (Lamp

does not meet this specification. Method)

D1298 Test Method for Density, Relative Density, or API

1.3 Appendix X1 contains an explanation for the rationale

Gravity of Crude Petroleum and Liquid Petroleum Prod-

of the specification. Appendix X2 details the reasons for the

ucts by Hydrometer Method

individual specification requirements.

D2386 Test Method for Freezing Point of Aviation Fuels

D2392 Test Method for Color of Dyed Aviation Gasolines

1.4 The values stated in SI units are to be regarded as

D2622 Test Method for Sulfur in Petroleum Products by

standard. The values given in parentheses after SI units are

Wavelength Dispersive X-ray Fluorescence Spectrometry

provided for information only and are not considered standard.

D2699 Test Method for Research Octane Number of Spark-

1.5 This international standard was developed in accor-

Ignition Engine Fuel

dance with internationally recognized principles on standard-

D2700 Test Method for Motor Octane Number of Spark-

ization established in the Decision on Principles for the

Ignition Engine Fuel

Development of International Standards, Guides and Recom-

D3120 Test Method for Trace Quantities of Sulfur in Light

mendations issued by the World Trade Organization Technical

Liquid Petroleum Hydrocarbons by Oxidative Microcou-

Barriers to Trade (TBT) Committee.

lometry

D3231 Test Method for Phosphorus in Gasoline

D3237 Test Method for Lead in Gasoline by Atomic Absorp-

tion Spectroscopy

1 2

This specification is under the jurisdiction of ASTM Committee D02 on For referenced ASTM standards, visit the ASTM website, www.astm.org, or

Petroleum Products, Liquid Fuels, and Lubricants and is the direct responsibility of contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

Subcommittee D02.J0.02 on Aviation Piston Engine Fuels. Standards volume information, refer to the standard’s Document Summary page on

Current edition approved July 1, 2023. Published July 2023. Originally approved the ASTM website.

in 1998. Last previous edition approved in 2018 as D6227 – 18. DOI: 10.1520/ The last approved version of this historical standard is referenced on

D6227-18R23. www.astm.org.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

D6227 − 18 (2023)

D3338 Test Method for Estimation of Net Heat of Combus- 3.1.1.1 Discussion—The principal properties of aviation

tion of Aviation Fuels gasoline include volatility limits, stability, detonation-free

D4052 Test Method for Density, Relative Density, and API performance in the engine for which it is intended, and

Gravity of Liquids by Digital Density Meter suitability for low temperature performance.

D4057 Practice for Manual Sampling of Petroleum and

3.1.2 non-hydrocarbon, n—compound or compounds com-

Petroleum Products

posed of carbon, hydrogen and other elements such as O, N, S,

D4171 Specification for Fuel System Icing Inhibitors

and P.

D4294 Test Method for Sulfur in Petroleum and Petroleum

3.1.3 oxygenate, n—an oxygen-containing ashless organic

Products by Energy Dispersive X-ray Fluorescence Spec-

compound, such as an alcohol or ether, which may be used as

trometry

fuel or fuel supplement.

D4529 Test Method for Estimation of Net Heat of Combus-

tion of Aviation Fuels

4. Grades

D4809 Test Method for Heat of Combustion of Liquid

4.1 The specification covers two grades of unleaded avia-

Hydrocarbon Fuels by Bomb Calorimeter (Precision

tion gasoline designated Grade UL82 and Grade UL87.

Method)

D4815 Test Method for Determination of MTBE, ETBE,

5. General

TAME, DIPE, tertiary-Amyl Alcohol and C to C Alco-

1 4

hols in Gasoline by Gas Chromatography

5.1 This specification, unless otherwise provided, prescribes

D4953 Test Method for Vapor Pressure of Gasoline and

the required properties of unleaded aviation gasoline at the

Gasoline-Oxygenate Blends (Dry Method)

time and place of delivery.

D5059 Test Methods for Lead and Manganese in Gasoline

by X-Ray Fluorescence Spectroscopy

6. Material

D5191 Test Method for Vapor Pressure of Petroleum Prod-

6.1 Aviation gasoline, except as otherwise specified in this

ucts and Liquid Fuels (Mini Method)

specification, shall consist of blends of refined hydrocarbons

D5453 Test Method for Determination of Total Sulfur in

derived from crude petroleum, natural gasoline or blends,

Light Hydrocarbons, Spark Ignition Engine Fuel, Diesel

thereof, with specific aliphatic ethers, synthetic hydrocarbons,

Engine Fuel, and Engine Oil by Ultraviolet Fluorescence

or aromatic hydrocarbons. When applicable, methyl tertiary

D5482 Test Method for Vapor Pressure of Petroleum Prod-

-butyl ether (MTBE) shall conform to the requirements of

ucts and Liquid Fuels (Mini Method—Atmospheric)

Specification D5983. Types and quantities of trace alcohols

D5599 Test Method for Determination of Oxygenates in

shall meet the requirements of Table 1 and 6.2.4.2.

Gasoline by Gas Chromatography and Oxygen Selective

6.2 Only additives approved by this specification are per-

Flame Ionization Detection

mitted. In addition to identification dyes, corrosion inhibitors,

D5845 Test Method for Determination of MTBE, ETBE,

antioxidants, and metal deactivators, fuel system icing inhibitor

TAME, DIPE, Methanol, Ethanol and tert-Butanol in

additives are permitted under 6.2.4. Permitted additives may be

Gasoline by Infrared Spectroscopy

added to aviation gasoline in the amount and of the composi-

D5983 Specification for Methyl Tertiary-Butyl Ether

tion specified in the following list of approved materials. The

(MTBE) for Blending With Gasolines for Use as Auto-

quantities and types shall be declared by the manufacturer.

motive Spark-Ignition Engine Fuel

Additives added after the point of manufacture shall also be

D6469 Guide for Microbial Contamination in Fuels and Fuel

declared.

Systems

6.2.1 Antioxidants—The following oxidation inhibitors may

D7220 Test Method for Sulfur in Automotive, Heating, and

be added to the gasoline separately or in combination in total

Jet Fuels by Monochromatic Energy Dispersive X-ray

concentration not to exceed 12 mg of inhibitor (not including

Fluorescence Spectrometry

weight of solvent) per litre of fuel.

E29 Practice for Using Significant Digits in Test Data to

6.2.1.1 2,6-ditertiary-butyl-phenol.

Determine Conformance with Specifications

6.2.1.2 2,6-ditertiary-butyl-4-methyl-phenol.

2.2 Military Standard:

6.2.1.3 2,4-dimethyl-6-tertiary-butyl-phenol.

