ASTM F736-17(2023)

(Test Method)Standard Test Method for Impact Resistance of Monolithic Polycarbonate Sheet by Means of a Falling Weight

Standard Test Method for Impact Resistance of Monolithic Polycarbonate Sheet by Means of a Falling Weight

SIGNIFICANCE AND USE

5.1 This test method is applicable for qualitatively evaluating coated and uncoated monolithic polycarbonate sheet material, for monitoring process control, for screening studies, and as an aid in the prediction of hardware performance when exposed to impact service conditions.

5.2 A limitation of Type A specimen testing is that a thick sheet may not fail since the available impact energy is limited by the maximum drop height and falling weight capacity of the test apparatus. Use Specimen Type A for material less than 12.7 mm (0.50 in.) thick.

5.3 Within the range of drop heights of this system, tests employing different velocities are not expected to produce different results. However, for a given series of tests, the drop height should be held constant so that velocity of impact (strain rate) will not be a variable.

5.4 As the polycarbonate specimen undergoes large plastic deformation under impact, the down (opposite impact) side is under tensile loading and most influential in initiating failure. For that reason, polycarbonate sheet coated on one side should be tested with the coated side down.

5.5 Direct comparison of specimen Type A and specimen Type B test results should not be attempted. For test programs that will require the comparison of interlaboratory test results the specimen type and the approximate drop height must be specified.

5.6 Monolithic polycarbonate sheet is notch sensitive. Data obtained from other test methods, particularly notched Izod/Charpy test results, and extremely high- or low-strain rate test results, should not be compared directly to data obtained from this method. It is noted that Type A specimens, free of flaws, have not experienced the characteristic ductile-to-brittle transition between thin, less than 3.18 mm (1/8 in.), and thick, greater than 7.94 mm (5/16 in.), sheet as reflected by other test methods.

SCOPE

1.1 This test method covers the determination of the energy required to initiate failure in monolithic polycarbonate sheet material under specified conditions of impact using a free falling weight.

1.2 Two specimen types are defined as follows:

1.2.1 Type A consists of a flat plate test specimen and employs a clamped ring support.

1.2.2 Type B consists of a simply supported three-point loaded beam specimen (Fig. 1) for use with material which can not be failed using the Type A specimen. For a maximum drop height of 6.096 m (20 ft) and a maximum drop weight of 22.68 kg (50 lb), virgin polycarbonate greater than 12.70 mm (1/2 in.) thick will require use of the Type B specimen.

Note 1: See also ASTM Methods: D1709, D2444 and D3029.

FIG. 1 Type B Specimen Geometry and Loading

1.3 The values stated in SI units are to be regarded as standard. No other units of measurement are included in this standard.

1.3.1 Exception—The inch-pound units in parentheses are provided for information only.

1.4 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety, health, and environmental practices and determine the applicability of regulatory limitations prior to use. For specific hazard statement, See Section 7.

1.5 This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

General Information

Relations

Standards Content (Sample)

This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the

Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

Designation: F736 − 17 (Reapproved 2023)

Standard Test Method for

Impact Resistance of Monolithic Polycarbonate Sheet by

Means of a Falling Weight

ThisstandardisissuedunderthefixeddesignationF736;thenumberimmediatelyfollowingthedesignationindicatestheyearoforiginal

adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.Asuperscript

epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope 2. Referenced Documents

2.1 ASTM Standards:

1.1 This test method covers the determination of the energy

D618 Practice for Conditioning Plastics for Testing

required to initiate failure in monolithic polycarbonate sheet

D790 Test Methods for Flexural Properties of Unreinforced

material under specified conditions of impact using a free

and Reinforced Plastics and Electrical Insulating Materi-

falling weight.

als

1.2 Two specimen types are defined as follows:

1.2.1 Type A consists of a flat plate test specimen and 3. Terminology

employs a clamped ring support.

3.1 Definitions of Terms Specific to This Standard:

1.2.2 Type B consists of a simply supported three-point

3.1.1 failure (of test specimen)—failure is signified by the

loaded beam specimen (Fig. 1) for use with material which can

presence of any crack or split in the impact-deformed area that

not be failed using the TypeAspecimen. For a maximum drop was created by the impact of the falling weight and that can be

height of 6.096 m (20 ft) and a maximum drop weight of

seen by the naked eye.

