ASTM D790-15

(Test Method)Standard Test Methods for Flexural Properties of Unreinforced and Reinforced Plastics and Electrical Insulating Materials

Standard Test Methods for Flexural Properties of Unreinforced and Reinforced Plastics and Electrical Insulating Materials

SIGNIFICANCE AND USE

5.1 Flexural properties as determined by this test method are especially useful for quality control and specification purposes. They include:

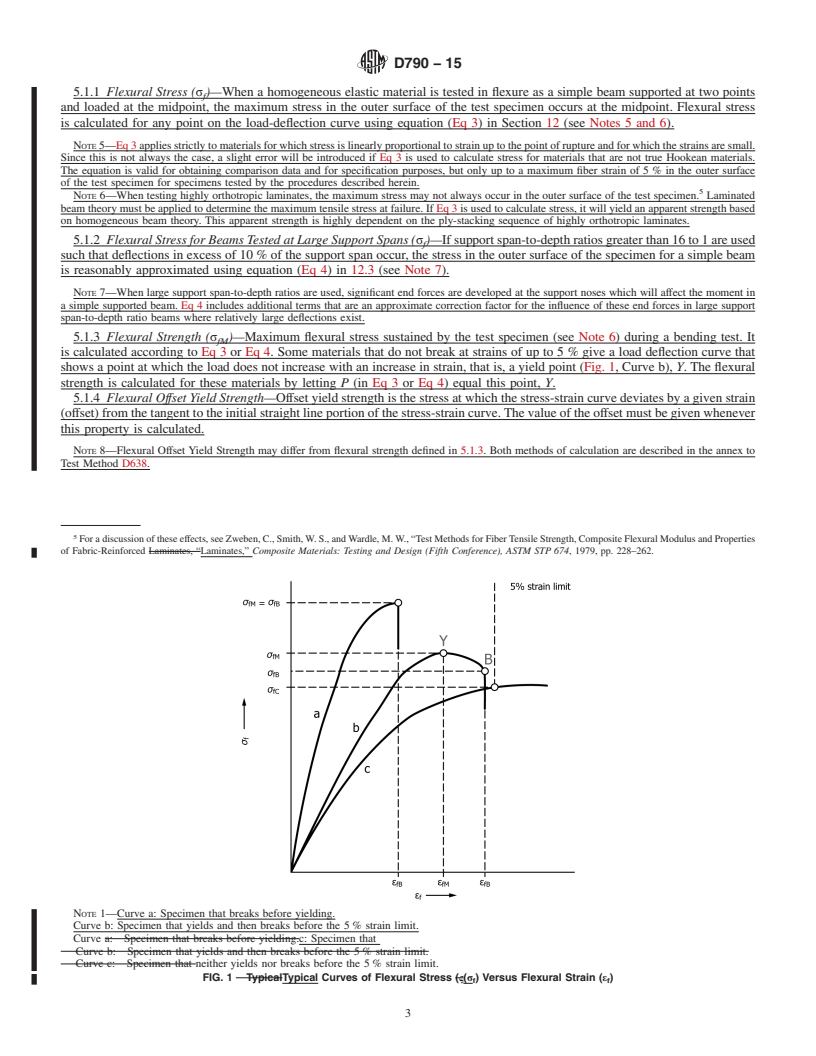

5.1.1 Flexural Stress (σf)—When a homogeneous elastic material is tested in flexure as a simple beam supported at two points and loaded at the midpoint, the maximum stress in the outer surface of the test specimen occurs at the midpoint. Flexural stress is calculated for any point on the load-deflection curve using equation (Eq 3) in Section 12 (see Notes 5 and 6).

Note 5: Eq 3 applies strictly to materials for which stress is linearly proportional to strain up to the point of rupture and for which the strains are small. Since this is not always the case, a slight error will be introduced if Eq 3 is used to calculate stress for materials that are not true Hookean materials. The equation is valid for obtaining comparison data and for specification purposes, but only up to a maximum fiber strain of 5 % in the outer surface of the test specimen for specimens tested by the procedures described herein.

Note 6: When testing highly orthotropic laminates, the maximum stress may not always occur in the outer surface of the test specimen.5 Laminated beam theory must be applied to determine the maximum tensile stress at failure. If Eq 3 is used to calculate stress, it will yield an apparent strength based on homogeneous beam theory. This apparent strength is highly dependent on the ply-stacking sequence of highly orthotropic laminates.

