ISO/DIS 18646-4

(Main)Robotics -- Performance criteria and related test methods for service robots

Robotics -- Performance criteria and related test methods for service robots

Robotique -- Critères de performance et méthodes d'essai correspondantes pour robots de service

General Information

Standards Content (sample)

DRAFT INTERNATIONAL STANDARD

ISO/DIS 18646-4

ISO/TC 299 Secretariat: SIS

Voting begins on: Voting terminates on:

2020-01-31 2020-04-24

Robotics — Performance criteria and related test methods

for service robots —

Part 4:

Lower-back support robots

Robotique — Critères de performance et méthodes d'essai correspondantes pour robots de service

ICS: 25.040.30THIS DOCUMENT IS A DRAFT CIRCULATED

FOR COMMENT AND APPROVAL. IT IS

THEREFORE SUBJECT TO CHANGE AND MAY

NOT BE REFERRED TO AS AN INTERNATIONAL

STANDARD UNTIL PUBLISHED AS SUCH.

IN ADDITION TO THEIR EVALUATION AS

BEING ACCEPTABLE FOR INDUSTRIAL,

This document is circulated as received from the committee secretariat.

TECHNOLOGICAL, COMMERCIAL AND

USER PURPOSES, DRAFT INTERNATIONAL

STANDARDS MAY ON OCCASION HAVE TO

BE CONSIDERED IN THE LIGHT OF THEIR

POTENTIAL TO BECOME STANDARDS TO

WHICH REFERENCE MAY BE MADE IN

Reference number

NATIONAL REGULATIONS.

ISO/DIS 18646-4:2020(E)

RECIPIENTS OF THIS DRAFT ARE INVITED

TO SUBMIT, WITH THEIR COMMENTS,

NOTIFICATION OF ANY RELEVANT PATENT

RIGHTS OF WHICH THEY ARE AWARE AND TO

PROVIDE SUPPORTING DOCUMENTATION. ISO 2020

---------------------- Page: 1 ----------------------

ISO/DIS 18646-4:2020(E)

COPYRIGHT PROTECTED DOCUMENT

© ISO 2020, Published in Switzerland

All rights reserved. Unless otherwise specified, no part of this publication may be reproduced or utilized otherwise in any form

or by any means, electronic or mechanical, including photocopying, or posting on the internet or an intranet, without prior

written permission. Permission can be requested from either ISO at the address below or ISO’s member body in the country of

the requester.ISO copyright office

Ch. de Blandonnet 8 • CP 401

CH-1214 Vernier, Geneva, Switzerland

Tel. +41 22 749 01 11

Fax +41 22 749 09 47

copyright@iso.org

www.iso.org

ii © ISO 2020 – All rights reserved

---------------------- Page: 2 ----------------------

ISO/DIS 18646-4:2020(E)

