ASTM D3535-07a(2013)

(Test Method)Standard Test Method for Resistance to Creep Under Static Loading for Structural Wood Laminating Adhesives Used Under Exterior Exposure Conditions

Standard Test Method for Resistance to Creep Under Static Loading for Structural Wood Laminating Adhesives Used Under Exterior Exposure Conditions

SIGNIFICANCE AND USE

5.1 This test method rates the performance of the adhesive in laminated wood as measured by resistance to creep under static load.

5.2 This test method will normally be used in conjunction with Specification D2559.

SCOPE

1.1 This test method covers adhesives suitable for the bonding of wood, including treated wood, into structural laminated wood products for general construction, for marine use, or for other uses where a high-strength general construction, creep-resistant, waterproof adhesive bond is required.

1.2 The values stated in SI units are to be regarded as the standard. The values given in parentheses are for information only.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: D3535 − 07a (Reapproved 2013)

Standard Test Method for

Resistance to Creep Under Static Loading for Structural

Wood Laminating Adhesives Used Under Exterior Exposure

1

Conditions

This standard is issued under the fixed designation D3535; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope assemblies of specially selected and prepared wood lamina-

tions securely bonded together with adhesives, with the fol-

1.1 This test method covers adhesives suitable for the

lowing characteristics: (1) the grain of all laminations is

bonding of wood, including treated wood, into structural

approximately parallel longitudinally; and (2) the laminations

laminated wood products for general construction, for marine

may be comprised of pieces end-joined to form any length, of

use, or for other uses where a high-strength general

pieces placed or glued edge-to-edge to make wider ones or of

construction, creep-resistant, waterproof adhesive bond is re-

pieces bent to curved form during gluing. (Synonym glulam)

quired.

ANSI/AITC A190.1 – 2002, American National Standard for

1.2 The values stated in SI units are to be regarded as the

Wood Products—Structural Glued Laminated Timber (Edited

standard. The values given in parentheses are for information

to conform with ASTM format).

only.

3.1.3 For other terms used in this test method, refer to

1.3 This standard does not purport to address all of the

Terminology D907.

safety concerns, if any, associated with its use. It is the

responsibility of the user of this standard to establish appro-

4. Summary of Test Method

priate safety and health practices and determine the applica-

4.1 Gluedlaminationsaresubjectedtoaconstantloadunder

bility of regulatory limitations prior to use.

various combinations of temperature and relative humidity.

The amount of creep is measured.

2. Referenced Documents

2

2.1 ASTM Standards:

5. Significance and Use

A125 Specification for Steel Springs, Helical, Heat-Treated

5.1 This test method rates the performance of the adhesive

D907 Terminology of Adhesives

in laminated wood as measured by resistance to creep under

D2559 Specification for Adhesives for Bonded Structural

static load.

Wood Products for Use Under Exterior Exposure Condi-

5.2 This test method will normally be used in conjunction

tions

with Specification D2559.

3. Terminology

6. Apparatus

3.1 Definitions:

3

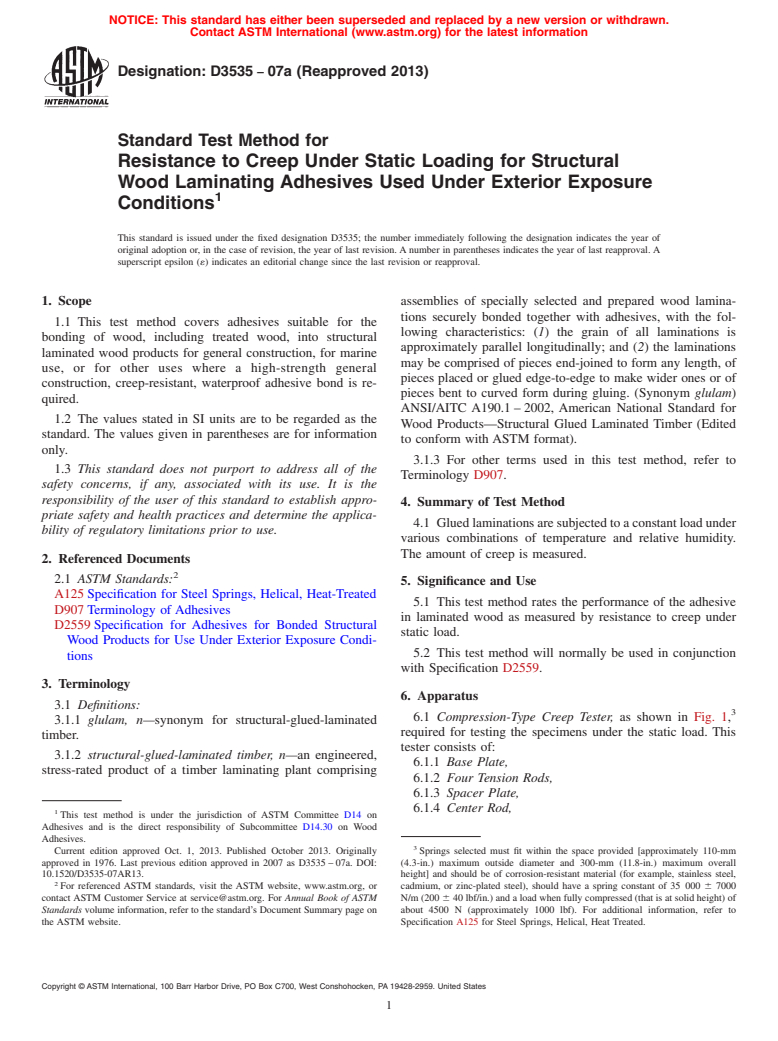

6.1 Compression-Type Creep Tester, as shown in Fig. 1,

3.1.1 glulam, n—synonym for structural-glued-laminated

required for testing the specimens under the static load. This

timber.

