ISO/PRF 23641

(Main)Flexible cellular polymeric materials -- Determination of antibacterial effectiveness

Flexible cellular polymeric materials -- Determination of antibacterial effectiveness

Titre manque

General Information

Standards Content (sample)

INTERNATIONAL ISO

STANDARD 23641

First edition

Flexible cellular polymeric

materials — Determination of

antibacterial effectiveness

PROOF/ÉPREUVE

Reference number

ISO 23641:2021(E)

ISO 2021

---------------------- Page: 1 ----------------------

ISO 23641:2021(E)

COPYRIGHT PROTECTED DOCUMENT

© ISO 2021

All rights reserved. Unless otherwise specified, or required in the context of its implementation, no part of this publication may

be reproduced or utilized otherwise in any form or by any means, electronic or mechanical, including photocopying, or posting

on the internet or an intranet, without prior written permission. Permission can be requested from either ISO at the address

below or ISO’s member body in the country of the requester.ISO copyright office

CP 401 • Ch. de Blandonnet 8

CH-1214 Vernier, Geneva

Phone: +41 22 749 01 11

Email: copyright@iso.org

Website: www.iso.org

Published in Switzerland

ii PROOF/ÉPREUVE © ISO 2021 – All rights reserved

---------------------- Page: 2 ----------------------

ISO 23641:2021(E)

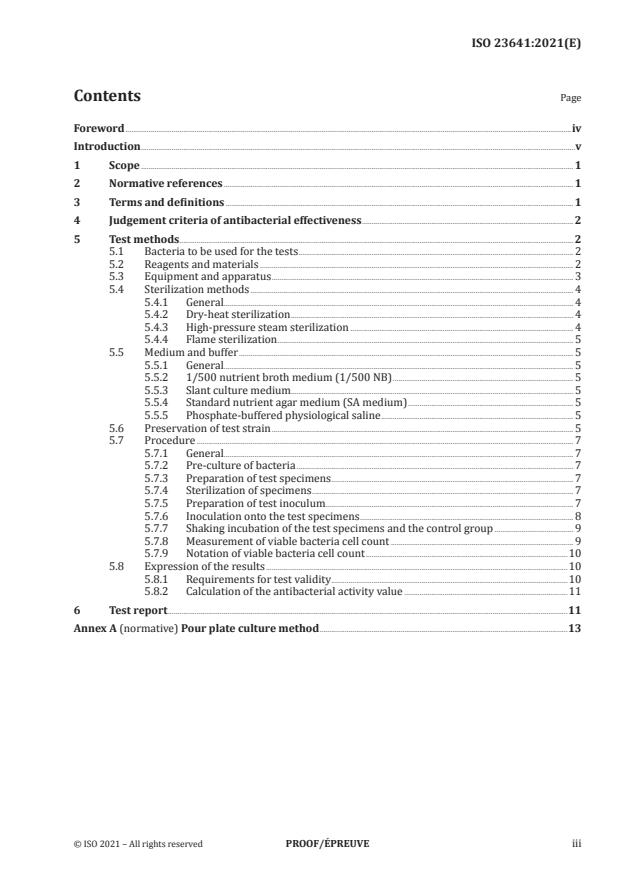

Contents Page

Foreword ........................................................................................................................................................................................................................................iv

Introduction ..................................................................................................................................................................................................................................v

1 Scope ................................................................................................................................................................................................................................. 1

2 Normative references ...................................................................................................................................................................................... 1

3 Terms and definitions ..................................................................................................................................................................................... 1

4 Judgement criteria of antibacterial effectiveness .............................................................................................................. 2

5 Test methods ............................................................................................................................................................................................................. 2

5.1 Bacteria to be used for the tests ............................................................................................................................................... 2

5.2 Reagents and materials ................................................................................................................................................................... 2

5.3 Equipment and apparatus ............................................................................................................................................................. 3

5.4 Sterilization methods ........................................................................................................................................................................ 4

5.4.1 General...................................................................................................................................................................................... 4

5.4.2 Dry-heat sterilization ................................................................................................................................................... 4

5.4.3 High-pressure steam sterilization .................................................................................................................... 4

5.4.4 Flame sterilization .......................................................................................................................................................... 5

5.5 Medium and buffer .............................................................................................................................................................................. 5

5.5.1 General...................................................................................................................................................................................... 5

5.5.2 1/500 nutrient broth medium (1/500 NB) .............................................................................................. 5

5.5.3 Slant culture medium................................................................................................................................................... 5

5.5.4 Standard nutrient agar medium (SA medium) ...................................................................................... 5

