ASTM D6646-03(2022)

(Test Method)Standard Test Method for Determination of the Accelerated Hydrogen Sulfide Breakthrough Capacity of Granular and Pelletized Activated Carbon

Standard Test Method for Determination of the Accelerated Hydrogen Sulfide Breakthrough Capacity of Granular and Pelletized Activated Carbon

SIGNIFICANCE AND USE

5.1 This method compares the performance of granular or pelletized activated carbons used in odor control applications, such as sewage treatment plants, pump stations, etc. The method determines the relative breakthrough performance of activated carbon for removing hydrogen sulfide from a humidified gas stream. Other organic contaminants present in field operations may affect the H2S breakthrough capacity of the carbon; these are not addressed by this test. This test does not simulate actual conditions encountered in an odor control application, and is therefore meant only to compare the hydrogen sulfide breakthrough capacities of different carbons under the conditions of the laboratory test.

5.2 This test does not duplicate conditions that an adsorber would encounter in practical service. The mass transfer zone in the 23 cm column used in this test is proportionally much larger than that in the typical bed used in industrial applications. This difference favors a carbon that functions more rapidly for removal of H2S over a carbon with slower kinetics. Also, the 1 % H2S challenge gas concentration used here engenders a significant temperature rise in the carbon bed. This effect may also differentiate between carbons in a way that is not reflected in the conditions of practical service.

5.3 This standard as written is applicable only to granular and pelletized activated carbons with mean particle diameters less than 2.5 mm. Application of this standard to activated carbons with mean particle diameters (MPD) greater than 2.5 mm will require a larger diameter adsorption column. The ratio of column inside diameter to MPD should be greater than 10 in order to avoid wall effects. In these cases it is suggested that bed superficial velocity and contact time be held invariant at the conditions specified in this standard (4.77 cm/s and 4.8 s). Although not covered by this standard, data obtained from these tests may be reported as in paragraph 12 along with additional ...

SCOPE

1.1 This test method is intended to evaluate the performance of virgin, newly impregnated or in-service, granular or pelletized activated carbon for the removal of hydrogen sulfide from an air stream, under the laboratory test conditions described herein. A humidified air stream containing 1 % (by volume) hydrogen sulfide is passed through a carbon bed until 50 ppm breakthrough of H2S is observed. The H2S adsorption capacity of the carbon per unit volume at 99.5 % removal efficiency (g H2S/cm3 carbon) is then calculated. This test is not necessarily applicable to non-carbon adsorptive materials.

1.2 This standard as written is applicable only to granular and pelletized activated carbons with mean particle diameters (MPD) less than 2.5 mm. See paragraph 5.3 if activated carbons with larger MPDs are to be tested.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety, health, and environmental practices and determine the applicability of regulatory limitations prior to use.

1.4 This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

General Information

Relations

Standards Content (Sample)

This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the

Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

Designation:D6646 −03 (Reapproved 2022)

Standard Test Method for

Determination of the Accelerated Hydrogen Sulfide

Breakthrough Capacity of Granular and Pelletized Activated

Carbon

This standard is issued under the fixed designation D6646; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope D2854Test Method for Apparent Density of Activated

Carbon

1.1 Thistestmethodisintendedtoevaluatetheperformance

D2867Test Methods for Moisture in Activated Carbon

of virgin, newly impregnated or in-service, granular or pellet-

E300Practice for Sampling Industrial Chemicals

ized activated carbon for the removal of hydrogen sulfide from

an air stream, under the laboratory test conditions described

3. Terminology

herein. A humidified air stream containing 1% (by volume)

3.1 Terms relating to this standard are defined in D2652.

hydrogen sulfide is passed through a carbon bed until 50 ppm

breakthrough of H S is observed.The H S adsorption capacity

2 2 4. Summary of Test Method

of the carbon per unit volume at 99.5% removal efficiency (g

4.1 Breakthrough capacity is determined by passing a

H S/cm carbon) is then calculated.This test is not necessarily

stream of humidified air containing 1 volume% hydrogen

applicable to non-carbon adsorptive materials.

sulfide through a sample of granular or pelletized activated

1.2 This standard as written is applicable only to granular

carbon of known volume under specified conditions until the

and pelletized activated carbons with mean particle diameters

concentrationofhydrogensulfideintheeffluentgasreaches50

(MPD) less than 2.5 mm. See paragraph 5.3 if activated

ppmv.

carbons with larger MPDs are to be tested.

