ASTM F1458-04(2008)

(Test Method)Standard Test Method for Measurement of Cut Resistance to Chain Saw of Foot Protective Devices

Standard Test Method for Measurement of Cut Resistance to Chain Saw of Foot Protective Devices

SIGNIFICANCE AND USE

The purpose of this test method is to provide a measurable criterion of performance defining the level of cut resistance to the cutting action of a saw chain provided by foot protective devices.

The protection, which can be demonstrated by the foot protective devices, tested in accordance with this test method, is achieved by (1) the material resisting cutting when put in contact with the moving saw chain; (2) a part of the material being drawn into the saw chain and drive mechanism to block the saw chain movement; (3) the materials resisting cutting and absorbing rotational energy so that saw chain speed can be slowed down sufficiently to stop the movement of the saw chain; or (4) any combination of these.

In case of a dispute arising from differences in reported test results, when using this test method for acceptance testing of commercial shipments, the purchaser and the supplier should perform comparative tests to determine if there is a statistical bias between their laboratories. Competent statistical assistance is recommended for the investigation of bias. As a minimum, the two parties should take a group of test specimens from the same lot of components to be evaluated. The test specimens should then be randomly assigned in equal numbers to each laboratory for testing. If a bias is found, either its cause must be determined and corrected, or the purchaser and the supplier must agree to interpret future test results in light of the known bias.

SCOPE

1.1 This test method measures cut resistance of foot protective devices that are designed to protect the foot when operating a chain saw.

1.2 This test method may be used to test for compliance to minimum performance requirements in established safety standards.

1.2.1 By agreement between the purchaser and the supplier, or as required by established safety standards, this test method can be used to determine any one or both of the following: (1) chainspeed 50 (CS50), (2) success/failure (jamming/chain stop) at specified chain speed.

1.3 This test method may be used to determine levels of protection for areas of coverage as stipulated in established safety standards.

1.4 The values stated in SI units are to be regarded as standard.

Note 1—The values stated in each system may not be exact equivalents; therefore, each system must be used independently of the other, without combining values in any way.

1.5 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Buy Standard

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: F1458 − 04(Reapproved 2008)

Standard Test Method for

Measurement of Cut Resistance to Chain Saw of Foot

Protective Devices

This standard is issued under the fixed designation F1458; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope D1776 Practice for Conditioning and Testing Textiles

F1414 Test Method for Measurement of Cut Resistance to

1.1 This test method measures cut resistance of foot protec-

Chain Saw in Lower Body (Legs) Protective Clothing

tive devices that are designed to protect the foot when

F1494 Terminology Relating to Protective Clothing

operating a chain saw.

2.2 AATCC Test Methods:

1.2 This test method may be used to test for compliance to

AATCC 96 Dimensional Changes in Laundering of Woven

minimum performance requirements in established safety stan-

and Knitted Fabrics, Except Wool (1988)

dards.

AATCC 158 Dimensional Changes on Drycleaning in Per-

1.2.1 By agreement between the purchaser and the supplier,

chloroethylene: Machine Method

or as required by established safety standards, this test method

2.3 Military Standards:

can be used to determine any one or both of the following: (1)

MIL-STD-105 Sampling Procedure and Tables for Inspec-

chainspeed 50 (CS50), (2) success/failure (jamming/chain

tion by Attributes

stop) at specified chain speed.

MIL-C-12369 Cloth, Ballistic, Nylon

1.3 This test method may be used to determine levels of

2.4 Federal Standard:

protection for areas of coverage as stipulated in established

FS 5100-86 Type II, Cloth, Duck, Nylon, Polyurethane

safety standards.

Coated

1.4 The values stated in SI units are to be regarded as

standard. 3. Terminology

3.1 Definitions:

NOTE 1—The values stated in each system may not be exact equiva-

lents; therefore, each system must be used independently of the other,

3.1.1 centerline, n—in foot protective devices, a line that

without combining values in any way.

extendsfromthetoeofthefootwearhorizontallyalongthesole

1.5 This standard does not purport to address all of the

to the heel vertically to the top of the footwear, and diagonally

safety concerns, if any, associated with its use. It is the

to the point of intersection at the toe.

responsibility of the user of this standard to establish appro-

3.1.2 chain saw, n—a portable power-operated tool that has

priate safety and health practices and determine the applica-

cutters linked in a chain used for cutting wood.

bility of regulatory limitations prior to use.

3.1.3 chain speed, n—the velocity of synchronized move-

ment of linked cutters around a bar and sprocket.

2. Referenced Documents

3.1.4 chainspeed 50 (CS50), n—for chain saw protection,

2.1 ASTM Standards:

the mean velocity at which cut through occurs.

