EN 16771:2016

(Main)Railway applications - Infrastructure - Aluminothermic welding of grooved rails

Railway applications - Infrastructure - Aluminothermic welding of grooved rails

This standard defines the laboratory tests and requirements for approval of an aluminothermic welding process using welds produced in workshop conditions.

It applies to the joining of new, grooved rails as described in EN 14811 of the same profile and steel grade. Welding of construction profiles and machined profiles are not covered in this standard.

Compliance with the requirements of this standard does not in itself ensure the suitability of a welding process for specific conditions of track and traffic.

The standard does not cover welds made between different rail sections, worn rails or different rail grades.

In addition to the definitive requirements, this standard also requires the items detailed in Clause 4 to be documented. For compliance with this standard, it is important that both the definitive requirements and the documented items be satisfied.

Bahnanwendungen - Infrastruktur - Aluminothermisches Schweißen von Rillenschienen

Diese Norm legt Laborprüfungen und Anforderungen zur Zulassung eines aluminothermischen Schweißverfahrens unter Verwendung von Schweißungen fest, die unter Werkstattbedingungen hergestellt wurden.

Diese Norm umfasst die Verbindung neuer Rillenschienen, wie in EN 14811 beschrieben, des gleichen Profils und der gleichen Stahlsorte. Das Schweißen von Bauprofilen und bearbeiteten Profilen wird in dieser Norm nicht behandelt.

Die Erfüllung der Anforderungen dieser Norm bedingt jedoch nicht notwendigerweise die Eignung des Schweißprozesses unter den spezifischen Bedingungen von Oberbau und Betrieb.

Die Norm berücksichtigt keine Schweißungen unterschiedlicher Schienenquerschnitte, unterschiedlich abgenutzter Schienen und unterschiedlicher Stahlsorten.

Zusätzlich zu den in dieser Norm festgelegten Anforderungen sind gleichfalls die in Abschnitt 4 aufgeführten Angaben zu dokumentieren. Für die Konformität mit dieser Norm ist es wichtig, sowohl die festgelegten Anforderungen als auch die Dokumentation der Angaben zu erfüllen.

Applications ferroviaires - Infrastructures - Soudage par aluminothermie des rails à gorge

La présente norme définit les essais de laboratoire et les exigences pour l’approbation d’un procédé de soudage des rails par aluminothermie effectués dans des conditions opératoires d’atelier.

Elle s'applique à l'assemblage de rails à gorge neufs, tels que décrits dans l'EN 14811, de même profil et de même nuance d'acier. Elle ne traite pas du soudage des profils de construction et des profils usinés.

La conformité aux exigences de la présente norme n’assure pas par elle-même l’aptitude à l’emploi d’un procédé de soudage dans des conditions spécifiques de voie ferrée et de trafic.

La présente norme ne s'applique pas au soudage des rails de profils, d'usures ou de nuances différentes.

Outre les exigences définitives, la présente norme exige également que les éléments détaillés à l'Article 4 soient documentés. Pour être conforme à la présente norme, il est important que les exigences définitives ainsi que les éléments à documenter soient remplis.

Železniške naprave - Infrastruktura - Aluminotermično varjenje tirnice z žlebom

Ta standard opredeljuje laboratorijske preskuse in zahteve za odobritev postopka aluminotermičnega varjenja z uporabo zvarov, izdelanih v delavnici.

Uporablja se za združevanje novih tirnic z žlebom, kot je opisano v standardu EN 14811, istega profila in razreda jekla. Varjenje konstrukcijskih in strojnih profilov ni obravnavano v tem standardu.

Skladnost z zahtevami iz tega standarda sama po sebi še ne zagotavlja ustreznosti postopka varjenja za določene pogoje glede proge in prometa.

Standard ne obravnava zvarov, izdelanih iz različnih delov tirnic, obrabljenih tirnic ali različnih razredov tirnic.

Poleg dokončnih zahtev ta standard zahteva tudi, da so postavke, opredeljene v točki 4, dokumentirane. Za skladnost s tem standardom je pomembno, da so izpolnjene tako dokončne zahteve kot dokumentirane postavke.

