ASTM E2448-11e1

(Test Method)Standard Test Method for Determining the Superplastic Properties of Metallic Sheet Materials

Standard Test Method for Determining the Superplastic Properties of Metallic Sheet Materials

SIGNIFICANCE AND USE

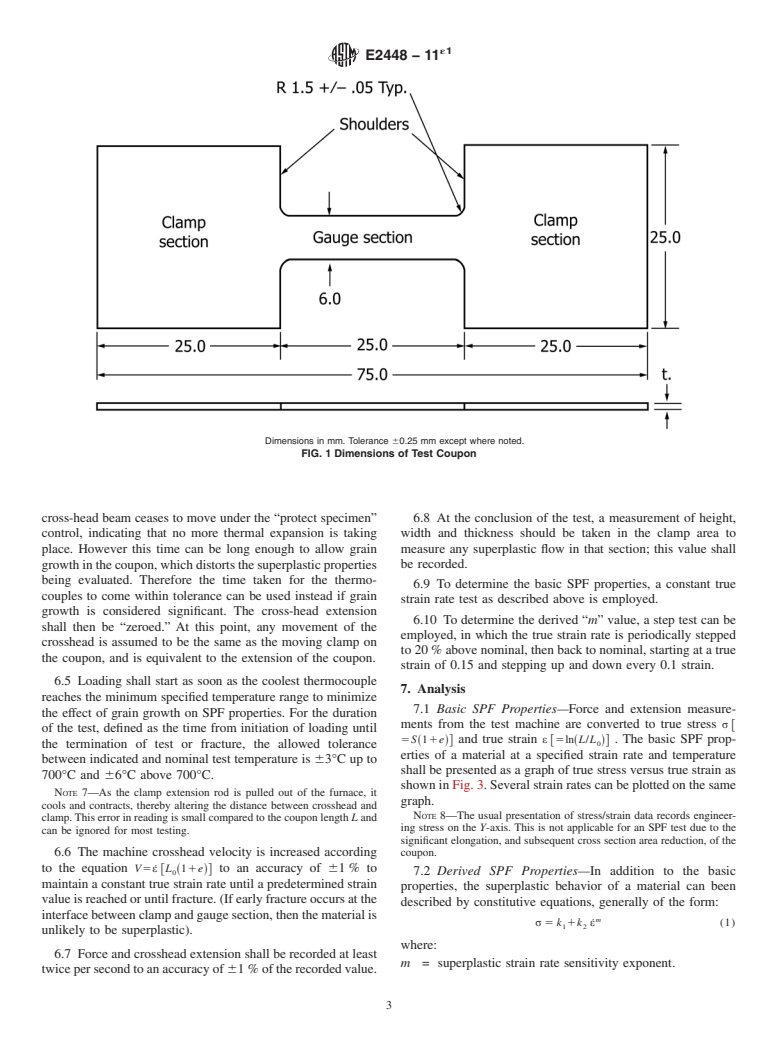

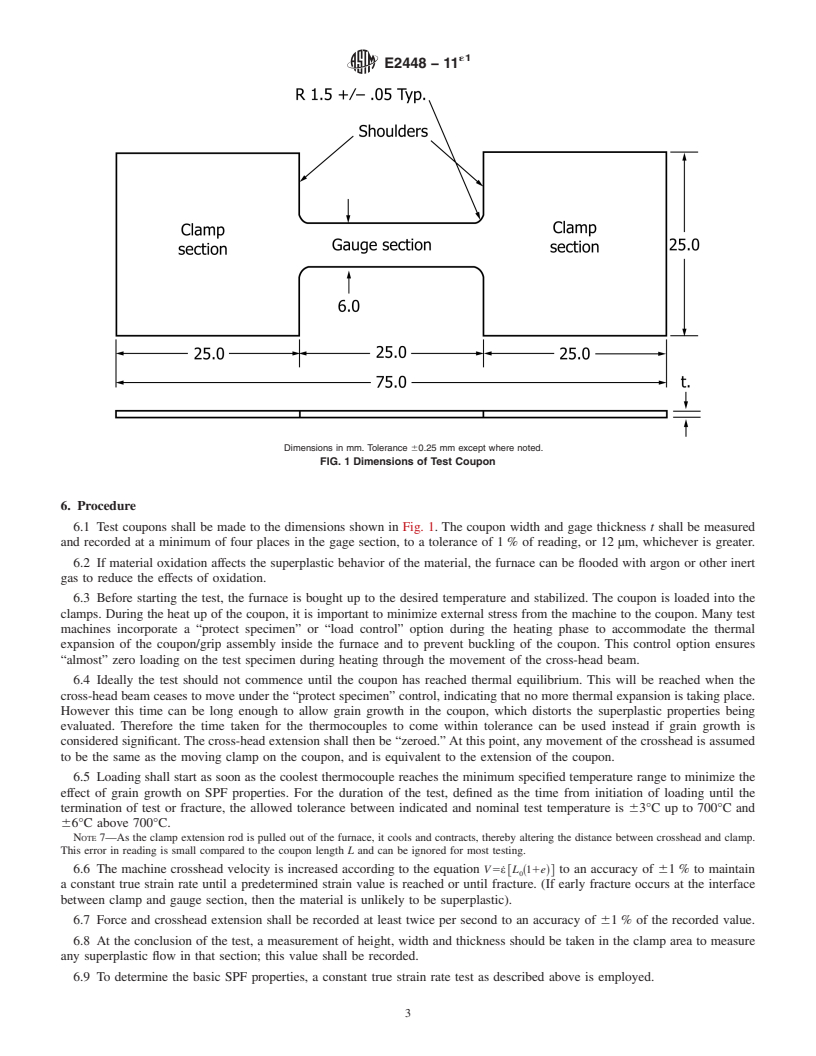

4.1 The determination of the superplastic properties of a metallic sheet material is important for the observation, development and comparison of superplastic materials. It is also necessary to predict the correct forming parameters during an SPF process. SPF tensile testing has peculiar characteristics compared to conventional mechanical testing, which distort the true values of stress, strain, strain hardening, and strain rate at the very large elongations encountered in an SPF pull test, consequently conventional mechanical test methods cannot be used. This test method addresses those characteristics by optimizing the shape of the test coupon and specifying a new test procedure.

4.2 The evaluation of a superplastic material can be divided into two parts. Firstly, the basic superplastic-forming (SPF) properties of the material are measured using the four parameters of stress, temperature, strain, and strain rate. These are obtained using conversions from the raw data of a tensile test. Secondly, derived properties useful to define an SPF material are obtained from the basic properties using specific equations.

SCOPE

1.1 This test method describes the procedure for determining the superplastic forming properties (SPF) of a metallic sheet material. It includes tests both for the basic SPF properties and also for derived SPF properties. The test for basic properties encompasses effects due to strain hardening or softening.

1.2 This test method covers sheet materials with thicknesses of at least 0.5 mm but not greater than 6 mm. It characterizes the material under a uni-axial tensile stress condition.

Note 1: Most industrial applications of superplastic forming involve a multi-axial stress condition in a sheet; however it is more convenient to characterize a material under a uni-axial tensile stress condition. Tests should be performed in different orientations to the rolling direction of the sheet to ascertain initial anisotropy.

1.3 This method has been used successfully between strain rates of 10-5 to 10-1 per second.

1.4 This method has been used successfully on Aluminum and Titanium alloys. The use of the method with other metals should be verified.