tester consists of:

3.1.2 structural-glued-laminated timber, n—an engineered,

6.1.1 Base Plate,

stress-rated product of a timber laminating plant comprising

6.1.2 Four Tension Rods,

6.1.3 Spacer Plate,

6.1.4 Center Rod,

1

This test method is under the jurisdiction of ASTM Committee D14 on

Adhesives and is the direct responsibility of Subcommittee D14.30 on Wood

Adhesives.

3

Current edition approved Oct. 1, 2013. Published October 2013. Originally Springs selected must fit within the space provided [approximately 110-mm

approved in 1976. Last previous edition approved in 2007 as D3535 – 07a. DOI: (4.3-in.) maximum outside diameter and 300-mm (11.8-in.) maximum overall

10.1520/D3535-07AR13. height] and should be of corrosion-resistant material (for example, stainless steel,

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or cadmium, or zinc-plated steel), should have a spring constant of 35 000 6 7000

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM N/m (200 6 40 lbf/in.) and a load when fully compressed (that is at solid height) of

Standards volume information, refer to the standard’s Document Summary page on about 4500 N (approximately 1000 lbf). For additional information, refer to

the ASTM website. Specification A125 for Steel Springs, Helical, Heat Treated.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

D3535 − 07a (2013)

Metric Equivalents

mm in. mm in.

1

3.18 ⁄8 127 5

3 1

4.77 ⁄16 139.7 5 ⁄2

3 3

9.53 ⁄8 148 5 ⁄4

7 1

11.1 ⁄16 165.1 6 ⁄2

5 1

15.9 ⁄8 267 10 ⁄2

3

19.1 ⁄4 304.8 12

1

25.4 1 311.1 12 ⁄4

1 1

38.1 1 ⁄2 336.5 13 ⁄4

1 3

54.0 2 ⁄8 415 16 ⁄8

3

60.3 2 ⁄8 660.4 26

1

63.5 2 ⁄2

3

FIG. 1 Compression-Type Creep Tester

2

---------------------- Page: 2 ----------------------

D3535 − 07a (2013)

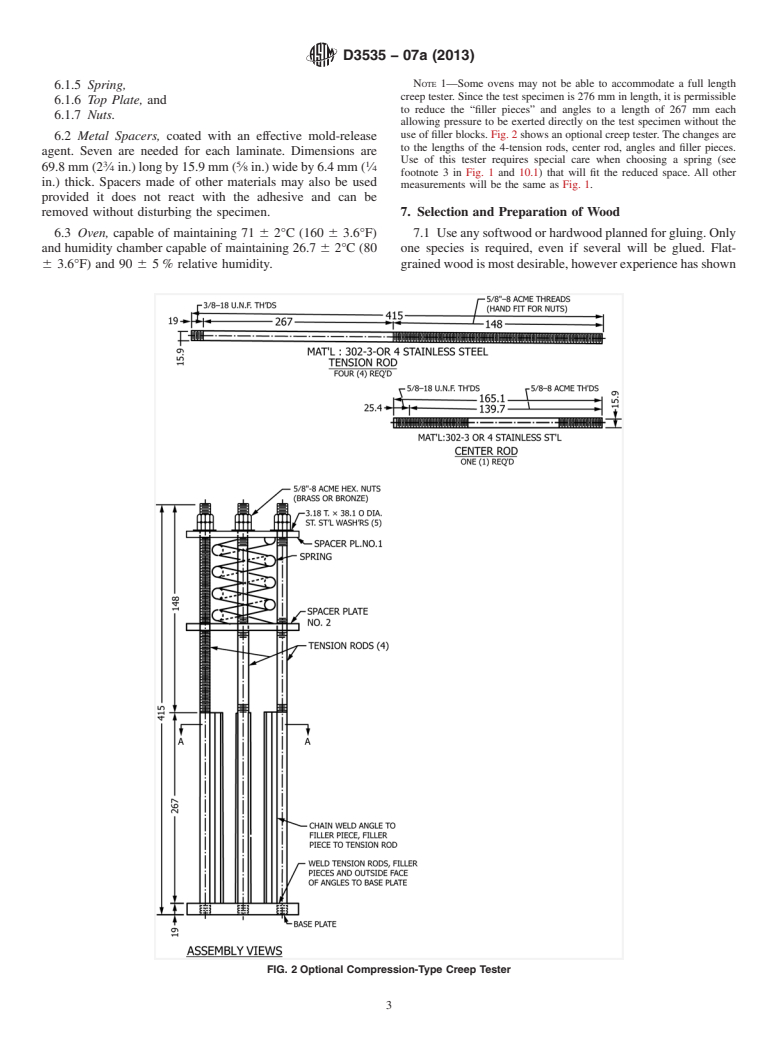

NOTE 1—Some ovens may not be able to accommodate a full length

6.1.5 Spring,

creep tester. Since the test specimen is 276 mm in len

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.