ISO/FDIS 8655-7

(Main)Piston-operated volumetric apparatus

Piston-operated volumetric apparatus

Appareils volumétriques à piston

General Information

RELATIONS

Standards Content (sample)

FINAL

INTERNATIONAL ISO/FDIS

DRAFT

STANDARD 8655-7

ISO/TC 48

Piston-operated volumetric

Secretariat: DIN

apparatus —

Voting begins on:

2021-11-17

Part 7:

Voting terminates on:

Alternative measurement procedures

2022-01-12

for the determination of volume

Appareils volumétriques à piston —

Partie 7: Modes opératoires de mesure alternatifs pour la

détermination de volumes

ISO/CEN PARALLEL PROCESSING

RECIPIENTS OF THIS DRAFT ARE INVITED TO

SUBMIT, WITH THEIR COMMENTS, NOTIFICATION

OF ANY RELEVANT PATENT RIGHTS OF WHICH

THEY ARE AWARE AND TO PROVIDE SUPPOR TING

DOCUMENTATION.

IN ADDITION TO THEIR EVALUATION AS

Reference number

BEING ACCEPTABLE FOR INDUSTRIAL, TECHNO-

ISO/FDIS 8655-7:2021(E)

LOGICAL, COMMERCIAL AND USER PURPOSES,

DRAFT INTERNATIONAL STANDARDS MAY ON

OCCASION HAVE TO BE CONSIDERED IN THE

LIGHT OF THEIR POTENTIAL TO BECOME STAN-

DARDS TO WHICH REFERENCE MAY BE MADE IN

NATIONAL REGULATIONS. © ISO 2021

---------------------- Page: 1 ----------------------

ISO/FDIS 8655-7:2021(E)

COPYRIGHT PROTECTED DOCUMENT

© ISO 2021

All rights reserved. Unless otherwise specified, or required in the context of its implementation, no part of this publication may

be reproduced or utilized otherwise in any form or by any means, electronic or mechanical, including photocopying, or posting on

the internet or an intranet, without prior written permission. Permission can be requested from either ISO at the address below

or ISO’s member body in the country of the requester.ISO copyright office

CP 401 • Ch. de Blandonnet 8

CH-1214 Vernier, Geneva

Phone: +41 22 749 01 11

Email: copyright@iso.org

Website: www.iso.org

Published in Switzerland

© ISO 2021 – All rights reserved

---------------------- Page: 2 ----------------------

ISO/FDIS 8655-7:2021(E)

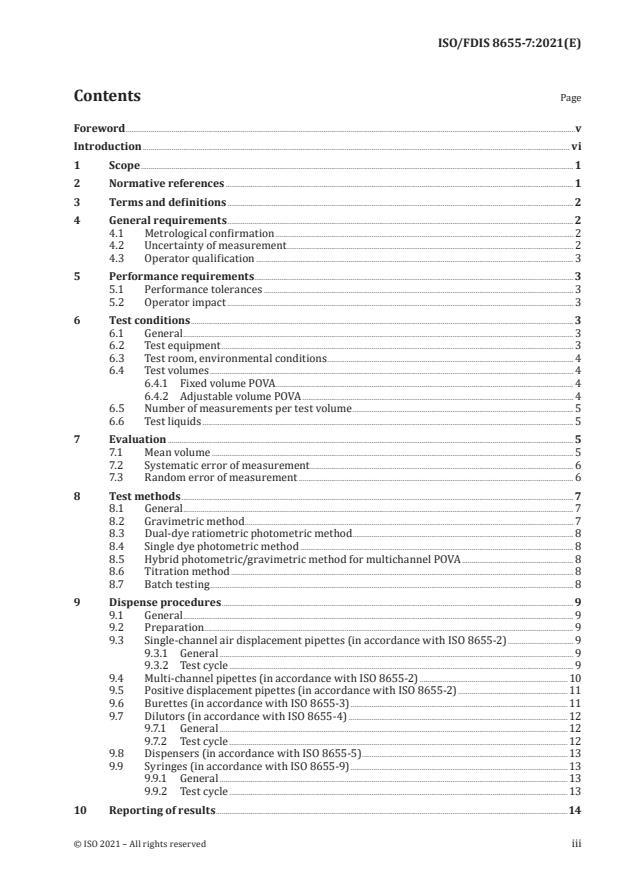

Contents Page

Foreword ..........................................................................................................................................................................................................................................v

Introduction .............................................................................................................................................................................................................................. vi

1 Scope ................................................................................................................................................................................................................................. 1

2 Normative references ..................................................................................................................................................................................... 1

3 Terms and definitions .................................................................................................................................................................................... 2

