ASTM D2444-99

(Test Method)Standard Test Method for Determination of the Impact Resistance of Thermoplastic Pipe and Fittings by Means of a Tup (Falling Weight)

Standard Test Method for Determination of the Impact Resistance of Thermoplastic Pipe and Fittings by Means of a Tup (Falling Weight)

SCOPE

1.1 This test method covers the determination of the impact resistance of thermoplastic pipe and fittings under specified conditions of impact by means of a tup (falling weight). Three interchangeable striking noses are used on the tup, differing in geometrical configuration. Two specimen holders are described.

1.2 The values stated in inch-pound units are to be regarded as the standard. The values in parentheses are provided for information purposes only.

1.3 This standard does not purport to address all of the safety problems, if any, associated with its use. It is the responsibility of whoever uses this standard to consult and establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

An American National Standard

Designation: D 2444 – 99

Standard Test Method for

Determination of the Impact Resistance of Thermoplastic

Pipe and Fittings by Means of a Tup (Falling Weight)

This standard is issued under the fixed designation D 2444; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the Department of Defense.

1. Scope 3.2.1 As the basis for establishing impact test requirements

in product standards,

1.1 This test method covers the determination of the impact

3.2.2 To measure the effect of changes in materials or

resistance of thermoplastic pipe and fittings under specified

processing, and

conditions of impact by means of a tup (falling weight). Three

3.2.3 To measure the effect of the environment.

interchangeable striking noses are used on the tup, differing in

geometrical configuration. Two specimen holders are de-

4. Apparatus

scribed.

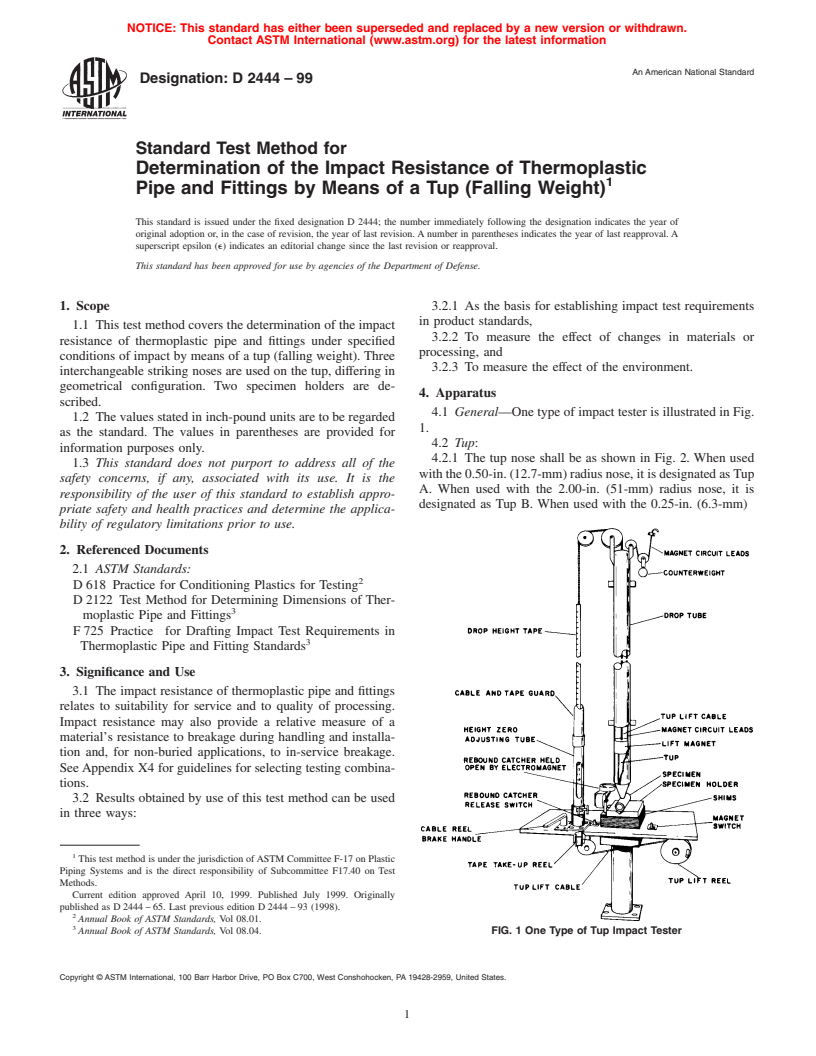

4.1 General—One type of impact tester is illustrated in Fig.

1.2 The values stated in inch-pound units are to be regarded

1.

as the standard. The values in parentheses are provided for

4.2 Tup:

information purposes only.

