ASTM B823-20

(Specification)Standard Specification for Materials for Copper Base Powder Metallurgy (PM) Structural Parts

Standard Specification for Materials for Copper Base Powder Metallurgy (PM) Structural Parts

SCOPE

1.1 This specification covers a variety of copper base powder metallurgy (PM) structural materials, including those used in applications where high electrical conductivity is required. It includes a classification system, or material designation code. With the classification system, this specification includes chemical composition and minimum tensile yield strength.

Note 1: Paragraphs 6.1 and 8.1 govern material classification by the designation code. The classification system is explained in the Appendix.

Note 2: Materials classified as C-0000 are expected to be used in applications where high electrical conductivity is required.

1.2 Units—With the exception of density values, for which the gram per cubic centimetre (g/cm3) unit is the industry standard, the values stated in inch-pound units are to be regarded as the standard. The values given in parentheses are mathematical conversions to SI units that are provided for information only and are not considered standard.

1.3 This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

General Information

Relations

Buy Standard

Standards Content (Sample)

This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the

Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

Designation:B823 −20

Standard Specification for

Materials for Copper Base Powder Metallurgy (PM)

1

Structural Parts

This standard is issued under the fixed designation B823; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope* B963 Test Methods for Oil Content, Oil-Impregnation

Efficiency, and Surface-Connected Porosity of Sintered

1.1 This specification covers a variety of copper base

Powder Metallurgy (PM) Products Using Archimedes’

powder metallurgy (PM) structural materials, including those

Principle

used in applications where high electrical conductivity is

E8Test Methods for Tension Testing of Metallic Materials

required. It includes a classification system, or material desig-

[Metric] E0008_E0008M

nation code. With the classification system, this specification

E29Practice for Using Significant Digits in Test Data to

includes chemical composition and minimum tensile yield

Determine Conformance with Specifications

strength.

3

2.2 MPIF Standard:

NOTE 1—Paragraphs 6.1 and 8.1 govern material classification by the

MPIF Standard35,Materials Standards for PM Structural

designation code. The classification system is explained in theAppendix.

Parts

NOTE 2—Materials classified as C-0000 are expected to be used in

applications where high electrical conductivity is required.

3. Terminology

1.2 Units—With the exception of density values, for which

3 3.1 Definitions—Definitions of powder metallurgy terms

the gram per cubic centimetre (g/cm ) unit is the industry

can be found in Terminology B243. Additional descriptive

standard, the values stated in inch-pound units are to be

information is available under “General Information on PM

regarded as the standard. The values given in parentheses are

Gray Pages” on the B09 page of the ASTM website.

mathematical conversions to SI units that are provided for

information only and are not considered standard.

4. Ordering Information

1.3 This international standard was developed in accor-

4.1 Materials for parts covered by this specification shall be

dance with internationally recognized principles on standard-

ordered by materials designation code.

ization established in the Decision on Principles for the

4.2 Ordersforpartsunderthisspecificationmayincludethe

Development of International Standards, Guides and Recom-

following information:

mendations issued by the World Trade Organization Technical

4.2.1 Certification, if required (see Section 13),

Barriers to Trade (TBT) Committee.