MIL-PRF-25017F Performance Specification for Inhibitor,

6.2.1.4 2,6-ditertiary-butyl-phenol, 75 % minimum.

Corrosion/Lubricity Improver, Fuel Soluble

Tertiary and tritertiary-butyl-phenols, 25 % maximum.

QPL-25017 Qualified Products List of Products Qualified

6.2.1.5 2,4-dimethyl-6-tertiary-butyl-phenol, 55 % mini-

Under Performance Specification MIL-PRF-25017F

mum; 4-methyl-2,6-ditertiary-butyl phenol 15 % minimum; the

3. Terminology

remainder as a mixture of monomethyl and dimethyl-tertiary-

butyl-phenols.

3.1 Definitions:

6.2.1.6 2,4-dimethyl-6-tertiary-butyl-phenol, 72 % mini-

3.1.1 aviation gasoline, n—gasoline possessing specific

mum.

properties suitable for fueling aircraft powered by reciprocat-

Mixture of tertiary-butyl-methyl-phenols and tertiary-butyl-

ing spark ignition engines.

dimethyl-phenols, 28 % maximum.

6.2.1.7 2,6-ditertiary-butyl-4-methyl-phenol, 35 % mini-

Available from Standardization Document Order Desk, 700 Robbins Ave.,

Bldg. 4D, Philadelphia, PA 19111–5094 Attn: NPODS. mum.

D6227 − 18 (2023)