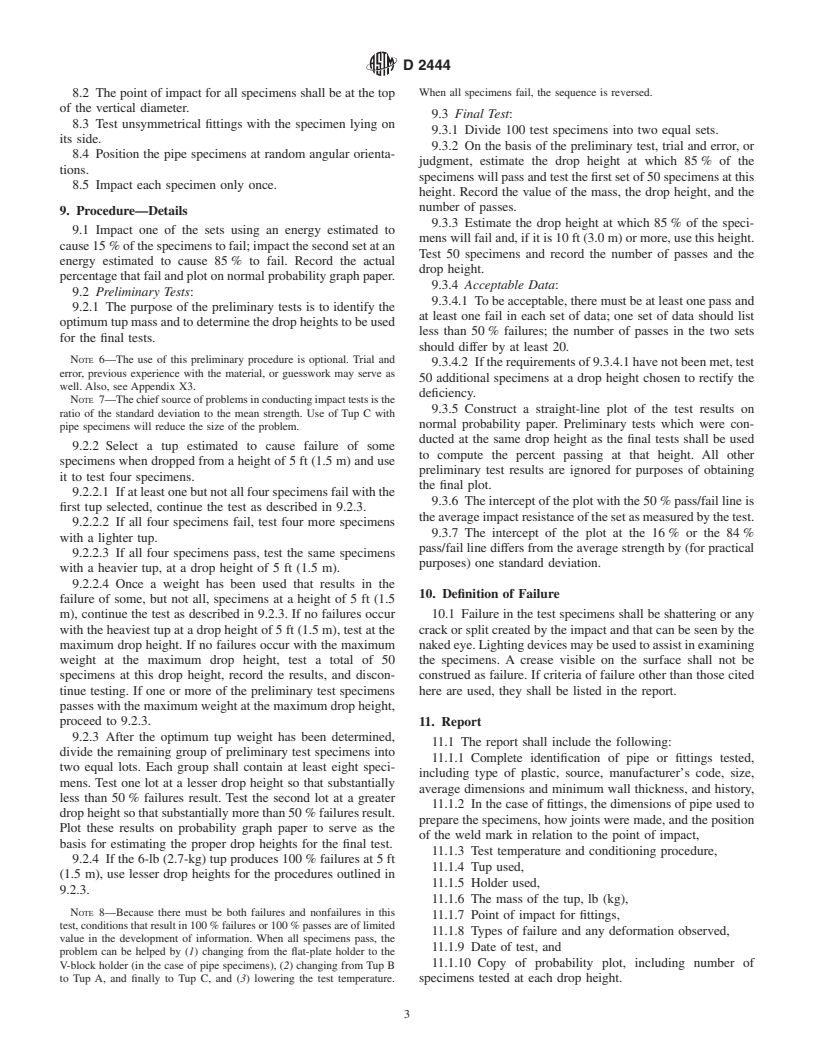

4.2.1 The tup nose shall be as shown in Fig. 2. When used

1.3 This standard does not purport to address all of the

with the 0.50-in. (12.7-mm) radius nose, it is designated asTup

safety concerns, if any, associated with its use. It is the

A. When used with the 2.00-in. (51-mm) radius nose, it is

responsibility of the user of this standard to establish appro-

designated as Tup B. When used with the 0.25-in. (6.3-mm)

priate safety and health practices and determine the applica-

bility of regulatory limitations prior to use.