5.5.5 Phosphate-buffered physiological saline .................................................................................................... 5

5.6 Preservation of test strain ............................................................................................................................................................. 5

5.7 Procedure .................................................................................................................................................................................................... 7

5.7.1 General...................................................................................................................................................................................... 7

5.7.2 Pre-culture of bacteria ................................................................................................................................................ 7

5.7.3 Preparation of test specimens .............................................................................................................................. 7

5.7.4 Sterilization of specimens ........................................................................................................................................ 7

5.7.5 Preparation of test inoculum ................................................................................................................................. 7

5.7.6 Inoculation onto the test specimens ............................................................................................................... 8

5.7.7 Shaking incubation of the test specimens and the control group ......................................... 9

5.7.8 Measurement of viable bacteria cell count ............................................................................................... 9

5.7.9 Notation of viable bacteria cell count .........................................................................................................10

5.8 Expression of the results .............................................................................................................................................................10

5.8.1 Requirements for test validity ...........................................................................................................................10

5.8.2 Calculation of the antibacterial activity value .....................................................................................11

6 Test report ................................................................................................................................................................................................................11

Annex A (normative) Pour plate culture method .................................................................................................................................13

© ISO 2021 – All rights reserved PROOF/ÉPREUVE iii---------------------- Page: 3 ----------------------

ISO 23641:2021(E)

Foreword

ISO (the International Organization for Standardization) is a worldwide federation of national standards

bodies (ISO member bodies). The work of preparing International Standards is normally carried out

through ISO technical committees. Each member body interested in a subject for which a technical

committee has been established has the right to be represented on that committee. International

organizations, governmental and non-governmental, in liaison with ISO, also take part in the work.

ISO collaborates closely with the International Electrotechnical Commission (IEC) on all matters of

electrotechnical standardization.The procedures used to develop this document and those intended for its further maintenance are

described in the ISO/IEC Directives, Part 1. In particular, the different approval criteria needed for the

different types of ISO documents should be noted. This document was drafted in accordance with the

editorial rules of the ISO/IEC Directives, Part 2 (see www .iso .org/ directives).

Attention is drawn to the possibility that some of the elements of this document may be the subject of

patent rights. ISO shall not be held responsible for identifying any or all such patent rights. Details of

any patent rights identified during the development of the document will be in the Introduction and/or

on the ISO list of patent declarations received (see www .iso .org/ patents).Any trade name used in this document is information given for the convenience of users and does not

constitute an endorsement.For an explanation of the voluntary nature of standards, the meaning of ISO specific terms and

expressions related to conformity assessment, as well as information about ISO's adherence to the

World Trade Organization (WTO) principles in the Technical Barriers to Trade (TBT), see www .iso .org/

iso/ foreword .html.This document was prepared by Technical Committee ISO/TC 45, Rubber and rubber products,

Subcommittee SC 4, Products (other than hoses).Any feedback or questions on this document should be directed to the user’s national standards body. A

complete listing of these bodies can be found at www .iso .org/ members .html.iv PROOF/ÉPREUVE © ISO 2021 – All rights reserved

---------------------- Page: 4 ----------------------

ISO 23641:2021(E)

Introduction

Products with a label or marking tag of antibacterial treatment, such as kitchen sponge cleaners,

mattresses, pillows and sofas, are available in markets worldwide. However, there is no common

standard to evaluate the effectiveness of the antibacterial treatment. The material used for these

products is usually a flexible cellular polymeric foam treated with antibacterial agents available

in the markets. Because of the porosity of the material, efficient contact between a testing bacterial

suspension and the material is critical in an evaluation of the effectiveness of antibacterial treatment.

A specific procedure has been developed and adopted for this test method so that the test bacteria can

efficiently make contact with the open cell surface of the flexible cellular polymeric test specimens.

This document will help consumers to know whether these products have the appropriate quality of

antibacterial effectiveness.© ISO 2021 – All rights reserved PROOF/ÉPREUVE v

---------------------- Page: 5 ----------------------

INTERNATIONAL STANDARD ISO 23641:2021(E)

Flexible cellular polymeric materials — Determination of

antibacterial effectiveness

WARNING — Persons using this document should be familiar with microbiology. This document

does not purport to address all of the safety problems, if any, associated with its use. It is the

responsibility of the user of this document to establish appropriate safety and health practices

and to determine the applicability of any national regulatory conditions.1 Scope

This document specifies a method of determining the antibacterial effectiveness of open-cell flexible

cellular polymeric antibacterial treated materials, including their intermediate and final products.