General Information

- Status

- Published

- Publication Date

- 08-Nov-2016

- Technical Committee

- CEN/TC 256 - Railway applications

- Drafting Committee

- CEN/TC 256/SC 1/WG 4 - Rails

- Current Stage

- 9093 - Decision to confirm - Review Enquiry

- Start Date

- 13-Jun-2022

- Completion Date

- 14-Apr-2025

Overview - EN 16771:2016 (CEN)

EN 16771:2016 specifies the laboratory tests and approval requirements for aluminothermic welding of grooved rails (welds produced in workshop conditions). Prepared by CEN/TC 256, it applies to joining new grooved rails of the same profile and steel grade (as described in EN 14811). The standard defines the approval procedure for a single welding process (process identification, documentation, and laboratory testing) but does not cover construction or machined profiles, welds between different rail sections, worn rails, or welding between different rail grades. Compliance with EN 16771 provides laboratory evidence of weld quality but does not automatically guarantee suitability for specific track or traffic conditions.

Key topics and technical requirements

- Scope & limitations: Applies only to new grooved rails of identical profile/grade; excludes worn or mixed-grade welds.

- Process identification & documentation: Requires a detailed process manual and drawings covering pouring/casting system, mould geometry, riser configuration, consumables, critical timings, safety and storage conditions.

- Mandatory documented items (Clause 4): Railway authority must specify items such as required heat‑softened zone width and pre‑heat limitations.

- Laboratory tests and acceptance criteria:

- Visual surface examination (as-cast and ground)

- Running-surface hardness testing (Brinell/Vickers references)

- Slow bend (fracture) testing

- Internal examination: weld soundness, fusion zone shape & dimensions

- Microscopic examination of fusion zone and HAZ

- Measurement of heat‑softened zone width (hardness distribution)

- Chemical analysis of weld/rail materials

- Ultrasonic inspection procedures (Annex G) and other normative annexes for test methods

- Approval workflow: Initial compliance testing (category 1/2 schemes), possible extensions to other profile groups, and re‑approval after process changes.

Practical applications

- Establishes a laboratory-based approval route for aluminothermic welding processes used to fabricate grooved-rail welds in workshops or near-track environments.

- Useful for ensuring consistent weld quality before field trials or trackside implementation.

- Helps railway authorities, infrastructure managers, and contractors assess whether a supplier’s aluminothermic welding process meets defined metallurgical and mechanical criteria.

Who should use this standard

- Railway authorities and infrastructure owners (for specifying approval requirements)

- Welding process suppliers and manufacturers (to obtain process approval)

- Accredited testing laboratories and NDT personnel (to perform required laboratory tests)

- Track maintenance contractors and quality assurance teams

Related standards

- EN 14811 (grooved rail profiles)

- EN ISO 6506‑1 (Brinell hardness)

- EN ISO 6507‑1 (Vickers hardness)

- EN ISO 9712 (NDT personnel qualification)

Keywords: EN 16771, aluminothermic welding, grooved rails, railway infrastructure, weld approval, laboratory tests, fusion zone, heat‑softened zone, process manual.

Frequently Asked Questions

EN 16771:2016 is a standard published by the European Committee for Standardization (CEN). Its full title is "Railway applications - Infrastructure - Aluminothermic welding of grooved rails". This standard covers: This standard defines the laboratory tests and requirements for approval of an aluminothermic welding process using welds produced in workshop conditions. It applies to the joining of new, grooved rails as described in EN 14811 of the same profile and steel grade. Welding of construction profiles and machined profiles are not covered in this standard. Compliance with the requirements of this standard does not in itself ensure the suitability of a welding process for specific conditions of track and traffic. The standard does not cover welds made between different rail sections, worn rails or different rail grades. In addition to the definitive requirements, this standard also requires the items detailed in Clause 4 to be documented. For compliance with this standard, it is important that both the definitive requirements and the documented items be satisfied.

This standard defines the laboratory tests and requirements for approval of an aluminothermic welding process using welds produced in workshop conditions. It applies to the joining of new, grooved rails as described in EN 14811 of the same profile and steel grade. Welding of construction profiles and machined profiles are not covered in this standard. Compliance with the requirements of this standard does not in itself ensure the suitability of a welding process for specific conditions of track and traffic. The standard does not cover welds made between different rail sections, worn rails or different rail grades. In addition to the definitive requirements, this standard also requires the items detailed in Clause 4 to be documented. For compliance with this standard, it is important that both the definitive requirements and the documented items be satisfied.

EN 16771:2016 is classified under the following ICS (International Classification for Standards) categories: 25.160.10 - Welding processes; 93.100 - Construction of railways. The ICS classification helps identify the subject area and facilitates finding related standards.

You can purchase EN 16771:2016 directly from iTeh Standards. The document is available in PDF format and is delivered instantly after payment. Add the standard to your cart and complete the secure checkout process. iTeh Standards is an authorized distributor of CEN standards.