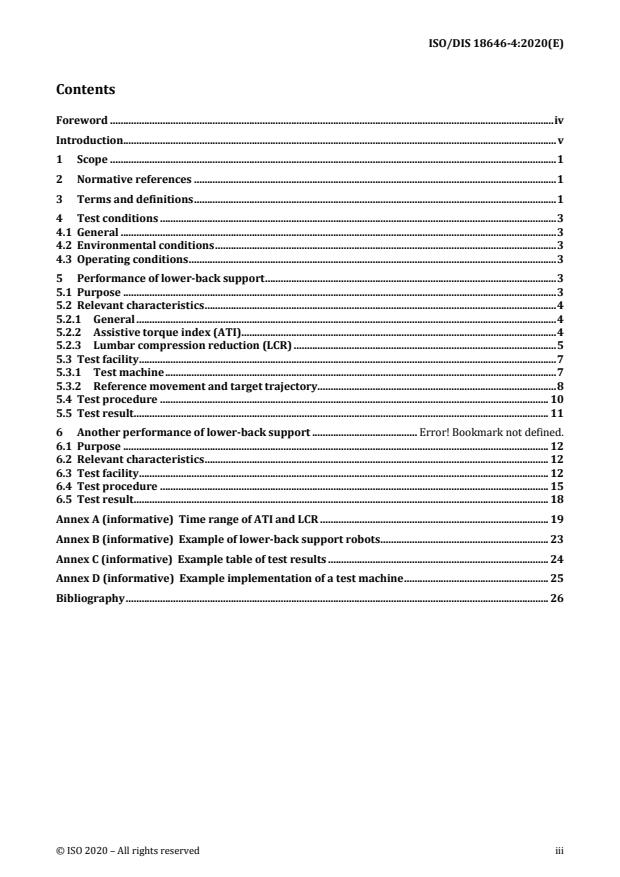

Contents

Foreword ......................................................................................................................................................................... iv

Introduction..................................................................................................................................................................... v

1 Scope .......................................................................................................................................................................... 1

2 Normative references .......................................................................................................................................... 1

3 Terms and definitions .......................................................................................................................................... 1

4 Test conditions ....................................................................................................................................................... 3

4.1 General ...................................................................................................................................................................... 3

4.2 Environmental conditions .................................................................................................................................. 3

4.3 Operating conditions ............................................................................................................................................ 3

5 Performance of lower-back support ............................................................................................................... 3

5.1 Purpose ..................................................................................................................................................................... 3

5.2 Relevant characteristics ...................................................................................................................................... 4

5.2.1 General ................................................................................................................................................................ 4

5.2.2 Assistive torque index (ATI) ........................................................................................................................ 4

5.2.3 Lumbar compression reduction (LCR) .................................................................................................... 5

5.3 Test facility ............................................................................................................................................................... 7

5.3.1 Test machine ..................................................................................................................................................... 7

5.3.2 Reference movement and target trajectory........................................................................................... 8

5.4 Test procedure .................................................................................................................................................... 10

5.5 Test result .............................................................................................................................................................. 11

6 Another performance of lower-back support ........................................ Error! Bookmark not defined.

6.1 Purpose .................................................................................................................................................................. 12

6.2 Relevant characteristics ................................................................................................................................... 12

6.3 Test facility ............................................................................................................................................................ 12

6.4 Test procedure .................................................................................................................................................... 15

6.5 Test result .............................................................................................................................................................. 18

Annex A (informative) Time range of ATI and LCR ....................................................................................... 19

Annex B (informative) Example of lower-back support robots ................................................................ 23

Annex C (informative) Example table of test results .................................................................................... 24

Annex D (informative) Example implementation of a test machine ....................................................... 25

Bibliography ................................................................................................................................................................. 26

© ISO 2020 – All rights reserved iii---------------------- Page: 3 ----------------------

ISO/DIS 18646-4:2020(E)

Foreword

ISO (the International Organization for Standardization) is a worldwide federation of national

standards bodies (ISO member bodies). The work of preparing International Standards is normally

carried out through ISO technical committees. Each member body interested in a subject for which a

technical committee has been established has the right to be represented on that committee.

International organizations, governmental and non-governmental, in liaison with ISO, also take part in

the work. ISO collaborates closely with the International Electrotechnical Commission (IEC) on all

matters of electrotechnical standardization.The procedures used to develop this document and those intended for its further maintenance are

described in the ISO/IEC Directives, Part 1. In particular, the different approval criteria needed for the

different types of ISO documents should be noted. This document was drafted in accordance with the

editorial rules of the ISO/IEC Directives, Part 2 (see www.iso.org/directives).Attention is drawn to the possibility that some of the elements of this document may be the subject of

patent rights. ISO shall not be held responsible for identifying any or all such patent rights. Details of

any patent rights identified during the development of the document will be in the Introduction and/or

on the ISO list of patent declarations received (see www.iso.org/patents).Any trade name used in this document is information given for the convenience of users and does not

constitute an endorsement.For an explanation of the voluntary nature of standards, the meaning of ISO specific terms and

expressions related to conformity assessment, as well as information about ISO's adherence to the

World Trade Organization (WTO) principles in the Technical Barriers to Trade (TBT), see

www.iso.org/iso/foreword.html.This document was prepared by Technical Committee ISO/TC 299, Robotics.

