ASTM A66-21

(Specification)Standard Specification for Steel Screw Spikes

Standard Specification for Steel Screw Spikes

ABSTRACT

This specification deals with steel screw spikes used as fastenings between railroad rails, tie plates, and ties. The steel shall be made by electric-furnace or basic-oxygen, may be cast by continuous process or in ingots, and the heads and threads of the spikes may be formed by hot- or cold-forming methods. Tension and bend tests of the material shall be made. Inspection, certification, and product marking are also covered.

SCOPE

1.1 This specification covers steel screw spikes used as fastenings between railroad rails, tie plates, and ties.

1.2 The values stated in inch-pound units are to be regarded as standard. The values given in parentheses are mathematical conversions to SI units that are provided for information only and are not considered standard.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety, health, and environmental practices and determine the applicability of regulatory limitations prior to use.

1.4 This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

General Information

Buy Standard

Standards Content (Sample)

This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the

Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

Designation:A66 −21

Standard Specification for

1

Steel Screw Spikes

This standard is issued under the fixed designationA66; the number immediately following the designation indicates the year of original

adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.Asuperscript

epsilon (´) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the U.S. Department of Defense.

1. Scope 3.1.3 Type of Point—pilot point or not pointed,

3.1.4 Dimensions—diameter and length, under head,

1.1 This specification covers steel screw spikes used as

fastenings between railroad rails, tie plates, and ties. 3.1.5 Supplementary Requirement if to apply (see S1)

3.1.6 Certification and Test Report (see 11.1).

1.2 The values stated in inch-pound units are to be regarded

as standard. The values given in parentheses are mathematical

4. Manufacture

conversions to SI units that are provided for information only

and are not considered standard.

4.1 The steel shall be made by any of the following

1.3 This standard does not purport to address all of the

processes: electric-furnace or basic-oxygen.

safety concerns, if any, associated with its use. It is the

4.2 The steel may be cast by a continuous process, or in

responsibility of the user of this standard to establish appro-

ingots.

priate safety, health, and environmental practices and deter-

mine the applicability of regulatory limitations prior to use.

4.3 The heads and threads of the spikes may be formed by

1.4 This international standard was developed in accor-

hot- or cold-forming methods.

dance with internationally recognized principles on standard-

4.4 Thecompositionofthesteelshallbeconsistentwiththat

ization established in the Decision on Principles for the

shown in Table 1. The manufacturer may add other alloying

Development of International Standards, Guides and Recom-

elements at their discretion to meet mechanical properties of

mendations issued by the World Trade Organization Technical

Table2butmustreportsuchelementsinthematerialtestreport

Barriers to Trade (TBT) Committee.

of chemical composition and mechanical properties.

2. Referenced Documents

2

5. Mechanical Requirements

2.1 ASTM Standards:

A370 Test Methods and Definitions for Mechanical Testing

5.1 Tensile Requirements:

of Steel Products

5.1.1 The material as represented by a tension test of a

A700 Guide for Packaging, Marking, and Loading Methods

full-size finished spike, or a specimen machined from a

for Steel Products for Shipment

finished spike, shall conform to the requirements prescribed in

Table 2.

3. Ordering Information

5.1.2 Tension tests of full-size spikes shall be performed

3.1 Orders for screw spikes under this specification shall

using a 10° wedge as described in Test Methods and Defini-

include the following information as appropriate:

tions A370, Supplement S11.1.5.

3.1.1 Quantity (weight),

3

5.1.3 Where the design of the spike is such that full-size

3.1.2 Style of Head—A, B, or C or other, including draw-

testing is impracticable, the tension test may be made on a

ings if necessary,

specimen machined from a finished spike. Dimensions of the

test specimen shall conform to the requirements of Test

1

This specification is under the jurisdiction of ASTM Committee A01 on Steel,

Methods and Definitions A370.

Stainless Steel and Related Alloys and is the direct responsibility of Subcommittee

A01.01 on Steel Rails and Accessories.

5.1.4 When a machined specimen test is performed, the

Current edition approved Nov. 1, 2021. Published November 2021. Originally

elongation requirement prescribed in Table 2 shall apply. If a

approved in 1916. Last previous edition approved in 2013 as A66 – 07 (2013). DOI:

screw spike is machined and the specimen is tested and

10.1520/A0066-21.

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or reported. the elongation meets or exceeds 18 %, the bend test

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

is not required. See 5.2.

Standards volume information, refer to the standard’s Document Summary page on

5.1.5 The yield point shall be determined by the drop of the

the ASTM website.