4 General requirements .................................................................................................................................................................................... 2

4.1 Metrological confirmation ........................................................................................................................................................... 2

4.2 Uncertainty of measurement ..................................................................................................................................................... 2

4.3 Operator qualification ..................................................................................................................................................................... 3

5 Performance requirements ........................................................................................................................................... ...........................3

5.1 Performance tolerances ................................................................................................................................................................. 3

5.2 Operator impact .................................................................................................................................................................................... 3

6 Test conditions .......................................................................................................................................................................................................3

6.1 General ........................................................................................................................................................................................................... 3

6.2 Test equipment ....................................................................................................................................................................................... 3

6.3 Test room, environmental conditions ................................................................................................................................ 4

6.4 Test volumes ............................................................................................................................................................................................. 4

6.4.1 Fixed volume POVA........................................................................................................................................................... 4

6.4.2 Adjustable volume POVA ............................................................................................................................................. 4

6.5 Number of measurements per test volume ................................................................................................................... 5

6.6 Test liquids ................................................................................................................................................................................................. 5

7 Evaluation ................................................................................................................................................................................................................... 5

7.1 Mean volume ............................................................................................................................................................................................ 5

7.2 Systematic error of measurement ......................................................................................................................................... 6

7.3 Random error of measurement ............................................................................................................................................... 6

8 Test methods ............................................................................................................................................................................................................ 7

8.1 General ........................................................................................................................................................................................................... 7

8.2 Gravimetric method ........................................................................................................................................... ................................ 7

8.3 Dual-dye ratiometric photometric method ................................................................................................................... 8

8.4 Single dye photometric method .............................................................................................................................................. 8

8.5 Hybrid photometric/gravimetric method for multichannel POVA .......................................................... 8

8.6 Titration method .................................................................................................................................................................................. 8

8.7 Batch testing ............................................................................................................................................................................................. 8

9 Dispense procedures .......................................................................................................................................................................................9

9.1 General ........................................................................................................................................................................................................... 9

9.2 Preparation ................................................................................................................................................................................................ 9

9.3 Single-channel air displacement pipettes (in accordance with ISO 8655-2) .................................. 9

9.3.1 General ........................................................................................................................................................................................ 9

9.3.2 Test cycle ................................................................................................................................................................................... 9

9.4 Multi-channel pipettes (in accordance with ISO 8655-2) ............................................................................. 10

9.5 Positive displacement pipettes (in accordance with ISO 8655-2) ......................................................... 11

9.6 Burettes (in accordance with ISO 8655-3) ................................................................................................................. 11

9.7 Dilutors (in accordance with ISO 8655-4) ..................................................................................................................12

9.7.1 General .....................................................................................................................................................................................12

9.7.2 Test cycle ................................................................................................................................................................................12

9.8 Dispensers (in accordance with ISO 8655-5) ........................................................................................................... 13

9.9 Syringes (in accordance with ISO 8655-9) ................................................................................................................. 13

9.9.1 General .....................................................................................................................................................................................13

9.9.2 Test cycle ................................................................................................................................................................................ 13

10 Reporting of results .......................................................................................................................................................................................14

iii© ISO 2021 – All rights reserved

---------------------- Page: 3 ----------------------

ISO/FDIS 8655-7:2021(E)

Annex A (normative) Gravimetric procedure .........................................................................................................................................16

Annex B (normative) Dual-dye ratiometric photometric procedure .............................................................................21

Annex C (normative) Single dye photometric procedure ...........................................................................................................29

Annex D (normative) Photometric/gravimetric hybrid procedure ................................................................................33

Annex E (normative) Titrimetric procedure............................................................................................................................................41

Annex F (normative) Conversion of liquid mass to volume ......................................................................................................45

Bibliography .............................................................................................................................................................................................................................48

© ISO 2021 – All rights reserved---------------------- Page: 4 ----------------------

ISO/FDIS 8655-7:2021(E)

Foreword

ISO (the International Organization for Standardization) is a worldwide federation of national standards

bodies (ISO member bodies). The work of preparing International Standards is normally carried out

through ISO technical committees. Each member body interested in a subject for which a technical

committee has been established has the right to be represented on that committee. International

organizations, governmental and non-governmental, in liaison with ISO, also take part in the work.

