ASTM D6606-00(2005)

(Test Method)Standard Test Method for Viscosity and Yield of Vehicles and Varnishes by the Duke Viscometer

Standard Test Method for Viscosity and Yield of Vehicles and Varnishes by the Duke Viscometer

SIGNIFICANCE AND USE

Actual direct measurements of apparent viscosity and stress at shear rates of interest can be useful in the practical control of ink viscosity during production and the specification acceptance between supplier and purchaser.

Use of the Duke automated viscometer provides direct measurements for viscosity and yield value versus extrapolating data points that may be far from the desired shear rates.

SCOPE

1.1 This test method covers the procedure for determining the viscosity of varnishes, ink vehicles, and similar liquids that are essentially nonvolatile and unreactive under ordinary room conditions using the Duke Automated high-shear rod and collar viscometer.

1.2 The instrument in this test method is similar in principle to the falling-rod viscometer described in Test Method D 4040 except that the collar is motor driven and the range of available shear stresses is considerably greater. This instrument is capable of measured and extrapolated viscosity and yield values provided the proper model is chosen for the given application. See Section 6 for the ranges of specified models.

1.3 The values stated in SI units are to be regarded as the standard. The values given in parentheses are for information only.

1.4 This standard does not purport to address all of the safety concerns, if any, that may be associated with its use. It is the responsibility of the user of this standard to establish any appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation:D6606–00(Reapproved2005)

Standard Test Method for

Viscosity and Yield of Vehicles and Varnishes by the Duke

Viscometer

This standard is issued under the fixed designation D6606; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope 3. Terminology

1.1 This test method covers the procedure for determining 3.1 Definitions— Terms relative to this test method are

theviscosityofvarnishes,inkvehicles,andsimilarliquidsthat defined in Test Method D4040 except for those found in 3.2.

are essentially nonvolatile and unreactive under ordinary room 3.2 Definitions of Terms Specific to This Standard:

conditionsusingtheDukeAutomatedhigh-shearrodandcollar 3.2.1 yield value, n—The Lehman’s yield value that is

−1

viscometer. defined as the stress at 2.5 s .

1.2 Theinstrumentinthistestmethodissimilarinprinciple 3.2.1.1 Discussion—This value can be either extrapolated

to the falling-rod viscometer described in Test Method D4040 or measured.

exceptthatthecollarismotordrivenandtherangeofavailable 3.2.2 shortness ratio, n—a ratio to determine the shortness

shear stresses is considerably greater. This instrument is characteristic of the fluid where SR = yield value/apparent

capable of measured and extrapolated viscosity and yield viscosity.

values provided the proper model is chosen for the given

4. Summary of Test Method

application. See Section 6 for the ranges of specified models.

1.3 The values stated in SI units are to be regarded as 4.1 This automated test method is based upon accurate

measurement of the force that is transferred at a known

standard. No other units of measurement are included in this

standard. temperature into a stationary vertical rod as a fluid such as

printing ink/varnish moves through a precision measurement

1.4 This standard does not purport to address all of the

safety concerns, if any, that may be associated with its use. It gap formed between the outside diameter of the rod and the

inside diameter of collar of specific geometry as said collar

is the responsibility of the user of this standard to establish any

moves upward along the length of the rod at specified

appropriate safety and health practices and determine the

applicability of regulatory limitations prior to use. velocities.

4.2 The operator of the instrument and the customer must

2. Referenced Documents

agree on the preprogrammed test sequence, which is to be run

2.1 ASTM Standards: for a given material and the desired test temperature. Supervi-

D4040 Test Method for Rheological Properties of Paste sory personnel should know the specifics of each prepro-

Printing and Vehicles by the Falling-Rod Viscometer grammed test sequence, how to change a given test sequence,

and how to make a new test sequence.

4.3 This test method provides actual measured test data of

This test method is under the jurisdiction of ASTM Committee D01 on Paint

fluids at specified shear rates, which can be programmed to

and Related Coatings, Materials, andApplications and is the direct responsibility of

relate. In addition to actual measured data, extrapolated data

Subcommittee D01.37 on Ink Vehicles.

