ISO/DIS 7507-2

(Main)Petroleum and liquid petroleum products -- Calibration of vertical cylindrical tanks

Petroleum and liquid petroleum products -- Calibration of vertical cylindrical tanks

Pétrole et produits pétroliers liquides -- Jaugeage des réservoirs cylindriques verticaux

General Information

RELATIONS

Standards Content (sample)

DRAFT INTERNATIONAL STANDARD

ISO/DIS 7507-2

ISO/TC 28/SC 2 Secretariat: BSI

Voting begins on: Voting terminates on:

2021-03-16 2021-06-08

Petroleum and liquid petroleum products — Calibration of

vertical cylindrical tanks —

Part 2:

Optical-reference-line method or electro-optical distance-

ranging method

Pétrole et produits pétroliers liquides — Jaugeage des réservoirs cylindriques verticaux —

Partie 2: Mesurage par ligne de référence optique ou mesurage électro-optique de la distance

ICS: 75.180.30THIS DOCUMENT IS A DRAFT CIRCULATED

FOR COMMENT AND APPROVAL. IT IS

THEREFORE SUBJECT TO CHANGE AND MAY

NOT BE REFERRED TO AS AN INTERNATIONAL

STANDARD UNTIL PUBLISHED AS SUCH.

IN ADDITION TO THEIR EVALUATION AS

BEING ACCEPTABLE FOR INDUSTRIAL,

This document is circulated as received from the committee secretariat.

TECHNOLOGICAL, COMMERCIAL AND

USER PURPOSES, DRAFT INTERNATIONAL

STANDARDS MAY ON OCCASION HAVE TO

BE CONSIDERED IN THE LIGHT OF THEIR

POTENTIAL TO BECOME STANDARDS TO

WHICH REFERENCE MAY BE MADE IN

Reference number

NATIONAL REGULATIONS.

ISO/DIS 7507-2:2021(E)

RECIPIENTS OF THIS DRAFT ARE INVITED

TO SUBMIT, WITH THEIR COMMENTS,

NOTIFICATION OF ANY RELEVANT PATENT

RIGHTS OF WHICH THEY ARE AWARE AND TO

PROVIDE SUPPORTING DOCUMENTATION. ISO 2021

---------------------- Page: 1 ----------------------

ISO/DIS 7507-2:2021(E)

COPYRIGHT PROTECTED DOCUMENT

© ISO 2021

All rights reserved. Unless otherwise specified, or required in the context of its implementation, no part of this publication may

be reproduced or utilized otherwise in any form or by any means, electronic or mechanical, including photocopying, or posting

on the internet or an intranet, without prior written permission. Permission can be requested from either ISO at the address

below or ISO’s member body in the country of the requester.ISO copyright office

CP 401 • Ch. de Blandonnet 8

CH-1214 Vernier, Geneva

Phone: +41 22 749 01 11

Email: copyright@iso.org

Website: www.iso.org

Published in Switzerland

ii © ISO 2021 – All rights reserved

---------------------- Page: 2 ----------------------

ISO/DIS 7507-2:2021(E)

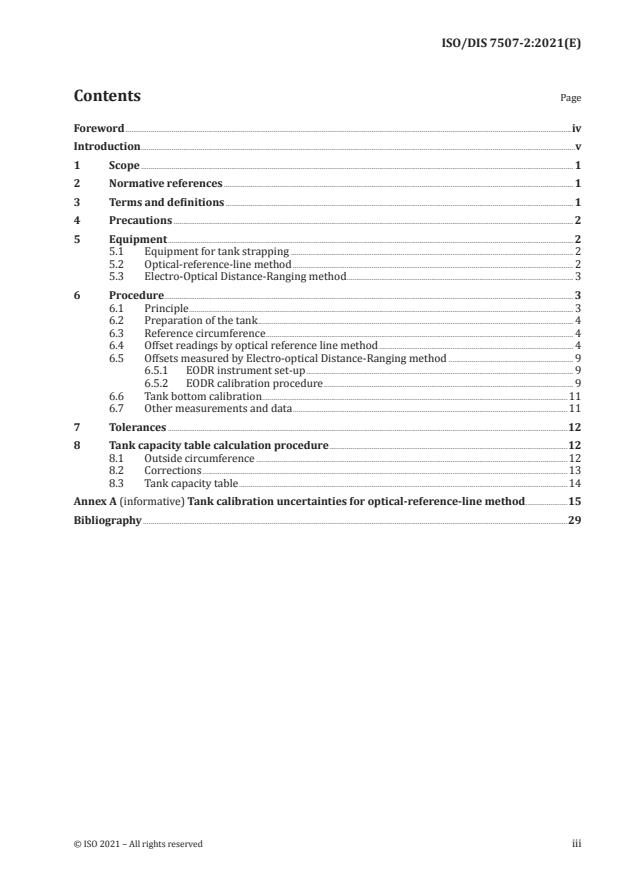

Contents Page

Foreword ........................................................................................................................................................................................................................................iv