2. Referenced Documents

2.1 ASTM Standards:

D 618 Practice for Conditioning Plastics for Testing

D 2122 Test Method for Determining Dimensions of Ther-

moplastic Pipe and Fittings

F 725 Practice for Drafting Impact Test Requirements in

Thermoplastic Pipe and Fitting Standards

3. Significance and Use

3.1 The impact resistance of thermoplastic pipe and fittings

relates to suitability for service and to quality of processing.

Impact resistance may also provide a relative measure of a

material’s resistance to breakage during handling and installa-

tion and, for non-buried applications, to in-service breakage.

SeeAppendix X4 for guidelines for selecting testing combina-

tions.

3.2 Results obtained by use of this test method can be used

in three ways:

This test method is under the jurisdiction ofASTM Committee F-17 on Plastic

Piping Systems and is the direct responsibility of Subcommittee F17.40 on Test

Methods.

Current edition approved April 10, 1999. Published July 1999. Originally

published as D 2444 – 65. Last previous edition D 2444 – 93 (1998).

Annual Book of ASTM Standards, Vol 08.01.

Annual Book of ASTM Standards, Vol 08.04. FIG. 1 One Type of Tup Impact Tester

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

D 2444

4.3.3 Means shall be provided (1) to hold the tup at steps of

2 in. (50.8 mm) for a distance of 2 to 10 ft (610 mm to 3.0 m)

above the specimen holder, (2) to release the tup in a

reproducible manner, (3) to allow the tup to fall freely, and (4)

to catch the tup on the first rebound. Refer to Fig. 1.

4.4 Specimen Holder—Two specimen holders are de-

scribed. The V-block (Holder A) is usually used with Tups A

and C; the flat plate (Holder B) is often used with Tup B or for

testing fittings.

4.4.1 The V-block holder shall be at least as long as the

specimen being tested and shall have a 90-deg included angle.

It may be fabricated or of solid construction. The side supports

shallbeofsufficientdepthtosupportthespecimenintheVand

not on the top edges of the V-block.

NOTE 5—Both aluminum and steel have been found suitable for the

holders.

4.4.2 The flat-plate holder shall consist of a plate approxi-

mately 8 by 12 by 1 in. (203 by 305 by 25.4 mm) in which a

groove to position the pipe specimen shall be cut. This groove

shall be about 0.12 in. (3 mm) in depth with the edges rounded

to a radius of about 0.06 in. (1.5 mm). Fittings that do not

contact the plate directly under the point of impact shall be

supported at this point by a flat steel plate or shim. The

specimen holder shall be mounted on a rigid base fastened to

a concrete slab. Means shall be provided to center the speci-

mens under the drop tube. A bar or rod placed inside the

specimen and retained by a light spring may be employed if

difficulty is encountered in holding the specimen in position.

NOTE 1—Dimensions are in inches (millimetres).

FIG. 2 Tup Nose Detail

5. Test Specimens

5.1 The pipe specimens shall be equal in length to the

radius nose, it is designated as Tup C.

nominal outside diameter but not less than 6 in. (152 mm) in

length. Burrs shall be removed.

NOTE 1—It is suggested that tups be made of scratch-resistant steel to

5.2 Fittings shall be tested either unassembled or assembled

reduce damage to the nose. Badly scarred noses may affect test results.

to pieces of pipe each 6 in. in length.

4.2.2 The mass of the tup shall be 6, 12, 20, or 30 lb (2.7,

5.4, 9.1, or 13.6 kg).

6. Number of Test Specimens

4.3 Drop Tube:

6.1 A minimum of 20 specimens are required for prelimi-

4.3.1 The drop tube shall be of sufficient length (approxi-

nary tests.

mately 12 ft (3.7 m)) to provide for a fall of at least 10 ft (3.0

6.2 A minimum of 100 specimens are required for final

m) and shall be mounted so that the lengthwise direction is

tests, and 50 additional specimens may be required.

vertical as measured with a plumb bob or a spirit level at least

2 ft (610 mm) in length.

