ASTM E519-00

(Test Method)Standard Test Method for Diagonal Tension (Shear) in Masonry Assemblages

Standard Test Method for Diagonal Tension (Shear) in Masonry Assemblages

SCOPE

1.1 This test method covers determination of the diagonal tensile or shear strength of 1.2 by 1.2-m (4 by 4-ft) masonry assemblages by loading them in compression along one diagonal (see Fig. 1), thus causing a diagonal tension failure with the specimen splitting apart parallel to the direction of load.

1.2 Annex A1 provides suggestions regarding the determination of the diagonal-tension strength of masonry under combined diagonal-tension and compressive loading.

1.3 The values stated in SI units are to be regarded as the standard. The values given in parentheses are provided for information only.

1.4 This standard may involve hazardous materials, operations, and equipment. This standard does not purport to address all of the safety problems, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or discontinued.

Contact ASTM International (www.astm.org) for the latest information.

Designation: E 519 – 00 An American National Standard

Standard Test Method for

Diagonal Tension (Shear) in Masonry Assemblages

This standard is issued under the fixed designation E 519; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the Department of Defense.

1. Scope *

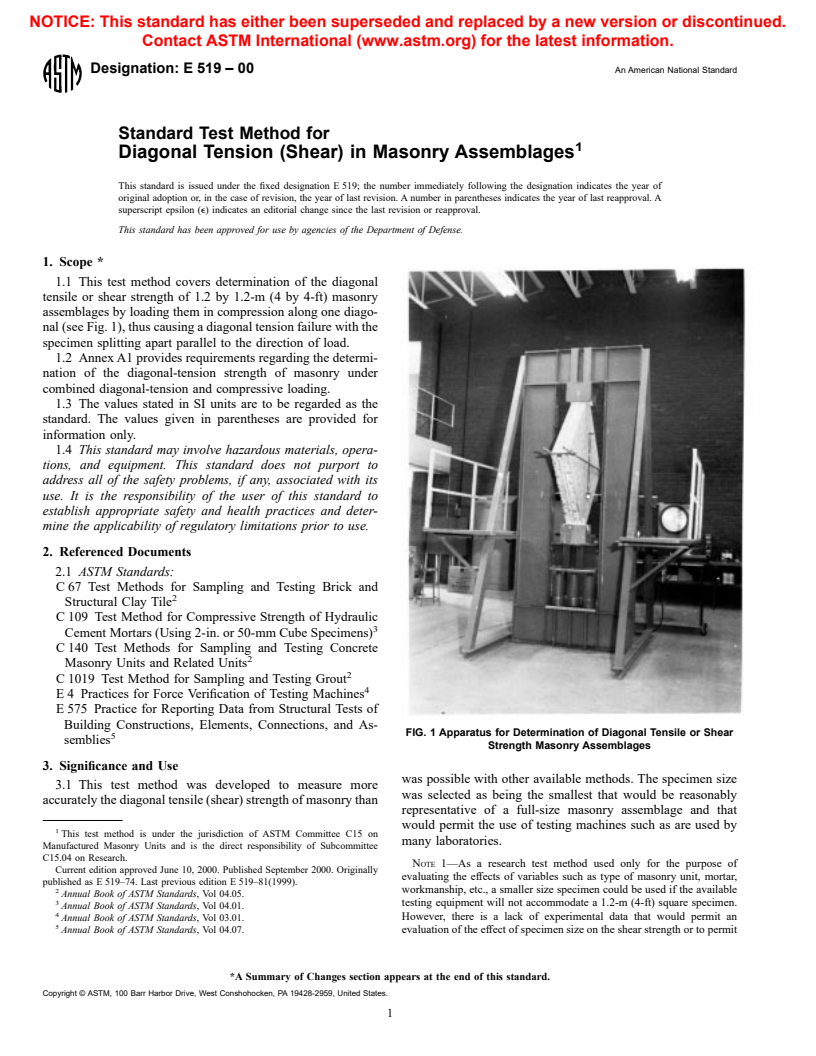

1.1 This test method covers determination of the diagonal

tensile or shear strength of 1.2 by 1.2-m (4 by 4-ft) masonry

assemblages by loading them in compression along one diago-

nal (see Fig. 1), thus causing a diagonal tension failure with the

specimen splitting apart parallel to the direction of load.

1.2 Annex A1 provides requirements regarding the determi-

nation of the diagonal-tension strength of masonry under

combined diagonal-tension and compressive loading.

1.3 The values stated in SI units are to be regarded as the

standard. The values given in parentheses are provided for

information only.

1.4 This standard may involve hazardous materials, opera-

tions, and equipment. This standard does not purport to

address all of the safety problems, if any, associated with its

use. It is the responsibility of the user of this standard to

establish appropriate safety and health practices and deter-

mine the applicability of regulatory limitations prior to use.

