ASTM C1926-23

(Test Method)Standard Test Method for Measurement of Glass Dissolution Rate Using Stirred Dilute Reactor Conditions on Monolithic Samples

Standard Test Method for Measurement of Glass Dissolution Rate Using Stirred Dilute Reactor Conditions on Monolithic Samples

SIGNIFICANCE AND USE

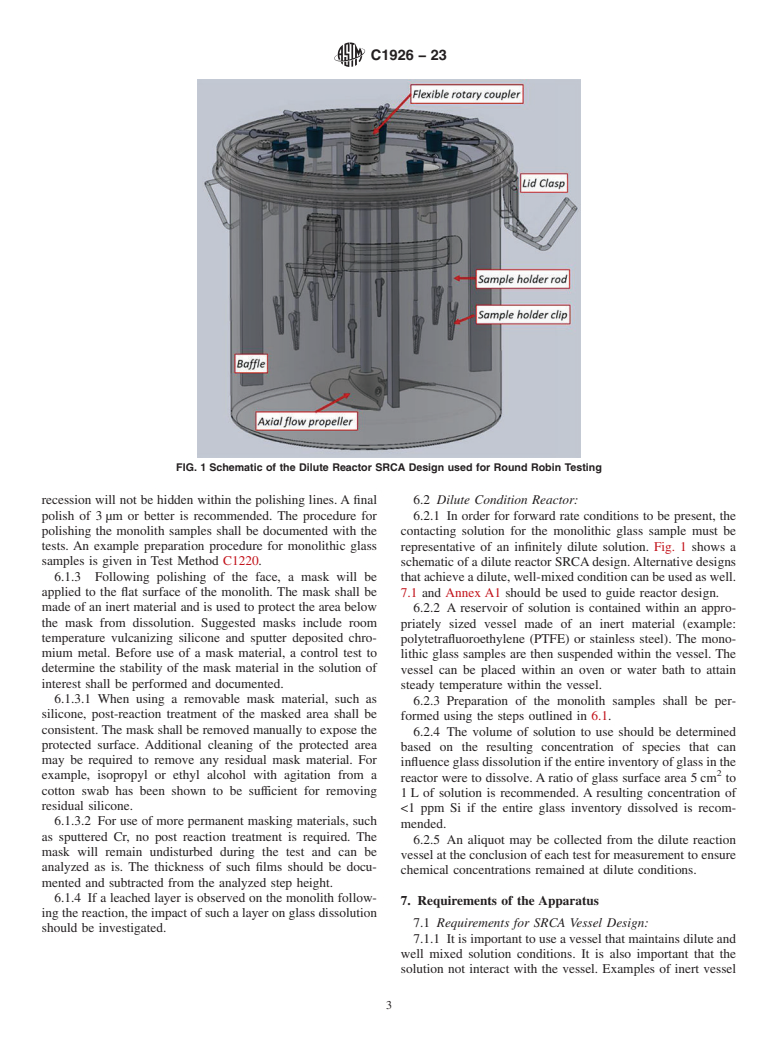

5.1 This test method provides a description of the design of the Stirred Reactor Coupon Analysis (SRCA) apparatus and identifies aspects of the performance of the SRCA tests and interpretation of the test results that must be addressed by the experimenter to provide confidence in the measured dissolution rate.

5.2 The SRCA methods described in this test method can be used to characterize several aspects of glass corrosion that can be included in mechanistic models of long-term durability of glasses, including nuclear waste glasses.

5.3 Depending on the test parameters investigated, the SRCA results can be used to measure the intrinsic dilute glass dissolution rate, as well as the effects of conditions such as temperature, pH, and solution chemistry on the dissolution rate.

5.4 Due to the scalable nature of the method, it is particularly applicable to studies of the impact of glass composition on dilute-condition corrosion. Models of glass behavior can be parameterized by testing glass composition matrices and establishing quantitative structure-property relationships.

5.5 The step heights present on the corroded sample can be measured by a variety of techniques including profilometry (optical or stylus), atomic force microscopy, interferometry or other techniques capable of determining relative depths on a sample surface. The sample can also be interrogated with other techniques such as scanning electron microscopy to characterize the corrosion behavior. These further analyses can determine if the sample corroded homogenously and possible formation of secondary phases or leached layers. Occurrence of these features may impact the accuracy of glass dissolution. This test method does not address these solid-state characterizations.

SCOPE

1.1 This test method describes a test method in which the dissolution rate of a homogenous silicate glass is measured through corrosion of monolithic samples in stirred dilute conditions.

1.2 Although the test method was designed for simulated nuclear waste glass compositions per Guide C1174, the method is applicable to glass compositions for other applications including, but not limited to, display glass, pharmaceutical glass, bioglass, and container glass compositions.

1.3 Various test solutions can be used at temperatures less than 100 °C. While the durability of the glass can be impacted by dissolving species from the glass, and thus the test can be conducted in dilute conditions or concentrated condition to determine the impact of such species, care must be taken to avoid, acknowledge, or account for the production of alteration layers which may confound the step height measurements.