7. Conditioning

4.3.2 Care must be taken to ensure that the tup falls freely;

7.1 Condition the test specimens at 40 h, 23°C, 50 % RH

it must not “chatter” down the tube.

and 50 6 5 % relative humidity for not less than 40 h prior to

NOTE 2—No material for the drop tube is specified. However, a

test in accordance with Procedure A of Practice D 618, for

colddrawn seamless steel tubing with an inside diameter of 2.563 6 0.003

those tests where conditioning is required.

in. (65.10 6 0.08 mm), or acrylonitrile-butadiene-styrene (ABS) or

7.2 TestConditions—Conduct the test in a room maintained

poly(vinyl chloride) (PVC) plastic pipe, 2 ⁄2 in. nominal pipe size, with a

at the test temperature or, if the test is made in an atmosphere

standard dimension ratio (SDR) of 21, have been found to be satisfactory.

or at a temperature other than that at which the specimens are

NOTE 3—Provided equivalent results are obtained, the tup may be

conditioned, conduct the test as soon as possible after removal

dropped without a drop tube or guided by other means. The drop tube is

used to reduce the hazard to operators and property that may occur when

from the conditioning atmosphere, but in any case within 15 s.

the tup rebounds. It also helps guide and center the tup so that it will be

Incaseofdisagreement,conductthetestsinaroommaintained

more likely to strike the top of the test specimen. It may also be necessary

at the test temperature.

to provide a protective barrier around the specimen, particularly for larger

sizesofpipeandfittings,toprotecttheoperatorfromflyingbrokenpieces.

8. Procedure—General

NOTE 4—The tup may not fall freely if the clearance between the tup

8.1 Measure the dimensions of the test specimens in accor-

and tube is too large or too small, or if it is restrained by a partial vacuum

above the tup, such as can be caused by the hold and release device. dance with Test Method D 2122.

D 2444

When all specimens fail, the sequence is reversed.

8.2 The point of impact for all specimens shall be at the top

of the vertical diameter.

9.3 Final Test:

8.3 Test unsymmetrical fittings with the specimen lying on

9.3.1 Divide 100 test specimens into two equal sets.

its side.

9.3.2 On the basis of the preliminary test, trial and error, or

8.4 Position the pipe specimens at random angular orienta-

judgment, estimate the drop height at which 85 % of the

tions.

specimens will pass and test the first set of 50 specimens at this

8.5 Impact each specimen only once.

height. Record the value of the mass, the drop height, and the

number of passes.

9. Procedure—Details

9.3.3 Estimate the drop height at which 85 % of the speci-

9.1 Impact one of the sets using an energy estimated to

mens will fail and, if it is 10 ft (3.0 m) or more, use this height.

cause15 %ofthespecimenstofail;impactthesecondsetatan

Test 50 specimens and record the number of passes and the

energy estimated to cause 85 % to fail. Record the actual

drop height.

percentage that fail and plot on normal probability graph paper.

9.3.4 Acceptable Data:

9.2 Preliminary Tests:

9.3.4.1 To be acceptable, there must be at least one pass and

9.2.1 The purpose of the preliminary tests is to identify the

at least one fail in each set of data; one set of data should list

optimum tup mass and to determine the drop heights to be used

less than 50 % failures; the number of passes in the two sets

for the final tests.

should differ by at least 20.

NOTE 6—The use of this preliminary procedure is optional. Trial and

9.3.4.2 If the requirements of 9.3.4.1 have not been met, test

error, previous experience with the material, or guesswork may serve as

50 additional specimens at a drop height chosen to rectify the

well. Also, see Appendix X3.

deficiency.

NOTE 7—The chief source of problems in conducting impact tests is the

9.3.5 Construct a straight-line plot of the test results on

ratio of the standard deviation to the mean strength. Use of Tup C with

normal probability paper. Preliminary tests which were con-

pipe specimens will reduce the size of the problem.

ducted at the same drop height as the final tests shall be used

9.2.2 Select a tup estimated to cause failure of some

to compute the percent passing at that height. All other

specimens when dropped from a height of 5 ft (1.5 m) and use

preliminary test results are ignored for purposes of obtaining

it to test four specimens.

the final plot.

9.2.2.1 If at least one but not all four specimens fail with the

9.3.6 The intercept of the plot with the 50 % pass/fail line is

first tup selected, continue the test as described in 9.2.3.

theaverageimpactresistanceofthesetasmeasuredbythetest.

