ASTM D3800M-11

(Test Method)Standard Test Method for Density of High-Modulus Fibers

Standard Test Method for Density of High-Modulus Fibers

SIGNIFICANCE AND USE

Fiber density is useful in the evaluation of new materials at the research and development level and is one of the material properties normally given in fiber specifications.

Fiber density is used to determine fiber strength and modulus both of a fiber bundle and an individual filament. These properties are based on load or modulus slope over an effective area. Fiber density may be used with lineal mass of the fiber to give an approximation of effective tow area. Tow area divided by the average number of filaments in a tow gives an approximation of the effective area of an individual filament.

Fiber density is used as a constituent property when determining reinforcement volume and void volume based on reinforcement mass and laminate density.

SCOPE

1.1 This test method covers the determination of the density of high-modulus fibers and is applicable to both continuous and discontinuous fibers.

1.2 The values stated in SI units are to be regarded as standard. No other units of measurement are included in this standard.

1.3 This standard may involve hazardous materials, operations, and equipment. This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use. See Section 9 for additional information.

General Information

Relations

Buy Standard

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: D3800M − 11

StandardTest Method for

1

Density of High-Modulus Fibers

This standard is issued under the fixed designation D3800M; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the U.S. Department of Defense.

1. Scope E177 Practice for Use of the Terms Precision and Bias in

ASTM Test Methods

1.1 This test method covers the determination of the density

ofhigh-modulusfibersandisapplicabletobothcontinuousand

3. Terminology

discontinuous fibers.

3.1 Definitions—Terminology D3878 defines terms relating

1.2 The values stated in SI units are to be regarded as

tocompositematerials.TerminologyE12definestermsrelating

standard. No other units of measurement are included in this

to density. Practice E177 defines terms relating to statistics. In

standard.

theeventofaconflictbetweenterms,TerminologyD3878shall

1.3 This standard may involve hazardous materials,

have precedence over other standards.

operations, and equipment. This standard does not purport to

3.2 Symbols:

address all of the safety concerns, if any, associated with its

3.2.1 ρ —density of standard

use. It is the responsibility of the user of this standard to s

establish appropriate safety and health practices and deter-

3.2.2 ρ—density of liquid

l

mine the applicability of regulatory limitations prior to use.

3.2.3 ρ—density of fiber

f

See Section 9 for additional information.

3.2.4 ρ —density of the measured fiber containing sizing

mf

3.2.5 ρ —density of the measured liquid containing surfac-

2. Referenced Documents

ml

tant

2

2.1 ASTM Standards:

3.2.6 ρ —density of surfactant

D891 TestMethodsforSpecificGravity,Apparent,ofLiquid sur

Industrial Chemicals

3.2.7 ρ —density of sizing

sz

D1505 Test Method for Density of Plastics by the Density-

3.2.8 ρ —density of water

w

Gradient Technique

3.2.9 s—standard deviation

D3878 Terminology for Composite Materials

3.2.10 M —weight of suspension wire in air

D5229/D5229M Test Method for MoistureAbsorption Prop-

1

erties and Equilibrium Conditioning of Polymer Matrix

3.2.11 M —weight of suspension wire in liquid (to immer-

2

Composite Materials

sion point)

D6308 Guide for Identification of Composite Materials in

3.2.12 M —weight of suspension wire plus item whose

3

Computerized Material Property Databases (Withdrawn

density is to be determined (in air)

3

1999)

3.2.13 M —weight of suspension wire plus item whose

4

E12 Terminology Relating to Density and Specific Gravity

3

density is to be determined (in liquid)

of Solids, Liquids, and Gases (Withdrawn 1996)

3.2.14 M –M —weight of item for density to be deter-

3 1

mined in air

1

This test method is under the jurisdiction of ASTM Committee D30 on

3.2.15 M –M —weight of item for density to be deter-

4 2

Composite Materials and is the direct responsibility of Subcommittee D30.03 on

mined in liquid

Constituent/Precursor Properties.

Current edition approved Aug. 1, 2011. Published September 2011. Originally

approved in 1979. Last previous edition approved in 2010 as D3800 – 99 (2010).

4. Summary of Test Method

DOI: 10.1520/D3800M-11.

2

4.1 Procedure A—Buoyancy (Archimedes) Method:

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

4.1.1 The sample is weighed in air and weighed in a liquid

Standards volume information, refer to the standard’s Document Summary page on

that will thoroughly wet the sample and is of a lower density.

the ASTM website.

3

4.1.2 The difference in weight of the sample in the two

The last approved version of this historical standard is referenced on

www.astm.org. media is the buoyancy force. This force is converted to sample

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

D3800M − 11

volume by dividing it by the liquid density. The sample weight 6.1.5 Effect of Surfactant Density—The addition of a sur-

in air divided by the sample volume equals the sample density. factant to a liquid may produce bias if not considered. The

effect may be shown by the following equation:

4.2 Procedure B—Sink-Float Technique:

100 2 x ρ 1x ρ

~ ! ~ !