3

Consult manufacturer’s literature for design details forA, B, and C-style heads. beam or halt in the gage of the testing machine.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

A66−21

A

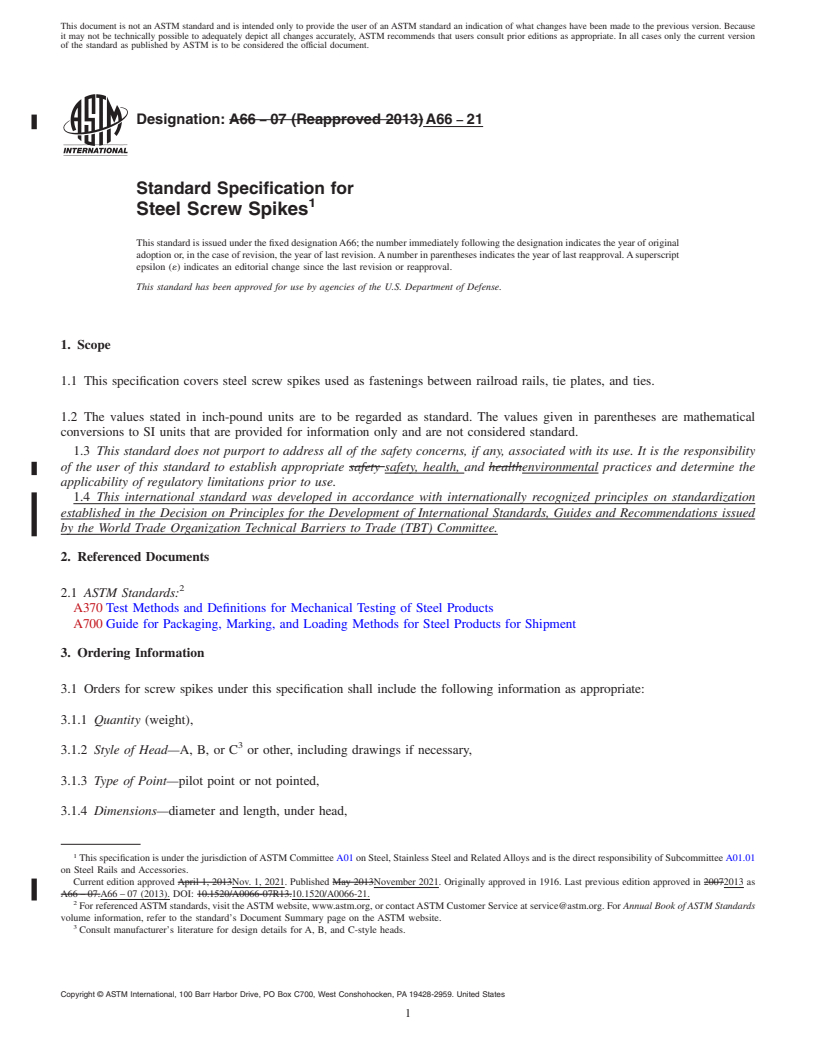

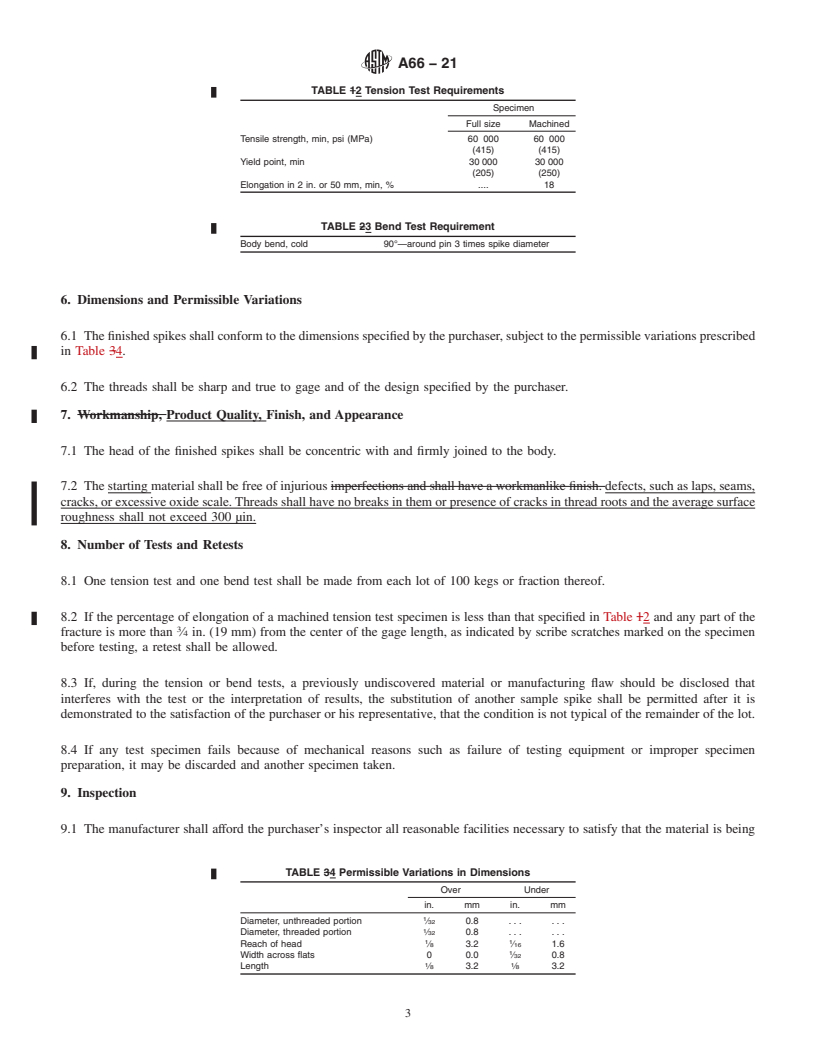

TABLE 1 Chemical Requirements TABLE 4 Permissible Variations in Dimensions

Over Under

NOTE 1—All alloy c

...

This document is not an ASTM standard and is intended only to provide the user of an ASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

Designation: A66 − 07 (Reapproved 2013) A66 − 21

Standard Specification for

1

Steel Screw Spikes

This standard is issued under the fixed designation A66; the number immediately following the designation indicates the year of original

adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A superscript

epsilon (´) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the U.S. Department of Defense.

1. Scope

1.1 This specification covers steel screw spikes used as fastenings between railroad rails, tie plates, and ties.

1.2 The values stated in inch-pound units are to be regarded as standard. The values given in parentheses are mathematical

conversions to SI units that are provided for information only and are not considered standard.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility

of the user of this standard to establish appropriate safety safety, health, and healthenvironmental practices and determine the

applicability of regulatory limitations prior to use.

1.4 This international standard was developed in accordance with internationally recognized principles on standardization

established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued

by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

2. Referenced Documents

2

2.1 ASTM Standards:

A370 Test Methods and Definitions for Mechanical Testing of Steel Products

A700 Guide for Packaging, Marking, and Loading Methods for Steel Products for Shipment

3. Ordering Information

3.1 Orders for screw spikes under this specification shall include the following information as appropriate:

3.1.1 Quantity (weight),

3

3.1.2 Style of Head—A, B, or C or other, including drawings if necessary,

3.1.3 Type of Point—pilot point or not pointed,

3.1.4 Dimensions—diameter and length, under head,

1