4.2.2 Dimensions (see Section 9),

2. Referenced Documents

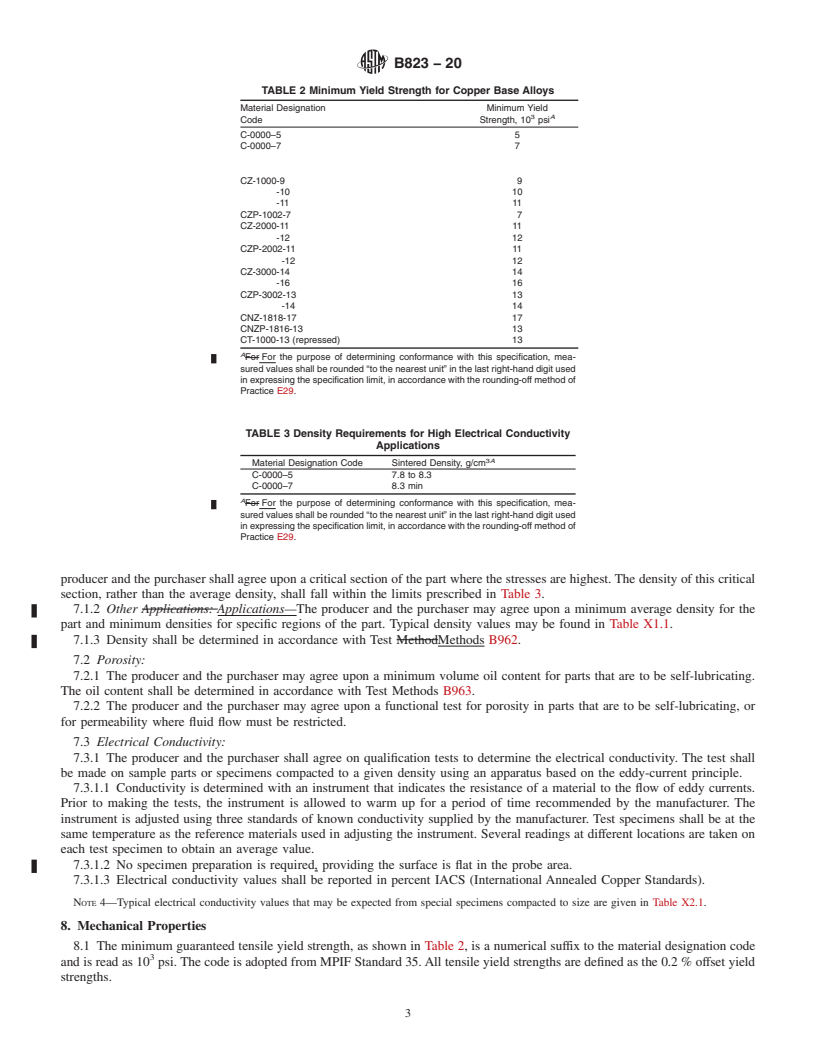

4.2.3 Chemical composition (see 6.1, 10.1, and Table 1),

2

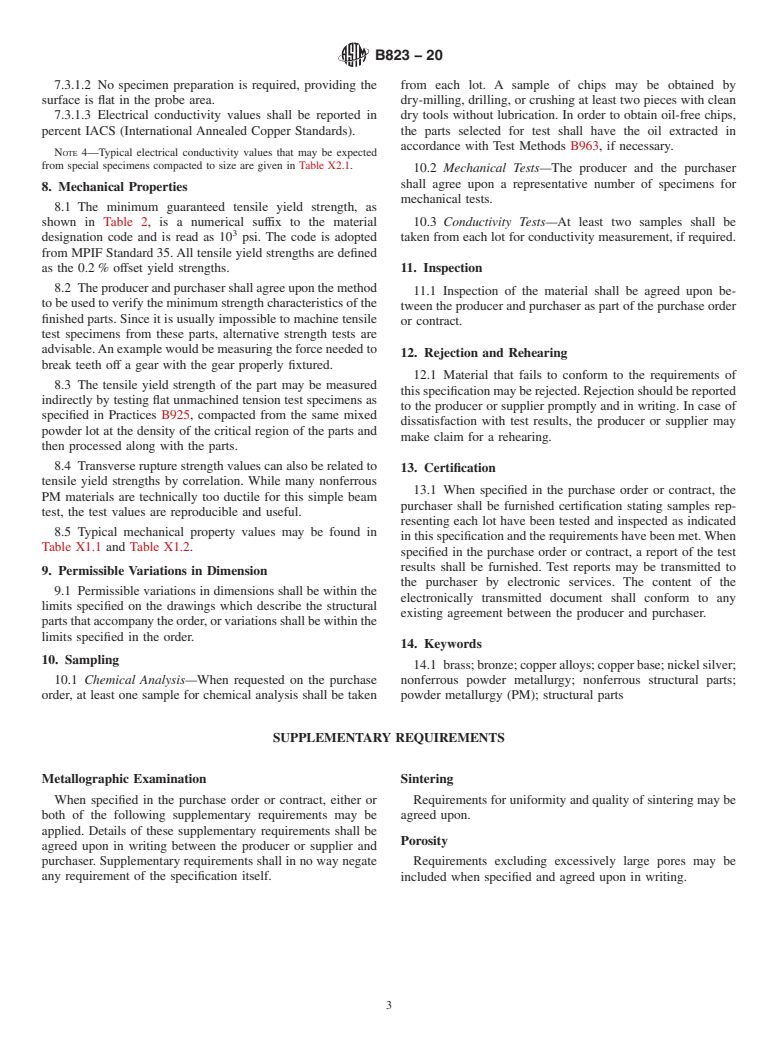

4.2.4 Test methods and mechanical properties (see 8.2 , 8.3,

2.1 ASTM Standards:

Table 2, Table X1.1, and Table X1.2),

B243Terminology of Powder Metallurgy

4.2.5 Density (see 7.1 and Table 3),

B925Practices for Production and Preparation of Powder

4.2.6 Porosity and oil content (see 7.3),

Metallurgy (PM) Test Specimens

4.2.7 Electrical properties (see 7.3 and Table X2.1), and

B962Test Methods for Density of Compacted or Sintered

4.2.8 Special packaging, if required.

Powder Metallurgy (PM) Products Using Archimedes’

Principle

5. Materials and Manufacture

1 5.1 Structural parts shall be made by compacting and

This specification is under the jurisdiction ofASTM Committee B09 on Metal

Powders and Metal Powder Products and is the direct responsibility of Subcom- sinteringmetalpowders.Partsmayalsobemadebyrepressing

mittee B09.05 on Structural Parts.

and resintering sintered parts, if necessary, to produce finished

Current edition approved April 1, 2020. Published May 2020. Originally

parts in conformance with the requirements of this specifica-

approved in 1992. Last previous edition approved in 2015 as B823–15. DOI:

tion.

