ASTM B496-16(2021)

(Specification)Standard Specification for Compact Round Concentric-Lay-Stranded Copper Conductors

Standard Specification for Compact Round Concentric-Lay-Stranded Copper Conductors

ABSTRACT

This specification covers bare compact round concentric-lay-stranded conductors made from uncoated round copper wires for general use for electrical purposes. Welds and brazes shall be made in rods and wires prior to final drawing. The conductors shall conform to the required construction values of nominal cross-sectional area, diameter, mass per unit length and dc electrical resistance. Tests for the physical and electrical properties of wires composing the conductors shall be made before stranding.

SCOPE

1.1 This specification covers bare compact round concentric-lay-stranded conductors made from uncoated round copper wires for general use for electrical purposes. These conductors shall be constructed with a central core surrounded by one or more layers of helically laid compacted wires (Explanatory Note 1 and Note 2).

1.2 The values stated in inch-pound units are to be regarded as standard. The values given in parentheses are mathematical conversions to SI units that are provided for information only and are not considered standard.

1.2.1 For density, resistivity, and temperature, the values stated in SI units are to be regarded as standard.

1.3 This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

General Information

Relations

Standards Content (Sample)

This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the

Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

Designation: B496 −16 (Reapproved 2021)

Standard Specification for

Compact Round Concentric-Lay-Stranded Copper

Conductors

This standard is issued under the fixed designation B496; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope 3. Ordering Information

1.1 This specification covers bare compact round 3.1 Orders for material under this specification shall include

concentric-lay-stranded conductors made from uncoated round

the following information:

copper wires for general use for electrical purposes. These

3.1.1 Quantity of each size (Table 1),

conductors shall be constructed with a central core surrounded

3.1.2 Conductor size; circular-mil area or AWG, (Section 6

by one or more layers of helically laid compacted wires

and Table 1),

(Explanatory Note 1 and Note 2).

3.1.3 Packaging (Section 15), if required,

1.2 The values stated in inch-pound units are to be regarded

3.1.4 Special package marking, and

as standard. The values given in parentheses are mathematical

3.1.5 Place of inspection (Section 14).

conversions to SI units that are provided for information only

and are not considered standard.

4. Joints

1.2.1 For density, resistivity, and temperature, the values

4.1 Welds and brazes may be made in rods or in wires prior

stated in SI units are to be regarded as standard.

to final drawing.

1.3 This international standard was developed in accor-

4.2 Welds and brazes may be made in the individual round

dance with internationally recognized principles on standard-

drawn wires for compact conductors, but shall not be closer

ization established in the Decision on Principles for the

together than 1 ft (300 mm) for conductor of 19 wires or less

Development of International Standards, Guides and Recom-

or closer than 1 ft (300 mm) in a layer for conductor of more

mendations issued by the World Trade Organization Technical

than 19 wires.

Barriers to Trade (TBT) Committee.

4.3 No joint nor splice shall be made in a compact-stranded

2. Referenced Documents

conductor as a whole.

2.1 The following documents of the issue in effect on date

5. Lay

of material purchase form a part of this specification to the

extent referenced herein:

5.1 The length of lay of the outer layer shall not be less than

8normorethan16timestheoutsidediameterofthecompleted

2.2 ASTM Standards:

conductor.The maximum length of lay for compact conductors

B3 Specification for Soft or Annealed Copper Wire

AWG 2 (33.6 mm ) and smaller shall be 17.5 times the outside

B263 Test Method for Determination of Cross-Sectional

diameter of the conductor.

Area of Stranded Conductors

B354 Terminology Relating to Uninsulated Metallic Electri-

5.2 The direction of lay of the outer layer shall be left-hand,

cal Conductors

and it shall be reversed in successive layers, unidirectional, or

unilay.

