ASTM D3336-05(2015)

(Test Method)Standard Test Method for Life of Lubricating Greases in Ball Bearings at Elevated Temperatures

Standard Test Method for Life of Lubricating Greases in Ball Bearings at Elevated Temperatures

SIGNIFICANCE AND USE

4.1 This test method can be used to evaluate the ability of grease to provide adequate lubrication for extended periods of ball bearings operating under light loads at high speeds and elevated temperatures.

SCOPE

1.1 This test method covers the evaluation of the performance of lubricating greases in ball bearings operating under light loads at high speeds and elevated temperatures.

1.2 The values stated in inch-pound units are to be regarded as standard. The values given in parentheses are mathematical conversions to SI units that are provided for information only and are not considered standard.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use. For specific warning statements, see 8.1.

General Information

Relations

Buy Standard

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: D3336 − 05 (Reapproved 2015)

Standard Test Method for

Life of Lubricating Greases in Ball Bearings at Elevated

1

Temperatures

This standard is issued under the fixed designation D3336; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the U.S. Department of Defense.

1. Scope temperature. Tests are continued until failure or completion of

a specified number of hours of running time.

1.1 This test method covers the evaluation of the perfor-

mance of lubricating greases in ball bearings operating under

4. Significance and Use

light loads at high speeds and elevated temperatures.

4.1 This test method can be used to evaluate the ability of

1.2 The values stated in inch-pound units are to be regarded

grease to provide adequate lubrication for extended periods of

as standard. The values given in parentheses are mathematical

ball bearings operating under light loads at high speeds and

conversions to SI units that are provided for information only

elevated temperatures.

and are not considered standard.