2. Referenced Documents

2.1 ASTM Standards:

C 67 Test Methods for Sampling and Testing Brick and

Structural Clay Tile

C 109 Test Method for Compressive Strength of Hydraulic

Cement Mortars (Using 2-in. or 50-mm Cube Specimens)

C 140 Test Methods for Sampling and Testing Concrete

Masonry Units and Related Units

C 1019 Test Method for Sampling and Testing Grout

E 4 Practices for Force Verification of Testing Machines

E 575 Practice for Reporting Data from Structural Tests of

Building Constructions, Elements, Connections, and As-

FIG. 1 Apparatus for Determination of Diagonal Tensile or Shear

semblies

Strength Masonry Assemblages

3. Significance and Use

was possible with other available methods. The specimen size

3.1 This test method was developed to measure more

was selected as being the smallest that would be reasonably

accurately the diagonal tensile (shear) strength of masonry than

representative of a full-size masonry assemblage and that

would permit the use of testing machines such as are used by

This test method is under the jurisdiction of ASTM Committee C15 on

many laboratories.

Manufactured Masonry Units and is the direct responsibility of Subcommittee

C15.04 on Research.

NOTE 1—As a research test method used only for the purpose of

Current edition approved June 10, 2000. Published September 2000. Originally

evaluating the effects of variables such as type of masonry unit, mortar,

published as E 519–74. Last previous edition E 519–81(1999).

2 workmanship, etc., a smaller size specimen could be used if the available

Annual Book of ASTM Standards, Vol 04.05.

testing equipment will not accommodate a 1.2-m (4-ft) square specimen.

Annual Book of ASTM Standards, Vol 04.01.

However, there is a lack of experimental data that would permit an

Annual Book of ASTM Standards, Vol 03.01.

Annual Book of ASTM Standards, Vol 04.07. evaluation of the effect of specimen size on the shear strength or to permit

*A Summary of Changes section appears at the end of this standard.

Copyright © ASTM, 100 Barr Harbor Drive, West Conshohocken, PA 19428-2959, United States.

E 519

a correlation between the results of small-scale specimen tests and larger

specimens.

4. Apparatus

4.1 Testing Machine—The testing machine shall have suf-

ficient compressive load capacity and provide the rate of

loading prescribed in 6.4. It shall be power-operated and

capable of applying the load continuously, rather than inter-

mittently, and without shock. It shall conform to the require-

ments of the Calculation and Report sections of Practices E 4.

NOTE 2—In order to accommodate a 1.2-m (4-ft) square specimen

placed in the machine so that its diagonal is in a vertical position, the

machine should have a clear opening height of at least 2.13 m (7 ft).

4.2 Loading Shoes—Two steel loading shoes (see Fig. 2 and

Fig. 3) shall be used to apply the machine load to the specimen.

The length of bearing of the shoe shall be 152 mm (6 in.).

NOTE 3—Experimental work has indicated that the maximum length of

bearing of the shoe should be approximately ⁄8the length of the edge of

the specimen to avoid excessive bearing stress.

5. Test Specimens

5.1 Size—The nominal size of each specimen shall be 1.2 by

1.2 m (4 by 4 ft) by the thickness of the wall type being tested.

The 1.2-m dimensions shall be within 6 mm ( ⁄4 in.) of each

other.

5.2 Number of Specimens—Tests shall be made on at least

three like specimens constructed with the same size and type of

masonry units, mortar, and workmanship.

5.3 Curing—After construction, specimens shall not be

moved for at least 7 days. They shall be stored in laboratory air

for not less than 28 days. The laboratory shall be maintained at

a temperature of 297 6 8 K (75 6 15°F) with relative

NOTE 1—Material = cold-rolled steel.

humidities between 25 and 75 %, and shall be free of drafts.

NOTE 2—Number and spacing of stiffeners will depend upon the

5.4 Mortar—Three 50-mm (2-in.) compressive strength

thickness (t) of the wall specimen to be tested.

cubes shall be molded from a sample of each batch of mortar

used to build the specimens and stored under the same

Table of Metric Equivalents

conditions as the specimens with which they are associated.

Metric Inch-Pound Metric Inch-Pound

The tests shall be conducted in accordance with Test Method

Units, mm Units, in. Units, mm Units, in.

C 109. The cubes shall be tested on the same day as the

3 1

A10 ⁄8 F89 3 ⁄2

specimen.

1 1

B13 ⁄2 G 114 4 ⁄2

5 3

C16 ⁄8 H 146 5 ⁄4

D22 ⁄8 I 152 6

E 25 1 J 254 10

FIG. 3 Dimensions of Loading Shoe

5.5 Masonry Units—Masonry units shall be sampled and

tested in accordance with the following applicable methods:

Test Method C 67 for clay brick or tile or Method C 140 for

concrete masonry units.

5.6 Grout—When specified, grout shall be sampled and

tested in accordance with Test Method C 1019.

6. Procedure

6.1 Placement of Loading Shoes—Position the upper and

lower loading shoes so as to be centered on the upper and lower

bearing surfaces of the testing machine.

6.2 Specimen Placement—Seat the specimen in a centered

and plumb position in a bed of gypsum capping material placed

FIG. 2 Loading Shoe (Two Required) in the lower loading shoe. When necessary (see A1.3), fill the

E 519

DV1DH

spaces between the specimen and the side-confining plates with

g5 (3)

g

the capping material also.

6.3 Instrumentation—When required, measure the shorten-

where:

ing of the v

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.