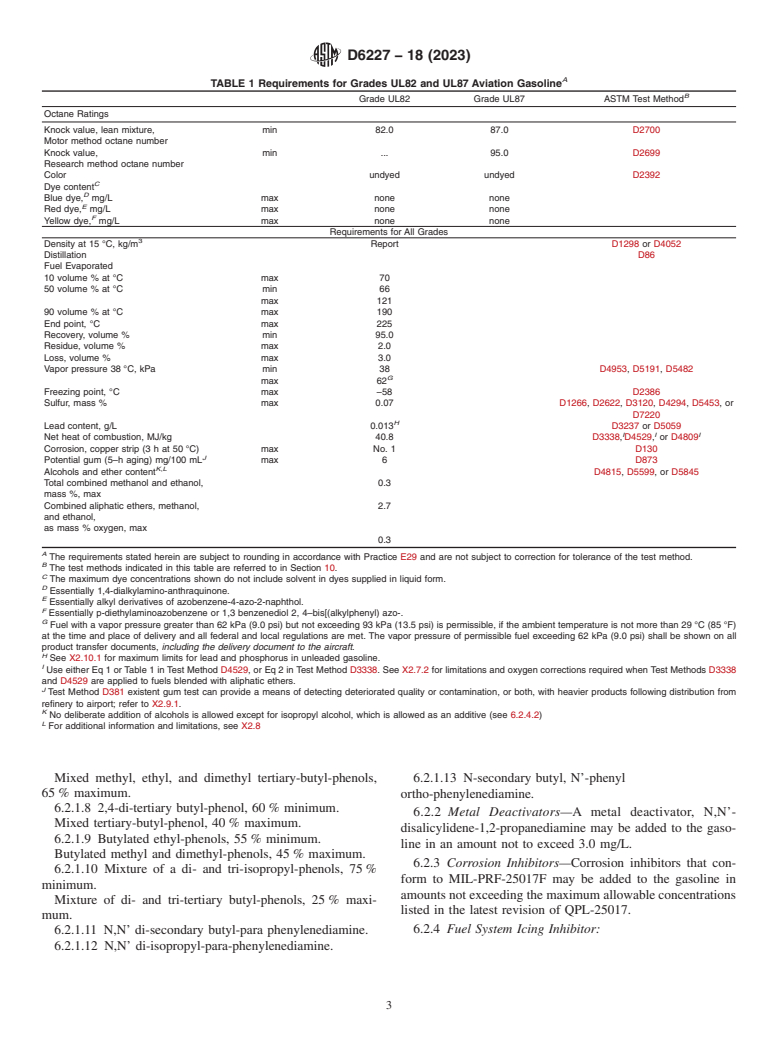

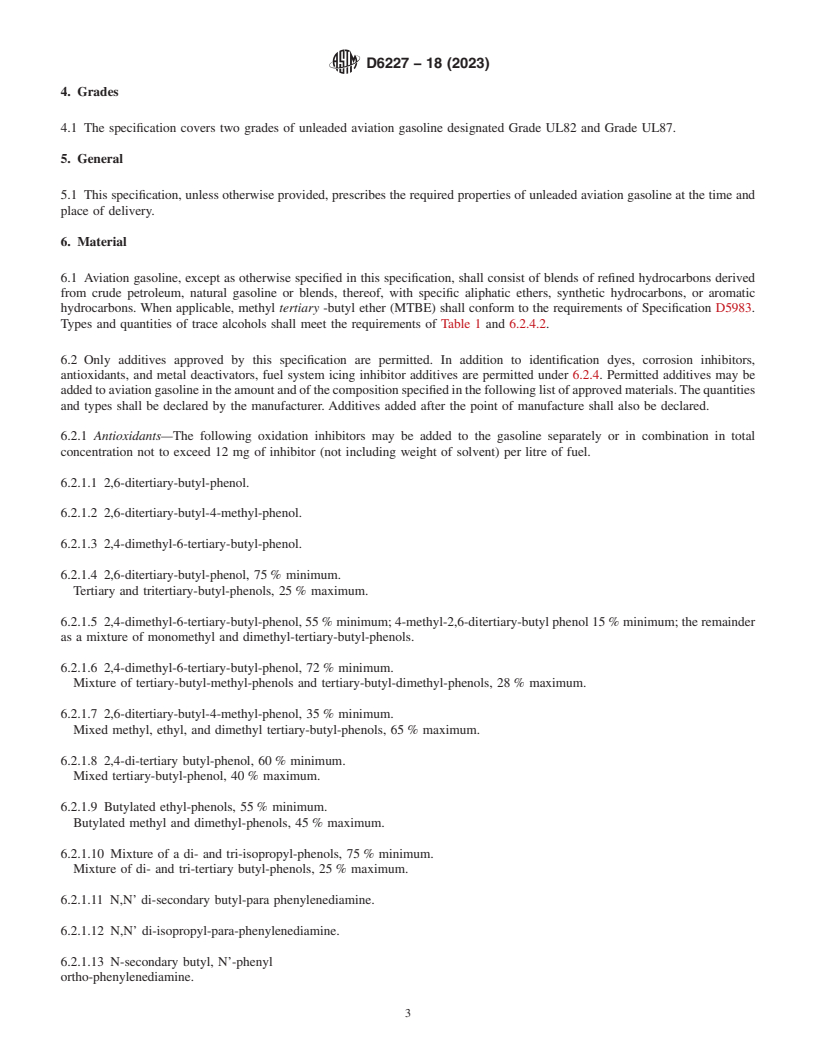

A

TABLE 1 Requirements for Grades UL82 and UL87 Aviation Gasoline

B

Grade UL82 Grade UL87 ASTM Test Method

Octane Ratings

Knock value, lean mixture, min 82.0 87.0 D2700

Motor method octane number

Knock value, min . 95.0 D2699

Research method octane number

Color undyed undyed D2392

C

Dye content

D

Blue dye, mg/L max none none

E

Red dye, mg/L max none none

F

Yellow dye, mg/L max none none

Requirements for All Grades

Density at 15 °C, kg/m Report D1298 or D4052

Distillation D86

Fuel Evaporated

10 volume % at °C max 70

50 volume % at °C min 66

max 121

90 volume % at °C max 190

End point, °C max 225

Recovery, volume % min 95.0

Residue, volume % max 2.0

Loss, volume % max 3.0

Vapor pressure 38 °C, kPa min 38 D4953, D5191, D5482

G

max 62

Freezing point, °C max –58 D2386

Sulfur, mass % max 0.07 D1266, D2622, D3120, D4294, D5453, or

D7220

H

Lead content, g/L 0.013 D3237 or D5059

I I I

Net heat of combustion, MJ/kg 40.8 D3338, D4529, or D4809

Corrosion, copper strip (3 h at 50 °C) max No. 1 D130

J

Potential gum (5–h aging) mg/100 mL max 6 D873

K,L

Alcohols and ether content D4815, D5599, or D5845

Total combined methanol and ethanol, 0.3

mass %, max

Combined aliphatic ethers, methanol, 2.7

and ethanol,

as mass % oxygen, max

0.3

A

The requirements stated herein are subject to rounding in accordance with Practice E29 and are not subject to correction for tolerance of the test method.

B

The test methods indicated in this table are referred to in Section 10.

C

The maximum dye concentrations shown do not include solvent in dyes supplied in liquid form.

D

Essentially 1,4-dialkylamino-anthraquinone.

E

Essentially alkyl derivatives of azobenzene-4-azo-2-naphthol.

F

Essentially p-diethylaminoazobenzene or 1,3 benzenediol 2, 4–bis[(alkylphenyl) azo-.

G

Fuel with a vapor pressure greater than 62 kPa (9.0 psi) but not exceeding 93 kPa (13.5 psi) is permissible, if the ambient temperature is not more than 29 °C (85 °F)

at the time and place of delivery and all federal and local regulations are met. The vapor pressure of permissible fuel exceeding 62 kPa (9.0 psi) shall be shown on all

product transfer documents, including the delivery document to the aircraft.

H

See X2.10.1 for maximum limits for lead and phosphorus in unleaded gasoline.

I

Use either Eq 1 or Table 1 in Test Method D4529, or Eq 2 in Test Method D3338. See X2.7.2 for limitations and oxygen corrections required when Test Methods D3338

and D4529 are applied to fuels blended with aliphatic ethers.

J

Test Method D381 existent gum test can provide a means of detecting deteriorated quality or contamination, or both, with heavier products following distribution from

refinery to airport; refer to X2.9.1.

K

No deliberate addition of alcohols is allowed except for isopropyl alcohol, which is allowed as an additive (see 6.2.4.2)

L

For additional information and limitations, see X2.8

Mixed methyl, ethyl, and dimethyl tertiary-butyl-phenols, 6.2.1.13 N-secondary butyl, N’-phenyl

65 % maximum. ortho-phenylenediamine.

6.2.1.8 2,4-di-tertiary butyl-phenol, 60 % minimum.

6.2.2 Metal Deactivators—A metal deactivator, N,N’-

Mixed tertiary-butyl-phenol, 40 % maximum.

disalicylidene-1,2-propanediamine may be added to the gaso-

6.2.1.9 Butylated ethyl-phenols, 55 % minimum.

line in an amount not to exceed 3.0 mg/L.

Butylated methyl and dimethyl-phenols, 45 % maximum.

6.2.3 Corrosion Inhibitors—Corrosion inhibitors that con-

6.2.1.10 Mixture of a di- and tri-isopropyl-phenols, 75 %

form to MIL-PRF-25017F may be added to the gasoline in

minimum.

amounts not exceeding the maximum allowable concentrations

Mixture of di- and tri-tertiary butyl-phenols, 25 % maxi-

listed in the latest revision of QPL-25017.

mum.

6.2.4 Fuel System Icing Inhibitor:

6.2.1.11 N,N’ di-secondary butyl-para phenylenediamine.

6.2.1.12 N,N’ di-isopropyl-para-phenylenediamine.

D6227 − 18 (2023)

6.2.4.1 Diethylene glycol monomethyl ether, conforming to 10.1.1 Research Octane—Test Method D2699.

the requirements of Specification D4171 (Type III), may be 10.1.2 Motor Octane—Test Method D2700.

used in concentrations of 0.10 to 0.15 volume %.

10.1.3 Color—Test Method D2392.

6.2.4.2 Isopropyl alcohol conforming to the requirements of

10.1.4 Distillation—Test Method D86.

Specification D4171 (Type II) may be used in concentrations

10.1.5 Net Heat of Combustion—Test Method D3338,

recommended by the aircraft manufacturers when required by

D4529, or D4809.

the aircraft owner operator.

10.1.6 Freezing Point—Test Method D2386.

10.1.7 Vapor Pressure—Test Method D4953, D5191 or

7. Detailed Requirements

D5482.

7.1 The aviation gasoline shall conform to the requirements

10.1.8 Lead Content—Test Method D3237 or D5059 (Test

in Table 1.

Method C).

10.1.9 Copper Strip Corrosion—Test Method D130 (3 h at

8. Workmanship

50 °C (122 °F)).

8.1 The finished fuel shall be visually free of water,

10.1.10 Sulfur—Test Method D1266, D2622, D3120,

sediment, and suspended matter.

D4294, D5453, or

...