D123 Terminology Relating to Textiles

3.1.4.1 Discussion—This value establishes the relationship

D1056 Specification for Flexible Cellular Materials—

between the probability of cutting through the chain saw leg

Sponge or Expanded Rubber

protective clothing (or foot protective device) and the speed of

the saw chain. For lower chain speeds, the probability of cut

ThistestmethodisunderthejurisdictionofASTMCommitteeF23onPersonal

Protective Clothing and Equipment and is the direct responsibility of Subcommittee

F23.20 on Physical. Available from American Association of Textile Chemists and Colorists

Current edition approved June 15, 2008. Published July 2008. Originally (AATCC), P.O. Box 12215, Research Triangle Park, NC 27709, http://

approved in 1998. Last previous edition approved in 2004 as F1458 - 04. DOI: www.aatcc.org.

10.1520/F1458-04R08. Available from Standardization Documents Order Desk, DODSSP, Bldg. 4,

For referenced ASTM standards, visit the ASTM website, www.astm.org, or Section D, 700 Robbins Ave., Philadelphia, PA 19111-5098, http://

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM www.dodssp.daps.mil.

Standards volume information, refer to the standard’s Document Summary page on Available from Superintendent of Documents, U.S. Government Printing

the ASTM website. Office, Washington, DC 20402.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

F1458 − 04 (2008)

through approaches zero, while for higher chain speeds, the an electronic means to measure chain speed just prior to

probability of cut through approaches one. contact with test specimen and after contact is initiated.

3.1.5 chain stop, n—for chain saw cut resistance, the

5. Significance and Use

resultingactionwhenamaterialclogs(jams)thedrivesprocket

or slows the speed sufficiently to prevent advancement of the 5.1 The purpose of this test method is to provide a measur-

saw chain.

able criterion of performance defining the level of cut resis-

tance to the cutting action of a saw chain provided by foot

3.1.6 cut resistance, n—the ability of a material, while in

protective devices.

contact with the linked cutters, to resist cut through of the

cutters of a moving saw chain, independent of either jamming 5.2 The protection, which can be demonstrated by the foot

or chain stop. protective devices, tested in accordance with this test method,

is achieved by (1) the material resisting cutting when put in

3.1.7 foot, n—the terminal part of the vertebrate leg, includ-

contact with the moving saw chain; (2) a part of the material

ing the ankle, upon which an individual stands.

being drawn into the saw chain and drive mechanism to block

3.1.8 foot protective device, n— for chain saw cut

thesawchainmovement;(3)thematerialsresistingcuttingand

resistance, an article of personal equipment which covers the

absorbing rotational energy so that saw chain speed can be

foot and ankle for the purpose of providing limited protection

slowed down sufficiently to stop the movement of the saw

from injury due to contact with a moving saw chain.

chain; or (4) any combination of these.

3.1.9 footwear, n—a boot or shoe of any construction.

5.3 In case of a dispute arising from differences in reported

3.1.10 gaiter, n—for chain saw cut resistance, a foot pro-

test results, when using this test method for acceptance testing

tective device permanently attached to the outside of the of commercial shipments, the purchaser and the supplier

footwear.

should perform comparative tests to determine if there is a

statistical bias between their laboratories. Competent statistical

3.1.11 jamming, n—for chain saw cut resistance, the clog-

assistance is recommended for the investigation of bias. As a

ging action manifested by a protective garment or device that

minimum, the two parties should take a group of test speci-

can produce a chain stop.

mensfromthesamelotofcomponentstobeevaluated.Thetest

3.1.12 sawchain,n—aclosedloopofcutterslinkedtogether

specimens should then be randomly assigned in equal numbers

for use in a portable power-operated tool.

to each laboratory for testing. If a bias is found, either its cause

3.1.13 toe area cut zone, n— in the testing of foot protective must be determined and corrected, or the purchaser and the

devices, that area excluding the sole that extends from the supplier must agree to interpret future test results in light of the

frontmost part of the footwear to a vertical plane 15 6 0.25 known bias.

mm behind the toe box; or in the absence of a toe box, the area

that extends to a vertical plane 65 6 6.25 mm from the front of 6. Apparatus

the footwear.

6.1 Specimen Holder for Calibration, in accordance with

3.1.14 toe box, n—in testing of foot protective devices, a

Test Method F1414.

component inserted into the toe area of footwear.

6.2 Mounting Bracket for Footwear and Footwear with

3.1.15 upper, n—that area of the footwear above the sole.