A list of all parts in the ISO 18646 series can be found on the ISO website.

Any feedback or questions on this document should be directed to the user’s national standards body. A

complete listing of these bodies can be found at www.iso.org/members.html.iv © ISO 2020 – All rights reserved

---------------------- Page: 4 ----------------------

ISO/DIS 18646-4:2020(E)

Introduction

ISO 18646-4 is intended to facilitate understanding of performance of lower-back support robots. This

standard defines the important performance characteristics, describes how they shall be specified, and

recommends how they should be tested.The characteristics for which test methods are given in this International Standard are those considered

to affect robot performance significantly. The user of this International Standard selects which

performance characteristics are to be tested, in accordance with the specific requirements.

The performance criteria specified in this part of International Standard should not be interpreted as

the verification or validation of safety requirements. The verification and validation of safety

requirements will be specified in other standards developed by ISO TC 299.The International Organization for Standardization (ISO) draws attention to the fact that it is claimed

that compliance with this part of ISO 18646 can involve the use of patents concerning the test machines

of the performance of wearable robots for lower-back support referred to throughout the document.

ISO takes no position concerning the evidence, validity, and scope of these patents.

The holders of these patents have assured ISO that they are willing to grant free licences or negotiate

licenses under reasonable and non-discriminatory terms and conditions with applicants throughout the

world. In this respect, the statements of the holders of these patents right are registered with ISO.

© ISO 2020 – All rights reserved v---------------------- Page: 5 ----------------------

ISO/DIS 18646-4:2020(E)

Robotics — Performance criteria and related test methods for

service robots — Part 4: Lower-back support robots

1 Scope

This International Standard describes methods of specifying and evaluating the performance of lower-

back support robots.This standard applies regardless of the purpose and application of lower-back support robots and the

driving methods (e.g. electric, hydraulic, pneumatic, etc.). This standard does not apply to medical

robots, although the test methods specified in this standard can be utilized for medical robots.

This International Standard is not intended for the verification or validation of safety requirements.

2 Normative referencesThere are no normative references in this document.

3 Terms and definitions

For the purposes of this document, the terms and definitions given in ISO 8373:2012, ISO 13482:2014

and the following apply.ISO and IEC maintain terminological databases for use in standardization at the following addresses:

— ISO Online browsing platform: available at https://www.iso.org/obp— IEC Electropedia: available at http://www.electropedia.org/

3.1

robot

programmed actuated mechanism with a degree of autonomy, moving within its environment, to

perform intended tasksNote 1 to entry: A robot includes the control system and interface of the control system.

Note 2 to entry: The classification of robot into industrial robot or service robot is done according to its intended

application.[SOURCE: ISO 8373:2012, 2.6, modified to add “programmed” and removed mention of axes]

3.2wearable robot

robot that supplements or augments of personal capabilities while attached to a human during use

Note 1 to entry: Wearable robots are referred to as restraint-type physical assistant robots in ISO 13482:2014.

3.3lower-back support robot

wearable robot to reduce the load in the lower back of the user by its assistive force or torque

3.4user

person wearing a wearable robot to his/her body and directly receives its assistive force or torque

© ISO 2020 – All rights reserved 1---------------------- Page: 6 ----------------------

ISO/DIS 18646-4:2020(E)

[SOURCE: ISO 13482:2014, 3.26, modified]

3.5

operator

person designated to make parameter and program changes, and to start, monitor, and stop the

intended operation of the wearable robotNote 1 to entry: An operator may be the same person as a user.

[SOURCE: ISO 13482:2014, 3.25, modified]

3.6

attach

fastening of the wearable robot on the user to start using the robot

3.7

detach

unfastening of the wearable robot from the user when finished using the robot

3.8

restraint part

part of the wearable robot binding a corresponding attached body part of the user to transmit an

assistive force or torque3.9

assistive torque

output torque of the wearable robot to assist a user to perform required tasks

3.10

attached body part

part of the user’s body attached to the restraint part of the wearable robot

3.11

input method

interface allowing the user to control the assistive force or torque of the wearable robot by an

appropriate input signal3.11.1

biological input

input method where biological signals that are in correlation to the force or torque the user exerts at

his/her body part intended for assistance are used as the inputNote 1 to entry: Biological signals include bioelectrical signals.