5.1.2 Flexural Stress for Beams Tested at Large Support Spans (σf)—If support span-to-depth ratios greater than 16 to 1 are used such that deflections in excess of 10 % of the support span occur, the stress in the outer surface of the specimen for a simple beam is reasonably approximated using equation (Eq 4) in 12.3 (see Note 7).

Note 7: When large support span-to-depth ratios are used, significant end forces are developed at the support noses which will affect the moment in a simple supported...

SCOPE

1.1 These test methods are used to determine the flexural properties of unreinforced and reinforced plastics, including highmodulus composites and electrical insulating materials utilizing a three-point loading system to apply a load to simply supported beam (specimen). The method is generally applicable to both rigid and semi-rigid materials, but flexural strength cannot be determined for those materials that do not break or that do not fail yield in the outer surface of the test specimen within the 5.0 % strain limit.

1.2 Test specimens of rectangular cross section are injection molded or, cut from molded or extruded sheets or plates, or cut from molded or extruded shapes. Specimens must be solid and uniformly rectangular. The specimen rests on two supports and is loaded by means of a loading nose midway between the supports.

1.3 Measure deflection in one of two ways; using crosshead position or a deflectometer. Please note that studies have shown that deflection data obtained with a deflectometer will differ from data obtained using crosshead position. The method of deflection measurement shall be reported.

Note 1: Requirements for quality control in production environments are usually met by measuring deflection using crosshead position. However, more accurate measurement may be obtained by using an deflection indicator such as a deflectometer.

Note 2: Materials that do not rupture by the maximum strain allowed under this test method may be more suited to a 4-point bend test. The basic difference between the two test methods is in the location of the maximum bending moment and maximum axial fiber stresses. The maximum axial fiber stresses occur on a line under the loading nose in 3-point bending and over the area between the loading noses in 4-point bending. A four-point loading system method can be found in Test Method D6272.

1.4 The values stated in SI units are to be regarded as the standard. The val...

General Information

Relations

Buy Standard

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: D790 − 15

StandardTest Methods for

Flexural Properties of Unreinforced and Reinforced Plastics

1

and Electrical Insulating Materials

This standard is issued under the fixed designation D790; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the U.S. Department of Defense.

1. Scope* 1.5 The text of this standard references notes and footnotes

that provide explanatory material. These notes and footnotes

1.1 These test methods are used to determine the flexural

(excluding those in tables and figures) shall not be considered

properties of unreinforced and reinforced plastics, including

as requirements of the standard.

highmodulus composites and electrical insulating materials

1.6 This standard does not purport to address all of the

utilizing a three-point loading system to apply a load to simply

safety concerns, if any, associated with its use. It is the

supported beam (specimen). The method is generally appli-

responsibility of the user of this standard to establish appro-

cable to both rigid and semi-rigid materials, but flexural

priate safety and health practices and determine the applica-

strength cannot be determined for those materials that do not

bility of regulatory limitations prior to use.

break or that do not fail yield in the outer surface of the test

specimen within the 5.0 % strain limit.

NOTE 3—This standard and ISO 178 address the same subject matter,

but differ in technical content.

1.2 Test specimens of rectangular cross section are injection

molded or, cut from molded or extruded sheets or plates, or cut

2. Referenced Documents

from molded or extruded shapes. Specimens must be solid and

2

2.1 ASTM Standards:

uniformly rectangular.The specimen rests on two supports and

D618 Practice for Conditioning Plastics for Testing

is loaded by means of a loading nose midway between the

D638 Test Method for Tensile Properties of Plastics

supports.

D883 Terminology Relating to Plastics

1.3 Measure deflection in one of two ways; using crosshead

D2309 Tests for Rubber Property—Compression Set In-

positionoradeflectometer.Pleasenotethatstudieshaveshown

3

duced by Nuclear Radiation (Withdrawn 1981)

that deflection data obtained with a deflectometer will differ

D4000 Classification System for Specifying Plastic Materi-

from data obtained using crosshead position. The method of

als

deflection measurement shall be reported.

D4101 Specification for Polypropylene Injection and Extru-

NOTE 1—Requirements for quality control in production environments

sion Materials

are usually met by measuring deflection using crosshead position.

D5947 Test Methods for Physical Dimensions of Solid

However, more accurate measurement may be obtained by using an

Plastics Specimens

deflection indicator such as a deflectometer.