Protective Devices:

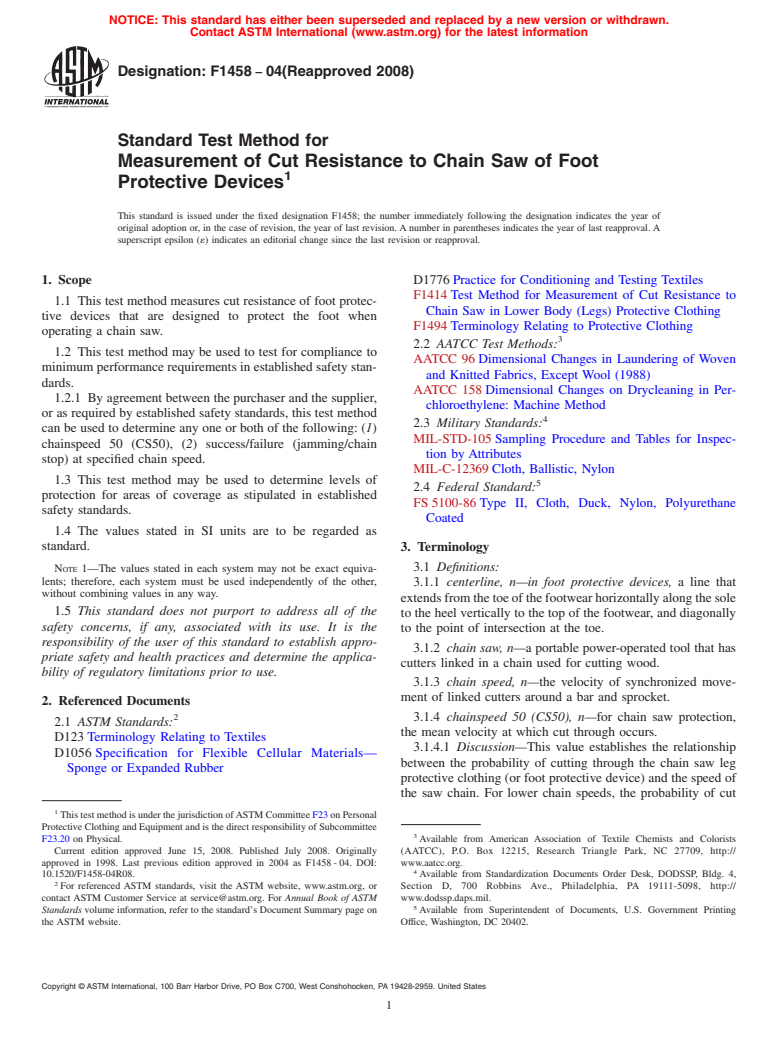

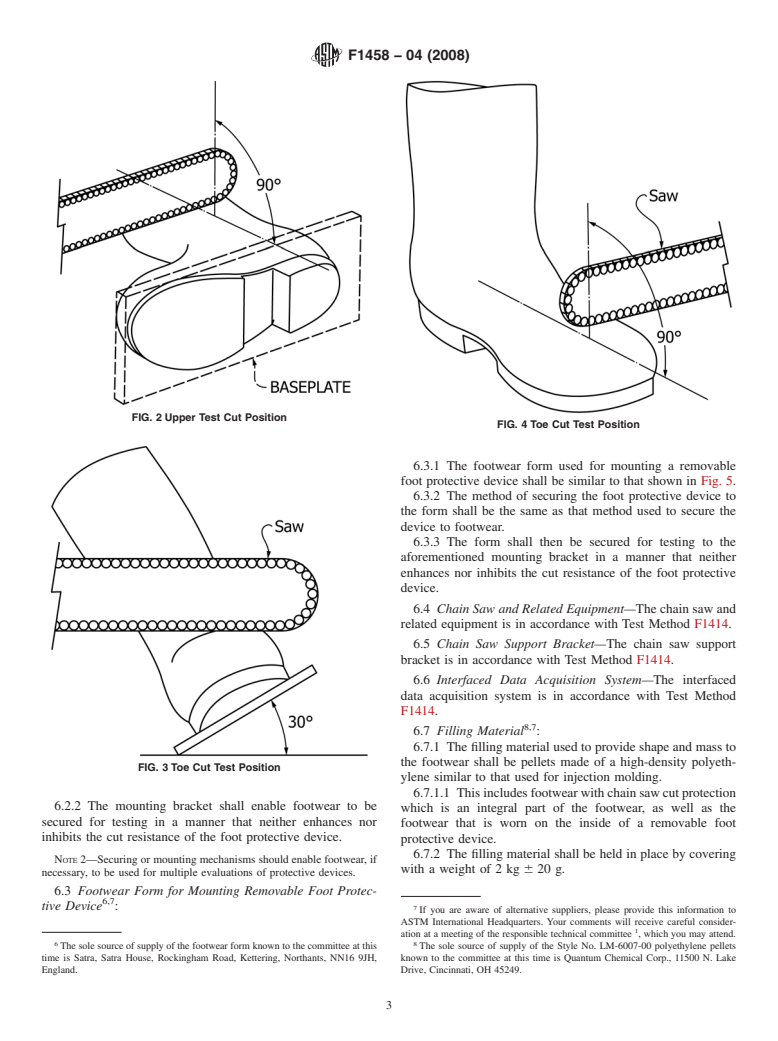

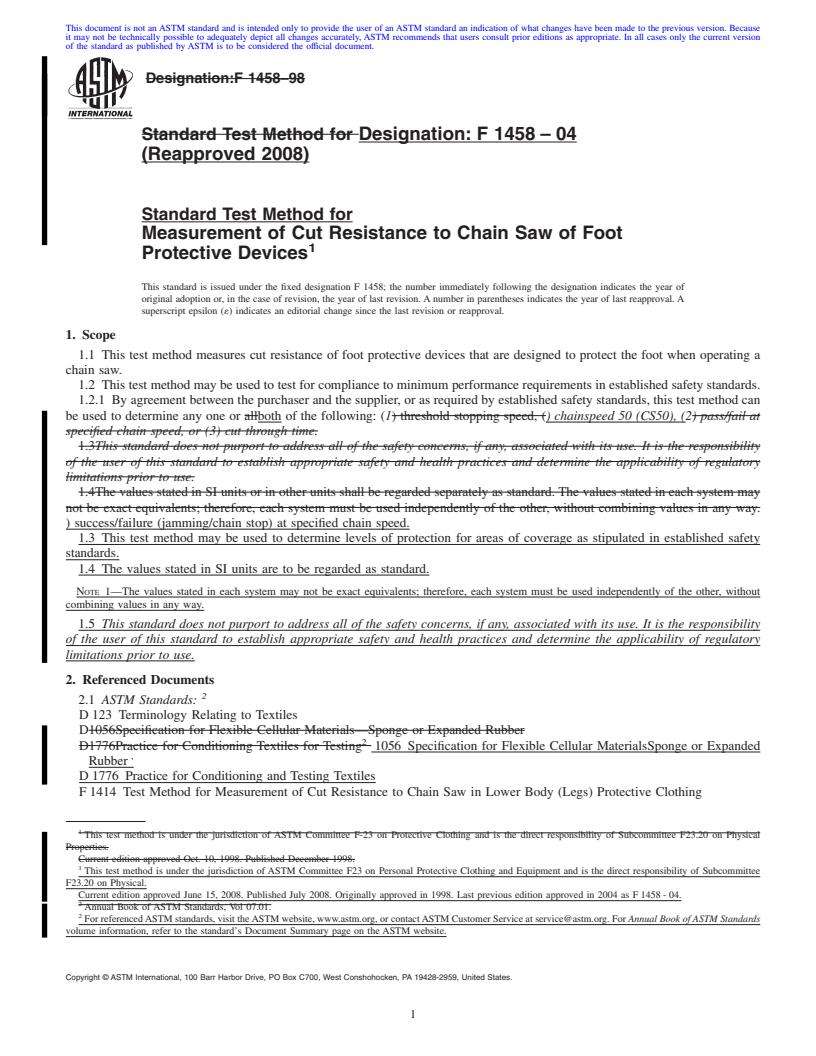

6.2.1 The mounting bracket must enable the footwear to be

3.1.16 upper cut zone, n— in the testing of foot protective

moved so that test cuts can be made at stipulated positions (see

devices, the area starting at the top of the area of protection on

Fig. 1 to 4).

the footwear and extending downward to include the entire

upper, but excluding the toe area cut zone.

3.2 Fordefinitionsofotherprotectiveclothingtermsusedin

this test method, refer to Terminology F1494.

4. Summary of Test Method

4.1 Test specimens are securely mounted on a test appara-

tus.

4.2 Achain saw, of specific characteristic and operating at a

designatedspeed,isbroughtintocontactwiththetestspecimen

at specified locations.

4.2.1 Thecuttingactionofthesawchainwillachieveoneof

three results (1) complete cut through, (2) no cut through while

saw chain continues to run, or (3) complete chain stop.

4.3 Data collection of cut resistance and CS50 is measured

electronically by means of wires placed on the top and the

bottom of the test specimen to measure cut through time, and FIG. 1 Upper Cut Test Position

F1458 − 04 (2008)