Introduction ..................................................................................................................................................................................................................................v

1 Scope ................................................................................................................................................................................................................................. 1

2 Normative references ...................................................................................................................................................................................... 1

3 Terms and definitions ..................................................................................................................................................................................... 1

4 Precautions ................................................................................................................................................................................................................ 2

5 Equipment ................................................................................................................................................................................................................... 2

5.1 Equipment for tank strapping ................................................................................................................................................... 2

5.2 Optical-reference-line method .................................................................................................................................................. 2

5.3 Electro-Optical Distance-Ranging method ...................................................................................................................... 3

6 Procedure..................................................................................................................................................................................................................... 3

6.1 Principle ........................................................................................................................................................................................................ 3

6.2 Preparation of the tank .................................................................................................................................................................... 4

6.3 Reference circumference ................................................................................................................................................................ 4

6.4 Offset readings by optical reference line method ..................................................................................................... 4

6.5 Offsets measured by Electro-optical Distance-Ranging method ................................................................. 9

6.5.1 EODR instrument set-up ........................................................................................................................................... 9

6.5.2 EODR calibration procedure .................................................................................................................................. 9

6.6 Tank bottom calibration ...............................................................................................................................................................11

6.7 Other measurements and data ...............................................................................................................................................11

7 Tolerances ................................................................................................................................................................................................................12

8 Tank capacity table calculation procedure ............................................................................................................................12

8.1 Outside circumference ..................................................................................................................................................................12

8.2 Corrections ..............................................................................................................................................................................................13

8.3 Tank capacity table ...........................................................................................................................................................................14

Annex A (informative) Tank calibration uncertainties for optical-reference-line method ......................15

Bibliography .............................................................................................................................................................................................................................29

© ISO 2021 – All rights reserved iii---------------------- Page: 3 ----------------------

ISO/DIS 7507-2:2021(E)

Foreword

ISO (the International Organization for Standardization) is a worldwide federation of national standards

bodies (ISO member bodies). The work of preparing International Standards is normally carried out

through ISO technical committees. Each member body interested in a subject for which a technical

committee has been established has the right to be represented on that committee. International

organizations, governmental and non-governmental, in liaison with ISO, also take part in the work.

ISO collaborates closely with the International Electrotechnical Commission (IEC) on all matters of

electrotechnical standardization.The procedures used to develop this document and those intended for its further maintenance are

described in the ISO/IEC Directives, Part 1. In particular, the different approval criteria needed for the

different types of ISO documents should be noted. This document was drafted in accordance with the

editorial rules of the ISO/IEC Directives, Part 2 (see www .iso .org/ directives).

Attention is drawn to the possibility that some of the elements of this document may be the subject of

patent rights. ISO shall not be held responsible for identifying any or all such patent rights. Details of

any patent rights identified during the development of the document will be in the Introduction and/or

on the ISO list of patent declarations received (see www .iso .org/ patents).Any trade name used in this document is information given for the convenience of users and does not

constitute an endorsement.For an explanation of the voluntary nature of standards, the meaning of ISO specific terms and

expressions related to conformity assessment, as well as information about ISO's adherence to the

World Trade Organization (WTO) principles in the Technical Barriers to Trade (TBT), see www .iso .org/

iso/ foreword .html.This document was prepared by Technical Committee ISO/TC 28, Petroleum products and lubricants,

Subcommittee SC 2, Measurement of petroleum and related products.This document is a committee draft.

This third edition is intended to cancel and replace the second edition (ISO 7507-2:2005), which has

been technically revised.The main changes compared to the previous edition are as follows:

— Offsets between reference circumference and specified levels are measured by Electro-Optical

Distance-Ranging method.A list of all parts in the ISO 7507 series can be found on the ISO website.