5,6

5. Apparatus

1.3 This standard does not purport to address all of the

7

safety concerns, if any, associated with its use. It is the

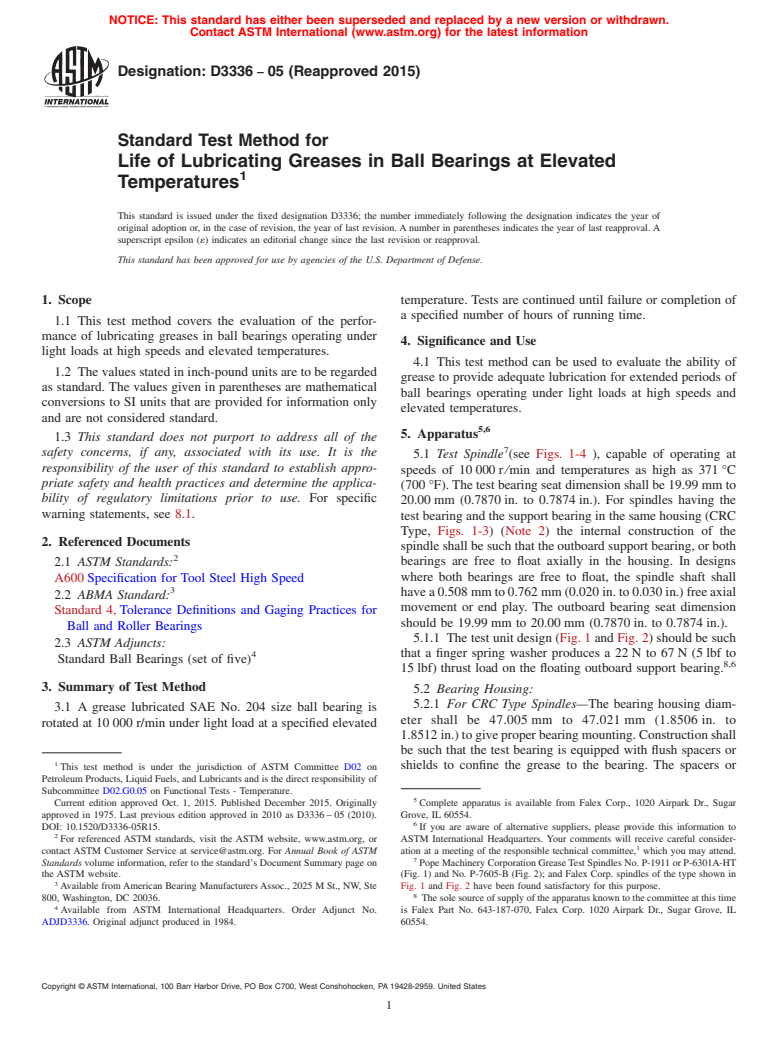

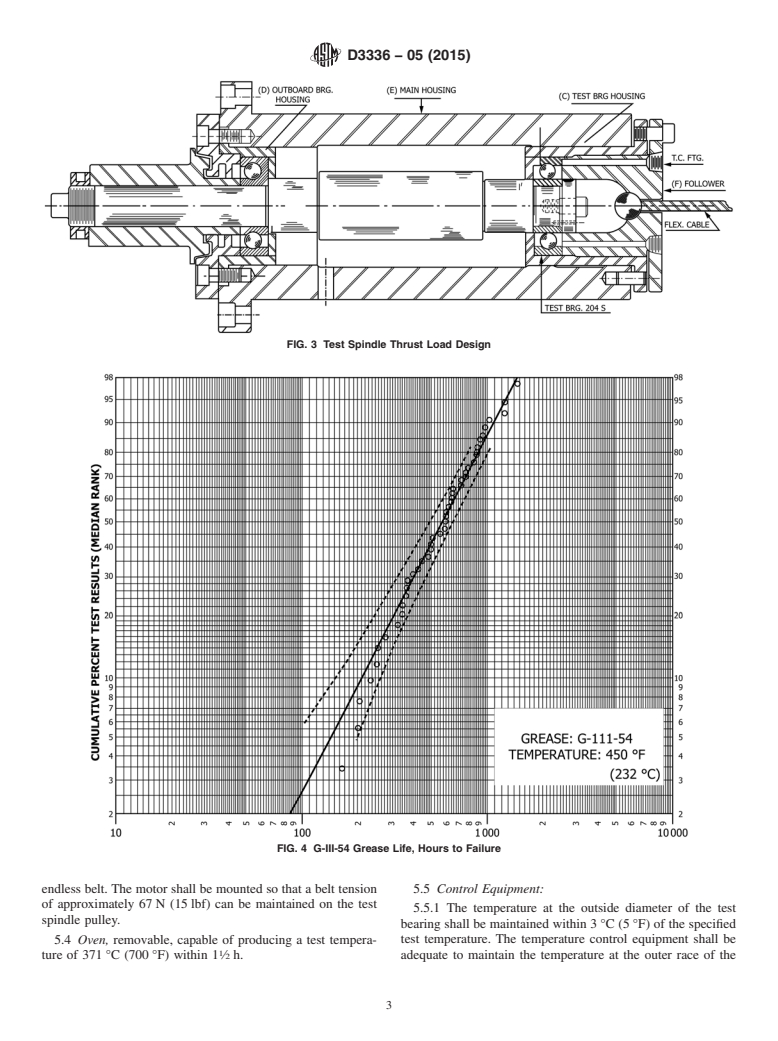

5.1 Test Spindle (see Figs. 1-4 ), capable of operating at

responsibility of the user of this standard to establish appro-

speeds of 10 000 r⁄min and temperatures as high as 371 °C

priate safety and health practices and determine the applica-

(700 °F).The test bearing seat dimension shall be 19.99 mm to

bility of regulatory limitations prior to use. For specific

20.00 mm (0.7870 in. to 0.7874 in.). For spindles having the

warning statements, see 8.1.

test bearing and the support bearing in the same housing (CRC

Type, Figs. 1-3)(Note 2) the internal construction of the

2. Referenced Documents

spindle shall be such that the outboard support bearing, or both

2

bearings are free to float axially in the housing. In designs

2.1 ASTM Standards:

A600 Specification for Tool Steel High Speed where both bearings are free to float, the spindle shaft shall

3

havea0.508 mmto0.762 mm(0.020 in.to0.030 in.)freeaxial

2.2 ABMA Standard:

movement or end play. The outboard bearing seat dimension

Standard 4, Tolerance Definitions and Gaging Practices for

should be 19.99 mm to 20.00 mm (0.7870 in. to 0.7874 in.).