3.11.2

kinematic input

input method where movement and/or posture of the user’s body parts intended for assistance are

used as the input3.11.3

command input

any other input method different from biological input or kinematic input

Note 1 to entry: Command input includes the use of commanding devices, breath switches or voice input.

Note 2 to entry: Command input includes the use of biological signals that are not in correlation to the force or

torque the user exerts at the body part intended for assistance.2 © ISO 2020 – All rights reserved

---------------------- Page: 7 ----------------------

ISO/DIS 18646-4:2020(E)

Note 3 to entry: Command input includes movement and/or posture of the user’s body parts not intended for

assistance.3.12

assistive torque index

ATI

measure of how much the output torque of the user is reduced when the user performs a specific

movement during a specific time range using the lower-back support robot3.13

lumbar compression reduction

LCR

measure of how much the compressive force on the user’s lumbar disks is reduced when the user

performs a specific movement during a specific time range using the lower-back support robot

4 Test conditions4.1 General

The lower-back support robot shall be completely assembled, sufficiently charged and operational. All

self-diagnostic tests shall be satisfactorily completed. It should also be ensured that the robot operates

in a safe manner throughout the test.The tests shall be preceded by the preparations for operation as specified by the manufacturer.

All conditions specified in Clause 4 should be satisfied for the tests described in this standard, unless it

is stated otherwise in the specific clauses.Each test described in each clause of this standard may have different test configurations which require

separate test procedures. For each test configuration, multiple trials can be conducted, if specified in

the test procedure.4.2 Environmental conditions

The following environmental conditions shall be maintained during all tests.

— Ambient temperature: 10 – 30 degrees in Celsius

— Relative humidity:0 – 80%

If the environmental conditions specified by the manufacturer are outside the given conditions, then it

shall be declared in the test results.4.3 Operating conditions

All performance shall be measured under normal operating conditions. When the performance is

measured in other conditions, it shall be declared together with the test results.

5 Test method for assistive torque index and lumbar compression reduction5.1 Purpose

This clause describes the methods of specifying and evaluating the performance of lower-back support

robots.© ISO 2020 – All rights reserved 3

---------------------- Page: 8 ----------------------

ISO/DIS 18646-4:2020(E)

Note: Theoretical backgrounds and validation experiments are provided in [6].

5.2 Relevant characteristics

5.2.1 General

Two performance indices are introduced for this test method: Assistive torque index (ATI) and Lumbar

compression reduction (LCR).By assistive torque of the robot, user’s extension force of hip joints and/or trunk would be reduced and

then compressive force on his/her lumbar disks might be reduced. Ideally, lumbar compression should

be proportional to the extension force of user’s hip joint and the posture of the trunk. And the extension

force can be reduced by the assistive torque of the robot. Therefore, for the robot with such

characteristics, lumbar compression is not needed to be measured because lumbar compression can be

inferred from assistive torque and the posture.For some robots for which lumbar compression could be increased because of robot’s mechanical

structure, mass and mass distribution above the lumbar joint and/or actuation method (e.g. artificial

muscles on user’s back skin), lumbar compression should be measured together with assistive torque.

Note: According to [1], compressive force on his/her lumbar disks might be the major cause of back injury and,

therefore, often used as an index to estimate the risk of back injury. Based on this background, LCR is introduced

as a performance indication of the robot.5.2.2 Assistive torque index (ATI)

Lower Lower Hold Raise

The Assistive Torque Index (ATI) consists of 5 representative values ATI , ATI , ATI , ATI

1000 200 1000 1000Raise

and ATI , which are calculated by the following equations with 𝑡 and 𝑡 specified in Table 1. The