5. Significance and Use

1.3 This standard does not purport to address all of the

5.1 This method compares the performance of granular or

safety concerns, if any, associated with its use. It is the

pelletized activated carbons used in odor control applications,

responsibility of the user of this standard to establish appro-

such as sewage treatment plants, pump stations, etc. The

priate safety, health, and environmental practices and deter-

method determines the relative breakthrough performance of

mine the applicability of regulatory limitations prior to use.

activatedcarbonforremovinghydrogensulfidefromahumidi-

1.4 This international standard was developed in accor-

fied gas stream. Other organic contaminants present in field

dance with internationally recognized principles on standard-

operations may affect the H S breakthrough capacity of the

ization established in the Decision on Principles for the

carbon; these are not addressed by this test. This test does not

Development of International Standards, Guides and Recom-

simulate actual conditions encountered in an odor control

mendations issued by the World Trade Organization Technical

application, and is therefore meant only to compare the

Barriers to Trade (TBT) Committee.

hydrogen sulfide breakthrough capacities of different carbons

under the conditions of the laboratory test.

2. Referenced Documents

5.2 This test does not duplicate conditions that an adsorber

2.1 ASTM Standards:

D2652Terminology Relating to Activated Carbon wouldencounterinpracticalservice.Themasstransferzonein

the 23 cm column used in this test is proportionally much

larger than that in the typical bed used in industrial applica-

tions. This difference favors a carbon that functions more

This test method is under the jurisdiction of ASTM Committee D28 on

rapidly for removal of H S over a carbon with slower kinetics.

Activated Carbon and is the direct responsibility of Subcommittee D28.04 on Gas

Phase Evaluation Tests.

Also, the 1% H S challenge gas concentration used here

Current edition approved Sept. 1, 2022. Published October 2022. Originally

engendersasignificanttemperatureriseinthecarbonbed.This

approved in 2001. Last previous edition approved in 2014 as D6646– 03 (2014).

effect may also differentiate between carbons in a way that is

DOI: 10.1520/D6646-03R22.

For referenced ASTM standards, visit the ASTM website, www.astm.org, or not reflected in the conditions of practical service.

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

5.3 This standard as written is applicable only to granular

Standards volume information, refer to the standard’s Document Summary page on

the ASTM website. and pelletized activated carbons with mean particle diameters

Copyright ©ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA19428-2959. United States

D6646−03 (2022)

less than 2.5 mm. Application of this standard to activated

carbons with mean particle diameters (MPD) greater than 2.5

mmwillrequirealargerdiameteradsorptioncolumn.Theratio

ofcolumninsidediametertoMPDshouldbegreaterthan10in

order to avoid wall effects. In these cases it is suggested that

bed superficial velocity and contact time be held invariant at

the conditions specified in this standard (4.77 cm/s and 4.8 s).

Although not covered by this standard, data obtained from

these tests may be reported as in paragraph 12 along with

additional information about column diameter, volume of

carbon, and volumetric flow rate used.

5.4 For pelletized carbons, it is felt that the equivalent

spherical diameter of the pellet is the most suitable parameter

for determining the appropriate adsorption column inside

diameter. The equivalent spherical diameter is calculated

according to the following equation.

3XdXh

D 5 (1)

eqv

d12Xh

where:

d = the diameter, and

h = the length of the pellet in mm.

An average of 50 to 100 measurements is recommended to

determinetheaveragelengthofapellet.AnnexA3isatableto

guide the user in selecting bed diameter and flow rates from

typical equivalent diameters (or MPD) of pelletized carbon.

