ASTM F1887-14(2019)e1

(Test Method)Standard Test Method for Measuring the Coefficient of Restitution (COR) of Baseballs and Softballs

Standard Test Method for Measuring the Coefficient of Restitution (COR) of Baseballs and Softballs

SIGNIFICANCE AND USE

5.1 The ball coefficient of restitution is a ball dynamic property of relative velocity change caused by impact with a rigid wall.

5.2 This test method is suitable for obtaining data in research and development, quality control, and classifying balls by liveliness.

5.3 Sports associations can use coefficient of restitution standards in specifications for official baseballs and softballs.

5.4 This same test procedure can be utilized at impact speeds other then that prescribed in this procedure and so noted in any reported test results.

SCOPE

1.1 This procedure is intended to standardize a method of measuring the coefficient of restitution (COR) of baseballs and softballs.

1.2 This procedure is established to provide a single, repeatable, and uniform test method.

1.3 This procedure is for a ball that is intended for use in the game of baseball or softball.

1.4 The test method is based on ball speed measurements before and after impact with either of two test surfaces: wood or metal.

1.5 The values stated in SI units are to be regarded as the standard. The values given in parentheses are for information only.

1.6 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety, health, and environmental practices and determine the applicability of regulatory limitations prior to use.

1.7 This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

General Information

Relations

Standards Content (Sample)

This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the

Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

´1

Designation: F1887 − 14 (Reapproved 2019) An American National Standard

Standard Test Method for

Measuring the Coefficient of Restitution (COR) of Baseballs

and Softballs

This standard is issued under the fixed designation F1887; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

ε NOTE—Corrected 4.1 and 7.1 editorially in January 2020.

1. Scope 3. Terminology

1.1 This procedure is intended to standardize a method of 3.1 Definitions of Terms Specific to This Standard:

measuring the coefficient of restitution (COR) of baseballs and 3.1.1 baseball and softball, n—any ball defined by the rules

softballs. for the game of baseball or softball.

3.1.2 coeffıcient of restitution (COR), n— a numerical value

1.2 This procedure is established to provide a single,

determinedbytheexitspeedoftheballaftercontactdividedby

repeatable, and uniform test method.

the incoming speed of the ball before contact with a massive,

1.3 This procedure is for a ball that is intended for use in the

rigid, flat wall of either wood or metal.

game of baseball or softball.

4. Summary of Test Method

1.4 The test method is based on ball speed measurements

before and after impact with either of two test surfaces: wood

4.1 Method A—The strike plate is a rigid steel surface, and

or metal.

ball speed is measured before and after impact with the strike

plate.

1.5 The values stated in SI units are to be regarded as the

standard. The values given in parentheses are for information

4.2 Method B—The strike plate is a rigid wood surface, and

only.

ball speed is measured before and after impact with the strike

plate.

1.6 This standard does not purport to address all of the

safety concerns, if any, associated with its use. It is the

5. Significance and Use

responsibility of the user of this standard to establish appro-

5.1 The ball coefficient of restitution is a ball dynamic

priate safety, health, and environmental practices and deter-

mine the applicability of regulatory limitations prior to use. property of relative velocity change caused by impact with a

rigid wall.

1.7 This international standard was developed in accor-

dance with internationally recognized principles on standard-

5.2 This test method is suitable for obtaining data in

ization established in the Decision on Principles for the

research and development, quality control, and classifying

Development of International Standards, Guides and Recom-

balls by liveliness.

mendations issued by the World Trade Organization Technical

5.3 Sports associations can use coefficient of restitution

Barriers to Trade (TBT) Committee.

standards in specifications for official baseballs and softballs.

2. Referenced Documents 5.4 This same test procedure can be utilized at impact

speedsotherthenthatprescribedinthisprocedureandsonoted

2.1 ASTM Standards:

in any reported test results.