Ball and Roller Bearings

5.1.1 The test unit design (Fig. 1 and Fig. 2) should be such

2.3 ASTM Adjuncts:

4 that a finger spring washer produces a 22 N to 67 N (5 lbf to

Standard Ball Bearings (set of five)

8,6

15 lbf) thrust load on the floating outboard support bearing.

3. Summary of Test Method

5.2 Bearing Housing:

5.2.1 For CRC Type Spindles—The bearing housing diam-

3.1 A grease lubricated SAE No. 204 size ball bearing is

eter shall be 47.005 mm to 47.021 mm (1.8506 in. to

rotated at 10 000 r/min under light load at a specified elevated

1.8512 in.)togiveproperbearingmounting.Constructionshall

be such that the test bearing is equipped with flush spacers or

1

This test method is under the jurisdiction of ASTM Committee D02 on shields to confine the grease to the bearing. The spacers or

Petroleum Products, Liquid Fuels, and Lubricants and is the direct responsibility of

Subcommittee D02.G0.05 on Functional Tests - Temperature.

5

Current edition approved Oct. 1, 2015. Published December 2015. Originally Complete apparatus is available from Falex Corp., 1020 Airpark Dr., Sugar

approved in 1975. Last previous edition approved in 2010 as D3336 – 05 (2010). Grove, IL 60554.

6

DOI: 10.1520/D3336-05R15. If you are aware of alternative suppliers, please provide this information to

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or ASTM International Headquarters. Your comments will receive careful consider-

1

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM ation at a meeting of the responsible technical committee, which you may attend.

7

Standards volume information, refer to the standard’s Document Summary page on Pope Machinery Corporation GreaseTest Spindles No. P-1911 or P-6301A-HT

the ASTM website. (Fig. 1) and No. P-7605-B (Fig. 2); and Falex Corp. spindles of the type shown in

3

Available fromAmerican Bearing ManufacturersAssoc., 2025 M St., NW, Ste Fig. 1 and Fig. 2 have been found satisfactory for this purpose.

8

800, Washington, DC 20036. The sole source of supply of the apparatus known to the committee at this time

4

Available from ASTM International Headquarters. Order Adjunct No. is Falex Part No. 643-187-070, Falex Corp. 1020 Airpark Dr., Sugar Grove, IL

ADJD3336. Original adjunct

...

This document is not an ASTM standard and is intended only to provide the user of an ASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

Designation: D3336 − 05 (Reapproved 2010) D3336 − 05 (Reapproved 2015)

Standard Test Method for

Life of Lubricating Greases in Ball Bearings at Elevated

1

Temperatures

This standard is issued under the fixed designation D3336; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the U.S. Department of Defense.

1. Scope

1.1 This test method covers the evaluation of the performance of lubricating greases in ball bearings operating under light loads

at high speeds and elevated temperatures.

1.2 The values stated in inch-pound units are to be regarded as standard. The values given in parentheses are mathematical

conversions to SI units that are provided for information only and are not considered standard.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility

of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory

limitations prior to use. For specific warning statements, see 8.1.

2. Referenced Documents

2

2.1 ASTM Standards:

A600 Specification for Tool Steel High Speed

3

2.2 ABMA Standard:

Standard 4, Tolerance Definitions and Gaging Practices for Ball and Roller Bearings

2.3 ASTM Adjuncts:

4

Standard Ball Bearings (set of five)

3. Summary of Test Method

3.1 A grease lubricated SAE No. 204 size ball bearing is rotated at 10 000 rpm10 000 r/min under light load at a specified

elevated temperature. Tests are continued until failure or completion of a specified number of hours of running time.

4. Significance and Use

4.1 This test method can be used to evaluate the ability of grease to provide adequate lubrication for extended periods of ball

bearings operating under light loads at high speeds and elevated temperatures.