Standards Content (Sample)

2003-01.Slovenski inštitut za standardizacijo. Razmnoževanje celote ali delov tega standarda ni dovoljeno.Bahnanwendungen - Infrastruktur - Aluminiothermisches Schweißen von RillenschienenApplications ferroviaires - Infrastructures - Soudage par aluminothermie des rails à gorgeRailway applications - Infrastructure - Aluminothermic welding of grooved rails45.080Rails and railway components25.160.10Varilni postopki in varjenjeWelding processesICS:Ta slovenski standard je istoveten z:EN 16771:2016SIST EN 16771:2017en,fr,de01-januar-2017SIST EN 16771:2017SLOVENSKI

STANDARD

EUROPEAN STANDARD NORME EUROPÉENNE EUROPÄISCHE NORM

EN 16771

November

t r s x ICS

t wä s x rä s râ

{ uä s r r English Version

Railway applications æ Infrastructure æ Aluminothermic welding of grooved rails Applications ferroviaires æ Infrastructures æ Soudage par aluminothermie des rails à gorge

Bahnanwendungen æ Infrastruktur æ Aluminothermisches Schweißen von Rillenschienen This European Standard was approved by CEN on

s w July

t r s xä

egulations which stipulate the conditions for giving this European Standard the status of a national standard without any alterationä Upætoædate lists and bibliographical references concerning such national standards may be obtained on application to the CENæCENELEC Management Centre or to any CEN memberä

translation under the responsibility of a CEN member into its own language and notified to the CENæCENELEC Management Centre has the same status as the official versionsä

CEN members are the national standards bodies of Austriaá Belgiumá Bulgariaá Croatiaá Cyprusá Czech Republicá Denmarká Estoniaá Finlandá Former Yugoslav Republic of Macedoniaá Franceá Germanyá Greeceá Hungaryá Icelandá Irelandá Italyá Latviaá Lithuaniaá Luxembourgá Maltaá Netherlandsá Norwayá Polandá Portugalá Romaniaá Slovakiaá Sloveniaá Spainá Swedená Switzerlandá Turkey and United Kingdomä

EUROPEAN COMMITTEE FOR STANDARDIZATION COMITÉ EUROPÉEN DE NORMALISATION EUROPÄISCHES KOMITEE FÜR NORMUNG

CEN-CENELEC Management Centre:

Avenue Marnix 17,

B-1000 Brussels

t r s x CEN All rights of exploitation in any form and by any means reserved worldwide for CEN national Membersä Refä Noä EN

s x y y sã t r s x ESIST EN 16771:2017

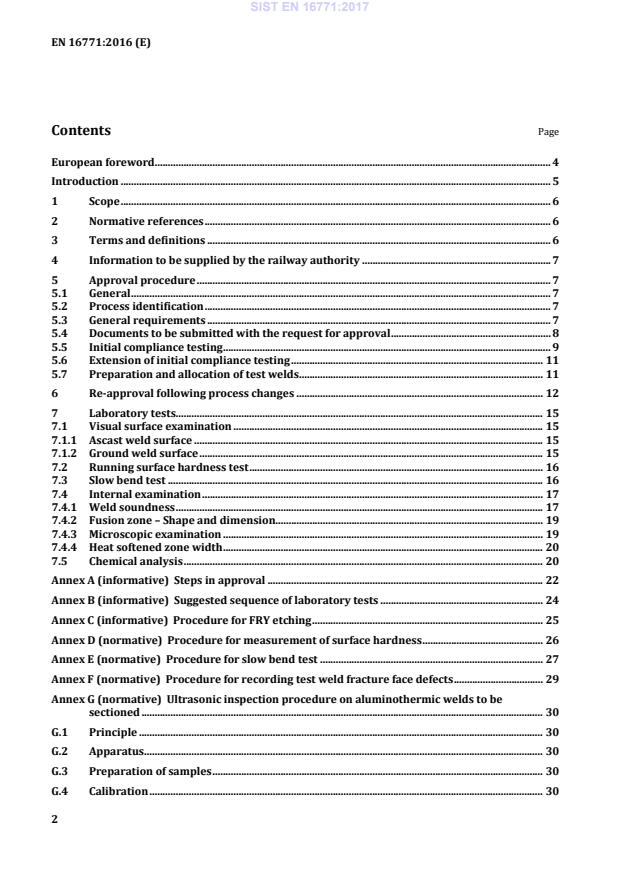

Steps in approval . 22 Annex B (informative)

Suggested sequence of laboratory tests . 24 Annex C (informative)

Procedure for FRY etching . 25 Annex D (normative)

Procedure for measurement of surface hardness . 26 Annex E (normative)