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: D6227 − 18 (Reapproved 2023)

Standard Specification for

Unleaded Aviation Gasoline Containing a Non-hydrocarbon

Component

This standard is issued under the fixed designation D6227; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope 2. Referenced Documents

1.1 This specification covers Grades UL82 and UL87 un- 2.1 ASTM Standards:

leaded aviation gasolines, which are defined by this specifica- D86 Test Method for Distillation of Petroleum Products and

Liquid Fuels at Atmospheric Pressure

tion and are only for use in engines and associated aircraft that

D130 Test Method for Corrosiveness to Copper from Petro-

are specifically approved by the engine and aircraft

leum Products by Copper Strip Test

manufacturers, and certified by the National Certifying Agen-

D357 Method of Test for Knock Characteristics of Motor

cies to use these fuels. Components containing hetro-atoms

Fuels Below 100 Octane Number by the Motor Method;

(oxygenates) may be present within the limits specified.

Replaced by D 2700 (Withdrawn 1969)

1.2 A fuel may be certified to meet this specification by a

D381 Test Method for Gum Content in Fuels by Jet Evapo-

producer as Grade UL82 or UL87 aviation gasoline only if

ration

blended from component(s) approved for use in these grades of

D873 Test Method for Oxidation Stability of Aviation Fuels

aviation gasoline by the refiner(s) of such components, because

(Potential Residue Method)

only the refiner(s) can attest to the component source and

D909 Test Method for Supercharge Rating of Spark-Ignition

processing, absence of contamination, and the additives used

Aviation Gasoline

and their concentrations. Consequently, reclassifying of any

D910 Specification for Leaded Aviation Gasolines

other product to Grade UL82 or Grade UL87 aviation gasoline D1266 Test Method for Sulfur in Petroleum Products (Lamp

does not meet this specification. Method)

D1298 Test Method for Density, Relative Density, or API

1.3 Appendix X1 contains an explanation for the rationale

Gravity of Crude Petroleum and Liquid Petroleum Prod-

of the specification. Appendix X2 details the reasons for the

ucts by Hydrometer Method

individual specification requirements.

D2386 Test Method for Freezing Point of Aviation Fuels

D2392 Test Method for Color of Dyed Aviation Gasolines

1.4 The values stated in SI units are to be regarded as

D2622 Test Method for Sulfur in Petroleum Products by

standard. The values given in parentheses after SI units are

Wavelength Dispersive X-ray Fluorescence Spectrometry

provided for information only and are not considered standard.

D2699 Test Method for Research Octane Number of Spark-

1.5 This international standard was developed in accor-

Ignition Engine Fuel

dance with internationally recognized principles on standard-

D2700 Test Method for Motor Octane Number of Spark-

ization established in the Decision on Principles for the

Ignition Engine Fuel

Development of International Standards, Guides and Recom-

D3120 Test Method for Trace Quantities of Sulfur in Light

mendations issued by the World Trade Organization Technical

Liquid Petroleum Hydrocarbons by Oxidative Microcou-

Barriers to Trade (TBT) Committee.

lometry

D3231 Test Method for Phosphorus in Gasoline

D3237 Test Method for Lead in Gasoline by Atomic Absorp-

tion Spectroscopy

1 2

This specification is under the jurisdiction of ASTM Committee D02 on For referenced ASTM standards, visit the ASTM website, www.astm.org, or

Petroleum Products, Liquid Fuels, and Lubricants and is the direct responsibility of contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

Subcommittee D02.J0.02 on Aviation Piston Engine Fuels. Standards volume information, refer to the standard’s Document Summary page on

Current edition approved July 1, 2023. Published July 2023. Originally approved the ASTM website.

in 1998. Last previous edition approved in 2018 as D6227 – 18. DOI: 10.1520/ The last approved version of this historical standard is referenced on

D6227-18R23. www.astm.org.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

D6227 − 18 (2023)

D3338 Test Method for Estimation of Net Heat of Combus- 3.1.1.1 Discussion—The principal properties of aviation

tion of Aviation Fuels gasoline include volatility limits, stability, detonation-free

D4052 Test Method for Density, Relative Density, and API performance in the engine for which it is intended, and

Gravity of Liquids by Digital Density Meter suitability for low temperature performance.

D4057 Practice for Manual Sampling of Petroleum and

3.1.2 non-hydrocarbon, n—compound or compounds com-

Petroleum Products

posed of carbon, hydrogen and other elements such as O, N, S,

D4171 Specification for Fuel System Icing Inhibitors

and P.

D4294 Test Method for Sulfur in Petroleum and Petroleum

3.1.3 oxygenate, n—an oxygen-containing ashless organic

Products by Energy Dispersive X-ray Fluorescence Spec-

compound, such as an alcohol or ether, which may be used as

trometry

fuel or fuel supplement.

D4529 Test Method for Estimation of Net Heat of Combus-

tion of Aviation Fuels

4. Grades

D4809 Test Method for Heat of Combustion of Liquid

4.1 The specification covers two grades of unleaded avia-

Hydrocarbon Fuels by Bomb Calorimeter (Precision

tion gasoline designated Grade UL82 and Grade UL87.

Method)

D4815 Test Method for Determination of MTBE, ETBE,

5. General

TAME, DIPE, tertiary-Amyl Alcohol and C to C Alco-

1 4

hols in Gasoline by Gas Chromatography

5.1 This specification, unless otherwise provided, prescribes

D4953 Test Method for Vapor Pressure of Gasoline and

the required properties of unleaded aviation gasoline at the

Gasoline-Oxygenate Blends (Dry Method)

time and place of delivery.

D5059 Test Methods for Lead and Manganese in Gasoline

by X-Ray Fluorescence Spectroscopy

6. Material

D5191 Test Method for Vapor Pressure of Petroleum Prod-

6.1 Aviation gasoline, except as otherwise specified in this

ucts and Liquid Fuels (Mini Method)

specification, shall consist of blends of refined hydrocarbons

D5453 Test Method for Determination of Total Sulfur in

derived from crude petroleum, natural gasoline or blends,

Light Hydrocarbons, Spark Ignition Engine Fuel, Diesel

thereof, with specific aliphatic ethers, synthetic hydrocarbons,

Engine Fuel, and Engine Oil by Ultraviolet Fluorescence

or aromatic hydrocarbons. When applicable, methyl tertiary

D5482 Test Method for Vapor Pressure of Petroleum Prod-

-butyl ether (MTBE) shall conform to the requirements of

ucts and Liquid Fuels (Mini Method—Atmospheric)

Specification D5983. Types and quantities of trace alcohols

D5599 Test Method for Determination of Oxygenates in

shall meet the requirements of Table 1 and 6.2.4.2.