FIG. 2 Upper Test Cut Position

FIG. 4 Toe Cut Test Position

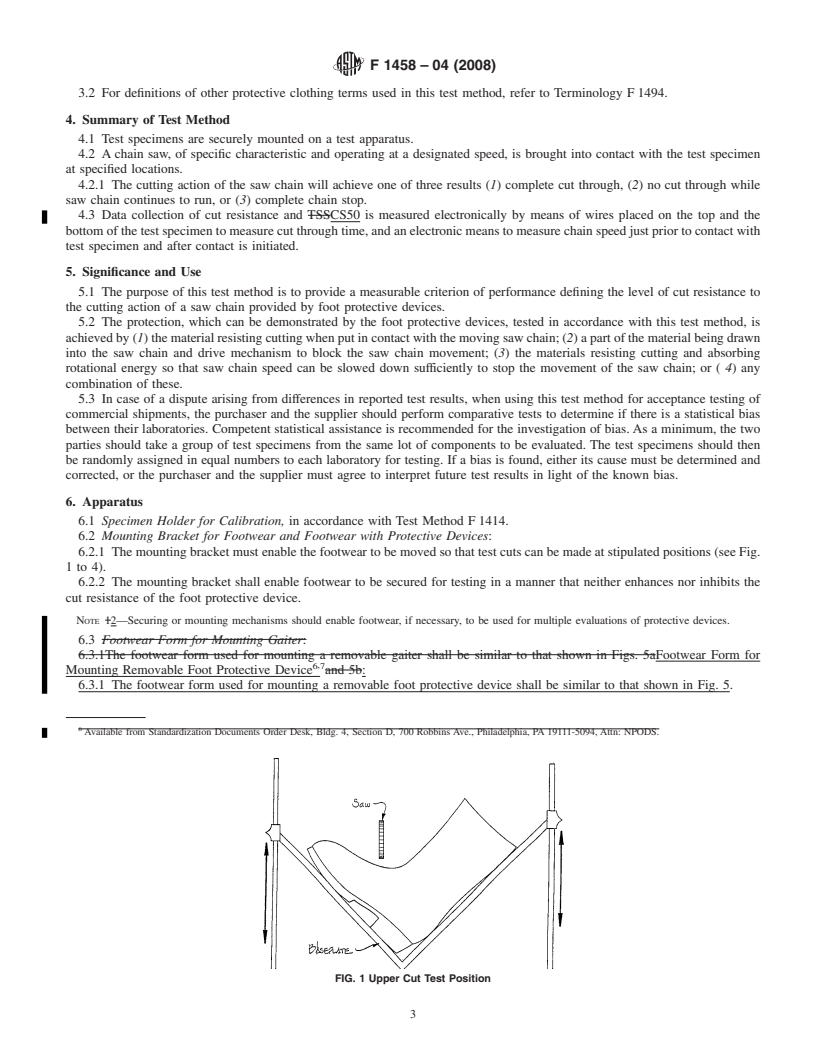

6.3.1 The footwear form used for mounting a removable

foot protective device shall be similar to that shown in Fig. 5.

6.3.2 The method of securing the foot protective device to

the form shall be the same as that method used to secure the

device to footwear.

6.3.3 The form shall then be secured for testing to the

aforementioned mounting bracket in a manner that neither

enhances nor inhibits the cut resistance of the foot protective

device.

6.4 Chain Saw and Related Equipment—The chain saw and

related equipment is in accordance with Test Method F1414.

6.5 Chain Saw Support Bracket—The chain saw support

bracket is in accordance with Test Method F1414.

6.6 Interfaced Data Acquisition System—The interfaced

data acquisition system is in accordance with Test Method

F1414.

8,7

6.7 Filling Material :

6.7.1 The filling material used to provide shape and mass to

the footwear shall be pellets made of a high-density polyeth-

FIG. 3 Toe Cut Test Position

ylene similar to that used for injection molding.

6.7.1.1 Thisincludesfootwearwithchainsawcutprotection

6.2.2 The mounting bracket shall enable footwear to be

which is an integral part of the footwear, as well as the

secured for testing in a manner that neither enhances nor

footwear that is worn on the inside of a removable foot

inhibits the cut resistance of the foot protective device.

protective device.

6.7.2 The filling material shall be held in place by covering

NOTE 2—Securing or mounting mechanisms should enable footwear, if

with a weight of 2 kg 6 20 g.

necessary, to be used for multiple evaluations of protective devices.

6.3 Footwear Form for Mounting Removable Foot Protec-

6,7

tive Device :

If you are aware of alternative suppliers, please provide this information to

ASTM International Headquarters. Your comments will receive careful consider-

ation at a meeting of the responsible technical committee , which you may attend.

6 8

The sole source of supply of the footwear form known to the committee at this The sole source of supply of the Style No. LM-6007-00 polyethylene pellets

time is Satra, Satra House, Rockingham Road, Kettering, Northants, NN16 9JH, known to the committee at this time is Quantum Chemical Corp., 11500 N. Lake

England. Drive, Cincinnati, OH 45249.

F1458 − 04 (2008)

determination must also consider how many units constitute a

meaningful measurement of consistent quality that will result

in achievement of similar values.

8.2 Number of Specimens:

8.2.1 A pair is considered as two test specimens, one

left-foot protective device and one right-foot protective device.

8.2.2 If this test method is used to determine CS50 a

minimum of six specimens (3 pairs) at each test cut position

will be needed.

8.2.3 If this test method is used to determine “pass/fail” at a

specific saw chain speed of an established safety standard, a

minimum of six specimens (3 pairs) at each test cut position

must pass.

8.2.4 If this test method is used to determine cut through

timeataspecifiedspeed,aminimumofsixspecimens(3pairs)

at each test cut position will be needed.

9. Calibration

9.1 The calibration procedures described in Test Method

F1414 shall be utilized for this test method.

10. Conditioning

10.1 Footwear:

10.1.1 Place the footwear in a room with an ambient

condition of 70 6 10°F (21 6 6°C) and a relative humidity of

50 6 15 %.