This document is suitable for flexible cellular polymeric materials because the test procedure enables

the test inoculum to efficiently contact with the surface of open cell in the flexible cellular polymeric

materials.2 Normative references

The following documents are referred to in the text in such a way that some or all of their content

constitutes requirements of this document. For dated references, only the edition cited applies. For

undated references, the latest edition of the referenced document (including any amendments) applies.

ISO 1923, Cellular plastics and rubbers — Determination of linear dimensions3 Terms and definitions

For the purposes of this document, the following terms and definitions apply.

ISO and IEC maintain terminological databases for use in standardization at the following addresses:

— ISO Online browsing platform: available at https:// www .iso .org/ obp— IEC Electropedia: available at http:// www .electropedia .org/

3.1

surface of flexible cellular polymeric material

surface that is not only the outer peripheral surface but also the true surface of open-cell structure of

flexible cellular polymeric material3.2

antibacterial

condition suppressing the growth of bacteria on the surface of flexible cellular polymeric material

3.3antibacterial agent

agent that inhibits the growth of bacteria on flexible cellular polymeric materials

3.4antibacterial treatment

treatment with antibacterial agents

3.5

antibacterial treated material

flexible cellular polymeric material that is treated with antibacterial agents

© ISO 2021 – All rights reserved PROOF/ÉPREUVE 1

---------------------- Page: 6 ----------------------

ISO 23641:2021(E)

3.6

antibacterial activity

difference in the logarithm of the viable cell counts found between an antibacterial-treated material

and an untreated material after inoculation with bacteria and incubation3.7

antibacterial effectiveness

ability of an antibacterial agent to inhibit the growth of bacteria on material treated with an

antibacterial agent, as determined by the value of the antibacterial activity4 Judgement criteria of antibacterial effectiveness

When the antibacterial activity value is not less than 2,0, the antibacterial effectiveness of antibacterial

treated material is judged to be significant. An antibacterial activity value of more than 2,0 may be

agreed between all interested parties.5 Test methods

5.1 Bacteria to be used for the tests

Both of the following species of bacteria shall be used:

a) Staphylococcus aureus;

b) Escherichia coli.

The bacterial strains to be used are shown in Table 1. If bacterial strains obtained from culture

collections other than those shown in Table 1 are used, they shall be obtained from a member agency

of the World Federation for Culture Collections (WFCC) or the Japan Society for Culture Collections

(JSCC) and shall be the same strains as those shown in Table 1. Prepare stock cultures of these species

in accordance with the supplier's directions.Table 1 — Bacterial strains to be used

Name Strain Culture collection

ATCC 6538P American Type Culture Collection

FDA 209P US Food and Drug Administration

NBRC 12732 National Institute of Technology and Evaluation

Staphylococcus aureus

CIP 53.156 Collection des Bacteries deI’Institut Pasteur Deutsche

DSM 346 Sammlung von Mikroorganismen und Zellkulturen Gmbh

NCIB 8625 National Collection of Industrial and Marine Bacteria Ltd

ATCC 8739 American Type Culture Collection

NBRC 3972 National Institute of Technology and Evaluation

Escherichia coli CIP 53.126 Collection des Bacteries deI’Institut Pasteur Deutsche

DSM 1576 Sammlung von Mikroorganismen und Zellkulturen GmbhNCIB 8545 National Collection of Industrial and Marine Bacteria Ltd

5.2 Reagents and materials

The following reagents and materials shall be used:

2 PROOF/ÉPREUVE © ISO 2021 – All rights reserved

---------------------- Page: 7 ----------------------

ISO 23641:2021(E)

5.2.1 Water, an analytical grade for microbiological media preparation, which is freshly distilled, ion-

exchanged, filtered with RO (reverse osmosis) or ultra-filtered, or a combination of these. It shall be free

from all toxic or bacteria inhibitory substances.5.2.2 Meat extract, for microbial test.

5.2.3 Peptone, for microbial test.

5.2.4 Sodium chloride, analytical grade, a grade appropriate for microbiological purposes or both.

5.2.5 Nonionic surfactant, polyoxyethylene sorbitan monooleate.NOTE The generic name of polyoxyethylene sorbitan monooleate is polysorbate 80 (Tween 80 ).

5.2.6 Sodium hydroxide, analytical grade, a grade appropriate for microbiological purposes or both.

5.2.7 Hydrochloric acid, analytical grade, a grade appropriate for microbiological purposes or both.

5.2.8 Agar, analytical grade, a grade appropriate for microbiological purposes or both.

5.2.9 Yeast extract, for microbial test.5.2.10 Trypton, for microbial test.

5.2.11 Glucose, for microbial test.

5.2.12 Potassium dihydrogen phosphate (KH PO ), analytical grade, a grade appropriate for

2 4microbiological purposes or both.