Procedure for slow bend test . 27 Annex F (normative)

Procedure for recording test weld fracture face defects . 29 Annex G (normative)

Ultrasonic inspection procedure on aluminothermic welds to be sectioned . 30 G.1 Principle . 30 G.2 Apparatus . 30 G.3 Preparation of samples . 30 G.4 Calibration . 30 SIST EN 16771:2017

Procedure for microscopic examination of the visible heat affected zone and fusion zone of welds . 32 Annex I (normative)

Procedure for measurement of the heat softened zone width . 33 I.1 Measurement of hardness . 33 I.2 Evaluation of hardness data . 34 Bibliography . 36

¶ 30 mm gap and ± 3 mm for > 30 mm to 50 mm gaps and ± 5 mm for > 50 mm gaps; f) preheating details; g) range of ignition to tap times for the portions; h) critical process timings; i) time (or temperature) before trains can pass; j) safety information. 5.4.2 Drawing with the required measurements. A drawing, as illustrated in Figure 1, which provides the measurements listed below: a) weld collar width (W1). The development of the weld collar shall be fully dimensioned around the weld; b) maximum depth of collar at section B-B (D1 and D2); c) minimum depth of collar at section B-B (d1 and d2); d) riser cross section at foot; SIST EN 16771:2017

Key 1 figure showing the width of the weld collar around the weld 2 riser cross section on the neutral axis mm2 3 25 % of the foot width 4 riser cross section at the foot mm2 5 longitudinal axis under the rail foot Figure 1 — Dimensions taken from mould pattern 5.4.3 Chemical analysis ranges and tolerances. The chemical analysis ranges and tolerances shall be in accordance with 7.5.1. 5.5 Initial compliance testing a) For the purposes of approval the standard, rail profiles (see EN 14811) shall be grouped as follows. SIST EN 16771:2017

Hardness test 7.2 6 5 B

Surface examination – Visual 7.1.1 7.1.2 6 5 C

Slow Bend Test 7.3 6 3 D

Ultrasonic inspection – Annex G 7.4.1.1 2 Nil E

Weld soundness 7.4.1 7.3 2 (2) Nil F

Fusion Zone – Shape and Dimensions 7.4.2 2 Nil G

Chemical analysis 7.5 3 3 H

Heat softened zone – Hardness distribution 7.4.4 2 2 I

Structure – Fusion Zone – Heat affected zone 7.4.3.3 7.4.3.2 2 2 1 1 NOTE () indicates weld soundness evaluation of the fracture face of the slow bend test specimens. a Category 1 Initial tests to be conducted using not heat treated grade on one rail profile from group 1 or 2 (Table 1 or 2). b Category 2 Tests required extending approval for heat treated grades. Tests on one rail profile cover all profile groups approved in categories 1 and 2. 5.6 Extension of initial compliance testing Initial compliance can be extended as follows: The relevant railway authority requirements defined in Clause 4 shall be met for each of the items below: a) to other group of rail profiles listed in Table 1 or 2 [5.5, a)], by doing the tests given in Table 3 category 1 [5.5, b)] on one profile of the appropriate group. Failure of any test shall cause non-compliance for the group of rail profiles being tested; b) to other rail grade by doing the tests given in Table 3 category 2 [5.5, b)]. Failure of any test shall cause non-compliance for that rail grade. Tests on one rail profile cover all profiles in group 1 or 2. 5.7 Preparation and allocation of test welds a) Welds required for the tests shall be produced in accordance with the process manual (5.4.1) under the supervision of the approving authority. Rails to be used for the production of test SIST EN 16771:2017

...

記事のタイトル:EN 16771:2016 - 鉄道施設 - グルーブドレールのアルミテルミック溶接 記事の内容:この規格は、作業場の条件で生産される溶接に対するアルミテルミック溶接工程の研究室試験と承認要件を定義しています。 この規格は、EN 14811で説明されているとおりのプロファイルと鋼種の同じグルーブドレールの結合に適用されます。建設プロファイルや加工プロファイルの溶接はこの規格ではカバーされていません。 この規格の要件を満たすことは、トラックおよび交通の特定の条件に対して溶接工程の適合性を保証するものではありません。 この規格は、異なるレールセクション間の溶接、摩耗したレール、異なるレールグレードによる溶接には適用されません。 確定的な要件に加えて、この規格はクローズ4で詳細に説明された項目の文書化を要求しています。この規格に準拠するためには、確定的な要件と文書化された項目の両方が満たされる必要があります。

The article discusses the standard EN 16771:2016, which is related to aluminothermic welding of grooved rails in railway applications. The standard defines laboratory tests and requirements for the approval of an aluminothermic welding process that is carried out in workshop conditions. It specifically applies to the joining of new grooved rails of the same profile and steel grade as described in EN 14811. However, it does not cover welding of construction profiles, machined profiles, welds between different rail sections, worn rails, or different rail grades. Additionally, the standard requires certain items to be documented, in addition to meeting the definitive requirements. It is important to satisfy both the definitive requirements and the documented items for compliance with this standard. It should be noted that compliance with this standard does not guarantee suitability for specific track and traffic conditions.