Gasoline by Gas Chromatography and Oxygen Selective

6.2 Only additives approved by this specification are per-

Flame Ionization Detection

mitted. In addition to identification dyes, corrosion inhibitors,

D5845 Test Method for Determination of MTBE, ETBE,

antioxidants, and metal deactivators, fuel system icing inhibitor

TAME, DIPE, Methanol, Ethanol and tert-Butanol in

additives are permitted under 6.2.4. Permitted additives may be

Gasoline by Infrared Spectroscopy

added to aviation gasoline in the amount and of the composi-

D5983 Specification for Methyl Tertiary-Butyl Ether

tion specified in the following list of approved materials. The

(MTBE) for Blending With Gasolines for Use as Auto-

quantities and types shall be declared by the manufacturer.

motive Spark-Ignition Engine Fuel

Additives added after the point of manufacture shall also be

D6469 Guide for Microbial Contamination in Fuels and Fuel

declared.

Systems

6.2.1 Antioxidants—The following oxidation inhibitors may

D7220 Test Method for Sulfur in Automotive, Heating, and

be added to the gasoline separately or in combination in total

Jet Fuels by Monochromatic Energy Dispersive X-ray

concentration not to exceed 12 mg of inhibitor (not including

Fluorescence Spectrometry

weight of solvent) per litre of fuel.

E29 Practice for Using Significant Digits in Test Data to

6.2.1.1 2,6-ditertiary-butyl-phenol.

Determine Conformance with Specifications

6.2.1.2 2,6-ditertiary-butyl-4-methyl-phenol.

2.2 Military Standard:

6.2.1.3 2,4-dimethyl-6-tertiary-butyl-phenol.

MIL-PRF-25017F Performance Specification for Inhibitor,

6.2.1.4 2,6-ditertiary-butyl-phenol, 75 % minimum.

Corrosion/Lubricity Improver, Fuel Soluble

Tertiary and tritertiary-butyl-phenols, 25 % maximum.

QPL-25017 Qualified Products List of Products Qualified

6.2.1.5 2,4-dimethyl-6-tertiary-butyl-phenol, 55 % mini-

Under Performance Specification MIL-PRF-25017F

mum; 4-methyl-2,6-ditertiary-butyl phenol 15 % minimum; the

3. Terminology

remainder as a mixture of monomethyl and dimethyl-tertiary-

butyl-phenols.

3.1 Definitions:

6.2.1.6 2,4-dimethyl-6-tertiary-butyl-phenol, 72 % mini-

3.1.1 aviation gasoline, n—gasoline possessing specific

mum.

properties suitable for fueling aircraft powered by reciprocat-

Mixture of tertiary-butyl-methyl-phenols and tertiary-butyl-

ing spark ignition engines.

dimethyl-phenols, 28 % maximum.

4 6.2.1.7 2,6-ditertiary-butyl-4-methyl-phenol, 35 % mini-

Available from Standardization Document Order Desk, 700 Robbins Ave.,

Bldg. 4D, Philadelphia, PA 19111–5094 Attn: NPODS. mum.

D6227 − 18 (2023)

A

TABLE 1 Requirements for Grades UL82 and UL87 Aviation Gasoline

B

Grade UL82 Grade UL87 ASTM Test Method

Octane Ratings

Knock value, lean mixture, min 82.0 87.0 D2700

Motor method octane number

Knock value, min . 95.0 D2699

Research method octane number

Color undyed undyed D2392

C

Dye content

D

Blue dye, mg/L max none none

E

Red dye, mg/L max none none

F

Yellow dye, mg/L max none none

Requirements for All Grades

Density at 15 °C, kg/m Report D1298 or D4052

Distillation D86

Fuel Evaporated

10 volume % at °C max 70

50 volume % at °C min 66

max 121

90 volume % at °C max 190

End point, °C max 225

Recovery, volume % min 95.0

Residue, volume % max 2.0

Loss, volume % max 3.0

Vapor pressure 38 °C, kPa min 38 D4953, D5191, D5482

G

max 62

Freezing point, °C max –58 D2386

Sulfur, mass % max 0.07 D1266, D2622, D3120, D4294, D5453, or

D7220

H

Lead content, g/L 0.013 D3237 or D5059

I I I

Net heat of combustion, MJ/kg 40.8 D3338, D4529, or D4809

Corrosion, copper strip (3 h at 50 °C) max No. 1 D130

J

Potential gum (5–h aging) mg/100 mL max 6 D873

K,L

Alcohols and ether content D4815, D5599, or D5845

Total combined methanol and ethanol, 0.3

mass %, max

Combined aliphatic ethers, methanol, 2.7

and ethanol,

as mass % oxygen, max

0.3

A

The requirements stated herein are subject to rounding in accordance with Practice E29 and are not subject to correction for tolerance of the test method.

B

The test methods indicated in this table are referred to in Section 10.

C

The maximum dye concentrations shown do not include solvent in dyes supplied in liquid form.

D

Essentially 1,4-dialkylamino-anthraquinone.

E

Essentially alkyl derivatives of azobenzene-4-azo-2-naphthol.

F

Essentially p-diethylaminoazobenzene or 1,3 benzenediol 2, 4–bis[(alkylphenyl) azo-.

G

Fuel with a vapor pressure greater than 62 kPa (9.0 psi) but not exceeding 93 kPa (13.5 psi) is permissible, if the ambient temperature is not more than 29 °C (85 °F)

at the time and place of delivery and all federal and local regulations are met. The vapor pressure of permissible fuel exceeding 62 kPa (9.0 psi) shall be shown on all

product transfer documents, including the delivery document to the aircraft.

H

See X2.10.1 for maximum limits for lead and phosphorus in unleaded gasoline.

I

Use either Eq 1 or Table 1 in Test Method D4529, or Eq 2 in Test Method D3338. See X2.7.2 for limitations and oxygen corrections required when Test Methods D3338

and D4529 are applied to fuels blended with aliphatic ethers.

J

Test Method D381 existent gum test can provide a means of detecting deteriorated quality or contamination, or both, with heavier products following distribution from

refinery to airport; refer to X2.9.1.

K

No deliberate addition of alcohols is allowed except for isopropyl alcohol, which is allowed as an additive (see 6.2.4.2)

L

For additional information and limitations, see X2.8

Mixed methyl, ethyl, and dimethyl tertiary-butyl-phenols, 6.2.1.13 N-secondary butyl, N’-phenyl

65 % maximum.

ortho-phenylenediamine.

6.2.1.8 2,4-di-tertiary butyl-phenol, 60 % minimum.

6.2.2 Metal Deactivators—A metal deactivator, N,N’-

Mixed tertiary-butyl-phenol, 40 % maximum.

disalicylidene-1,2-propanediamine may be added to the gaso-

6.2.1.9 Butylated ethyl-phenols, 55 % minimum.

line in an amount not to exceed 3.0 mg/L.