6. Apparatus and Materials

6.1 (561) % Hydrogen Sulfide in Nitrogen Mixture—The

concentration of hydrogen sulfide in the gas test mixture must

be known. It is recommended that gas cylinders specifically

manufactured for holding hydrogen sulfide gas be used. Ana-

lyzed and certified hydrogen sulfide in nitrogen gas mixtures

can be purchased from specialty gas suppliers. Annex A1 and

Annex A2 present methods that may be used to check the

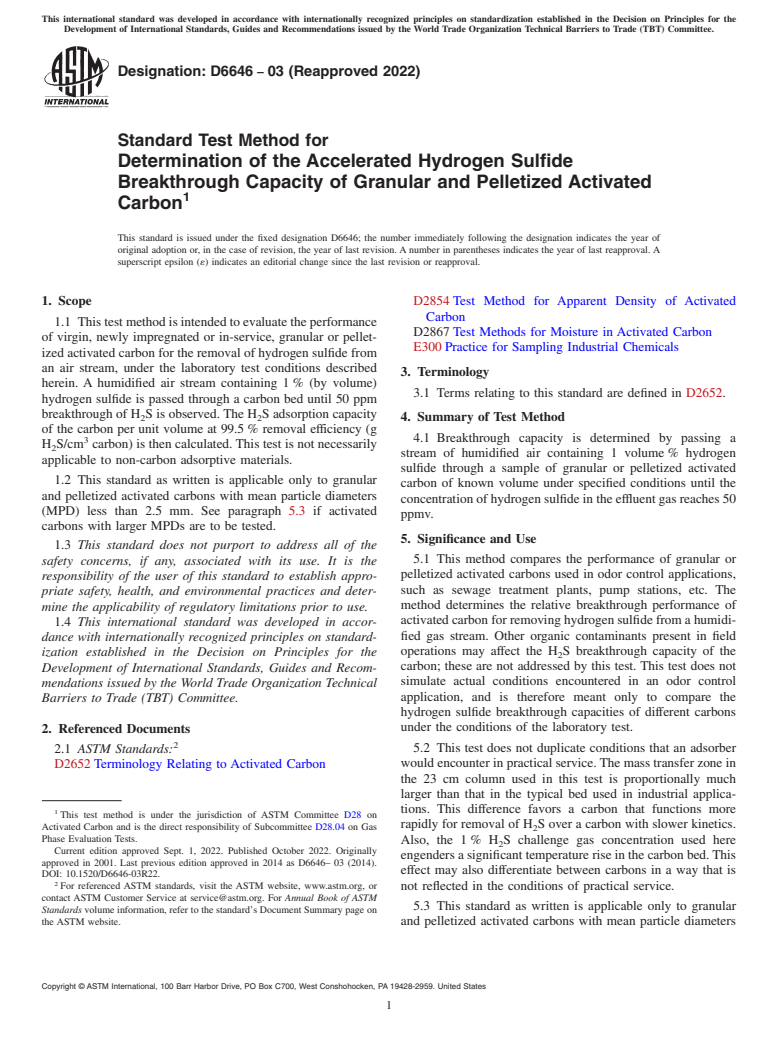

FIG. 1Schematic of Adsorption Tube

hydrogen sulfide concentration of hydrogen sulfide/nitrogen

gas mixtures. It is recommended that the hydrogen sulfide

concentration be checked if gas cylinders are stored for more

than three months, particularly after being partially depleted.

6.4 Flowmeter (0-500 mL/min Nitrogen; see Annex A3 for

Other organic contaminants that may be present in the hydro-

Guide to Higher Flow Range for Particles > 2.5 mm MPD)—

gensulfidetankcanaffecttheadsorptioncapacityofthecarbon

For hydrogen sulfide/N control, it is recommended that the

being tested.

wettable parts of this flow meter be made of PTFE or other

corrosion resistant material. Rotameter floats should be made

6.2 Hydrogen Sulfide Detector—The hydrogen sulfide de-

from non-metallic materials such as glass or sapphire.

tector used in this test must be demonstrated to reliably detect

50ppmhydrogensulfideinahumidifiedairstream.Inaddition 6.5 Flowmeter (0-2000 mL/minAir; see AnnexA3 for Guide

to certain “solid state” detectors, electrochemical type hydro-

to Higher Flow Range for Particles > 2.5 mm MPD)—

gen sulfide sensors, for example, Ecolyzer Model 6400 or

NOTE 1—Mass flow controllers have been found to be more reliable

Interscan LD-17, have been evaluated and fit this requirement.

than flowmeters and are highly recommended due to their ability to

Other means of hydrogen sulfide detection may be selected, as

automatically maintain precise gas flow rates. Rotameters are satisfactory

long as they are carefully calibrated and evaluated for this for this method, but may require more frequent attention in maintaining

proper test gas flows for the duration of the test.

application.

6.6 Two Stage Cylinder Regulator, Suitable for Corrosive

6.3 Adsorption Tube—The adsorption tube is shown in Fig.

Gas Service, for Hydrogen Sulfide Gas Cylinder.