Any feedback or questions on this document should be directed to the user’s national standards body. A

complete listing of these bodies can be found at www .iso .org/ members .html.iv © ISO 2021 – All rights reserved

---------------------- Page: 4 ----------------------

ISO/DIS 7507-2:2021(E)

Introduction

This part of ISO 7507 forms part of a series on tank calibration, including the following:

ISO 4269:2001, Petroleum and liquid petroleum products — Tank calibration by liquid measurement —

Incremental method using volumetric metersISO 7507-1:2003, Petroleum and liquid petroleum products — Calibration of vertical cylindrical tanks —

Part 1: Strapping methodISO 7507-3:2006, Petroleum and liquid petroleum products — Calibration of vertical cylindrical tanks —

Part 3: Optical-triangulation methodISO 7507-4:2010, Petroleum and liquid petroleum products — Calibration of vertical cylindrical tanks —

Part 4: Internal electro-optical distance-ranging methodISO 7507-5:2000, Petroleum and liquid petroleum products — Calibration of vertical cylindrical tanks —

Part 5: External electro-optical distance-ranging methodISO 8311:2013, Refrigerated light hydrocarbon fluids — Calibration of membrane tanks and independent

prismatic tanks in ships — Physical measurementISO 12917-1:2017, Petroleum and liquid petroleum products — Calibration of horizontal cylindrical

tanks — Part 1: Manual methodsISO 12917-2: 2002, Petroleum and liquid petroleum products — Calibration of horizontal cylindrical

tanks — Part 2: Internal electro-optical distance-ranging methodAttention is drawn to the possibility that some of the elements of this document may be the subject of

patent rights other than those in the patent database. ISO shall not be held responsible for identifying

any or all such patent rights.© ISO 2021 – All rights reserved v

---------------------- Page: 5 ----------------------

DRAFT INTERNATIONAL STANDARD ISO/DIS 7507-2:2021(E)

Petroleum and liquid petroleum products — Calibration of

vertical cylindrical tanks —

Part 2:

Optical-reference-line method or electro-optical distance-

ranging method

1 Scope

This part of ISO 7507 specifies a method for the calibration of tanks above eight metres in diameter

with cylindrical courses that are vertical. It provides a method for determining the volumetric quantity

of the liquid contained within a tank at gauged liquid levels.NOTE For optical-reference-line method, the optical (offset) measurements required to determine the

circumferences can be taken internally or externally, provided that insulation is removed if tank is insulated.

The method specified in this part of ISO 7507 is suitable for tilted tanks with up to 3 % deviation from

the vertical provided that a correction is applied for the measurement tilt, as described in ISO 7507-1.

This method is an alternative to other methods such as strapping (ISO 7507-1) and the optical-

triangulation method (ISO 7507-3).2 Normative references

The following documents are referred to in the text in such a way that some or all of their content

constitutes requirements of this document. For dated references, only the edition cited applies. For

undated references, the latest edition of the referenced document (including any amendments) applies.

ISO 4269:2001, Petroleum and liquid petroleum products — Tank calibration by liquid measurement —

Incremental method using volumetric metersISO 7507-1:2003, Petroleum and liquid petroleum products — Calibration of vertical cylindrical tanks —

Part 1: Strapping methodISO 7507-4:2010, Petroleum and liquid petroleum products — Calibration of vertical cylindrical tanks —

Part 4: Internal electro-optical distance-ranging method3 Terms and definitions

For the purposes of this document, the terms and definitions given in ISO 7507-1, ISO 7507-4 and the

following apply.ISO and IEC maintain terminological databases for use in standardization at the following addresses:

— ISO Online browsing platform: available at https:// www .iso .org/ obp— IEC Electropedia: available at http:// www .electropedia .org/

3.1

optical-reference-line

vertical optical ray (virtual) that is established using the optical device at a given location

© ISO 2021 – All rights reserved 1---------------------- Page: 6 ----------------------

ISO/DIS 7507-2:2021(E)

3.2

magnetic trolley

mechanical device that can be traversed up or down the tank shell wall to measure deviations in the

tank shell relative to the optical-reference-line using a horizontal scale that is mounted on the trolley

3.3station

location where the optical device and the magnetic trolley are placed for optical measurements

3.4horizontal station

station where the optical device is located as it is moved around the tank circumference

3.5vertical station

station where the magnetic trolley is located along the tank shell wall

3.6

reference circumference

circumference measured at the bottom course that forms the basis for subsequent computations

3.7reference offset

distance of the shell wall (at each horizontal station) from the optical-reference-line measured at the

bottom course where the reference circumference is measured4 Precautions

The general precautions and safety precautions specified in ISO 7507-1 shall apply to this part of

ISO 7507.5 Equipment

5.1 Equipment for tank strapping

Equipment as follow, specified in ISO 7507-1:

— strapping tapes;

— spring balance;

— step-over;

— littlejohn grip;

— dip-tape and dip-weight.