22.68 kg (50 lb), virgin polycarbonate greater than 12.70 mm

4. Summary of Test Method

( ⁄2 in.) thick will require use of the Type B specimen.

4.1 The test procedure to cause failure covers a range of

NOTE 1—See also ASTM Methods: D1709, D2444 and D3029.

impact energies and differs with respect to geometry and

1.3 The values stated in SI units are to be regarded as

support of test specimen Type A and test specimen Type B.

standard. No other units of measurement are included in this

Guidelines are established to control drop heights, impact

standard.

velocity, drop weights, impactor heads, impactor release,

1.3.1 Exception—The inch-pound units in parentheses are impactorrebound,impactlocation,andspecimenconfiguration

which are applicable to a falling weight impact tester designed

provided for information only.

to accommodate Type A or Type B test specimens, or both,

1.4 This standard does not purport to address all of the

fabricated from monolithic polycarbonate sheet material.

safety concerns, if any, associated with its use. It is the

responsibility of the user of this standard to establish appro-

5. Significance and Use

priate safety, health, and environmental practices and deter-

5.1 This test method is applicable for qualitatively evaluat-

mine the applicability of regulatory limitations prior to use.

ing coated and uncoated monolithic polycarbonate sheet

For specific hazard statement, See Section 7.

material, for monitoring process control, for screening studies,

1.5 This international standard was developed in accor-

and as an aid in the prediction of hardware performance when

dance with internationally recognized principles on standard-

exposed to impact service conditions.

ization established in the Decision on Principles for the

5.2 A limitation of Type A specimen testing is that a thick

Development of International Standards, Guides and Recom-

sheet may not fail since the available impact energy is limited

mendations issued by the World Trade Organization Technical

by the maximum drop height and falling weight capacity of the

Barriers to Trade (TBT) Committee.

test apparatus. Use Specimen Type A for material less than

12.7 mm (0.50 in.) thick.

This test method is under the jurisdiction of ASTM Committee F07 on

Aerospace and Aircraft and is the direct responsibility of Subcommittee F07.08 on

Transparent Enclosures and Materials. For referenced ASTM standards, visit the ASTM website, www.astm.org, or

Current edition approved Jan. 1, 2023. Published January 2023. Originally contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

approved in 1981. Last previous edition approved in 2017 as F736 – 17. DOI: Standards volume information, refer to the standard’s Document Summary page on

10.1520/F0736-17R23. theASTM website.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

F736 − 17 (2023)