Butylated methyl and dimethyl-phenols, 45 % maximum.

6.2.3 Corrosion Inhibitors—Corrosion inhibitors that con-

6.2.1.10 Mixture of a di- and tri-isopropyl-phenols, 75 %

form to MIL-PRF-25017F may be added to the gasoline in

minimum.

amounts not exceeding the maximum allowable concentrations

Mixture of di- and tri-tertiary butyl-phenols, 25 % maxi-

listed in the latest revision of QPL-25017.

mum.

6.2.4 Fuel System Icing Inhibitor:

6.2.1.11 N,N’ di-secondary butyl-para phenylenediamine.

6.2.1.12 N,N’ di-isopropyl-para-phenylenediamine.

D6227 − 18 (2023)

6.2.4.1 Diethylene glycol monomethyl ether, conforming to 10.1.1 Research Octane—Test Method D2699.

the requirements of Specification D4171 (Type III), may be

10.1.2 Motor Octane—Test Method D2700.

used in concentrations of 0.10 to 0.15 volume %.

10.1.3 Color—Test Method D2392.

6.2.4.2 Isopropyl alcohol conforming to the requirements of

10.1.4 Distillation—Test Method D86.

Specification D4171 (Type II) may be used in concentrations

10.1.5 Net Heat of Combustion—Test Method D3338,

recommended by the aircraft manufacturers when required by

D4529, or D4809.

the aircraft owner operator.

10.1.6 Freezing Point—Test Method D2386.

10.1.7 Vapor Pressure—Test Method D4953, D5191 or

7. Detailed Requirements

D5482.

7.1 The aviation gasoline shall conform to the requirements

10.1.8 Lead Content—Test Method D3237 or D5059 (Test

in Table 1.

Method C).

10.1.9 Copper Strip Corrosion—Test Method D130 (3 h at

8. Workmanship

50 °C (122 °F)).

8.1 The finished fuel shall be visually free of water,

10.1.10 Sulfur—Test Method D1266, D2622, D3120,

sediment, and suspended matter.

D4294, D5453, or D7220.

NOTE 1—See Practice D4057 for appropriate sampling procedures.

10.1.11 Potential Gum—Test Method D873, excep

...

This document is not an ASTM standard and is intended only to provide the user of an ASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

Designation: D6227 − 18 D6227 − 18 (Reapproved 2023)

Standard Specification for

Unleaded Aviation Gasoline Containing a Non-hydrocarbon

Component

This standard is issued under the fixed designation D6227; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope*Scope

1.1 This specification covers Grades UL82 and UL87 unleaded aviation gasolines, which are defined by this specification and are

only for use in engines and associated aircraft that are specifically approved by the engine and aircraft manufacturers, and certified

by the National Certifying Agencies to use these fuels. Components containing hetro-atoms (oxygenates) may be present within

the limits specified.

1.2 A fuel may be certified to meet this specification by a producer as Grade UL82 or UL87 aviation gasoline only if blended from

component(s) approved for use in these grades of aviation gasoline by the refiner(s) of such components, because only the refiner(s)

can attest to the component source and processing, absence of contamination, and the additives used and their concentrations.

Consequently, reclassifying of any other product to Grade UL82 or Grade UL87 aviation gasoline does not meet this specification.

1.3 Appendix X1 contains an explanation for the rationale of the specification. Appendix X2 details the reasons for the individual

specification requirements.

1.4 The values stated in SI units are to be regarded as standard. The values given in parentheses after SI units are provided for

information only and are not considered standard.

1.5 This international standard was developed in accordance with internationally recognized principles on standardization

established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued

by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

2. Referenced Documents

2.1 ASTM Standards:

D86 Test Method for Distillation of Petroleum Products and Liquid Fuels at Atmospheric Pressure

D130 Test Method for Corrosiveness to Copper from Petroleum Products by Copper Strip Test

D357 Method of Test for Knock Characteristics of Motor Fuels Below 100 Octane Number by the Motor Method; Replaced by

D 2700 (Withdrawn 1969)

D381 Test Method for Gum Content in Fuels by Jet Evaporation

D873 Test Method for Oxidation Stability of Aviation Fuels (Potential Residue Method)

This specification is under the jurisdiction of ASTM Committee D02 on Petroleum Products, Liquid Fuels, and Lubricants and is the direct responsibility of Subcommittee

D02.J0.02 on Aviation Piston Engine Fuels.

Current edition approved Oct. 1, 2018July 1, 2023. Published October 2018July 2023. Originally approved in 1998. Last previous edition approved in 20172018 as

D6227 – 17.D6227 – 18. DOI: 10.1520/D6227-18.10.1520/D6227-18R23.

For referenced ASTM standards, visit the ASTM website, www.astm.org, or contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM Standards

volume information, refer to the standard’s Document Summary page on the ASTM website.

The last approved version of this historical standard is referenced on www.astm.org.

*A Summary of Changes section appears at the end of this standard

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

D6227 − 18 (2023)

D909 Test Method for Supercharge Rating of Spark-Ignition Aviation Gasoline

D910 Specification for Leaded Aviation Gasolines

D1266 Test Method for Sulfur in Petroleum Products (Lamp Method)

D1298 Test Method for Density, Relative Density, or API Gravity of Crude Petroleum and Liquid Petroleum Products by

Hydrometer Method

D2386 Test Method for Freezing Point of Aviation Fuels

D2392 Test Method for Color of Dyed Aviation Gasolines

D2622 Test Method for Sulfur in Petroleum Products by Wavelength Dispersive X-ray Fluorescence Spectrometry

D2699 Test Method for Research Octane Number of Spark-Ignition Engine Fuel

D2700 Test Method for Motor Octane Number of Spark-Ignition Engine Fuel

D3120 Test Method for Trace Quantities of Sulfur in Light Liquid Petroleum Hydrocarbons by Oxidative Microcoulometry

D3231 Test Method for Phosphorus in Gasoline

D3237 Test Method for Lead in Gasoline by Atomic Absorption Spectroscopy

D3338 Test Method for Estimation of Net Heat of Combustion of Aviation Fuels

D4052 Test Method for Density, Relative Density, and API Gravity of Liquids by Digital Density Meter

D4057 Practice for Manual Sampling of Petroleum and Petroleum Products

D4171 Specification for Fuel System Icing Inhibitors

D4294 Test Method for Sulfur in Petroleum and Petroleum Products by Energy Dispersive X-ray Fluorescence Spectrometry

D4529 Test Method for Estimation of Net Heat of Combustion of Aviation Fuels

D4809 Test Method for Heat of Combustion of Liquid Hydrocarbon Fuels by Bomb Calorimeter (Precision Method)