5.3 Equipment and apparatus

The usual laboratory apparatus and, in particular, the following shall be used:

5.3.1 Inoculation loops, 4 mm in ring diameter, made of platinum.

5.3.2 Dry-heat sterilizer, capable of maintaining the temperature at a value between 160 °C and

180 °C.5.3.3 Stopper, made of cotton, silicone, metal or molleton.

5.3.4 Autoclave, capable of maintaining a temperature of (121 ± 2) °C and a pressure of (103 ± 5) kPa.

5.3.5 Clean bench, for microbial test.5.3.6 Biological safety cabinet, for antibacterial test.

5.3.7 Balance, capable of weighing to ± 0,01 g.

5.3.8 pH-meter, capable of measuring ± 0,2 units.

5.3.9 Incubator, capable of maintaining the temperature within ± 1 °C of the set point at equilibrium

conditions.© ISO 2021 – All rights reserved PROOF/ÉPREUVE 3

---------------------- Page: 8 ----------------------

ISO 23641:2021(E)

5.3.10 Sterilized cup, with an outside diameter of 63 mm to 65 mm, a depth of 31 mm to 35 mm and an

internal volume of 50 ml to 60 ml.NOTE Sterilized cups with dimensions and volumes other than those specified can lead to different results.

5.3.11 Bacteria spreader, for microbial test and with a tip width of 20 mm or more.

5.3.12 Glass rod, with a diameter of approximately 20 mm and a flat tip.5.3.13 Shaker with thermostatic chamber, capable of shaking at (150 ± 10) rpm with (30 ± 5) mm in

amplitude of horizontal direction, and chamber with temperature control accuracy within ± 1 °C.

NOTE A mechanical shaker can be used in a thermostatic chamber.5.3.14 Pipettes, having the most suitable volume for each use, with a tip made of glass or plastic and a

tolerance of 0,5 % or less.5.3.15 Petri dishes, made of glass, sterilized plastics or both, with an inner diameter of approximately

90 mm.5.4 Sterilization methods

5.4.1 General

Glass and plastic apparatus are thoroughly washed with alkali or neutral detergent, rinsed thoroughly

with water, dried and then sterilized. The method of sterilization is according to 5.4.2 or 5.4.3. In the

case of flame sterilization of inoculation loops, follow 5.4.4.The plastic apparatus shall have heat resistance capable of withstanding the sterilization treatment

temperature, or sterile apparatus may be used. When sterile apparatus is used, another sterilization is

not necessary.5.4.2 Dry-heat sterilization

Place the apparatus to be sterilized in a dry-heat sterilizer, using the following minimum times for the

given temperature:Temperature Minimum sterilization time

170 °C 60 min

160 °C 120 min

If the cotton stopper or wrapping paper of the apparatus to be sterilized gets wet with water after

completion of dry-heat sterilization, the apparatus shall not be used.5.4.3 High-pressure steam sterilization

Pour water into an autoclave and then place the objects to be sterilized in a wire mesh basket on a

wire mesh shelf. After locking the lid of the autoclave, increase the temperature and maintain at a

temperature of 121 °C and a pressure of 103 kPa for 15 min to 20 min. After sterilization, naturally cool

down to 100 °C or lower, before removing the objects from the autoclave. If further cooling is necessary,

use a clean bench or a biological safety cabinet. An autoclave should be cleaned with neutral detergent

and rinsed with water to prevent contamination by medium and processing chemicals.

4 PROOF/ÉPREUVE © ISO 2021 – All rights reserved---------------------- Page: 9 ----------------------

ISO 23641:2021(E)

5.4.4 Flame sterilization

Flame the whole apparatus with gas or alcohol flames. In the case of an inoculation loop, flame it until it

glows. In the case of test tubes, flame them for 2 s to 3 s.5.5 Medium and buffer

5.5.1 General

As the medium and buffer solution, those having the following composition are used. Commercially

available products can be used as long as they have the same composition.5.5.2 1/500 nutrient broth medium (1/500 NB)

Add 5,0 g of meat extract, 10,0 g of peptone and 5,0 g of sodium chloride to 1 000 ml of water, mix and

dissolve, and prepare nutrient broth medium. 800 ml of water is added to 2 ml of nutrient broth medium

and 0,5 g of non-ionic surfactant that has been weighed, mixed and dissolved, and wat

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.