This specification is under the jurisdiction of ASTM Committee A01 on Steel, Stainless Steel and Related Alloys and is the direct responsibility of Subcommittee A01.01

on Steel Rails and Accessories.

Current edition approved April 1, 2013Nov. 1, 2021. Published May 2013November 2021. Originally approved in 1916. Last previous edition approved in 20072013 as

A66 – 07.A66 – 07 (2013). DOI: 10.1520/A0066-07R13.10.1520/A0066-21.

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM Standards

volume information, refer to the standard’s Document Summary page on the ASTM website.

3

Consult manufacturer’s literature for design details for A, B, and C-style heads.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

A66 − 21

3.1.5 Supplementary Requirement if to apply (see S1)

3.1.6 Certification and Test Report (see 11.1).

4. Manufacture

4.1 The steel shall be made by any of the following processes: electric-furnace or basic-oxygen.

4.2 The steel may be cast by a continuous process, or in ingots.

4.3 The heads and threads of the spikes may be formed by hot- or cold-forming methods.

4.4 The composition of the steel shall be consistent with that shown in Table 1. The manufacturer may add other alloying elements

at their discretion to meet mechanical properties of Table 2 but must report such elements in the material test report of chemical

composition and mechanical properties.

5. Mechanical Requirements

5.1 Tensile Requirements:

5.1.1 The material as represented by a tension test of a full-size finished spike, or a specimen machined from a finished spike, shall

conform to the requirements prescribed in Table 12.

5.1.2 Tension tests of full-size spikes shall be performed using a 10° wedge as described in Test Methods and Definitions A370,

Supplement S11.1.5.

5.1.3 Where the design of the spike is such that full-size testing is impracticable, the tension test may be made on a specimen

machined from a finished spike. Dimensions of the test specimen shall conform to the requirements of Test Methods and

Definitions A370.

5.1.4 When a machined specimen test is performed, the elongation requirement prescribed in Table 12 shall apply. If a screw spike

is machined and the specimen is tested and reported. the elongation meets or exceeds 18 %, the bend test is not r

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.