10.1.2 Footwear shall be conditioned in this manner for at

least 24 h.

FIG. 5 Footwear Form for Gaiter/Liner

10.2 Foot Protective Devices Permanently Attached:

NOTE 3—The weight can be a bag containing leadshot, sand, steel

10.2.1 Textile Materials—Condition textile foot protective

pellets, or some other material to achieve the desired mass.

devices that are permanently attached to the footwear in the

same manner as footwear.

7. Hazards

10.2.2 Non-Textile Materials—Condition non-textile foot

NOTE 4—Warning: The chain saw equipment used in the procedure of

protective devices that are permanently attached to the foot-

this test method can pose a potential danger to the technician if specific

safety precautions are not followed.

wear in the same manner as footwear.

7.1 As a minimum safety precaution, it is suggested that the

10.3 Foot Protective Devices Not Permanently Attached:

spark plug wire be disengaged until the engine needs to be

10.3.1 Textile Materials—Condition textile foot protective

started.

devicesthatarenotpermanentlyattachedtothefootwearinthe

same manner as footwear.

7.2 As a further safety precaution, it is suggested that the

10.3.2 Non-Textile Materials—Condition non-textile foot

sparkplugwirebegroundedbycircuitryaftercuttingthelower

protective devices that are not permanently attached to the

wireofthedatacollectionsystem.Ifthesawchainstopsbefore

footwear in the same manner as footwear.

the wire is cut, or if the saw chain slides over the specimen, a

timershouldlimitthetestandstoptheenginebygroundingthe

11. Procedure

electric circuitry of the chain saw.

11.1 Preparation and Mounting of Specimen:

7.3 The technician performing these tests should use hear-

11.1.1 Footwear with Integral Chain Saw Protection or

ing protection to avoid potential loss of hearing.

Gaiter

7.4 The technician performing these tests should use eye

11.1.1.1 To test the toe area cut zone of footwear with

protection to avoid potential eye injury.

integral chain saw protection or gaiter, fill the footwear with

7.5 The chain saw engine should be vented to prevent

filling material to a level above the ankle area of the footwear.

potential danger posed by carbon monoxide. The weight in accor

...

This document is not anASTM standard and is intended only to provide the user of anASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

Designation:F 1458–98

Standard Test Method for Designation:F 1458–04

(Reapproved 2008)

Standard Test Method for

Measurement of Cut Resistance to Chain Saw of Foot

Protective Devices

This standard is issued under the fixed designation F 1458; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope

1.1 This test method measures cut resistance of foot protective devices that are designed to protect the foot when operating a

chain saw.

1.2 This test method may be used to test for compliance to minimum performance requirements in established safety standards.

1.2.1 By agreement between the purchaser and the supplier, or as required by established safety standards, this test method can

be used to determine any one or allboth of the following: (1) threshold stopping speed, () chainspeed 50 (CS50), (2) pass/fail at

specified chain speed, or (3) cut through time.

1.3This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility

of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory

limitations prior to use.

1.4The values stated in SI units or in other units shall be regarded separately as standard. The values stated in each system may

not be exact equivalents; therefore, each system must be used independently of the other, without combining values in any way.

) success/failure (jamming/chain stop) at specified chain speed.

1.3 This test method may be used to determine levels of protection for areas of coverage as stipulated in established safety

standards.

1.4 The values stated in SI units are to be regarded as standard.

NOTE 1—The values stated in each system may not be exact equivalents; therefore, each system must be used independently of the other, without

combining values in any way.

1.5 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility

of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory

limitations prior to use.

2. Referenced Documents

2.1 ASTM Standards:

D 123 Terminology Relating to Textiles

D1056Specification for Flexible Cellular Materials—Sponge or Expanded Rubber

D1776Practice for Conditioning Textiles for Testing 1056 Specification for Flexible Cellular MaterialsSponge or Expanded

,

Rubber

D 1776 Practice for Conditioning and Testing Textiles

F 1414 Test Method for Measurement of Cut Resistance to Chain Saw in Lower Body (Legs) Protective Clothing

This test method is under the jurisdiction of ASTM Committee F-23 on Protective Clothing and is the direct responsibility of Subcommittee F23.20 on Physical

Properties.

Current edition approved Oct. 10, 1998. Published December 1998.

This test method is under the jurisdiction of ASTM Committee F23 on Personal Protective Clothing and Equipment and is the direct responsibility of Subcommittee

F23.20 on Physical.

Current edition approved June 15, 2008. Published July 2008. Originally approved in 1998. Last previous edition approved in 2004 as F 1458 - 04.

Annual Book of ASTM Standards, Vol 07.01.