4.2.1 The sample is placed in a container containing a liquid l sur

ρ 5 (2)

ml

100

that will thoroughly wet the sample and is of a lower density.

A liquid of higher density than the sample and miscible with

where

the first liquid is then added slowly to the container under

x = mass of surfactant as a percentage of total mass of the

constant gentle m

...

This document is not an ASTM standard and is intended only to provide the user of an ASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

Designation:D3800–99 (Reapproved 2010) Designation: D3800M – 11

Standard Test Method for

1

Density of High-Modulus Fibers

This standard is issued under the fixed designation D3800M; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the Department of Defense.

1. Scope

1.1 This test method covers the determination of the density of high-modulus fibers and is applicable to both continuous and

discontinuous fibers.

1.2The values stated in SI units are to be regarded as standard.

1.2 The values stated in SI units are to be regarded as standard. No other units of measurement are included in this standard.

1.3 This standard may involve hazardous materials, operations, and equipment. This standard does not purport to address all

of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate

safety and health practices and determine the applicability of regulatory limitations prior to use. See Section 9 for additional

information.

2. Referenced Documents

2

2.1 ASTM Standards:

D891 Test Methods for Specific Gravity, Apparent, of Liquid Industrial Chemicals

D1505 Test Method for Density of Plastics by the Density-Gradient Technique

D3878 Terminology for Composite Materials

D5229/D5229M Test Method for MoistureAbsorption Properties and Equilibrium Conditioning of Polymer Matrix Composite

Materials

D6308 Guide for Identification of Composite Materials in Computerized Material Property Databases

E12 Terminology Relating to Density and Specific Gravity of Solids, Liquids, and Gases

E177 Practice for Use of the Terms Precision and Bias in ASTM Test Methods

3. Terminology

3.1 Definitions—Terminology D3878 defines terms relating to composite materials. Terminology E12 defines terms relating to

density. Practice E177 defines terms relating to statistics. In the event of a conflict between terms, Terminology D3878 shall have

precedence over other standards.

3.2 Symbols: rs

r = density of standard

s

r = density of liquid

l

r = density of fiber

f

r = density of the measured fiber containing sizing

mf

r = density of the measured liquid containing surfactant

ml

r = density of surfactant

sur

r = density of sizing

sz

r = density of water

w

s = standard deviation

M = weight of suspension wire in air

1

M = weight of suspension wire in liquid (to immersion point)

2

1

This test method is under the jurisdiction of ASTM Committee D30 on Composite Materials and is the direct responsibility of Subcommittee D30.03 on

Constituent/Precursor Properties.

Current edition approved AprilAug. 1, 2010.2011. Published May 2010.September 2011. Originally approved in 1979. Last previous edition approved in 20042010 as

D3800 – 99 (2004).(2010). DOI: 10.1520/D3800-99R10.10.1520/D3800M-11.

2

For referencedASTM standards, visit theASTM website, www.astm.org, or contactASTM Customer Service at service@astm.org. For Annual Book of ASTM Standards

volume information, refer to the standard’s Document Summary page on the ASTM website.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