This specification is under the jurisdiction of ASTM Committee B01 on

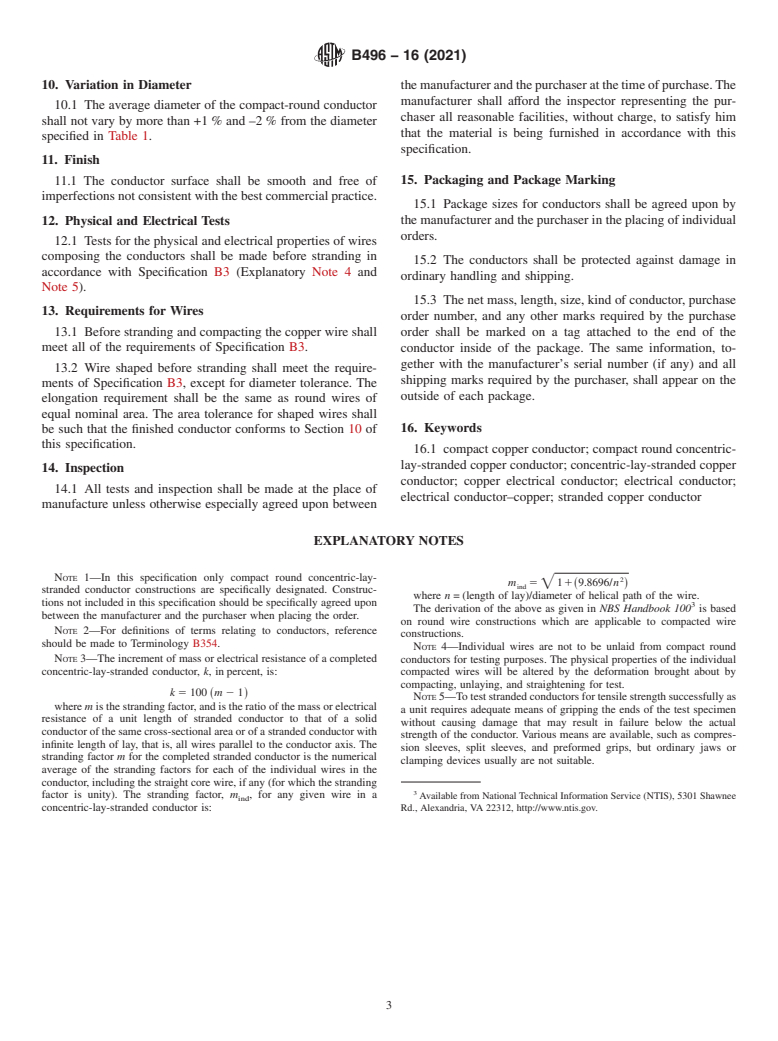

6. Construction

Electrical Conductors and is the direct responsibility of Subcommittee B01.04 on

Conductors of Copper and Copper Alloys. 6.1 The construction of the compact round concentric-lay-

Current edition approved Oct. 1, 2021. Published October 2021. Originally

stranded conductors shall be as shown in Table 1.

approved in 1969. Last previous edition approved in 2016 as B496 – 16. DOI:

10.1520/B0496-16R21.

6.2 The starting round copper wires used in the fabrication

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

of the compact round conductor shall be of such diameter as to

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

produce a finished conductor having a nominal cross-sectional

Standards volume information, refer to the standard’s Document Summary page on

the ASTM website. area and diameter as prescribed in Table 1.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

B496 − 16 (2021)

TABLE 1 Construction Requirements of Compact Round Concentric-Lay-Stranded Copper Conductors

Nominal Compact Conductor Nominal DC Resistance at

Conductor Size

Number of Nominal Mass, Nominal Mass,

Diameter 20 °C

Wires lb/1000 ft kg/km

cmil AWG mm in. mm Ω/1000 ft Ω/km

A,B

1 500 000 . 760 91 1.299 33.0 4631 6892 0.00705 0.0231

A,B

1 250 000 . 633 91 1.184 30.1 3859 5743 0.00846 0.0278

A,B

1 100 000 . 557 91 1.112 28.2 3396 5054 0.00962 0.0316

C

1 000 000 . 507 61 1.060 26.9 3086 4590 0.0106 0.0347

C

900 000 . 456 61 0.999 25.4 2780 4140 0.0118 0.0386

C

800 000 . 405 61 0.938 23.8 2469 3680 0.0132 0.0433

C

750 000 . 380 61 0.908 23.0 2316 3450 0.0141 0.0462

C

700 000 . 355 61 0.877 22.3 2160 3220 0.0151 0.0495

C

650 000 . 329 61 0.845 21.4 2006 2990 0.0163 0.0535

C

600 000 . 304 61 0.813 20.6 1850 2760 0.0176 0.0577

C

550 000 . 279 61 0.775 19.7 1700 2530 0.0192 0.0630

D

500 000 . 253 37 0.736 18.7 1542 2300 0.0212 0.0695

D

450 000 . 228 37 0.700 17.8 1390 2070 0.0235 0.0770

D

400 000 . 203 37 0.659 16.7 1236 1840 0.0264 0.0865

D

350 000 . 177 37 0.616 15.7 1080 1610 0.0302 0.0990

D

300 000 . 152 37 0.570 14.5 925 1380 0.0353 0.116

D

250 000 . 127 37 0.520 13.2 772 1150 0.0423 0.139

E

211 600 4/0 107 19 0.475 12.1 653 972 0.0500 0.164

E

167 800 3/0 85.0 19 0.423 10.8 518 771 0.0630 0.206

E

133 100 2/0 67.4 19 0.376 9.57 411 611 0.0795 0.261

E

105 600 1/0 53.5 19 0.336 8.55 326 485 0.100 0.328

E

83 690 1 42.4 19 0.299 7.60 259 385 0.126 0.413

66 360 2 33.6 7 0.268 6.81 205 305 0.159 0.521

41 740 4 21.2 7 0.213 5.41 129 192 0.253 0.830

26 240 6 13.3 7 0.169 4.29 80.9 121 0.403 1.32

16 510 8 8.37 7 0.134 3.40 51.0 75.9 0.641 2.10

A

85 wires minimum.

B

As agreed upon between the manufacturer and the customer, these sizes may be produced with a 61 to 58 wire construction of the appropriate wire size.

C

58 wires minimum.

D

35 wires minimum.

E

18 wires minimum.

TABLE 2 Temperature Correction Factors for Conductor

7. Density

Resistance

7.1 For the purpose of calculating linear densities, cross

Multiplying Factor for Conversion to

Temperature, °C

sections, and so forth, the density of the copper shall be taken

20 °C

3 3

as 8.89 g⁄cm (0.32117 lb⁄in.)at20°C.

0 1.085

5 1.063

8. Mass and Resistance

10 1.041

15 1.020

8.1 The mass per unit length and dc electrical resistance of

20 1.000

a compact round conductor are greater than the total of these 25 0.981

30 0.962

characteristics of the compressed wires composing the finished

35 0.944

conductor, depending upon the lay. The standard increment of

40 0.927

45 0.911

mass per unit length and electrical resistance shall be taken as

50 0.895

2 %. The nominal mass per unit length and dc resistance are

55 0.879

s

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.