Current edition approved Sept. 1, 2005. Published September 2005. Originally

using the “power law mathematical model” is provided that

approved in 2000. Last previous edition approved in 2000 as D6606–00. DOI:

correlates with manual testing methods as outlined in Test

10.1520/D6606-00R05.

Method D4040.

Thesolesourceofsupplyofanautomatedhighshearrodandcollarviscometer

known to the committee at this time is Duke Custom Systems, Inc., Pleasant View, 4.4 Specified test reference temperatures can range from 20

TN. If you are aware of alternative suppliers, please provide this information to

to 40°C. Allowable deviation from desired test reference

ASTM International Headquarters. Your comments will receive careful consider-

temperature could be specified differently in each test se-

ation at a meeting of the responsible technical committee, which you may attend.

quence.Allowableprogrammableiswithintherangeof0.05to

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

0.4°C.

Standards volume information, refer to the standard’s Document Summary page on

the ASTM website.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

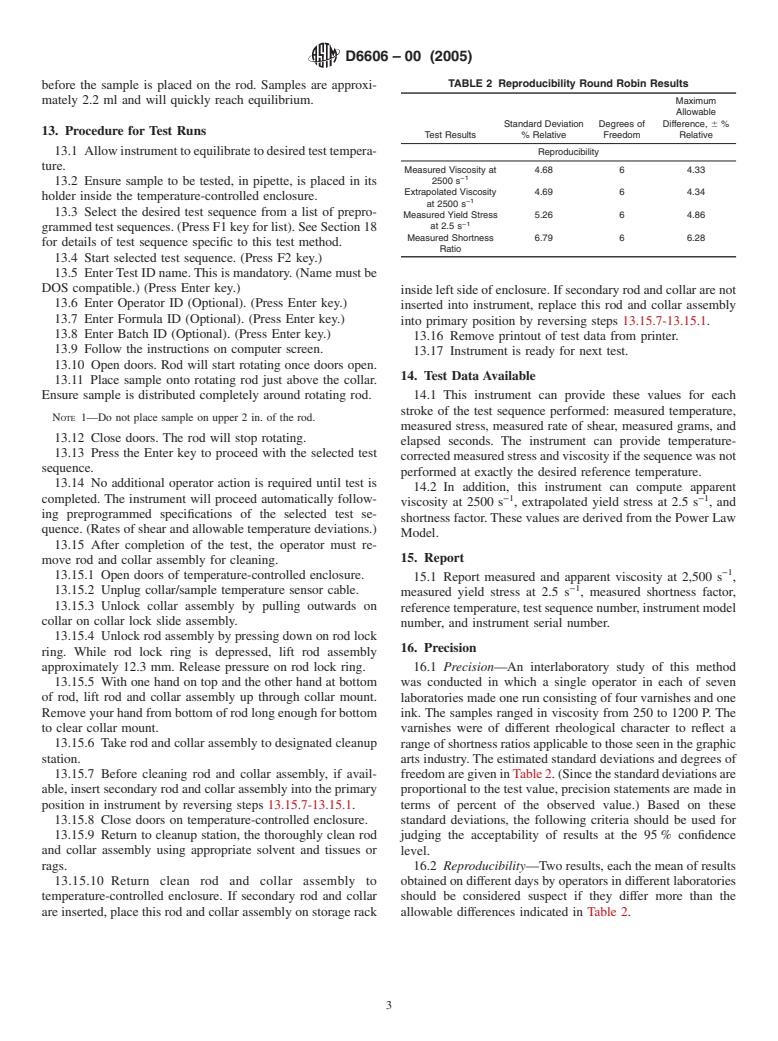

D6606–00 (2005)

TABLE 1 Performance Ranges For Each Model

Model Number Stress Range (Dynes/ Viscosity Range Shear Rate Range Temperature Range° C

2 −1 −1

cm ) Poise at 2500sec (sec )