E177 Practice for Use of the Terms Precision and Bias in

ASTM Test Methods

6. Apparatus

E691 Practice for Conducting an Interlaboratory Study to

6.1 Strike Plate, Method A:

Determine the Precision of a Test Method

6.1.1 Material, 5.08-cm (2-in.) thick steel.

6.1.2 Size, 61 by 61 cm (24 by 24 in.).

6.1.3 Mounting, secured flush to a massive rigid wall of

This test method is under the jurisdiction of ASTM Committee F08 on Sports

cinder block or concrete, minimally 20.3-cm (8-in.) thick, and

Equipment, Playing Surfaces, and Facilities and is the direct responsibility of

Subcommittee F08.26 on Baseball and Softball Equipment. bolted at all four corners sufficiently secure to prevent move-

Current edition approved April 1, 2019. Published May 2019. Originally

ment during ball impact.

approved in 1998. Last previous edition approved in 2014 as F1887 – 14. DOI:

10.1520/F1887-14R19E01. 6.2 Strike Plate, Method B:

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

´1

F1887 − 14 (2019)

FIG. 1 Test Apparatus

6.2.1 Material, 10.2-cm (4-in.) thick northern white ash 8. Conditioning

wood with moisture content between 10 and 15 % with a flat

8.1 Ball Conditioning and Test Room Conditions:

smooth surface.

8.1.1 Test balls shall be stored in an environmentally

6.2.2 Same as 6.1.2.

controlled space for at least 14 days immediately before

6.2.3 Same as 6.1.3.

testing.

6.3 Ball Throwing Device—A ball throwing device capable 8.1.2 Temperature is to be maintained at 72 6 4°F (22 6

of delivering the ball through the electronic speed monitor at 2°C).

26.82 m/s (60 mph) with a maximum tolerance of 60.30 m/s. 8.1.3 Relative humidity is to be maintained between 40 and

The machine should be calibrated using the electronic speed 60 %.

monitor. 8.1.4 Temperature and relative humidity are to be measured

and recorded hourly within 60.5°F (60.3°C) and 62% RH

6.4 Electronic Speed Monitors—An electronic ball speed

over conditioning and test duration.

measuring system consisting of two vertical light screens

mounted 30.48 cm (12 in.) apart with a tolerance of 60.32 cm,

9. Procedure

and a photoelectric sensor located at each screen that triggers

9.1 The ball throwing device is set to deliver the ball at

a timing device on ball passage to measure the time for the ball

26.82 6 0.305 m/s (60 mph). All shots above or below this

to traverse the distance between the two vertical planes before

tolerance range will not be used.

and after impact with the strike plate. Resolution shall be

60.03 m/s. 9.2 Each ball is shot at the strike plate a minimum of six

times to a maximum of 12 times. A minimum 30-s rest period

6.5 Ball Trajectory Target—A lightweight target with a

is required between each shot.

30.48-cm (12-in.) diameter circular opening positioned at the

9.3 Only those speed readings for impacts falling within the

second light screen and centered on the ball line of travel

between the throwing device and the center of the strike plate. 6-in. target at the strike plate, within the 12-in. target at the

second speed monitor, and thrown within the prescribed speed

7. Preparation of Apparatus

range will be used in the calculation of COR.

7.1 Mount the strike plate on a rigid wall such that the

9.4 The average of the six acceptable COR values for each

center is approximately 1.22 m (4 ft) from the floor.Tighten all

ball is used to determine the ball COR.

mounting bolts before each test.Torque to 81.35 N-m (60 ft-lb)

9.4.1 Formulae:

min.

1 Vb1 Vb2 Vb3 Vb4 Vb5 Vb6

COR 5 Vb/Va 5 1 1 1 1 1 (1)

F G

7.2 Position the first speed monitor (light screen) 30.48 6

6 Va1 Va2 Va3 Va4 Va5 Va6

0.32 cm (12 6 0.125 in.) from the strike plate (see Fig. 1).

where:

7.3 Position the second speed monitor (light screen) 30.48

Va = incoming speed, and

6 0.079 cm (12 6 0.312 in.) from the first speed monitor.

Vb = exit speed.