5.2 Optical-reference-line method

5.2.1 Optical-reference-line device, such as a precision optical plummet, a precision engineer’s level

with a pentaprism attachment, or a precision engineer’s theodolite with a pentaprism attachment.

NOTE 1 These are optical instruments with a means of attachment to either a tripod, magnetic bracket or

other stable means of support.The instrument, when set on its support and levelled, either manually using bubble vials or automatically

if an automatic levelling device is fitted, shall be capable of giving a vertical line of sight.

2 © ISO 2021 – All rights reserved---------------------- Page: 7 ----------------------

ISO/DIS 7507-2:2021(E)

The instrument should preferably be of short focal length so that, when set up at a practical working

height, it can be focused on the scale at the reference strapping level.The instrument including digital device with laser beam element shall have a resolution of at least

1:20 000 and be equipped with a telescope with a magnification of not less than 20. The pentaprism

attachment for use with an engineer’s level or engineer’s theodolite shall not introduce any significant

collimation errors.NOTE 2 Optical plummets can be fitted with a single optical train, i.e. a zenith plummet, a double optical

train or a single superimposed optical train giving both upward and downward lines of sight, i.e. a nadir/zenith

plummet. It is preferable that the plummet does not have any movable elements in its optical train, such as

mirrors or pentaprisms, to ensure stability of the line of sight.5.2.2 Magnetic trolley, of robust construction. Its design shall include the following features.

1. The magnet(s) shall be of sufficient power to ensure that the trolley does not lose contact with the

tank shell in conditions of high wind or when ring joints have to be negotiated or when there are

heavy layers of paint or scale.2. The magnet(s) shall be adjustable for height so that the clearance between the magnet faces and

the tank may be varied to suit the tank construction and condition.3. Manual magnetic trolley shall have a cord or wire cable attached to enable it to be raised or lowered

from the tank roof or via a pulley system, from ground level. Automatic magnetic trolley can be

moved up and down by electronic motor built in and controlled by remote control.4. A graduated scale or laser receiving element to indicate the actual offset measurement shall be

attached securely to the trolley at its centreline. When the trolley is in its operational mode, the

scale shall be either perpendicular to the tank shell or horizontal.5. The scale shall be attached to the trolley as closely as possible to the centreline of an axis in order

to reduce errors caused by deformations in the tank.NOTE Trolleys that are not magnetic can be used to maintain contact with the tank shell.

5.2.3 Graduated scale, made of steel and marked in millimetre increments. The length of the scale

shall be as short as is practicable and shall be determined by the distance at which the optical equipment

can be set up from the tank side. The scale shall be calibrated to a resolution of 1 mm or better using

standard methods and standard reference devices.5.3 Electro-Optical Distance-Ranging method

Equipment is described in ISO 7507-4.

6 Procedure

6.1 Principle

This calibration method is based on the accurate measurement of a reference circumference using a

calibrated measuring tape at one level on an accessible, non-obstructed course. Repeat measurements

agreeing within specified tolerances are made to avoid any systematic error in the derived

circumferences. The derived circumferences are calculated from the measured reference circumference,

and measurements of offsets taken at the specified levels and at the reference circumference. These

offsets are a measure of the deviation of the tank wall. They are measured at a specified number of

vertical stations, spaced equally around the tank.NOTE For examples see Figures 1 to 3.