200 1 2superscript and the subscript of ATI indicate a phase of reference movement and a time duration in

milliseconds, respectively.ref

ATI = ∫ 𝜓 (𝜏 (𝑡), 𝜏(𝑡)) 𝑑𝑡

𝑡 −𝑡

2 1

𝑡 − 𝑡

2 1 𝑡

where

𝑥 − 𝑦 if 𝑥 ≥ 0

𝜓(𝑥, 𝑦) = { ,

( )

− 𝑥 − 𝑦 if 𝑥 < 0

ref

is the actual output torque of the hip joints of the test machine (see 5.3.1) during the

𝜏 (𝑡)reference movements without robot;

𝜏(𝑡) is the actual output torque of the hip joints of the test machine (see 5.3.1) during the

reference movements with the robot.Note 1: In general, assistive torque of the robot interferes the duration of the movement and the necessary force

or torque of the user. This is a source of instability of the test results. Therefore, this standard adopts a time

average within a specific time range during the reference movements.ref

Note 2: Because the reference movements defined in 5.3.2 are antigravity movements, 𝜏 (𝑡) is expected always

negative and the relationship 𝜓(𝑥, 𝑦) = −(𝑥 − 𝑦) always applies. However, this standard defines 𝜓 in a more

general form to make 𝜓 positive when the necessary torque for the reference movement and the torque of the

robot are in the same direction.4 © ISO 2020 – All rights reserved

---------------------- Page: 9 ----------------------

ISO/DIS 18646-4:2020(E)

Note 3: When 𝜓 is positive, the torque of the robot in the antigravity direction (extension) can reduce the

necessary torque of the user to achieve the reference movements. Or, in some cases, the user has to output the

torque in the gravity direction (flexion) to resist the torque of the robot. When 𝜓 is negative, the torque of the

robot in the gravity direction (flexion) can increase the necessary torque of the user to achieve the reference

movements.5.2.3 Lumbar compression reduction (LCR)

Lower Lower

The Lumbar Compression Reduction (LCR) consists of 5 representative values LCR , LCR ,

1000 200Hold Raise Raise

LCR , LCR and LCR , which are calculated by the following equations with 𝑡 and 𝑡 specified

1000 1000 200 1 2in Table 1. The superscript and the subscript of LCR indicate a phase of reference movement and a time

duration in milliseconds, respectively.ref

LCR = ∫ 𝜓 (𝐹 (𝑡), 𝐹(𝑡)) 𝑑𝑡

𝑡 −𝑡

2 1

𝑡 − 𝑡

2 1 𝑡

where

𝑥 − 𝑦 if 𝑥 ≥ 0

( )

𝜓 𝑥, 𝑦 = { ,

−(𝑥 − 𝑦) if 𝑥 < 0

ref ref ref

( ) ( ) ( )

𝐹 𝑡 = 𝜙 (𝑀 𝑡 ) + 𝐹 𝑡 ,

𝑦 𝑧

𝐹(𝑡) = 𝜙 (𝑀 (𝑡)) + 𝐹 (𝑡) ,

𝑦 𝑧

𝑥/0.05 𝑖𝑓 𝑥 ≥ 0

( )

𝜙 𝑥 = { ,

−𝑥/0.1 𝑖𝑓 𝑥 < 0

ref

( ) is the actual lumbar compressive force of the test machine in z-axis direction during the

𝐹 𝑡reference movements (without robot);

( )

𝐹 𝑡 is the actual lumbar compressive force of the test machine in z-axis direction during the

reference movements (with robot);ref

𝑀 (𝑡) is the actual lumbar bending moment of the test machine around y-axis during the

reference movements (without robot);𝑀 (𝑡) is the actual lumbar bending moment of the test machine around y-axis during the

reference movements (with robot).Note 1: In general, assistive torque of a robot interferes the duration of the movement and the compressive force on the

lumbar disks of the user. This is a source of instability of the test results. Therefore, this standard adopts a time average within

a specific time range during the reference movements.Note 2: A human would stiffen his/her muscles to resist the change of posture by the lumbar bending moment around the y-

axis. This tension of the muscles is known as a source of compressive force on lumbar disks. On the other hand, the test

machine does not have muscles and its mechanical structure of back does not allow any change of posture unlike the spine.