D-2010 D-2010E 75−1.0310 4 − 400 2.5 − 10,000 19–40

D-2012 D-2012E

D-2020 D-2020E 150−2.0310 10 − 800 2.5 − 10,000 19–40

D-2022 D-2022E

D-2050 D-2050E 300−5.0310 20 − 1,600 2.5 − 7,500 19–40

D-2052 D-2052E

D-2100 D-2100E 600 − 10.0310 40 − 3,200 2.5 − 7,500 19–40

D-2102 D-2102E

5. Significance and Use 9.3 Leveltheviscometerbyturningtheadjustablefeetupor

downuntilthespiritleveliscenteredandtheinstrumentisfree

5.1 Actual direct measurements of apparent viscosity and

from wobble.

stress at shear rates of interest can be useful in the practical

9.4 Clean the rod and collar thoroughly with tissues wetted

controlofinkviscosityduringproductionandthespecification

with naphtha or other appropriate solvent. Remove residual

acceptance between supplier and purchaser.

solvent with clean dry tissue. Ensure rod and collar are free of

5.2 Use of the Duke automated viscometer provides direct

lint or other particles from tissue or environment. Warning:

measurements for viscosity and yield value versus extrapolat-

Failure to clean instrument adequately will severely influence

ing data points that may be far from the desired shear rates.

results.

6. Apparatus 9.5 Ensure identification code on rod and collar match.

9.6 Properly install and lock into viscometer the rod with

6.1 Table 1 describes each model of the Duke automated

rod cup and collar in accordance with manufacturer’s recom-

high shear rod and collar viscometer with the appropriate

mendations.

ranges for the ink or varnish being tested.

9.7 Plug in collar/sample temperature probe.

7. Materials

9.8 Allow instrument to equilibrate at a desired test tem-

perature.

7.1 ASTM Standard Viscosity Fluids—(For calibration pur-

poses only.) At approximately 100, 200, and 400 poise, span

10. Calibration

the practical range of the instrument without inducing self-

heating errors. The required fluids are N4000 (100 poise at 10.1 Ensure instrument is within calibration window by

25°C), S8000 (200 poise at 25°C), and N15000 (400 poise at

reading information contained in “Days to Next Calibration

25°C). Window”onthecomputerscreen.Thenumberofdaysuntilthe

7.2 Lint and Metal-Free Rags or Tissues of appropriate

next factory-authorized calibration is displayed whenever the

size, so that they may be pulled or pushed completely through instrument is not in active use.

the collar in a single pass.

10.2 Periodically check calibration as in Section 17.

7.3 Naphtha or other Low-Boiling Solvent in a wash bottle

or closed metal container.

11. Sample Preparation

11.1 Transport sample to be tested to the test area and

8. Hazards

preserveinasuitablecleanclosedcontainer.Skinpapershould

8.1 Warning: Solvents may be hazardous to the skin and

be used for oxidative fluids.

eyes. In addition to other precautions, always wear protective

11.2 Samples should be uniform dispersions or structures

gloves and safety glasses during cleanup to avoid solvent

throughout. Samples to be tested should be free of bubbles,

contact with skin and eyes. See supplier’s material safety data

skin,orotherdebris.Ifvariationsinstructurearesuspected,the

sheet for further information on each solvent used.

sample must be remixed until it is of uniform consistency.

8.2 Instrument Warning: Never operate the instrument with

11.3 Fillpipetwiththesampleandplacefilledpipetintothe

the rod installed without fluid in the collar.

temperature-controlled enclosure of viscometer. Warning: Do

not work the sample vigorously. Be sure to close the sample

9. Preparation of Apparatus

container immediately after removing the desired sample to be

9.1 Set the viscometer up on a sturdy vibration-free bench

tested.

capable of supporting at least 6.75 sq. m.

9.2 Locate the viscometer in an area free of direct sunlight

12. Conditioning

to prevent sun-induced heating inside the clear temperature-

12.1 The test sequence and reference temperatures are

controlled enclosure.

programmable and are protected by password security to

prevent unauthorized changes from desired temperatures. The

The sole source of supply of the certified standard viscosity oil known to the

reference temperature for this test method is 25.0° and the

committee at this time is Cannon Instrument Company, P.O. Box 16, State College,

enclosure temperature for this test method is 24.95°C.

PA16801. If you are aware of alternative suppliers, please provide this information

12.2 The pipet

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.