© ISO 2021 – All rights reserved 3

---------------------- Page: 8 ----------------------

ISO/DIS 7507-2:2021(E)

6.2 Preparation of the tank

For new tanks or for tanks after repair, fill the tank to its normal working capacity with water or liquid

intended to be filled during normal operation at least once and allow it to stand for at least 24 h prior to

calibration.If the tank is calibrated with liquid in it, record the depth, temperature and density of the liquid at the

time of calibration. Do not make transfers of liquid during the calibration.For floating-roof tanks where offset measurements may be taken internally, the roof shall be in its

lowest position, resting on the legs.6.3 Reference circumference

Reference circumference has a direct impact on the calibrated volume of entire tank. It, therefore, shall

be measured as accurately as possible.Determine the reference circumference using the reference method described in ISO 7507-1 and the

following.a) Take multiple measurements of the reference circumference either prior to the commencement

or after the completion of the optical readings. If the first three consecutive measurements agree

within the tolerances specified in Clause 7, take their mean average as the reference circumference

and their standard deviation as the standard uncertainty. If they do not agree within the tolerances

specified in Clause 7, repeat the measurements until two standard deviations of the mean of all

measurements is less than the half of the tolerances specified in Clause 7. Use the mean as the

measured reference circumference and the standard deviation as the standard uncertainty. Use

standard procedures to eliminate obvious outliers.b) Take the measurement of the reference circumference at a position where work conditions allow

reliable measurements, and which is within the focal range of the optical instrument. Strap the

tank, aiming at one of the following levels:1) 1/4 of the course height above the lower horizontal seam,

2) 1/4 of the course height below the upper horizontal seam;

and repeat the measurement to achieve measurements agreeing within the tolerances specified in

Clause 7.6.4 Offset readings by optical reference line method

6.4.1 Set up the optical-reference-line device (5.2), magnetic trolley (5.3) and graduated scale (5.4)

successively at the horizontal stations (see 6.4.2) that are equally spaced around the tank, as close as

possible to the tank wall. Reference lines shall be chosen such that the trolley does not run over a vertical

seam or its weld.4 © ISO 2021 – All rights reserved

---------------------- Page: 9 ----------------------

ISO/DIS 7507-2:2021(E)

6.4.2 The minimum number of horizontal stations shall be as given in Table 1.

Table 1 — Minimum number of horizontal stations

Circumference Minimum number of horizontal

m stations

≤ 50 10

> 50, ≤ 100 12

> 100, ≤ 150 16

> 150, ≤ 200 20

> 200, ≤ 250 24

> 250, ≤ 300 30

> 300 36

NOTE 1 The number of horizontal stations divided by the number of plates in

tank segments should not be equal to an integer (e.g. 1, 2, 3, etc.) in order to avoid

systematic errors.NOTE 2 Using the minimum number of horizontal stations, especially for smaller tanks,

can lead to larger-than-acceptable uncertainties.© ISO 2021 – All rights reserved 5

---------------------- Page: 10 ----------------------

ISO/DIS 7507-2:2021(E)

Dimensions in millimetres

a) Tank elevation

Key

1 to 7 horizontal levels 11 graduated scale

8 optical-reference-line 12 weld seam (horizontal)

9 weld seam (vertical) 13 reference circumference taken close to location 1

10 magnetic trolley 14 optical equipment

b) Plan of horizontal stations

NOTE The horizontal stations are designated A to K in the plan view (see also 6.4.2). Of these, only E and F

are shown in the elevation.Figure 1 — Optical measurement of offsets from tank wall (typical case)

6 © ISO 2021 – All rights reserved

---------------------- Page: 11 ----------------------

ISO/DIS 7507-2:2021(E)

a) Centreline flush b) Outside flush c) Inside flush

Key

1 optical-reference-line

2 tank centreline

External reference circumference = C

External reference radius (bottom course) = Cem/2π = R

Outer radius of second course = R’ , R’ ,

1 2

Course thicknesses = t , t , etc.

1 2

Reference offset = a

Reference radius = R

Individual course offsets = m , m , etc.

1 2

Internal reference radius = R – t = Cem/2π – t = R

1 1 1

Internal radius, second course, bottom = R′

Internal radius, second course, top = R′

Figure 2 — Determination of internal radius from offsets to external optical-reference-line

© ISO 2021 – All rights reserved 7---------------------- Page: 12 ----------------------

ISO/DIS 7507-2:2021(E)

a) Centreline flush b) Outside flush c) Inside flush

Key

1 optical-reference-line

2 tank centreline

External reference circumference = C

External reference radius (bottom course) = Cem/2π = R

Outer radius of second course = R’ , R’ ,

1 2

Course thicknesses = t , t , etc.

1 2

Reference offset = a

Reference radius = R

Individual course offsets = m , m , etc.