For referencedASTM standards, visit theASTM website, www.astm.org, or contactASTM Customer Service at service@astm.org. For Annual Book of ASTM Standards

volume information, refer to the standard’s Document Summary page on the ASTM website.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

F 1458–04 (2008)

F 1494 Terminology Relating to Protective Clothing

2.2 AATCC Test Methods:

AATCC 96 Dimensional Changes in Laundering of Woven and Knitted Fabrics, Except Wool (1988)

AATCC 158 Dimensional Changes on Drycleaning in Perchloroethylene: Machine Method

2.3 Military Standards:

MIL-STD-105 Sampling Procedure and Tables for Inspection by Attributes

MIL-C-12369 Cloth, Ballistic, Nylon

2.4 Federal Standard:

FS 5100-86 Type II, Cloth, Duck, Nylon, Polyurethane Coated

3. Terminology

3.1 Definitions:

3.1.1 centerline, n—in foot protective devices, a line that extends from the toe of the footwear horizontally along the sole to the

heel vertically to the top of the footwear, and diagonally to the point of intersection at the toe.

3.1.2 chain saw, n—a portable power-operated tool that has cutters linked in a chain used for cutting wood.

3.1.3 chain speed, n—the velocity of synchronized movement of linked cutters around a bar and sprocket.

3.1.4 chainspeed 50 (CS50), n—for chain saw protection, the mean velocity at which cut through occurs.

3.1.4.1 Discussion—This value establishes the relationship between the probability of cutting through the chain saw leg

protectiveclothing(orfootprotectivedevice)andthespeedofthesawchain.Forlowerchainspeeds,theprobabilityofcutthrough

approaches zero, while for higher chain speeds, the probability of cut through approaches one.

3.1.5 chain stop, n—for chain saw cut resistance, the resulting action when a material clogs (jams) the drive sprocket or slows

the speed sufficiently to prevent advancement of the saw chain.

3.1.53.1.6 cut resistance, n—the ability of a material, while in contact with the linked cutters, to resist penetration of the cutter

of a moving saw chain, independent of either jamming or chain stop.

3.1.6cut-through time, n—the time required for a running saw chain to effect complete penetration through a protective device.

—the ability of a material, while in contact with the linked cutters, to resist cut through of the cutters of a moving saw chain,

independent of either jamming or chain stop.

3.1.7 foot, n—the terminal part of the vertebrate leg, including the ankle, upon which an individual stands (see foot protective

device). stands.

3.1.8 foot protective device, n— for chain saw cut resistance, an article of personal equipment worn overwhich covers the foot

and ankle for the purpose of providing limited protection from injury due to contact with a moving saw chain.

3.1.9 footwear, n—a boot or shoe of any construction.

3.1.10 gaiter, n—for chain saw cut resistance, a foot protective device worn outside the footwear. a foot protective device

permanently attached to the outside of the footwear.

3.1.11 jamming, n—for chain saw cut resistance, the clogging action manifested by a protective garment or device that can

produce a chain stop.

3.1.12 liner, n—a foot protective device worn inside the footwear.

3.1.13saw chain, n—a closed loop of cutters linked together for use in a portable power-operated tool.

3.1.14chain speed 50 (CS50), n— for chain saw cut protection, the median velocity at which cut through occurs.

3.1.14.1Discussion—This value establishes the relationship between the probability of cutting through the protective clothing

(or foot protective device) and the speed of the chain saw. For low chain speeds, the probability of cut through approaches zero,

while for higher chain speeds, the probability of cut through approaches one.

3.1.15

3.1.13 toe area cut zone, n— in the testing of foot protective devices,thatareaexcludingthesolethatextendsfromthefrontmost

part of the footwear to a vertical plane 15 6 0.25 mm behind the toe box; or in the absence of a toe box, the area that extends to

a vertical plane 65 6 6.25 mm from the front of the footwear.

3.1.16

3.1.14 toe box, n—in testing of foot protective devices, a component inserted into the toe area of footwear.

3.1.17

3.1.15 upper, n—that area of the footwear above the sole.

3.1.18

3.1.16 upper cut zone, n— in the testing of foot protective devices, the area starting at the top of the area of protection on the

footwear and extending downward to include the entire upper, but excluding the toe area cut zone.

Annual Book of ASTM Standards, Vol 08.01.

Available from American Association of Textile Chemists and Colorists (AATCC), P.O. Box 12215, Research Triangle Park, NC 27709, http://www.aatcc.org.

Annual Book of ASTM Standards, Vol 11.03.

Available from Standardization Documents Order Desk, DODSSP, Bldg. 4, Section D, 700 Robbins Ave., Philadelphia, PA 19111-5098, http://www.dodssp.daps.mil.

Available from American Association of Textile Chemists and Colorists, P.O. Box 12215, Research Triangle Park, NC 27709.

Available from Superintendent of Documents, U.S. Government Printing Office, Washington, DC 20402.

F 1458–04 (2008)

3.2 For definitions of other protective clothing terms used in this test method, refer to Terminology F 1494.

4. Summary of Test Method

4.1 Test specimens are securely mounted on a test apparatus.

4.2 A chain saw, of specific characteristic and operating at a designated speed, is brought into contact with the test specimen

at specified locations.