1.5 The values stated in SI units are to be regarded as standard. No other units of measurement are included in this standard.

1.6 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Buy Standard

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

´1

Designation: E2448 − 11

Standard Test Method for

Determining the Superplastic Properties of Metallic Sheet

1

Materials

This standard is issued under the fixed designation E2448; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1

ε NOTE—Footnote 4 was editorially corrected in October 2015.

1. Scope 2. Referenced Documents

2

1.1 This test method describes the procedure for determin-

2.1 ASTM Standards:

ing the superplastic forming properties (SPF) of a metallic E4 Practices for Force Verification of Testing Machines

sheet material. It includes tests both for the basic SPF proper-

E6 Terminology Relating to Methods of Mechanical Testing

ties and also for derived SPF properties. The test for basic E21 TestMethodsforElevatedTemperatureTensionTestsof

properties encompasses effects due to strain hardening or

Metallic Materials

softening. E177 Practice for Use of the Terms Precision and Bias in

ASTM Test Methods

1.2 This test method covers sheet materials with thicknesses

E646 Test Method for Tensile Strain-Hardening Exponents

of at least 0.5 mm but not greater than 6 mm. It characterizes

(n -Values) of Metallic Sheet Materials

the material under a uni-axial tensile stress condition.

E691 Practice for Conducting an Interlaboratory Study to

NOTE 1—Most industrial applications of superplastic forming involve a

multi-axial stress condition in a sheet; however it is more convenient to Determine the Precision of a Test Method

characterize a material under a uni-axial tensile stress condition. Tests

should be performed in different orientations to the rolling direction of the

3. Terminology

sheet to ascertain initial anisotropy.

3.1 Definitions—Definitions such as gage length (L and L ),

0

1.3 This method has been used successfully between strain

-5 -1

truestress(σ),truestrain(ε),normalengineeringstress(S),and

rates of 10 to 10 per second.

engineering strain (e) are defined in Terminology E6. Thus,

1.4 This method has been used successfully on Aluminum

ε 5 ln L/L

~ !

0

and Titanium alloys. The use of the method with other metals

σ 5 S 11e

should be verified. ~ !