ref( ) ( )

Because of this, the equation for LCR uses the corrected lumbar compressive force 𝐹 𝑡 and 𝐹 𝑡 under the assumption that

ref( ) ( )

𝑀 𝑡 and 𝑀 𝑡 are all supported by virtual erector spinae muscles and virtual abdominal rectus muscles. This standard

𝑦 𝑦adopts a 0.05 m moment arm from the L5/S1 lumbar disk to the virtual erector spinae muscles and a 0.1 m moment arm to the

[4][5]virtual abdominal rectus muscles .

© ISO 2020 – All rights reserved 5

---------------------- Page: 10 ----------------------

ISO/DIS 18646-4:2020(E)

Note 3: During the reference movement, the weight of the upper body of the test machine is expected to always compress the

( )fixed lumbar joint and 𝜓 𝑥, 𝑦 = 𝑥 − 𝑦 always applies. However, this standard defines 𝜓 in a more general form to be

applicable to tensile forces and to be consistent to the equation of ATI.Note 4: When 𝜓 is positive, the lumbar stress of the user is expected to be reduced during the reference movement. When 𝜓

is negative, the lumbar stress of the user is expected to be increased during the reference movement.

6 © ISO 2020 – All rights reserved---------------------- Page: 11 ----------------------

ISO/DIS 18646-4:2020(E)

Table 1 — Time range to calculate ATI and LCR

Reference

a a

𝑡 𝑡

1 2

b b

ATI LCR

movements

Lower

Lower c

𝑡 [s]

LCR Lowering 𝑡 − 1 [s]

ATI 1000

1000

Lower

Lower c

Lowering 𝑡 − 0.2 [s] 𝑡 [s]

ATI LCR

d d

200 200

𝑡 𝑡

d d

Hold Hold

− 0.5 + 0.5

ATI LCR

1000 1000

2 [s] 2 [s]

Holding

Raise

Raise

LCR Raising 0 s 1 s

ATI

1000 1000

Raise Raise

LCR Raising 0 s 0.2 s

ATI

200 200

𝑡 and 𝑡 define a time range when the necessary torque of the user and the lumbar stress are the largest assuming

1 2the beginning time of each reference movement is 0 (see Annex A). Because the angle trajectories of the reference

movement is increasing or decreasing monotonically ATI and LCR can be considered as an average within a specific

angle range. However, because 1) assistive torque can generate varying angle trajectories, 2) it is difficult to define the

relevant angle ranges of the trunk, the hip joint and the knee joint simultaneously and 3) the amount of data points for

calculating the average can vary, this standard adopts a time average to define ATI and LCR.

Lower Hold RaiseLower Hold Raise

ATI and LCR with a 1 s average (ATI , ATI , ATI , LCR , LCR and LCR ) can also be considered

1000 10001000 1000 1000 1000

as an indication whether the robot can output assistive torque and reduce the lumbar stress continuously. On the

Lower RaiseLower Raise

other hand, ATI and LCR with a 0.2 s average (ATI , ATI , LCR and LCR ) can be an indication of how

200200 200 200

much the robot can reduce the peak of necessary torque and the compressive force on the lumbar disks responsively

(see Annex A). This is due to the fact that they only focus on a short time range. This standard adopts a 0.2 s response

[3][9]time for humans to reflect the reaction to sudden load on lumbar spinal cord .

𝑡 is the actual duration of the reference movement.

5.3 Test facility

5.3.1 Test machine

A test facility shall include a test machine to which a robot can be attached. The ratios of its dimensions

and the distribution of its mass shall comply with Figure 1. In this figure, the height and mass of a

representative user specified by the manufacturer are set as 100 %. The manufacturer may determine

all other values not indicated in Figure 1.The compressive force to the lumbar z-axis and the bending moment around the lumbar y-axis are

measured at the fixed lumbar joint as indicated in Figure 1. The fixed lumbar joint is loaded at least with

the weight of upper parts of the test machine.The hip joints and knee joints are only active joints. If a test machine with arms and hands is used

instead of a test machine with the substitutional weights at the shoulder joints, the arms of the test

machine should be directed in downward direction at any posture and each assembly of arm and hand

should have 7.4 % of the mass of the representative user.The density of each block of the test machine can be assumed to be constant.