D6272 Test Method for Flexural Properties of Unreinforced

NOTE 2—Materials that do not rupture by the maximum strain allowed

underthistestmethodmaybemoresuitedtoa4-pointbendtest.Thebasic and Reinforced Plastics and Electrical Insulating Materi-

differencebetweenthetwotestmethodsisinthelocationofthemaximum

als by Four-Point Bending

bending moment and maximum axial fiber stresses. The maximum axial

E4 Practices for Force Verification of Testing Machines

fiberstressesoccuronalineundertheloadingnosein3-pointbendingand

E691 Practice for Conducting an Interlaboratory Study to

over the area between the loading noses in 4-point bending. A four-point

Determine the Precision of a Test Method

loading system method can be found in Test Method D6272.

4

2.2 ISO Standard:

1.4 The values stated in SI units are to be regarded as the

ISO 178 Plastics—Determination of Flexural Properties

standard. The values provided in parentheses are for informa-

tion only.

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

1

These test methods are under the jurisdiction of ASTM Committee D20 on Standards volume information, refer to the standard’s Document Summary page on

Plastics and are the direct responsibility of Subcommittee D20.10 on Mechanical the ASTM website.

3

Properties. The last approved version of this historical standard is referenced on

Current edition approved Dec. 1, 2015. Published January 2016. Originally www.astm.org.

4

approved in 1970. Last previous edition approved in 2010 as D790 – 10. DOI: Available from American National Standards Institute (ANSI), 25 W. 43rd St.,

10.1520/D0790-15. 4th Floor, New York, NY 10036, http://www.ansi.org.

*A Summary of Changes section appe

...

This document is not an ASTM standard and is intended only to provide the user of an ASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

Designation: D790 − 10 D790 − 15

Standard Test Methods for

Flexural Properties of Unreinforced and Reinforced Plastics

1

and Electrical Insulating Materials

This standard is issued under the fixed designation D790; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the U.S. Department of Defense.

1. Scope*

1.1 These test methods cover the determination of are used to determine the flexural properties of unreinforced and reinforced

plastics, including high-modulushighmodulus composites and electrical insulating materials in the form of rectangular bars molded

directly or cut from sheets, plates, or molded shapes. These test methods are utilizing a three-point loading system to apply a load

to simply supported beam (specimen). The method is generally applicable to both rigid and semirigid materials. However,semi-

rigid materials, but flexural strength cannot be determined for those materials that do not break or that do not fail yield in the outer

surface of the test specimen within the 5.0 % strain limit of these test methods. These test methods utilize a three-point loading

system applied to a simply supported beam. A four-point loading system method can be found in Test Method 5.0 % strain limit.

D6272.

1.1.1 Procedure A, designed principally for materials that break at comparatively small deflections.

1.1.2 Procedure B, designed particularly for those materials that undergo large deflections during testing.

1.1.3 Procedure A shall be used for measurement of flexural properties, particularly flexural modulus, unless the material

specification states otherwise. Procedure B may be used for measurement of flexural strength only. Tangent modulus data obtained

by Procedure A tends to exhibit lower standard deviations than comparable data obtained by means of Procedure B.

1.2 Comparative tests may be run in accordance with either procedure, provided that the procedure is found satisfactory for the

material being tested. Test specimens of rectangular cross section are injection molded or, cut from molded or extruded sheets or

plates, or cut from molded or extruded shapes. Specimens must be solid and uniformly rectangular. The specimen rests on two

supports and is loaded by means of a loading nose midway between the supports.

1.3 Measure deflection in one of two ways; using crosshead position or a deflectometer. Please note that studies have shown

that deflection data obtained with a deflectometer will differ from data obtained using crosshead position. The method of deflection

measurement shall be reported.

NOTE 1—Requirements for quality control in production environments are usually met by measuring deflection using crosshead position. However,

more accurate measurement may be obtained by using an deflection indicator such as a deflectometer.

NOTE 2—Materials that do not rupture by the maximum strain allowed under this test method may be more suited to a 4-point bend test. The basic

difference between the two test methods is in the location of the maximum bending moment and maximum axial fiber stresses. The maximum axial fiber

stresses occur on a line under the loading nose in 3-point bending and over the area between the loading noses in 4-point bending. A four-point loading

system method can be found in Test Method D6272.

1.4 The values stated in SI units are to be regarded as the standard. The values provided in parentheses are for information only.

1.5 The text of this standard references notes and footnotes that provide explanatory material. These notes and footnotes

(excluding those in tables and figures) shall not be considered as requirements of the standard.

1.6 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility

of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory

limitations prior to use.

NOTE 3—These test methods are not technically equivalent to ISO 178.This standard and ISO 178 address the same subject matter, but differ in

technical content.

1

These test methods are under the jurisdiction of ASTM Committee D20 on Plastics and are the direct responsibility of Subcommittee D20.10 on Mechanical Properties.

Current edition approved April

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.