ISO collaborates closely with the International Electrotechnical Commission (IEC) on all matters of

electrotechnical standardization.The procedures used to develop this document and those intended for its further maintenance are

described in the ISO/IEC Directives, Part 1. In particular, the different approval criteria needed for the

different types of ISO documents should be noted. This document was drafted in accordance with the

editorial rules of the ISO/IEC Directives, Part 2 (see www.iso.org/directives).Attention is drawn to the possibility that some of the elements of this document may be the subject of

patent rights. ISO shall not be held responsible for identifying any or all such patent rights. Details of

any patent rights identified during the development of the document will be in the Introduction and/or

on the ISO list of patent declarations received (see www.iso.org/patents).Any trade name used in this document is information given for the convenience of users and does not

constitute an endorsement.For an explanation of the voluntary nature of standards, the meaning of ISO specific terms and

expressions related to conformity assessment, as well as information about ISO's adherence to

the World Trade Organization (WTO) principles in the Technical Barriers to Trade (TBT), see

www.iso.org/iso/foreword.html.This document was prepared by Technical Committee ISO/TC 48, Laboratory equipment, in collaboration

with the European Committee for Standardization (CEN) Technical Committee CEN/TC 332, Laboratory

equipment, in accordance with the Agreement on technical cooperation between ISO and CEN (Vienna

Agreement).This second edition cancels and replaces the first edition (ISO 8655-7:2005), which has been technically

revised. It also incorporates the Technical Corrigendum ISO 8655-7:2005/Cor.1:2008.

The main changes compared to the previous edition are as follows:— a gravimetric test method was added (see 8.2);

— a photometric/gravimetric hybrid test method was added (see 8.5);

— a batch testing method was added (see 8.7);

— measurement procedures for all methods are given in normative Annexes A to E;

— standard dispense procedures for POVA described in ISO 8655-2, ISO 8655−3, ISO 8655−4,

ISO 8655−5, and ISO 8655−9 were added (see Clause 9);— requirements for operator qualification have been added (see 4.3);

— requirements for testing of multi-channel POVA is described in more detail, with specific procedures

given for these apparatus (see 8.5, and Annex D);— Annexes A, B, and C of the first edition have been deleted and replaced.

A list of all parts in the ISO 8655 series can be found on the ISO website.

Any feedback or questions on this document should be directed to the user’s national standards body. A

complete listing of these bodies can be found at www.iso.org/members.html.© ISO 2021 – All rights reserved

---------------------- Page: 5 ----------------------

ISO/FDIS 8655-7:2021(E)

Introduction

The ISO 8655 series addresses the needs of:

— manufacturers, as a basis for quality control including, where appropriate, the issuance of

manufacturer’s declarations;— calibration laboratories, test houses, users of the equipment and other bodies as a basis for

independent calibration, testing, verification, and routine tests.The tests specified in the ISO 8655 series are intended to be carried out by trained personnel.

© ISO 2021 – All rights reserved---------------------- Page: 6 ----------------------

FINAL DRAFT INTERNATIONAL STANDARD ISO/FDIS 8655-7:2021(E)

Piston-operated volumetric apparatus —

Part 7:

Alternative measurement procedures for the

determination of volume

1 Scope

This document specifies alternative measurement procedures for the determination of volume of

piston-operated volumetric apparatus.The procedures are applicable to complete systems comprising the basic apparatus and all parts

selected for use with the apparatus, disposable or reusable, involved in the measurement by delivery

process (Ex). Methods described in this document are suitable for various maximum nominal volumes

of piston-operated volumetric apparatus. It is the responsibility of the user to select the appropriate

method.2 Normative references

The following documents are referred to in the text in such a way that some or all of their content

constitutes requirements of this document. For dated references, only the edition cited applies. For

undated references, the latest edition of the referenced document (including any amendments) applies.

ISO 1042, Laboratory glassware — One-mark volumetric flasksISO 2859-1, Sampling procedures for inspection by attributes — Part 1: Sampling schemes indexed by

acceptance quality limit (AQL) for lot-by-lot inspectionISO 3696:1987, Water for analytical laboratory use — Specification and test methods

ISO 3951-1, Sampling procedures for inspection by variables — Part 1: Specification for single sampling

plans indexed by acceptance quality limit (AQL) for lot-by-lot inspection for a single quality characteristic

and a single AQLISO 8655-1:— , Piston-operated volumetric apparatus — Part 1: Terminology, general requirements and

user recommendationsISO 8655-2:— , Piston-operated volumetric apparatus — Part 2: Pipettes

ISO 8655-3:2021, Piston-operated volumetric apparatus — Part 3: Burettes

ISO 8655-4:2021, Piston-operated volumetric apparatus — Part 4: Dilutors

ISO 8655-5:2021, Piston-operated volumetric apparatus — Part 5: Dispensers

ISO 8655-6, Piston-operated volumetric apparatus — Part 6: Gravimetric reference measurement

procedure for the determination of volumeISO 8655-8, Piston-operated volumetric apparatus — Part 8: Photometric reference measurement

procedure for the determination of volume1) Under preparation. Stage at the time of publication: ISO/FDIS 8655-1:2021.

