ASTM D7588-11

(Guide)Standard Guide for FT-IR Fingerprinting of a Non-Aqueous Liquid Paint as Supplied in the Manufacturer's Container

Standard Guide for FT-IR Fingerprinting of a Non-Aqueous Liquid Paint as Supplied in the Manufacturer's Container

SIGNIFICANCE AND USE

The ability to collect an infrared spectrum of a liquid paint as supplied in the container from the manufacturer is of significant importance when performing qualification testing. Historically, fingerprinting a material for such purpose involved separating the components of the paint and collecting an infrared spectrum of one or more of these components (vehicle, pigments, solvent, etc.) with Test Method D2621 being used for the identification of the vehicle. This unfortunately provides information only on the portion of the liquid paint analyzed whereas the technique shown in this practice provides a more complete picture of what is in the container provided. In addition, user expertise and time required to collect a spectrum is minimal versus traditional standards.

SCOPE

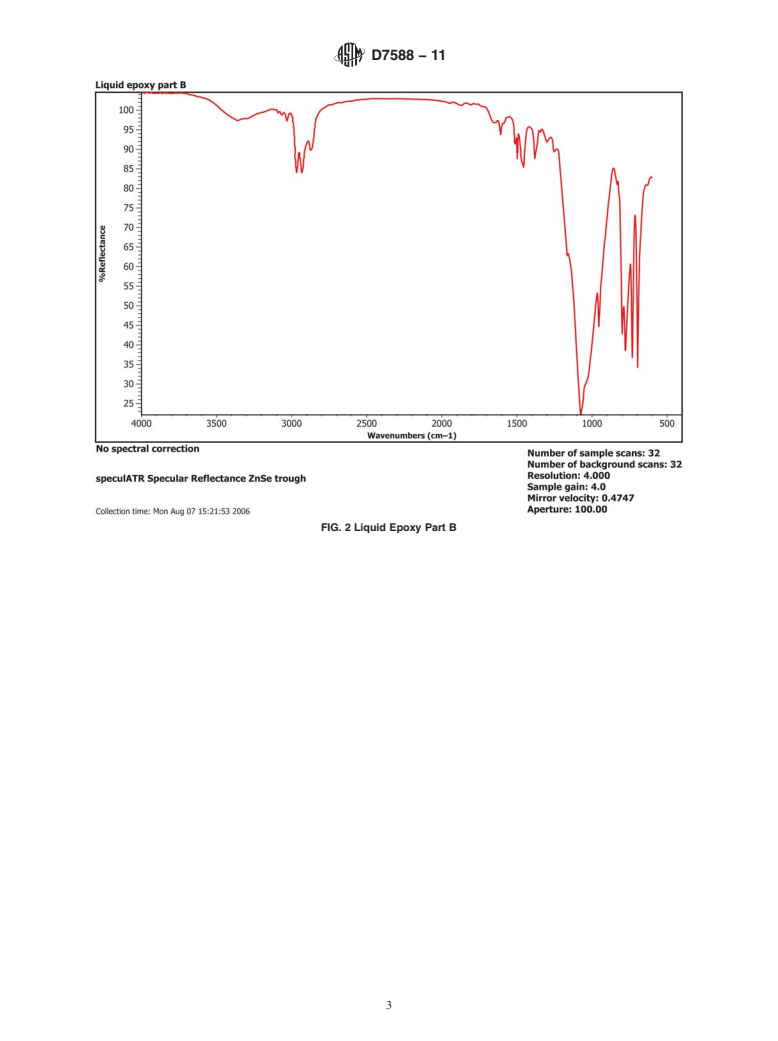

1.1 This guide covers the FT-IR fingerprinting of a liquid paint as supplied in the container without the need to separate components. Spectra collected using this technique have been found useful for paint manufacturers' quality control, trouble shooting and to verify that the paint being used is the same as the paint sample tested. This technique has been found useful for both single and multi-component coatings, the latter of which, where each component is analyzed separately (for example, amine cured epoxies and polyol/isocyanate urethanes).

1.2 The values stated in SI units are to be regarded as standard. No other units of measurement are included in this standard.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory requirements prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: D7588 − 11

Standard Guide for

FT-IR Fingerprinting of a Non-Aqueous Liquid Paint as

Supplied in the Manufacturer’s Container

This standard is issued under the fixed designation D7588; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope 3. Terminology

1.1 This guide covers the FT-IR fingerprinting of a liquid 3.1 Definitions—For definitions of terms and symbols, refer

to terminology in Terminology E131.

paint as supplied in the container without the need to separate

components. Spectra collected using this technique have been

4. Summary of Guide

found useful for paint manufacturers’ quality control, trouble

shooting and to verify that the paint being used is the same as

4.1 Infrared spectra are collected using an FT-IR spectro-

the paint sample tested. This technique has been found useful

photometer fitted with an ATR crystal, multi or single bounce.

for both single and multi-component coatings, the latter of

Samples are taken directly from the paint container as supplied

which, where each component is analyzed separately (for

by the manufacturer.

example, amine cured epoxies and polyol/isocyanate ure-

thanes).

5. Significance and Use

1.2 The values stated in SI units are to be regarded as

5.1 The ability to collect an infrared spectrum of a liquid

standard. No other units of measurement are included in this

paint as supplied in the container from the manufacturer is of

standard.

significant importance when performing qualification testing.

Historically, fingerprinting a material for such purpose in-

1.3 This standard does not purport to address all of the

volved separating the components of the paint and collecting

safety concerns, if any, associated with its use. It is the

an infrared spectrum of one or more of these components

responsibility of the user of this standard to establish appro-

(vehicle, pigments, solvent, etc.) with Test Method D2621

priate safety and health practices and determine the applica-

being used for the identification of the vehicle. This unfortu-

bility of regulatory requirements prior to use.

nately provides information only on the portion of the liquid

paint analyzed whereas the technique shown in this practice

2. Referenced Documents

provides a more complete picture of what is in the container

2.1 ASTM Standards:

provided. In addition, user expertise and time required to

D2621 Test Method for Infrared Identification of Vehicle

collect a spectrum is minimal versus traditional standards.

Solids From Solvent-Reducible Paints

E131 Terminology Relating to Molecular Spectroscopy

6. Apparatus

E168 Practices for General Techniques of Infrared Quanti-

6.1 Spectrophotometer—An FT-IR spectrophotometer with

tative Analysis

-1

a wavelength range of at least 600 to 4000 cm and a

E204 Practices for Identification of Material by Infrared

-1

resolution no less than 4 cm .

Absorption Spectroscopy, Using the ASTM Coded Band

and Chemical Classification Index (Withdrawn 2014)

6.2 Multi or Single Bounce Horizontal Attenuated Total

Reflectance (ATR) Trough—For many paint samples, a 45

degree single bounce Fresnel-type ZnSe crystal has been found

1 to provide satisfactory results for most liquid paints. Paint

This guide is under the jurisdiction of ASTM Committee D01 on Paint and

Related Coatings, Materials, and Applications and is the direct responsibility of

samples unsuitable for this setup will exhibit many 100 %

Subcommittee D01.21 on Chemical Analysis of Paints and Paint Materials.

absorptions not to be confused with the 100 % absorptions

Current edition approved June 1, 2011. Published June 1, 2011. DOI: 10.1520/

associated with the spectral cutoff of the instrument optics and

D7588-11.

crystal material. It should be noted that ATR spectra are

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

influenced by the depth of penetration

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.