5,6

5. Apparatus

7

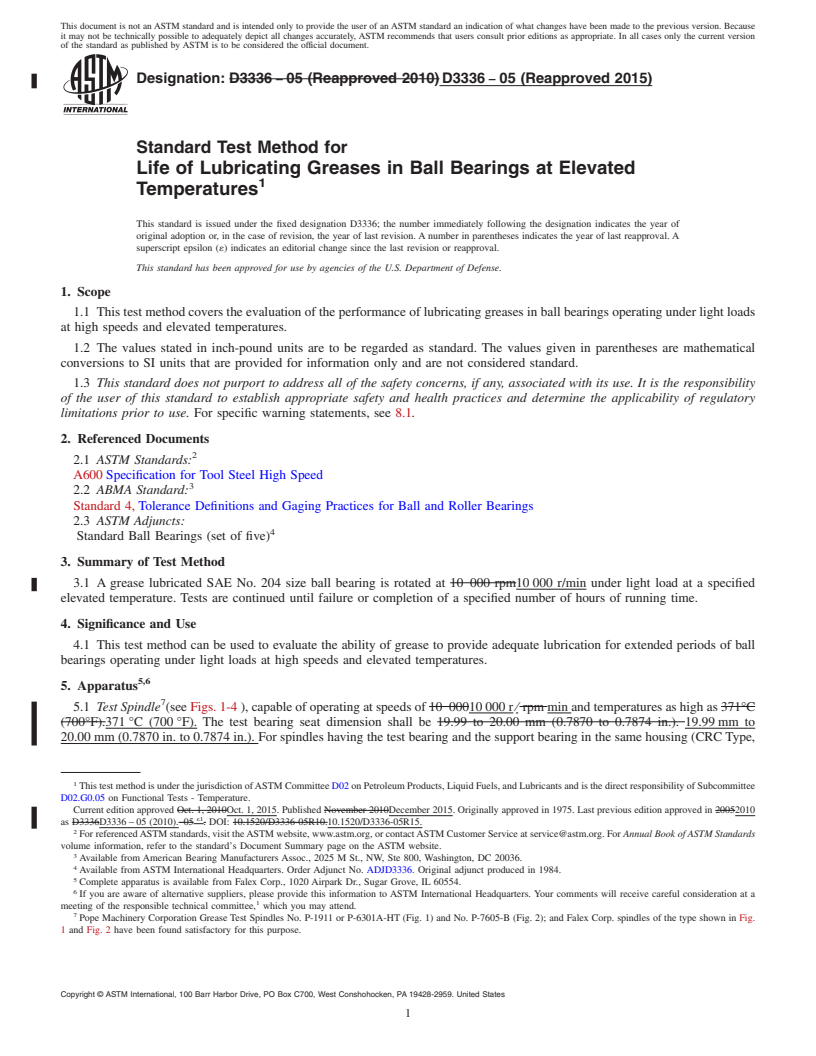

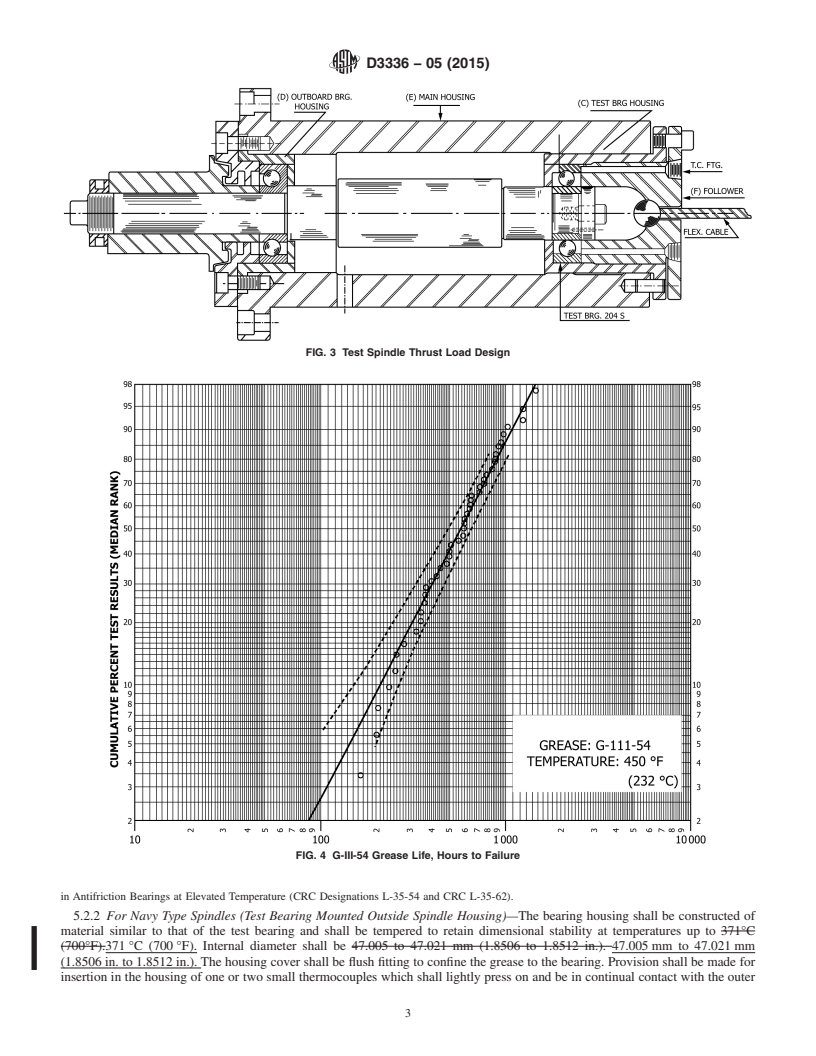

5.1 Test Spindle (see Figs. 1-4 ), capable of operating at speeds of 10 00010 000 r ⁄ rpm min and temperatures as high as 371°C

(700°F).371 °C (700 °F). The test bearing seat dimension shall be 19.99 to 20.00 mm (0.7870 to 0.7874 in.). 19.99 mm to

20.00 mm (0.7870 in. to 0.7874 in.). For spindles having the test bearing and the support bearing in the same housing (CRC Type,

1

This test method is under the jurisdiction of ASTM Committee D02 on Petroleum Products, Liquid Fuels, and Lubricants and is the direct responsibility of Subcommittee

D02.G0.05 on Functional Tests - Temperature.

Current edition approved Oct. 1, 2010Oct. 1, 2015. Published November 2010December 2015. Originally approved in 1975. Last previous edition approved in 20052010

ε1

as D3336D3336 – 05 (2010).–05 . DOI: 10.1520/D3336-05R10.10.1520/D3336-05R15.

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM Standards

volume information, refer to the standard’s Document Summary page on the ASTM website.

3

Available from American Bearing Manufacturers Assoc., 2025 M St., NW, Ste 800, Washington, DC 20036.

4

Available from ASTM International Headquarters. Order Adjunct No. ADJD3336. Original adjunct produced in 1984.

5

Complete apparatus is available from Falex Corp., 1020 Airpark Dr., Sugar Grove, IL 60554.

6

If you are aware of alternative suppliers, please provide this information to ASTM International Headquarters. Your comments will receive careful consideration at a

1

meeting of the responsible technical committee, which you may attend.

7

Pope Machinery Corporation Grease Test Spindles No. P-1911 or P-6301A-HT (Fig. 1) and No. P-7605-B (Fig. 2); and Falex Corp. spindles of the type shown in Fig.

1 and Fig. 2 have been found satisfactory for this purpose.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

D3336 − 05 (2015)

FIG. 1 Test Spindle (Both Bearings Floating)

FIG. 2 Test Spindle (with Radial Load)

Figs. 1-3) (Note 2) the internal construction of the spindle shall be such that the outboard support bearing, or both bearings are

free to float axially in the housing. In designs where both bearings are free to float, the spindle shaft shall have a 0.508 to 0.762

mm (0.020 to 0.030 in.) 0.508 mm to 0.762 mm (0.020 in. to 0.

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.