© ISO 2020 – All rights reserved 7

---------------------- Page: 12 ----------------------

ISO/DIS 18646-4:2020(E)

[2]

NOTE 1 The ratio of dimension is based on a literature ; it indicates the distance between a hip joint and L5/S1 spinal disk is

approximately 83/1610 (5.2 %) of the body height. Therefore, the fixed lumbar joint is located at the upper body part of the

test machine.NOTE 2 Assuming the arms and hands to be in a downward direction at any posture, the masses are concentrated to the

shoulder joints.NOTE 3 The distribution of mass is from Figure A.19 of IEC 60601-1:2012.

Figure 1 —Dimension ratio and mass distribution of a test machine

5.3.2 Reference movement and target trajectory

In this test, the test machine performs reference movements simulating lowering, holding and raising of

targetthe upper body. These reference movements are represented by a target trunk angle 𝜃 , the

distribution ratio between the hip joint and the knee joint 𝑘 and target duration 𝑡 .

( )The target trajectory of the trunk angle 𝜃 𝑡 is given as the following.

5 𝑛

Trunk angle 𝜃 (𝑡) = ∑ 𝑎 𝑡 , 𝑡 = [0, 𝑡 ]

t 𝑛=0 𝑛 d

under 𝑡 = 0 as the starting time of each reference movement, and 𝜃 (𝑡) = 0 at the upright position.

𝑎 for each reference movement are calculated with the initial angle 𝜃 (0), the final angle 𝜃 (𝑡 ) and the

𝑛 t t drestraint condition where 𝜃̇(0) = 0, 𝜃̇(𝑡 ) = 0, 𝜃̈(0) = 0 and 𝜃̈(𝑡 ) = 0. Ideally, 𝜃 (0) = 0 and 𝜃 (𝑡 ) =

t t d d t t dtarget target target

( ) ( ) ( )

𝜃 for lowering. Always 𝜃 𝑡 = 𝜃 for holding. 𝜃 0 = 𝜃 and 𝜃 𝑡 = 0 for raising.

t t t dt t t

The hip joint angle 𝜃 (𝑡) and the knee joint angle 𝜃 (𝑡) are given as the following.

h kHip joint angle 𝜃 (𝑡) = 𝑘𝜃 (𝑡)

h t

Knee joint angle 𝜃 (𝑡) = (1 − 𝑘)𝜃 (𝑡)

k t

( ) ( ) ( )

Note 1: These equations use the relationship where 𝜃 𝑡 = 𝜃 𝑡 + 𝜃 𝑡 .

t h k

8 © ISO 2020 – All rights reserved

---------------------- Page: 13 ----------------------

ISO/DIS 18646-4:2020(E)

( )

Note 2: The trunk angle 𝜃 𝑡 is defined as a quintic polynomial of time because actual trajectories of each angle when

humans lower, hold and raise a load are almost consistent with a quintic polynomial of time.

targetNote 3: If 𝜃 is 50 deg as shown in Table 2, 𝑘 can be 1.5 because 𝑘 actually obtained from measurement of humans’

movement varies from 1.3 to 1.7 depending on each individual and the weight of each load. 𝑡 can be 2 s.

Note 4: Generally, keeping a small angle at the trunk joint is preferred for reducing the lumbar stress during lowering,

holding and raising. In this case, 𝑘 can be more than 1.5 and 𝑡 for lowering and raising can be shorter than 2 s. For example, if

target𝜃 is 25 deg, 𝑘 of actually obtained from measurement of humans’ movement is approximately 3.0 and 𝑡 for lowering and

raising is 1.5 s.Table 2 shows an example of reference movements.

© ISO 2020 – All rights reserved 9

---------------------- Page: 14 -----

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.