2) Under preparation. Stage at the time of publication: ISO/FDIS 8655-2:2021.

© ISO 2021 – All rights reserved

---------------------- Page: 7 ----------------------

ISO/FDIS 8655-7:2021(E)

ISO 8655-9, Piston-operated volumetric apparatus — Part 9: Manually operated precision laboratory

syringesISO/IEC Guide 2, Standardization and related activities — General vocabulary

ISO/IEC Guide 99, International vocabulary of metrology — Basic and general concepts and associated

terms (VIM)3 Terms and definitions

For the purposes of this document, the terms and definitions given in ISO 8655-1, ISO/IEC Guide 2, and

ISO/IEC Guide 99 apply.ISO and IEC maintain terminological databases for use in standardization at the following addresses:

— IEC Electropedia: available at https:// www .electropedia .org/— ISO Online browsing platform: available at https:// www .iso .org/ obp

3.1

acceptance quality limit

AQL

worst tolerable quality level

Note 1 to entry: This concept only applies when a sampling scheme with rules for switching and for

discontinuation, such as in ISO 2859-1, ISO 3951-1 or ISO 3951-5 is used.Note 2 to entry: Although individual lots with quality as bad as the acceptance quality limit may be accepted

with fairly high probability, the designation of an acceptance quality limit does not suggest that this is a desirable

quality level. Sampling schemes found in International Standards such as ISO 2859-1, ISO 3951-1 or ISO 3951-5,

with their rules for switching and for discontinuation of sampling inspection, are designed to encourage suppliers

to have process averages consistently better than the AQL.4 General requirements

4.1 Metrological confirmation

Metrological confirmation of all POVA shall be performed on a regular basis to ensure the apparatus

conforms to requirements for its intended use. The requirements of the methods and procedures

described in this document are suitable to be used in the metrological confirmation of POVA. For

metrological confirmation, no less than ten replicate measurements per selected volume shall be

performed and the measurement procedures in this document shall be validated by comparison to one

of the reference measurement procedures described in ISO 8655-6 or ISO 8655-8.4.2 Uncertainty of measurement

When performing calibrations (ISO 8655-1:—, 6.4) according to measurement procedures described in

this document, the expanded measurement uncertainty of the mean delivered volume for each selected

volume shall be estimated and reported (see Clause 10 (m)).When performing testing (ISO 8655-1:2022, 6.4) or routine tests (ISO 8655-1:2022, 6.5), it is optional to

estimate and report the expanded measurement uncertainty.NOTE For further information on uncertainty for the photometric and gravimetric methods, refer to

[1] [2]ISO/TR 16153 and ISO/TR 20461 respectively.

© ISO 2021 – All rights reserved

---------------------- Page: 8 ----------------------

ISO/FDIS 8655-7:2021(E)

4.3 Operator qualification

An operator who uses POVA for volumetric transfers, performs metrological confirmation or routine

tests of POVA shall be adequately trained on the use of the type of POVA under test. Operator training

and competence should be documented.NOTE 1 Previously calibrated POVA can be used for the qualification of operators.

NOTE 2 Training and qualification requirements for operators of POVA are intended to be included in

ISO 8655-10.5 Performance requirements

5.1 Performance tolerances

Calibration and routine test results may be reported without comparison to performance tolerances.

If the results are verified against performance tolerances, these tolerances shall be stated on the test

report/certificate.Performance tolerances may be based on the user’s liquid handling process tolerances or the product

tolerances given in the part of ISO 8655 corresponding to the type of POVA under test or the tolerances

specified by the manufacturer, subject to them being fit for purpose.5.2 Operator impact

Measurement of volumetric performance includes random and systematic errors of the POVA, as well as

errors introduced by the device’s operator. The performance of a hand-held pipette is inseparable from

the performance of its operator.NOTE More information about operator impact is given in ISO 8655-10.

6 Test conditions

6.1 General

Test conditions described in this clause shall be validated for their suitability for the selected test

method and procedure. Test conditions, together with the test equipment and detailed test procedure,

impact the uncertainty of measurement. Examples for the calculation of the expanded uncertainty of

[1]the mean volume and of the uncertainty in use of a single delivered volume are given in ISO/TR 16153

[2]and ISO/TR 20461 .