D4815 Test Method for Determination of MTBE, ETBE, TAME, DIPE, tertiary-Amyl Alcohol and C to C Alcohols in

1 4

Gasoline by Gas Chromatography

D4953 Test Method for Vapor Pressure of Gasoline and Gasoline-Oxygenate Blends (Dry Method)

D5059 Test Methods for Lead and Manganese in Gasoline by X-Ray Fluorescence Spectroscopy

D5191 Test Method for Vapor Pressure of Petroleum Products and Liquid Fuels (Mini Method)

D5453 Test Method for Determination of Total Sulfur in Light Hydrocarbons, Spark Ignition Engine Fuel, Diesel Engine Fuel,

and Engine Oil by Ultraviolet Fluorescence

D5482 Test Method for Vapor Pressure of Petroleum Products and Liquid Fuels (Mini Method—Atmospheric)

D5599 Test Method for Determination of Oxygenates in Gasoline by Gas Chromatography and Oxygen Selective Flame

Ionization Detection

D5845 Test Method for Determination of MTBE, ETBE, TAME, DIPE, Methanol, Ethanol and tert-Butanol in Gasoline by

Infrared Spectroscopy

D5983 Specification for Methyl Tertiary-Butyl Ether (MTBE) for Blending With Gasolines for Use as Automotive Spark-

Ignition Engine Fuel

D6469 Guide for Microbial Contamination in Fuels and Fuel Systems

D7220 Test Method for Sulfur in Automotive, Heating, and Jet Fuels by Monochromatic Energy Dispersive X-ray Fluorescence

Spectrometry

E29 Practice for Using Significant Digits in Test Data to Determine Conformance with Specifications

2.2 Military Standard:

MIL-PRF-25017F Performance Specification for Inhibitor, Corrosion/Lubricity Improver, Fuel Soluble

QPL-25017 Qualified Products List of Products Qualified Under Performance Specification MIL-PRF-25017F

3. Terminology

3.1 Definitions:

3.1.1 aviation gasoline, n—gasoline possessing specific properties suitable for fueling aircraft powered by reciprocating spark

ignition engines.

3.1.1.1 Discussion—

The principal properties of aviation gasoline include volatility limits, stability, detonation-free performance in the engine for which

it is intended, and suitability for low temperature performance.

3.1.2 non-hydrocarbon, n—compound or compounds composed of carbon, hydrogen and other elements such as O, N, S, and P.

3.1.3 oxygenate, n—an oxygen-containing ashless organic compound, such as an alcohol or ether, which may be used as fuel or

fuel supplement.

Available from Standardization Document Order Desk, 700 Robbins Ave., Bldg. 4D, Philadelphia, PA 19111–5094 Attn: NPODS.

D6227 − 18 (2023)

4. Grades

4.1 The specification covers two grades of unleaded aviation gasoline designated Grade UL82 and Grade UL87.

5. General

5.1 This specification, unless otherwise provided, prescribes the required properties of unleaded aviation gasoline at the time and

place of delivery.

6. Material

6.1 Aviation gasoline, except as otherwise specified in this specification, shall consist of blends of refined hydrocarbons derived

from crude petroleum, natural gasoline or blends, thereof, with specific aliphatic ethers, synthetic hydrocarbons, or aromatic

hydrocarbons. When applicable, methyl tertiary -butyl ether (MTBE) shall conform to the requirements of Specification D5983.

Types and quantities of trace alcohols shall meet the requirements of Table 1 and 6.2.4.2.

6.2 Only additives approved by this specification are permitted. In addition to identification dyes, corrosion inhibitors,

antioxidants, and metal deactivators, fuel system icing inhibitor additives are permitted under 6.2.4. Permitted additives may be

added to aviation gasoline in the amount and of the composition specified in the following list of approved materials. The quantities

and types shall be declared by the manufacturer. Additives added after the point of manufacture shall also be declared.

6.2.1 Antioxidants—The following oxidation inhibitors may be added to the gasoline separately or in combination in total

concentration not to exceed 12 mg of inhibitor (not including weight of solvent) per litre of fuel.

6.2.1.1 2,6-ditertiary-butyl-phenol.

6.2.1.2 2,6-ditertiary-butyl-4-methyl-phenol.

6.2.1.3 2,4-dimethyl-6-tertiary-butyl-phenol.

6.2.1.4 2,6-ditertiary-butyl-phenol, 75 % minimum.

Tertiary and tritertiary-butyl-phenols, 25 % maximum.

6.2.1.5 2,4-dimethyl-6-tertiary-butyl-phenol, 55 % minimum; 4-methyl-2,6-ditertiary-butyl phenol 15 % minimum; the remainder

as a mixture of monomethyl and dimethyl-tertiary-butyl-phenols.

6.2.1.6 2,4-dimethyl-6-tertiary-butyl-phenol, 72 % minimum.

Mixture of tertiary-butyl-methyl-phenols and tertiary-butyl-dimethyl-phenols, 28 % maximum.

6.2.1.7 2,6-ditertiary-butyl-4-methyl-phenol, 35 % minimum.

Mixed methyl, ethyl, and dimethyl tertiary-butyl-phenols, 65 % maximum.

6.2.1.8 2,4-di-tertiary butyl-phenol, 60 % minimum.

Mixed tertiary-butyl-phenol, 40 % maximum.

6.2.1.9 Butylated ethyl-phenols, 55 % minimum.

Butylated methyl and dimethyl-phenols, 45 % maximum.

6.2.1.10 Mixture of a di- and tri-isopropyl-phenols, 75 % minimum.

Mixture of di- and tri-tertiary butyl-phenols, 25 % maximum.

6.2.1.11 N,N’ di-secondary butyl-para phenylenediamine.

6.2.1.12 N,N’ di-isopropyl-para-phenylenediamine.

6.2.1.13 N-secondary butyl, N’-phenyl

ortho-phenylenediamine.