1 2

Internal reference radius = R – t = Cem/2π – t = R

1 1 1

Internal radius, second course, bottom = R’

Internal radius, second course, top = R’

Figure 3 — Determination of internal radius from offsets to internal optical-reference-line

6.4.3 Verify the verticality of the optical-reference-line prior to the commencement of readings

by turning the optical instrument at the first horizontal station through 180°, whereby the difference

between the two readings of the diametrically opposite positions shall be within 1 in 20 000. Also, verify

the verticality of the optical-reference-line at each station at the completion of the readings. If verticality

has not been maintained, repeat the calibration procedure at this station.6.4.4 Take a minimum of two measurements of offsets from vertical per course at each horizontal

station, aiming at 1/4 of course height above the lower horizontal seam and at 1/4 of course height

below the upper horizontal seam. Read the graduated scale to the nearest millimetre.

6.4.5 At all horizontal stations, measure the reference offset and then take offset measurements

progressively at vertical stations on each course as the trolley is raised up the tank wall. After the last

offset measurement has been taken on the top course, lower the trolley to the bottom course and repeat

the reference offset. The initial and final reference offset readings shall agree to within two millimetres.

In further calculations, use the mean average of the initial and the final offset readings.

If agreement is not obtained, repeat vertical offset measurements at this horizontal station.

8 © ISO 2021 – All rights reserved---------------------- Page: 13 ----------------------

ISO/DIS 7507-2:2021(E)

6.5 Offsets measured by Electro-optical Distance-Ranging method

6.5.1 EODR instrument set-up

6.5.1.1 The instrument shall be set up with care, in accordance with the procedure and instructions

given by the manufacturer.6.5.1.2 Set up the instrument so as to be stable. Drive the legs of the tripod fully home into the ground.

6.5.1.3 Set the bed plate of the instrument as near as possible to the horizontal.

NOTE This ensures verticality of the swivel axis of the theodolite or total station.

6.5.1.4 The sighting lines from the instrument to the tank shell wall shall not be obstructed.

6.5.1.5 At least the minimum settling time recommended by the manufacturer should be allowed

before the instrument is used.6.5.1.6 The instrument shall be set horizontal, thus ensuring that the vertical axis (standing axis) is

vertical.6.5.2 EODR calibration procedure

6.5.2.1 All measurements should be carried out without interruption and as quickly as possible.

6.5.2.2 Set up the theodolite or total station outside the tank, as shown in Figure XX for ten theodolite

stations and as described in 6.5.1The minimum number of stations (T1, T2, etc.) per circumference shall be as given in Table 1.

The theodolite positions should be such that the target points are at least 300 mm from any vertical

welded seam and the tank shell wall not be obstructed.Care should be taken, especially for smaller tanks, that the stations are evenly distributed around

the tank.6.5.2.3 From each station and at the height at which the reference circumference was measured (see

6.3), make a sighting tangentially to the tank on either side of the theodolite as shown in Figure XX.

Maintain the same vertical angle of the theodolite in both sightings.NOTE This ensures that the intended targets on the tank are at the same level.

Record the horizontal angles subtended by the tangents at the theodolite and calculate the average

horizontal angle ϴhor .avg

© ISO 2021 – All rights reserved 9

---------------------- Page: 14 ----------------------

ISO/DIS 7507-2:2021(E)

Key

T1 … T10: theodolite stations

Figure 4 — Example of theodolite station locations

6.5.2.4 Select and clearly mark one reference target point on the tank wall as near to the average

horizontal angle ϴhor and to the reference circumference. Measure and record the slope distance,

avghorizontal and vertical angles or, if possible, the horizontal distance of this reference target point.

6.5.2.5 For each theodolite station (e.g. T1) and as near to the average horizontal angle ϴhor , sight

avgtwo target points per course, one at about ¼ of the course height above the lower horizontal seam, the

other at about ¼ of the course height below the upper horizontal seam. Measure and record the slope

distance, horizontal and vertical angles or, if possible, the horizontal distance of each target point.

NOTE horizontal distance = slope distance D × cos(Φ).10 © ISO 2021 – All rights reserved

---------------------- Page: 15 ----------------------

ISO/DIS 7507-2:2021(E)

Key

1 course height ϴ horizontal angle

2 EODR instrument Φ vertical angle

3 target points on tank wall D slope distance

Figure 5 — Illustration of calibration procedure

6.5.2.6 After all measurements have been completed, repeat the measurements to the reference target

point. If the repeated slope (or if possible horizontal) distance to the reference target point do not agree

with in 2 mm, repeat the procedure given in 6.5.2.1 to 6.5.2.56.5.2.7 Mo

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.