4.2.1 The cutting action of the saw chain will achieve one of three results (1) complete cut through, (2) no cut through while

saw chain continues to run, or (3) complete chain stop.

4.3 Data collection of cut resistance and TSSCS50 is measured electronically by means of wires placed on the top and the

bottom of the test specimen to measure cut through time, and an electronic means to measure chain speed just prior to contact with

test specimen and after contact is initiated.

5. Significance and Use

5.1 The purpose of this test method is to provide a measurable criterion of performance defining the level of cut resistance to

the cutting action of a saw chain provided by foot protective devices.

5.2 The protection, which can be demonstrated by the foot protective devices, tested in accordance with this test method, is

achievedby(1)thematerialresistingcuttingwhenputincontactwiththemovingsawchain;(2)apartofthematerialbeingdrawn

into the saw chain and drive mechanism to block the saw chain movement; (3) the materials resisting cutting and absorbing

rotational energy so that saw chain speed can be slowed down sufficiently to stop the movement of the saw chain; or ( 4) any

combination of these.

5.3 In case of a dispute arising from differences in reported test results, when using this test method for acceptance testing of

commercial shipments, the purchaser and the supplier should perform comparative tests to determine if there is a statistical bias

between their laboratories. Competent statistical assistance is recommended for the investigation of bias.As a minimum, the two

parties should take a group of test specimens from the same lot of components to be evaluated. The test specimens should then

be randomly assigned in equal numbers to each laboratory for testing. If a bias is found, either its cause must be determined and

corrected, or the purchaser and the supplier must agree to interpret future test results in light of the known bias.

6. Apparatus

6.1 Specimen Holder for Calibration, in accordance with Test Method F 1414.

6.2 Mounting Bracket for Footwear and Footwear with Protective Devices:

6.2.1 The mounting bracket must enable the footwear to be moved so that test cuts can be made at stipulated positions (see Fig.

1to4).

6.2.2 The mounting bracket shall enable footwear to be secured for testing in a manner that neither enhances nor inhibits the

cut resistance of the foot protective device.

NOTE 12—Securing or mounting mechanisms should enable footwear, if necessary, to be used for multiple evaluations of protective devices.

6.3 Footwear Form for Mounting Gaiter:

6.3.1The footwear form used for mounting a removable gaiter shall be similar to that shown in Figs. 5aFootwear Form for

6,7

Mounting Removable Foot Protective Device and 5b:

6.3.1 The footwear form used for mounting a removable foot protective device shall be similar to that shown in Fig. 5.

Available from Standardization Documents Order Desk, Bldg. 4, Section D, 700 Robbins Ave., Philadelphia, PA 19111-5094, Attn: NPODS.

FIG. 1 Upper Cut Test Position

F 1458–04 (2008)

FIG. 2 Upper Cut Test Cut Position

FIG. 3 Toe Cut Test Position

6.3.2 The method of securing the gaiter foot protective device to the form shall be the same as that method used to secure the

gaiterdevice to footwear.

6.3.3 The form shall then be secured for testing to the aforementioned mounting bracket in a manner that neither enhances nor

inhibits the cut resistance of the foot protective device.

6.4 Footwear Form for Mounting Liner:

6.4.1The footwear form used for mounting a liner shall be similar to that shown in Figs. 5a and 5b.

The sole source of supply of the footwear form known to the committee at this time is Satra, Satra House, Rockingham Road, Kettering, Northants, NN16 9JH, England.

Available from Superintendent of Documents, U.S. Government Printing Office, Washington, DC 20402.

If you are aware of alternative suppliers, please provide this information to ASTM International Headquarters. Your comments will receive careful consideration at a

meeting of the responsible technical committee , which you may attend.

F 1458–04 (2008)

FIG. 4 Toe Cut Test Position

6.4.2The method of securing the liner to the form shall be the same as that method used to secure the liner to the foot.

6.4.3The form shall then be secured for testing to the aforementioned mounting bracket in a manner that neither enhances nor

inhibits the cut resistance of the foot protective device.

6.5Chain Saw and Related Equipment —The chain saw and related equipment is in accordance with Test Method F 1414.

6.6

6.5 Chain Saw Support Bracket—The chain saw support bracket is in accordance with Test Method F 1414.

6.7

6.6 Interfaced Data Acquisition System—The interfaced data acquisition system is in accordance with Test Method F 1414.

6.8

8 ,7

6.7 Filling Material :

6.8.1The filling material used to provide shape and mass to the footwear shall be pellets made of a high-density polyethylene

similar to that used for injection molding.

6.8.2The filling material shall be held in place by covering with a weight of 2 kg620 g.

6.7.1 The filling material used to provide shape and mass to the footwear shall be pellets made of a high-density polyethylene

similar to that used for injection molding.

6.7.1.1 This includes footwear with cha

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.