D6227 − 18 (2023)

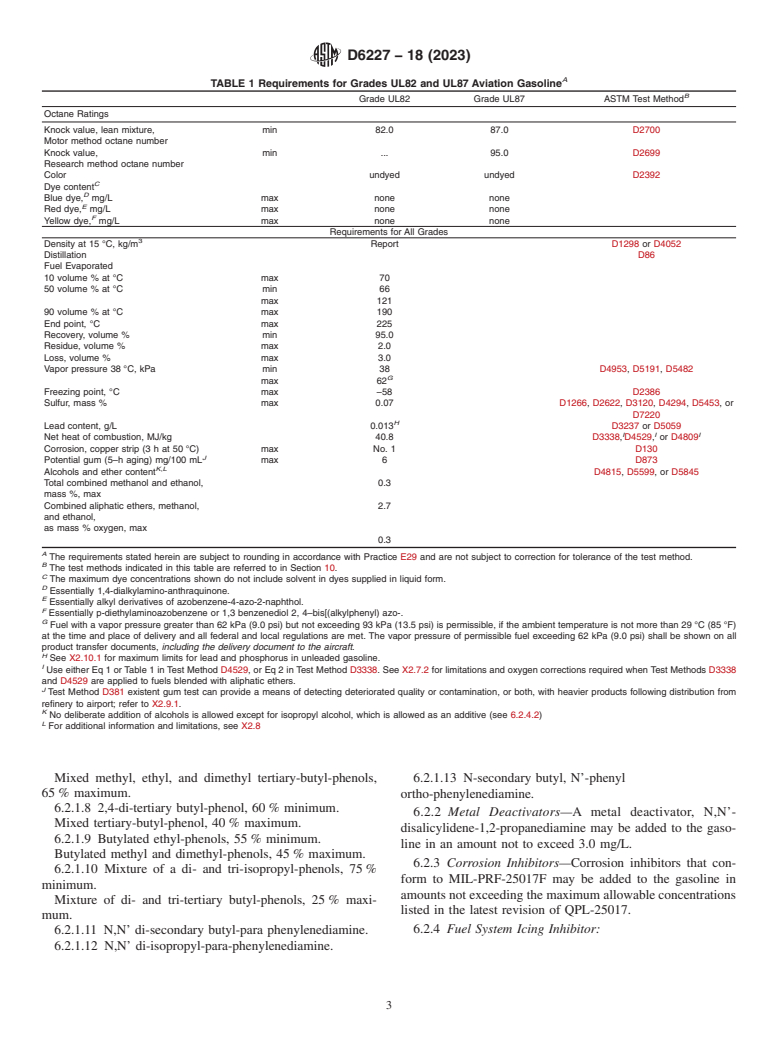

A

TABLE 1 Requirements for Grades UL82 and UL87 Aviation Gasoline

B

Grade UL82 Grade UL87 ASTM Test Method

Octane Ratings

Knock value, lean mixture, min 82.0 87.0 D2700

Motor method octane number

Knock value, min . 95.0 D2699

Research method octane number

Color undyed undyed D2392

C

Dye content

D

Blue dye, mg/L max none none

E

Red dye, mg/L max none none

F

Yellow dye, mg/L max none none

Requirements for All Grades

Density at 15°C, kg/m Report D1298 or D4052

Density at 15 °C, kg/m Report D1298 or D4052

Distillation D86

Fuel Evaporated

10 volume % at °C max 70

50 volume % at °C min 66

max 121

90 volume % at °C max 190

End point, °C max 225

Recovery, volume % min 95.0

Residue, volume % max 2.0

Loss, volume % max 3.0

Vapor pressure 38°C, kPa min 38 D4953, D5191, D5482

Vapor pressure 38 °C, kPa min 38 D4953, D5191

G

max 62

Freezing point, °C max –58 D2386

Sulfur, mass % max 0.07 D1266, D2622, D3120, D4294, D5453, or

D7220

H

Lead content, g/L 0.013 D3237 or D5059

I I I

Net heat of combustion, MJ/kg 40.8 D3338, D4529, or D4809

Corrosion, copper strip (3 h at 50°C) max No. 1 D130

Corrosion, copper strip (3 h at 50 °C) max No. 1 D130

J

Potential gum (5–h aging) mg/100 mL max 6 D873

K,L

Alcohols and ether content D4815, D5599, or D5845

Total combined methanol and ethanol, 0.3

mass %, max

Combined aliphatic ethers, methanol, 2.7

and ethanol,

as mass % oxygen, max

0.3

A

The requirements stated herein are subject to rounding in accordance with Practice E29 and are not subject to correction for tolerance of the test method.

B

The test methods indicated in this table are referred to in Section 10.

C

The maximum dye concentrations shown do not include solvent in dyes supplied in liquid form.

D

Essentially 1,4-dialkylamino-anthraquinone.

E

Essentially alkyl derivatives of azobenzene-4-azo-2-naphthol.

F

Essentially p-diethylaminoazobenzene or 1,3 benzenediol 2, 4–bis[(alkylphenyl) azo-.

G

Fuel with a vapor pressure greater than 62 kPa (9.0 psi) but not exceeding 93 kPa (13.5 psi) is permissible, if the ambient temperature is not more than 29°C (85°F)29 °C

(85 °F) at the time and place of delivery and all federal and local regulations are met. The vapor pressure of permissible fuel exceeding 62 kPa (9.0 psi) shall be shown

on all product transfer documents, including the delivery document to the aircraft.

H

See X2.10.1 for maximum limits for lead and phosphorus in unleaded gasoline.

I

Use either Eq 1 or Table 1 in Test Method D4529, or Eq 2 in Test Method D3338. See X2.7.2 for limitations and oxygen corrections required when Test Methods D3338

and D4529 are applied to fuels blended with aliphatic ethers.

J

Test Method D381 existent gum test can provide a means of detecting deteriorated quality or contamination, or both, with heavier products following distribution from

refinery to airport; refer to X2.9.1.

K

No deliberate addition of alcohols is allowed except for isopropyl alcohol, which is allowed as an additive (see 6.2.4.2)

L

For additional information and limitations, see X2.8

6.2.2 Metal Deactivators—A metal deactivator, N,N’-disalicylidene-1,2-propanediamine may be added to the gasoline in an

amount not to exceed 3.0 mg/L.

6.2.3 Corrosion Inhibitors—Corrosion inhibitors that conform to MIL-PRF-25017F may be added to the gasoline in amounts not

exceeding the maximum allowable concentrations listed in the latest revision of QPL-25017.

6.2.4 Fuel System Icing Inhibitor:

6.2.4.1 Diethylene glycol monomethyl ether, conforming to the requirements of Specification D4171 (Type III), may be used in

concentrations of 0.10 to 0.15 volume %.

D6227 − 18 (2023)

6.2.4.2 Isopropyl alcohol conforming to the requirements of Specification D4171 (Type II) may be used in concentrations

recommended by the aircraft manufacturers when required by the aircraft owner operator.

7. Detailed Requirements

7.1 The aviation gasoline shall conform to the requirements in Table 1.

8. Workmanship

8.1 The finished fuel shall be visually free of water, sediment, and suspended matter.

NOTE 1—See Practice D4057 for appropriate sampling procedures.

9. Reports

9.1 The

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.