1. Adsorption tubes are not commercially available; however,

they can be custom fabricated by a scientific glassblower. The 6.7 Air Line Pressure Regulator—Low Pressure—To main-

perforated support shown is necessary to support the carbon tainupto10psigpressureforupto2litersofair/minflowrate

bed and to enhance diffusion of the gases. (Adjust dimensions (see AnnexA3 for guide to airflow for tubes used for particles

accordingly from Annex A3, specifically diameter.) >2.5 mm MPD)

D6646−03 (2022)

6.8 Two Metering Valves—Suitable valves are the Whitey 6.14 Powder Funnel.

SS-21-RS4 (H S/N ) and B-21-RS4 (air). Other similar valves

2 2

6.15 Temperature Controlled Water Bath, to maintain the

maybeused.Iftherotametersin6.4and6.5areequippedwith

water bubbler at 25°C 6 2°C.

their own high quality metering valves, these valves are not

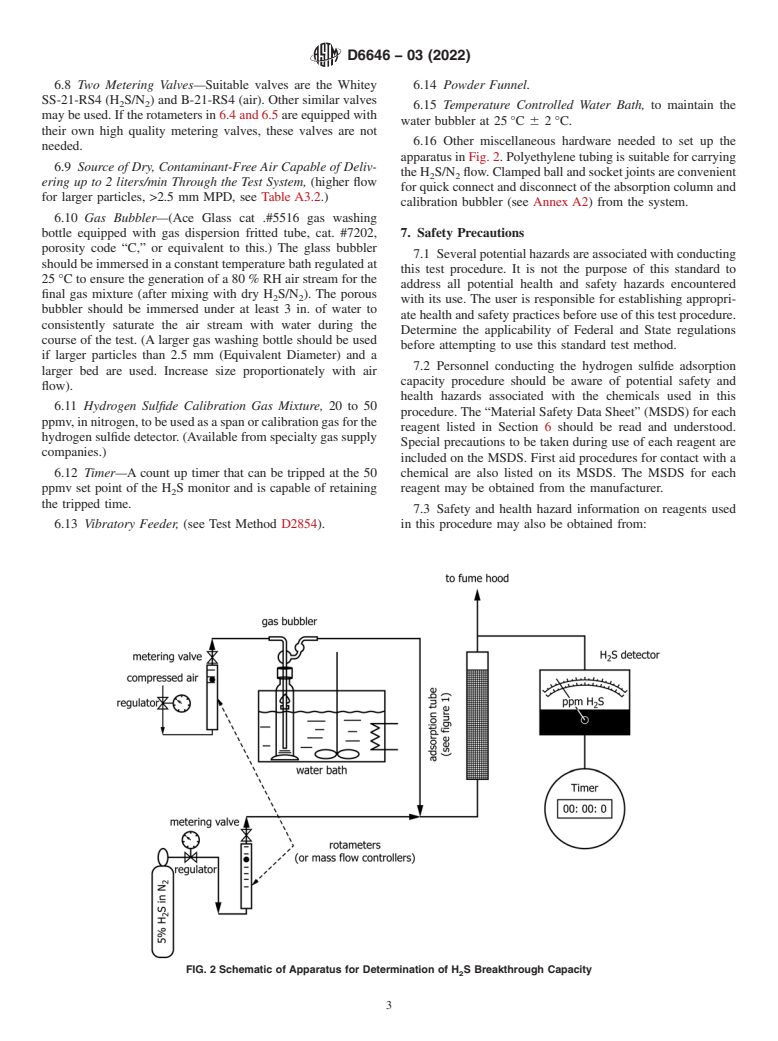

6.16 Other miscellaneous hardware needed to set up the

needed.

apparatusinFig.2.Polyethylenetubingissuitableforcarrying

6.9 Source of Dry, Contaminant-Free Air Capable of Deliv-

theH S/N flow.Clampedballandsocketjointsareconvenient

2 2

ering up to 2 liters/min Through the Test System, (higher flow

forquickconnectanddisconnectoftheabsorptioncolumnand

for larger particles, >2.5 mm MPD, see Table A3.2.)

calibration bubbler (see Annex A2) from the system.