6.2 Test equipment

All equipment used for the testing of POVA, including for the preparation of test solutions, shall be

chosen such that the required uncertainty of measurement can be obtained.All test equipment used shall be of suitable readability, accuracy, reproducibility and stability, consistent

with the required expanded uncertainty of measurement.Deviations from the test equipment given in this document shall be taken into account when calculating

the expanded measurement uncertainty and shall be proven to yield measurement results fit for the

intended purpose.© ISO 2021 – All rights reserved

---------------------- Page: 9 ----------------------

ISO/FDIS 8655-7:2021(E)

6.3 Test room, environmental conditions

The following applies:

a) The test room should be kept at a steady temperature throughout the entirety of the equilibration

time for the test equipment and POVA (±1 °C), and throughout the POVA testing time (±0,5 °C). All

test equipment, POVA, exchangeable parts (e. g. pipette tips), and reagents used shall be equilibrated

to the test room temperature.b) The air temperature, relative humidity, and barometric pressure at the time of the test shall be

recorded. At the start and at the end of the n replicate measurements, the temperature of the test

liquid shall be recorded.NOTE 1 Air temperature and barometric pressure are necessary for the conversion of liquid mass to

volume (see Annex F); the relative humidity is necessary for the stability of the room conditions and is

necessary for documentation in the test report.c) To aid evaluation of a POVA’s fitness for purpose, the test room conditions (temperature, relative

humidity, and barometric pressure) should reflect the environmental conditions under which the

POVA is used, within the constraints mentioned in a). This can be achieved when a POVA is tested

within the laboratory in which it is used. Other environmental and non-environmental factors can

influence a POVA’s fitness for purpose.d) The test environment should be draft free.

e) Prior to the test, the apparatus to be tested, all test equipment, and test solutions shall have stood

in the test room conditions for a sufficient time to reach equilibrium with the test room conditions.

f) The environmental conditions, air temperature and air humidity, shall be within the specified

limits for the test room for at least 2 h before starting the test (minimum equilibration time) and

during the test itself.NOTE 2 It is unlikely that this minimum equilibration time will be less than 2h and can be considerably

longer.NOTE 3 Calibration laboratories at test houses or pipette manufacturer’s quality control laboratories can

often precisely control environmental conditions to achieve a desired standard condition. It can be very

challenging to reproduce such results under different environmental conditions.6.4 Test volumes

6.4.1 Fixed volume POVA

In the case of a fixed-volume POVA, the selected volume V is the nominal volume V and is the only

S nomtest volume.

6.4.2 Adjustable volume POVA

a) For calibrations and testing, adjustable volume POVA shall be tested at least at three volumes:

— nominal volume,— 50 % of the nominal volume, or the closest possible (if equidistant, use the higher value);

— the lower limit of the useable volume range or 10 % of the nominal volume (whichever is the

greater).Measurement of further volumes is optional.

b) For routine tests, fewer than three volumes may be tested.

© ISO 2021 – All rights reserved

---------------------- Page: 10 ----------------------

ISO/FDIS 8655-7:2021(E)

In case the POVA is to be tested at only two volumes, the nominal volume and the lower limit of the

useable volume range, or 10 % of the nominal volume (whichever is the greater), shall be tested.

NOTE The linearity of delivered volumes between these two test points is unknown and is likely to increase

the risk for volumetric errors as compared to a test at three volumes.In case the POVA is tested only at one volume, it shall be tested at its nominal volume, or at the volume

at which it will be used.6.5 Number of measurements per test volume

The confidence of metrological confirmation increases with the number of replicate measurements

for each test volume. A minimum of 10 measurements per volume are required by the reference

measurement procedures specified in ISO 8655-6 and ISO 8655-8. For the test procedures specified in

this document, 10 measurements are recommended, but fewer replicate measurements may be made if

the expanded uncertainty of measurement for the POVA is fit for the intended purpose. The number of

replicates shall not be less than 4.After repair or adjustment of the POVA, a minimum of 10 measurements shall be performed.

The replicate volume measurements shall be used to calculate the systematic and the random errors of

measurement in accordance with Clause 8. When applicable, the reported uncertainty shall be based on

the number of replicates.6.6 Test liquids

POVA are typically supplied with adjustments using water. Calibrations or routine tests may be

performed using other liquids or solutions. For the purpose of this document, the term “test liquid”

is used for pure solvents, as well as for prepared chromophore or other solutions. The test liquid used

shall be described in sufficient detail to allow replication of the test and interpretation of the results.

The following characteristics of the test liquid shall be taken into account when determining the

measured volume: Z-factor when weighing, absorbances of the chromophores when using photometric

methods, and conductivity and reactivity when performing potentiometric titration.

Depending on the type of POVA, the following parameters can influence the amount of liquid aspirated

and/or dispensed: viscosity, density, chemical composition, and surface t...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.