9.2.2.2 If all four specimens fail, test four more specimens

9.3.7 The intercept of the plot at the 16 % or the 84 %

with a lighter tup.

pass/fail line differs from the average strength by (for practical

9.2.2.3 If all four specimens pass, test the same specimens

purposes) one standard deviation.

with a heavier tup, at a drop height of 5 ft (1.5 m).

9.2.2.4 Once a weight has been used that results in the

10. Definition of Failure

failure of some, but not all, specimens at a height of 5 ft (1.5

m), continue the test as described in 9.2.3. If no failures occur 10.1 Failure in the test specimens shall be shattering or any

with the heaviest tup at a drop height of 5 ft (1.5 m), test at the crack or split created by the impact and that can be seen by the

maximum drop height. If no failures occur with the maximum nakedeye.Lightingdevicesmaybeusedtoassistinexamining

weight at the maximum drop height, test a total of 50 the specimens. A crease visible on the surface shall not be

specimens at this drop height, record the results, and discon- construed as failure. If criteria of failure other than those cited

tinue testing. If one or more of the preliminary test specimens here are used, they shall be listed in the report.

passes with the maximum weight at the maximum drop height,

proceed to 9.2.3.

11. Report

9.2.3 After the optimum tup weight has been determined,

11.1 The report shall include the following:

divide the remaining group of preliminary test specimens into

11.1.1 Complete identification of pipe or fittings tested,

two equal lots. Each group shall contain at least eight speci-

including type of plastic, source, manufacturer’s code, size,

mens. Test one lot at a lesser drop height so that substantially

average dimensions and minimum wall thickness, and history,

less than 50 % failures result. Test the second lot at a greater

11.1.2 In the case of fittings, the dimensions of pipe used to

dropheightsothatsubstantiallymorethan50 %failuresresult.

prepare the specimens, how joints were made, and the position

Plot these results on probability graph paper to serve as the

of the weld mark in relation to the point of impact,

basis for estimating the proper drop heights for the final test.

11.1.3 Test temperature and conditioning procedure,

9.2.4 If the 6-lb (2.7-kg) tup produces 100 % failures at 5 ft

11.1.4 Tup used,

(1.5 m), use lesser drop heights for the procedures outlined in

11.1.5 Holder used,

9.2.3.

11.1.6 The mass of the tup, lb (kg),

NOTE 8—Because there must be both failures and nonfailures in this

11.1.7 Point of impact for fittings,

test, conditions that result in 100 % failures or 100 % passes are of limited

11.1.8 Types of failure and any deformation observed,

value in the development of information. When all specimens pass, the

11.1.9 Date of test, and

problem can be helped by (1) changing from the flat-plate holder to the

11.1.10 Copy of probability plot, including number of

V-block holder (in the case of pipe specimens), (2) changing from Tup B

to Tup A, and finally to Tup C, and (3) lowering the test temperature. specimens tested at each drop height.

D 2444

binomial tests is provided in Appendix X1.

12. Precision and Bias

12.1 This test method is neither precise nor accurate within

13. Keywords

the limits usually associated with those terms unless larger

numbers of test specimens are employed. Therefore, no state- 13.1 fittings; impact resistance; pipe; thermoplastic; tup

ment of bias can be made.

(falling weight)

NOTE 9—Abrief treatment of the subject of precision and accuracy for

APPENDIXES

(Nonmandatory Information)

X1. GUIDELINES FOR DETERMINING PRECISION AND ACCURACY BYAPPLYING BINOMIAL PROBABILITY

TECHNIQUES

X1.1 Tests that have only two possible results (pass or fail, estimate for p (true probability of success) is 0.64, and the

heads or tails, black or white) are governed by the rules of standard error equals:

probability.

0.64 ~1 2 0.64!

5 0.07 (X1.4)

Œ

X1.2 The most elementary application of the rules occurs

The confidence level is 68.27 % (note the similarity to plus

whenthetrueprobabilityofsuccessisknown.Whenafaircoin

and minus one sta

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.