1.4 The dissolution rate measured by this test is, by design, an average of all corrosion that occurs during the test. In dilute conditions, glass is assumed to dissolve congruently and the dissolution rate is assumed to be constant.

1.5 Tests are carried out via the placement of the monolithic samples in a large well-mixed volume of solution, achieving a high volume to surface area ratio resulting in dilute conditions with agitation of the solution.

1.6 This test method excludes test methods using powdered glass samples, or in which the reactor solution saturates with time. Glass fibers may be used without a mask if the diameter is known to high accuracy before the test.

1.7 Tests may be conducted with ASTM Type I water (see Specification D1193 and Terminology D1129), buffered water or other chemical solutions, simulated or actual groundwaters, biofluids, or other dissolving solutions.

1.8 Tests are conducted with monolithic glass samples with at least a single flat face. Although having two plane-parallel faces is helpful for certain step height measurements, it is not required. The geometric dimensions of the monolith are not required to be known. The reacted monolithic sample is to be analyzed following the reaction to measure a corroded d...

General Information

Relations

Standards Content (Sample)

This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the

Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

Designation: C1926 − 23

Standard Test Method for

Measurement of Glass Dissolution Rate Using Stirred Dilute

1

Reactor Conditions on Monolithic Samples

This standard is issued under the fixed designation C1926; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope faces is helpful for certain step height measurements, it is not

required. The geometric dimensions of the monolith are not

1.1 This test method describes a test method in which the

required to be known. The reacted monolithic sample is to be

dissolution rate of a homogenous silicate glass is measured

analyzed following the reaction to measure a corroded depth to

through corrosion of monolithic samples in stirred dilute

determine dissolution rate.

conditions.

1.9 Tests may be performed with radioactive samples.

1.2 Although the test method was designed for simulated

However, safety concerns working with radionuclides are not

nuclear waste glass compositions per Guide C1174, the method

addressed in this test method.

is applicable to glass compositions for other applications

including, but not limited to, display glass, pharmaceutical 1.10 Data from these tests can be used to determine the

glass, bioglass, and container glass compositions. value of kinetic rate model parameters needed to predict glass

corrosion behavior over long periods of time. For an example,

1.3 Various test solutions can be used at temperatures less

see Practice C1662, section 9.5.

than 100 °C. While the durability of the glass can be impacted

by dissolving species from the glass, and thus the test can be 1.11 This test method must be performed in accordance with

conducted in dilute conditions or concentrated condition to all quality assurance requirements for acceptance of the data.

determine the impact of such species, care must be taken to

1.12 Units—The values stated in SI units are regarded as the

avoid, acknowledge, or account for the production of alteration

standard. Any values given in parentheses are for information

layers which may confound the step height measurements.

only.

1.4 The dissolution rate measured by this test is, by design,

1.13 This standard does not purport to address all of the

an average of all corrosion that occurs during the test. In dilute

safety concerns, if any, associated with its use. It is the

conditions, glass is assumed to dissolve congruently and the

responsibility of the user of this standard to establish appro-

dissolution rate is assumed to be constant.

priate safety, health, and environmental practices and deter-

mine the applicability of regulatory limitations prior to use.

1.5 Tests are carried out via the placement of the monolithic

1.14 This international standard was developed in accor-

samples in a large well-mixed volume of solution, achieving a

dance with internationally recognized principles on standard-

high volume to surface area ratio resulting in dilute conditions

ization established in the Decision on Principles for the

with agitation of the solution.

Development of International Standards, Guides and Recom-

1.6 This test method excludes test methods using powdered

mendations issued by the World Trade Organization Technical

glass samples, or in which the reactor solution saturates with

Barriers to Trade (TBT) Committee.

time. Glass fibers may be used without a mask if the diameter

is known to high accuracy before the test.

2. Referenced Documents

1.7 Tests may be conducted with ASTM Type I water (see 2

2.1 ASTM Standards:

Specification D1193 and Terminology D1129), buffered water

C693 Test Method for Density of Glass by Buoyancy

or other chemical solutions, simulated or actual groundwaters,

C859 Terminology Relating to Nuclear Materials

biofluids, or other dissolving solutions.

C1174 Guide for Evaluation of Long-Term Behavior of

1.8 Tests are conducted with monolithic glass samples with Materials Used in Engineered Barrier Systems (EBS) for

at least a single flat face. Although having two plane-parallel

Geological Disposal of High-Level Radioactive Waste

1

This test method is under the jurisdiction of ASTM Committee C26 on Nuclear

2

Fuel Cycle and is the direct responsibility of Subcommittee C26.13 on Spent Fuel For referenced ASTM standards, visit the ASTM website, www.astm.org, or

and High Level Waste. contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

Current edition approved Feb. 1, 2023. Published April 2023. DOI: 10.1520/ Standards

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.