6.10 Gas Bubbler—(Ace Glass cat .#5516 gas washing

bottle equipped with gas dispersion fritted tube, cat. #7202, 7. Safety Precautions

porosity code “C,” or equivalent to this.) The glass bubbler

7.1 Severalpotentialhazardsareassociatedwithconducting

shouldbeimmersedinaconstanttemperaturebathregulatedat

this test procedure. It is not the purpose of this standard to

25°C to ensure the generation of a 80% RH air stream for the

address all potential health and safety hazards encountered

final gas mixture (after mixing with dry H S/N ). The porous

2 2

with its use. The user is responsible for establishing appropri-

bubbler should be immersed under at least 3 in. of water to

atehealthandsafetypracticesbeforeuseofthistestprocedure.

consistently saturate the air stream with water during the

Determine the applicability of Federal and State regulations

course of the test. (Alarger gas washing bottle should be used

before attempting to use this standard test method.

if larger particles than 2.5 mm (Equivalent Diameter) and a

7.2 Personnel conducting the hydrogen sulfide adsorption

larger bed are used. Increase size proportionately with air

capacity procedure should be aware of potential safety and

flow).

health hazards associated with the chemicals used in this

6.11 Hydrogen Sulfide Calibration Gas Mixture, 20 to 50

procedure.The “Material Safety Data Sheet” (MSDS) for each

ppmv,innitrogen,tobeusedasaspanorcalibrationgasforthe

reagent listed in Section 6 should be read and understood.

hydrogensulfidedetector.(Availablefromspecialtygassupply

Special precautions to be taken during use of each reagent are

companies.)

included on the MSDS. First aid procedures for contact with a

6.12 Timer—A count up timer that can be tripped at the 50 chemical are also listed on its MSDS. The MSDS for each

ppmv set point of the H S monitor and is capable of retaining reagent may be obtained from the manufacturer.

the tripped time.

7.3 Safety and health hazard information on reagents used

6.13 Vibratory Feeder, (see Test Method D2854). in this procedure may also be obtained from:

FIG. 2Schematic of Apparatus for Determination of H S Breakthrough Capacity

D6646−03 (2022)

7.3.1 Sax’s Dangerous Properties of Industrial Materials / determine the volume of water required to fill the adsorption

Richard J. Lewis, Sr., New York : J. Wiley, 2000. tube from the top of the carbon support to approximately the

7.3.2 NIOSH/OSHA Pocket Guide to Chemical Hazards, 22.9 cm mark.)

1997, U.S. Department of Labor, Occupational Safety and

10.8 Tare a clean, dry adsorption tube to the nearest 0.1 g.

Health Administration, Washington, D.C. Available from U.S.

Note and record.

Government Printing Office, Washington, D.C. or at http://

10.9 Fill the adsorption tube with 116 mL of carbon [bed

www.cdc.gov/niosh/npg/npg.html.

depthofapproximately22.9cm]usingavibratoryfeeder.(The

apparatus described in Test Method D2854, or equivalent is

8. Sampling

suitable for filling the adsorption tube.)The vibratory feeder is

8.1 Guidanceinsamplinggranularactivatedcarbonisgiven

to be adjusted so the adsorption tube is filled at a rate not less

in recommended Practice E300.

than 0.75mL⁄s or exceeding 1.0 mL/s. (See Annex A3 for

guide to larger volume if larger than 2.5 mm (Equivalent

9. Calibration

Diameter) particles are tested.)

9.1 Calibration of flowmeters, mass flow controllers, and

10.10 Weighthefilledadsorptiontubetothenearest0.1gm.

hydrogen sulfide detectors shall be performed by standard

Note and record.

laboratory methods.

10.11 Carefully transfer the filled adsorption tube to the test

NOTE 2—The test apparatus (Fig. 1) has metering valves at the

system and connect it to the test apparatus.

rotameter outlets. This is done to minimize changes in gas flow rates

caused by small backpressure changes during this long duration test.

NOTE 3—If a sample of non-impregnated, low moisture, virgin carbon

However, placement of metering valves in this position invalidates the

is being evaluated for adsorption capacity, it is advised that it be

atmospheric pressure calibration usually supplied by the rotameter manu-

conditioned for several hours with only humidified air passing through it

facturer. The apparatus in A2.4.2 may be used to calibrate the rotameters.

to equilibrate the moisture content of the carbon with the moisture in the

During this calibration, the gas delivery pressure must be the same as that

airstream.Themoisturecontentofthecarbonwillaffectthebreakthrough

used during the actual test.

capacity

9.2 Determine the percent H S in the H S/nitrogen tank

2 2

Start the H S/air flow and simultaneously start the timer.

using the methods outlined in Annex A1 or Annex A2 if the

10.12 Continue the H S/air flow until a breakthrough of 50

H S/nitrogen tank was not certified by the manufacturer.

ppmv is indicated. Record the time elapsed from the start of

H S/air flow to 50 ppm breakthrough.

10. Procedure 2

10.1 Assemble the test app

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.