記事のタイトル:EN 16771:2016-鉄道の応用-インフラ-溝付きレールの熱溶解溶接に関するもの 記事の内容:この規格は、作業場条件で行われる熱溶解溶接プロセスの実験室テストと承認要件を定義しています。これは、EN 14811で説明されている同一プロファイルおよび鋼種の新しい溝付きレールの接合に適用されます。建設プロファイルや加工プロファイルの溶接は、この規格では扱われていません。 この規格の要件を満たすことだけでは、トラックと交通の具体的な条件に対する溶接プロセスの適合性を保証するものではありません。この規格は、異なるレールの断面、摩耗したレール、異なるレールのグレード同士の溶接は対象外です。 最終要件に加えて、この規格では第4項に詳細に列挙された項目の文書化も求められます。この規格の遵守には、最終要件と文書化された項目の両方を満たすことが重要です。ただし、この規格の要件を満たすことは、トラックおよび交通の具体的な条件に対する適合性を保証するものではありません。

EN 16771:2016 is a standard that focuses on the aluminothermic welding of grooved rails in railway infrastructure. The standard outlines laboratory tests and requirements for approving this welding process, particularly for welds produced in workshop conditions. The standard specifically applies to the joining of new, grooved rails with the same profile and steel grade as specified in EN 14811. However, it does not cover the welding of construction profiles, machined profiles, or welds made between different rail sections, worn rails, or different rail grades. It is important to note that compliance with this standard does not automatically ensure the suitability of the welding process for specific track and traffic conditions. In addition to the definitive requirements, the standard also requires the documentation of certain items outlined in Clause 4. To comply with the standard, both the definitive requirements and the documented items need to be satisfied.

기사 제목: EN 16771: 2016-철도 응용-인프라-홈드 레일의 용융 접합에 대한 알루미노테르믹 용접 기사 내용: 이 표준은 작업장 조건에서 사용되는 용접으로 생성된 그루브 레일의 알루미노테르믹 용접 공정의 실험실 검사 및 승인 요구 사항을 정의합니다. 이 표준은 EN 14811의 동일한 프로필 및 강재 등급으로 설명된 새로운 그루브 레일의 접합에 적용됩니다. 건설 프로필 및 가공 프로필의 용접은 이 표준에서 다루지 않습니다. 이 표준의 요구 사항을 준수하는 것만으로는 트랙 및 교통 조건에 대한 용접 공정의 적합성이 보장되지 않습니다. 이 표준은 다른 레일 단면, 닳은 레일 또는 다른 레일 등급으로 만들어진 용접을 다루지 않습니다. 확정적인 요구 사항 외에도, 이 표준에는 절 4에 상세히 나열된 항목들이 문서화되어야 합니다. 이 표준의 준수를 위해서는 확정적인 요구 사항과 문서화된 항목 모두를 충족시키는 것이 중요합니다.

기사 제목: EN 16771:2016 - 철도 적용 - 인프라 - 홈드 레일의 알루미노텀 화학 용접 기사 내용: 이 표준은 작업장 조건에서 생산 된 용접으로 알루미노텀 화학 용접 공정의 연구실 테스트 및 승인 요구 사항을 정의합니다. 이는 EN 14811의 동일한 프로파일 및 강재 등급으로 설명 된 새로운 홈드 레일의 결합에 적용됩니다. 이 표준은 구성 프로파일 및 가공된 프로파일의 용접은 다루지 않습니다. 이 표준의 요구 사항을 준수하는 것만으로는 트랙과 교통의 특정 조건에 대한 용접 프로세스의 적합성을 보장하지 않습니다. 이 표준은 서로 다른 레일 섹션, 마모된 레일 또는 다른 레일 등급 사이의 용접을 다루지 않습니다. 확정 요구 사항 외에도, 이 표준은 절 4에 자세히 설명 된 항목의 문서화를 요구합니다. 이 표준을 준수하기 위해서는 확정 요구 사항과 문서화 된 항목이 모두 충족되어야 합니다.

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.

Loading comments...