10.1520/B0823-20.

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

3

Standards volume information, refer to the standard’s Document Summary page on Available from Metal Powder Industries Federation (MPIF), 105 College Rd.

the ASTM website. East, Princeton, NJ 08540, http://www.mpif.org.

*A Summary of Changes section appears at the end of this standard

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

B823−20

TABLE 1 Chemical Requirements TABLE 3 Density Requirements for High Electrical Conductivity

Appl

...

This document is not an ASTM standard and is intended only to provide the user of an ASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

Designation: B823 − 15 B823 − 20

Standard Specification for

Materials for Copper Base Powder Metallurgy (PM)

1

Structural Parts

This standard is issued under the fixed designation B823; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope*

1.1 This specification covers a variety of copper base powder metallurgy (PM) structural materials, including those used in

applications where high electrical conductivity is required. It includes a classification system, or material designation code. With

the classification system, this specification includes chemical composition and minimum tensile yield strength.

NOTE 1—Paragraphs 6.1 and 8.1 govern material classification by the designation code. The classification system is explained in the Appendix.

NOTE 2—Materials classified as C-0000 are expected to be used in applications where high electrical conductivity is required.

3

1.2 Units—With the exception of density values, for which the gram per cubic centimetre (g/cm ) unit is the industry standard,

the values stated in inch-pound units are to be regarded as the standard. Values in SI units result from conversion. They may be

approximate and are for information only. The values given in parentheses are mathematical conversions to SI units that are

provided for information only and are not considered standard.

1.3 This international standard was developed in accordance with internationally recognized principles on standardization

established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued

by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

2. Referenced Documents

2

2.1 ASTM Standards:

B243 Terminology of Powder Metallurgy

B925 Practices for Production and Preparation of Powder Metallurgy (PM) Test Specimens

B962 Test Methods for Density of Compacted or Sintered Powder Metallurgy (PM) Products Using Archimedes’ Principle

B963 Test Methods for Oil Content, Oil-Impregnation Efficiency, and Surface-Connected Porosity of Sintered Powder

Metallurgy (PM) Products Using Archimedes’ Principle

E8 Test Methods for Tension Testing of Metallic Materials [Metric] E0008_E0008M

E29 Practice for Using Significant Digits in Test Data to Determine Conformance with Specifications

3

2.2 MPIF Standard:

MPIF Standard 35, Materials Standards for PM Structural Parts

3. Terminology

3.1 Definitions—Definitions of powder metallurgy terms can be found in Terminology B243. Additional descriptive information

is available in the Related Materials section of Vol 02.05 of theunder “General Information on PM Gray Pages” on the B09 Annual

Book of ASTM Standards.page of the ASTM website.

4. Ordering Information

4.1 Materials for parts covered by this specification shall be ordered by materials designation code.

4.2 Orders for parts under this specification may include the following information:

4.2.1 Certification, if required (see Section 13),

1

This test method specification is under the jurisdiction of ASTM Committee B09 on Metal Powders and Metal Powder Products and is the direct responsibility of

Subcommittee B09.05 on Structural Parts.

Current edition approved Oct. 1, 2015April 1, 2020. Published November 2015May 2020. Originally approved in 1992. Last previous edition approved in 20092015 as

B823 – 09.B823 – 15. DOI: 10.1520/B0823-15.10.1520/B0823-20.

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM Standards

volume information, refer to the standard’s Document Summary page on the ASTM website.

3

Available from Metal Powder Industries Federation (MPIF), 105 College Rd. East, Princeton, NJ 08540, http://www.mpif.org.

*A Summary of Changes section appears at the end of this standard

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

B823 − 20

4.2.2 Dimensions (see Section 9),

4.2.3 Chemical composition (see 6.1, 10.1, and Table 1),

4.2.4 Test methods and mechanical properties (see 8.2 , 8.3, Table 2, Table X1.1, and Table X1.2),

4.2.5 Density (see 7.1 and Table 3),

4.2.6 Porosity and oil content (see 7.3),

4.2.7 Electrical properties (see 7.3 and Table X2.1), and

4.2.8

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.