7.4 Position the ball throwing device such that the ball

10. Report

impacts the strike plate within 15.24 cm (6 in.) of the center

and on rebound, passes through the 30.48 cm (12 in.) target 10.1 Report the following information:

mounted at the second light screen. 10.1.1 Name of the test facility and test operator,

´1

F1887 − 14 (2019)

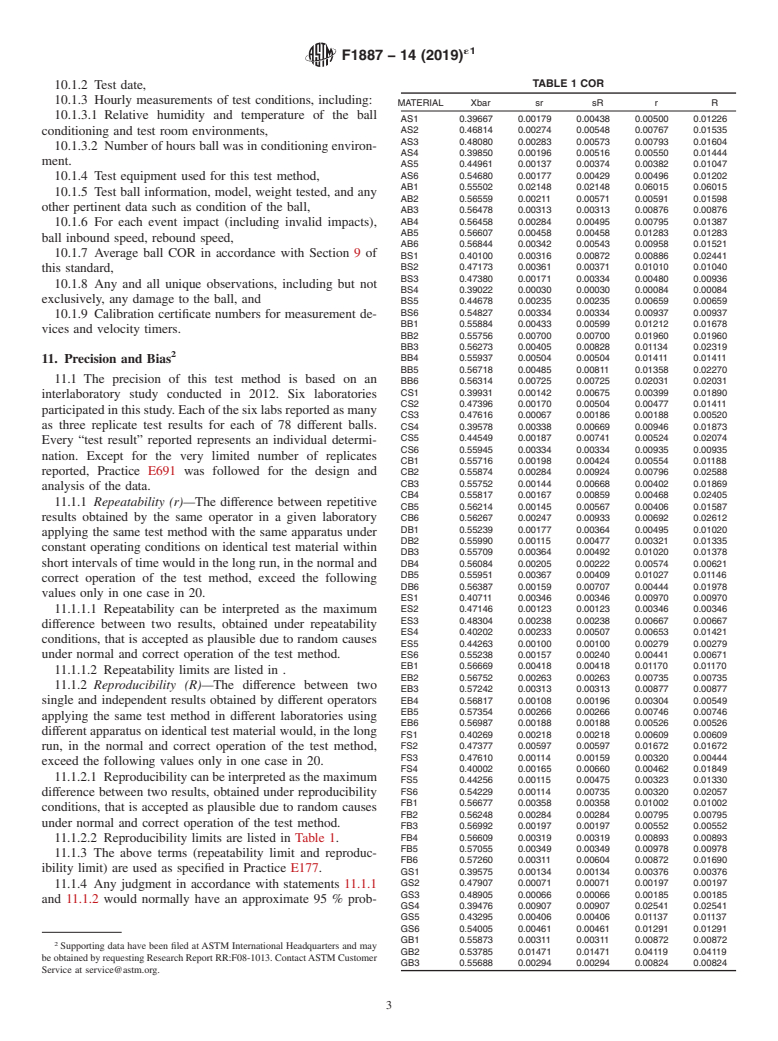

TABLE 1 COR

10.1.2 Test date,

10.1.3 Hourly measurements of test conditions, including:

MATERIAL Xbar sr sR r R

10.1.3.1 Relative humidity and temperature of the ball

AS1 0.39667 0.00179 0.00438 0.00500 0.01226

AS2 0.46814 0.00274 0.00548 0.00767 0.01535

conditioning and test room environments,

AS3 0.48080 0.00283 0.00573 0.00793 0.01604

10.1.3.2 Number of hours ball was in conditioning environ-

AS4 0.39850 0.00196 0.00516 0.00550 0.01444

ment.

AS5 0.44961 0.00137 0.00374 0.00382 0.01047

AS6 0.54680 0.00177 0.00429 0.00496 0.01202

10.1.4 Test equipment used for this test method,

AB1 0.55502 0.02148 0.02148 0.06015 0.06015

10.1.5 Test ball information, model, weight tested, and any

AB2 0.56559 0.00211 0.00571 0.00591 0.01598

other pertinent data such as condition of

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.