FIG. 1 Type B Specimen Geometry and Loading

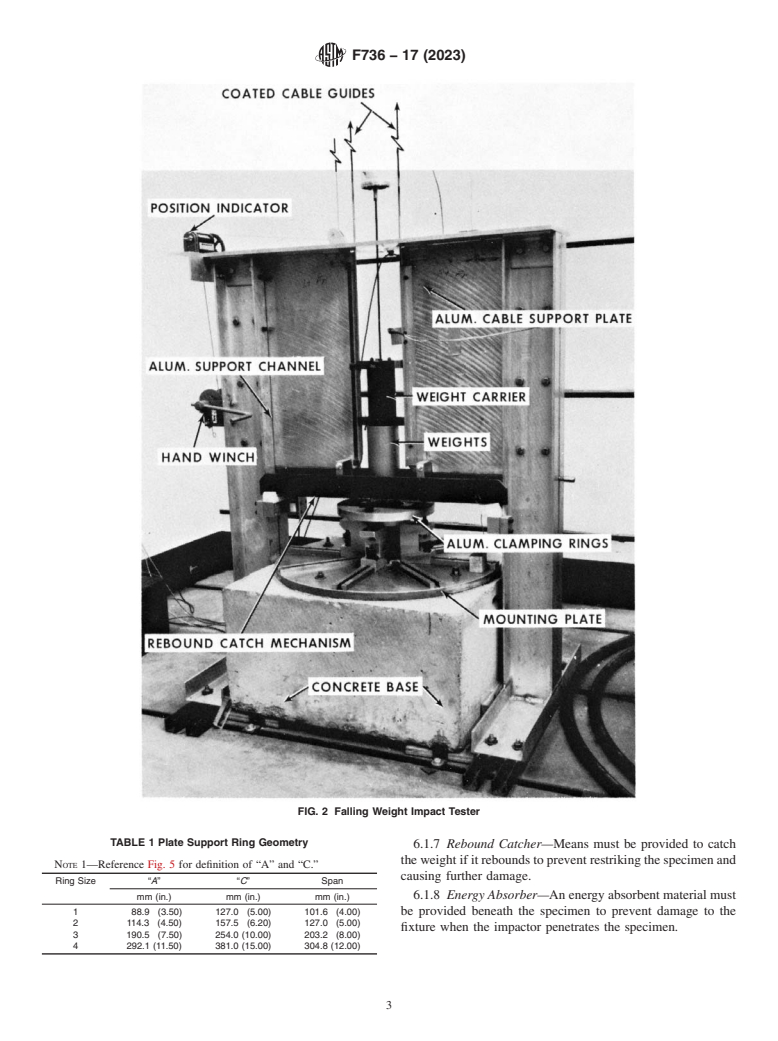

5.3 Within the range of drop heights of this system, tests 6.1.2 Drop Weight—Thefallingweightsshallbedetachable,

employing different velocities are not expected to produce

interchangeable, and variable in small known increments from

different results. However, for a given series of tests, the drop a total of 0.45 kg (1 lb) to a maximum drop weight of 50 kg

heightshouldbeheldconstantsothatvelocityofimpact(strain

(110 lb).

rate) will not be a variable.

6.1.3 Impactor—The loading nose to be used with Type A

5.4 As the polycarbonate specimen undergoes large plastic specimens is shown inFig. 3; withType Bspecimens as shown

deformation under impact, the down (opposite impact) side is

in Fig. 4. The impactor surface shall be free of nicks or other

under tensile loading and most influential in initiating failure.

surface irregularities. The impactor geometry for Type B

For that reason, polycarbonate sheet coated on one side should

specimens corresponds to Test Method D790.

be tested with the coated side down.

6.1.4 Impact Location—The center of mass of the falling

5.5 Direct comparison of specimen Type A and specimen weight shall be guided by a two cable system or other suitable

Type B test results should not be attempted. For test programs means to repeatedly strike within 2.54 mm (0.10 in.) of the

that will require the comparison of interlaboratory test results

center of the specimen support fixture as measured in the plane

the specimen type and the approximate drop height must be

of the specimen, in order to assure uniform, reproducible

specified.

drops. Friction retarding the falling weight shall be minimal so

that the impact velocity approaches

5.6 Monolithic polycarbonate sheet is notch sensitive. Data

obtained from other test methods, particularly notched Izod/

=

2gh

Charpy test results, and extremely high- or low-strain rate test

results, should not be compared directly to data obtained from where:

this method. It is noted that Type A specimens, free of flaws,

g = acceleration of gravity, and

have not experienced the characteristic ductile-to-brittle tran-

h = drop height.

sition between thin, less than 3.18 mm ( ⁄8 in.), and thick,

6.1.5 Supports—Clamp and support rings as shown inFig. 5

greater than 7.94 mm ( ⁄16 in.), sheet as reflected by other test

and Table 1 shall be used to accommodate Type A plate

methods.

specimens. Adjustable D790–Test Method 1 supports shall be

used to accommodate the Type B simply supported beam

6. Apparatus

specimens of 6 + 1 span-to-depth ratio. Specimens shall be

6.1 Impact Tester—The apparatus shall be constructed as

supported so that the surface to be impacted is horizontal and

shown in Fig. 2. Although not specified, materials called out

at an angle of 90 (6 1)° (π/2 radians) with respect to the falling

have been found to be satisfactory.

weight guides.

6.1.1 Drop Height—A lifting carrier shall be provided to

6.1.6 Release—An electromagnetic or mechanical releasing

raise or lower the falling weight impactor that will be adjust-

mechanism, capable of supporting the maximum falling

ablewithintherangeof0.305m(1ft)tomaximumdropheight

and measurable to the nearest 25.40 mm (1 in.). weight,shallbeusedtoassureuniformandreproducibledrops.

F736 − 17 (2023)

FIG. 2 F

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.