1

---------------------- Page: 1 ----------------------

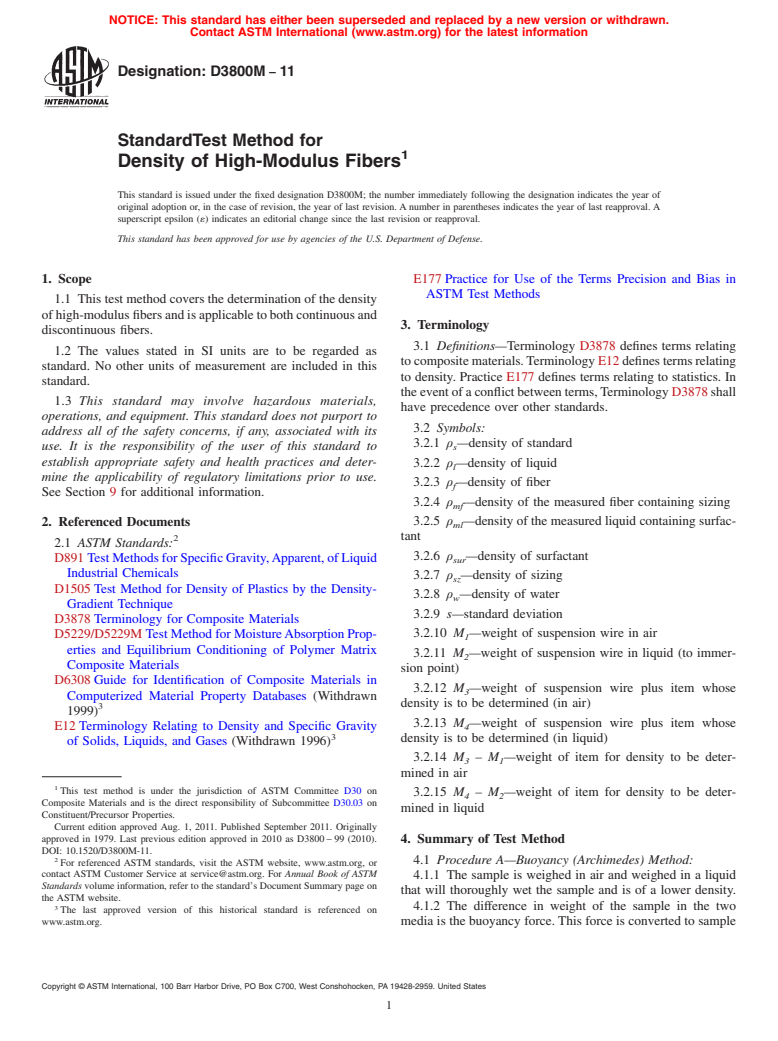

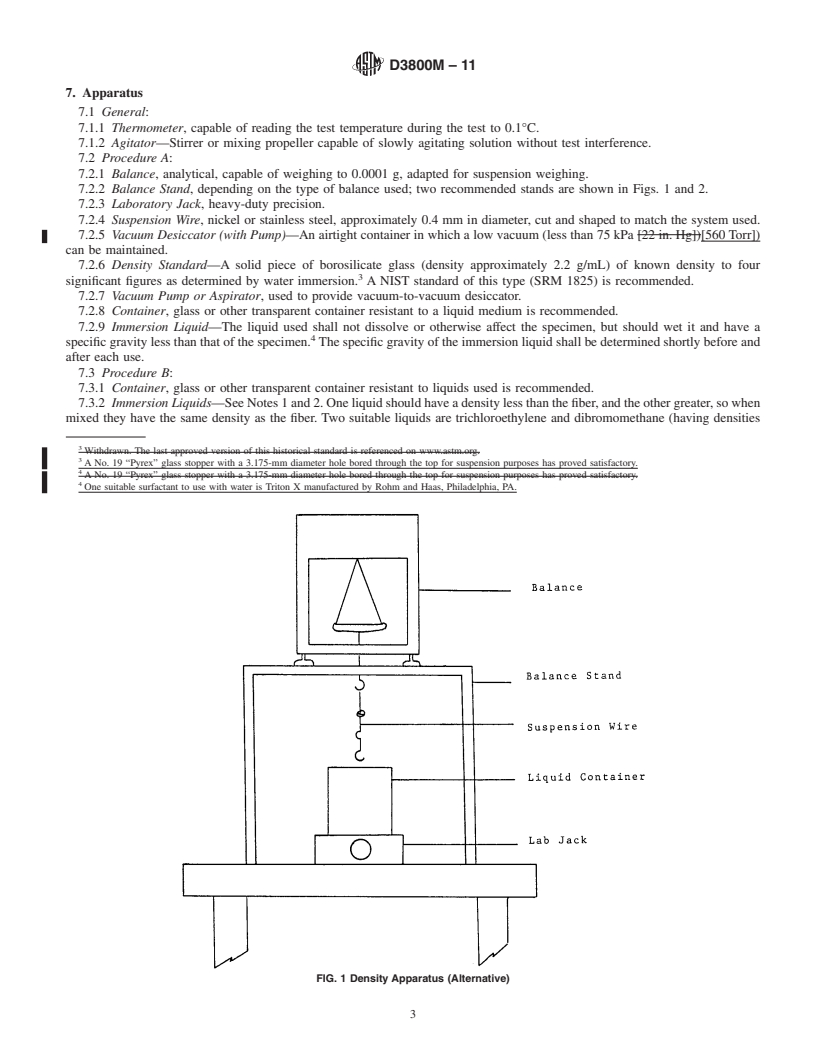

D3800M – 11

M = weight of suspension wire plus item whose density is to be determined (in air)

3

M = weight of suspension wire plus item whose density is to be determined (in liquid)

4

M weight weight —weight of item for density to be determined in liquid

3.2.1—weightr—density of standard

s

4.Summary of Test Method

3.2.2r—densityof of liquid

l

4.13.2.3Generalr—densityitem—Usingofrandomfiber selection techniques, a suitable size sample of high-modulus fiber can be tested by any of the three

f

procedures described in this test method. Procedure A using water with a surfactant as the liquid medium is preferred due to

3.2.4r —densityfor of the measured fiber containing sizing

mf

environmental3.2.5densityr —densityandsafetyof theconsiderations.measured liquidTheothercontainingmethodssurfactantshallnotbeusedifProcedureAisadequate.InterimuseofProcedures

ml

B or C is allowed while a comparison is made to results using Procedure A.

3.2.6r —densityto of surfactant

sur

3.2.7r —densitybe 4.2Profocedursizinge A—Buoyancy (Archimedes) Method:

sz

4.2.1The4.1.1The sample is weighed in

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.