NOTE 2—Engineering stress S and strain e are only valid up to the point

1.5 The values stated in SI units are to be regarded as

ofneckingorinstabilityofcrosssection.Forsuperplasticdeformation,the

standard. No other units of measurement are included in this

coupon undergoes an essentially uniform and constant neck along its

standard. length, and S and e are assumed in this standard to be valid. However at

the junction to the clamp sections of the coupon the cross section reduces

1.6 This standard does not purport to address all of the

from the original value to the final value, over a length of approximately

safety concerns, if any, associated with its use. It is the

4 % at each end. Also, there are local small instabilities of cross section

responsibility of the user of this standard to establish appro- overthegaugelength.Thesecontributetoanerrorinthecalculatedvalues

of ε and σ. In the absence of currently available extensometers that could

priate safety and health practices and determine the applica-

operate in the high temperature environment of an SPF test,ε andσ are to

bility of regulatory limitations prior to use.

be inferred from crosshead extension and force.

1

This test method is under the jurisdiction of ASTM Committee E28 on

Mechanical Testing and is the direct responsibility of Subcommittee E28.02 on

2

Ductility and Formability. For referenced ASTM standards, visit the ASTM website, www.astm.org, or

CurrenteditionapprovedJune1,2011.PublishedJuly2011.Originallyapproved contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

in 2005. Last previous edition approved in 2008 as E2448–08. DOI: 10.1520/ Standards volume information, refer to the standard’s Document Summary page on

E2448-11E01. the ASTM website.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

´1

E2448 − 11

3.2 Symbols Specific To This Standard: V = machine cross- 5. Apparatus

head velocity, the velocity of the traveling member of the test

5.1 The accuracy of the testing machine shall be within the

machine to which one of the coupon clamps is attached

permissible variation specified in Practices E4.

ε˙ = strain rate, measured as: V/@L ~11e!#

0

5.2 The apparatus shall be calibrated according to appropri-

NOTE 3—This is an operational definition of strain rate.

ate standards or manufacturer instructions.

m = strain rate sensitivity, defined as (ln∆σ)/

...

This document is not an ASTM standard and is intended only to provide the user of an ASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

´1

Designation: E2448 − 11 E2448 − 11

Standard Test Method for

Determining the Superplastic Properties of Metallic Sheet

1

Materials

This standard is issued under the fixed designation E2448; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1

ε NOTE—Footnote 4 was editorially corrected in October 2015.

1. Scope

1.1 This test method describes the procedure for determining the superplastic forming properties (SPF) of a metallic sheet

material. It includes tests both for the basic SPF properties and also for derived SPF properties. The test for basic properties

encompasses effects due to strain hardening or softening.

1.2 This test method covers sheet materials with thicknesses of at least 0.5 mm but not greater than 6 mm. It characterizes the

material under a uni-axial tensile stress condition.

NOTE 1—Most industrial applications of superplastic forming involve a multi-axial stress condition in a sheet; however it is more convenient to

characterize a material under a uni-axial tensile stress condition. Tests should be performed in different orientations to the rolling direction of the sheet

to ascertain initial anisotropy.

-5 -1

1.3 This method has been used successfully between strain rates of 10 to 10 per second.

1.4 This method has been used successfully on Aluminum and Titanium alloys. The use of the method with other metals should

be verified.

1.5 The values stated in SI units are to be regarded as standard. No other units of measurement are included in this standard.

1.6 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility

of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory

limitations prior to use.

2. Referenced Documents

2

2.1 ASTM Standards:

E4 Practices for Force Verification of Testing Machines

E6 Terminology Relating to Methods of Mechanical Testing

E21 Test Methods for Elevated Temperature Tension Tests of Metallic Materials

E177 Practice for Use of the Terms Precision and Bias in ASTM Test Methods

E646 Test Method for Tensile Strain-Hardening Exponents (n -Values) of Metallic Sheet Materials

E691 Practice for Conducting an Interlaboratory Study to Determine the Precision of a Test Method

3. Terminology

3.1 Definitions—Definitions such as gage length (L and L ), true stress (σ), true strain (ε), normal engineering stress (S), and

0

engineering strain (e) are defined in Terminology E6. Thus,

ε5 ln~L/L !

0

σ5 S 11e

~ !

NOTE 2—Engineering stress S and strain e are only valid up to the point of necking or instability of cross section. For superplastic deformation, the

coupon undergoes an essentially uniform and constant neck along its length, and S and e are assumed in this standard to be valid. However at the junction

to the clamp sections of the coupon the cross section reduces from the original value to the final value, over a length of approximately 4 % at each end.

1

This test method is under the jurisdiction of ASTM Committee E28 on Mechanical Testing and is the direct responsibility of Subcommittee E28.02 on Ductility and

Formability.

Current edition approved June 1, 2011. Published July 2011. Originally approved in 2005. Last previous edition approved in 2008 as E2448–08. DOI:

10.1520/E2448-11.10.1520/E2448-11E01.

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM Standards

volume information, refer to the standard’s Document Summary page on the ASTM website.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

´1

E2448 − 11

Also, there are local small instabilities of cross section over the gauge length. These contribute to an error in the calculated values of ε and σ. In the

absence of currently available extensometers that could operate in the high temperature environment of an SPF test, ε and σ are to be inferred from

crosshead extension and force.

3.2 Symbols Specific To This Standard: V = machine crosshead velocity, the velocity of the traveling member of the test machine

to which one of the coupon clamps is attached

ε˙ = strain rate, measured as:

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.