ISO 20329:2020

(Main)Plastics — Determination of abrasive wear by reciprocating linear sliding motion

Plastics — Determination of abrasive wear by reciprocating linear sliding motion

This document specifies a test method for the determination of abrasive wear resistance of plastics using abrasive material on a reciprocating motion. It also specifies calculation method for specific wear rate.

Plastiques — Détermination de la résistance à l'abrasion par la méthode du panneau d'essai en va-et-vient

General Information

Standards Content (Sample)

INTERNATIONAL ISO

STANDARD 20329

First edition

2020-09

Corrected version

2020-10

Plastics — Determination of abrasive

wear by reciprocating linear sliding

motion

Plastiques — Détermination de la résistance à l'abrasion par la

méthode du panneau d'essai en va-et-vient

Reference number

©

ISO 2020

© ISO 2020

All rights reserved. Unless otherwise specified, or required in the context of its implementation, no part of this publication may

be reproduced or utilized otherwise in any form or by any means, electronic or mechanical, including photocopying, or posting

on the internet or an intranet, without prior written permission. Permission can be requested from either ISO at the address

below or ISO’s member body in the country of the requester.

ISO copyright office

CP 401 • Ch. de Blandonnet 8

CH-1214 Vernier, Geneva

Phone: +41 22 749 01 11

Email: copyright@iso.org

Website: www.iso.org

Published in Switzerland

ii © ISO 2020 – All rights reserved

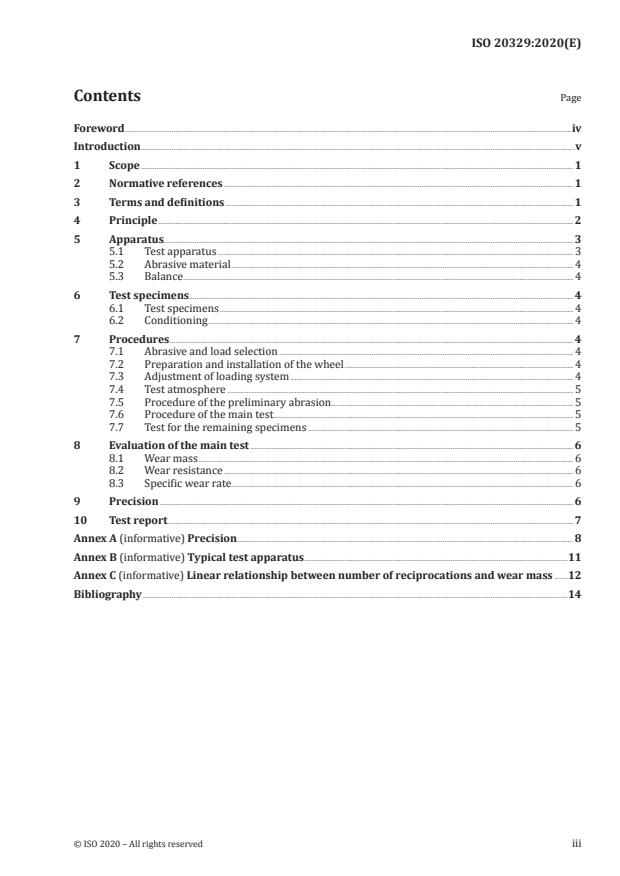

Contents Page

Foreword .iv

Introduction .v

1 Scope . 1

2 Normative references . 1

3 Terms and definitions . 1

4 Principle . 2

5 Apparatus . 3

5.1 Test apparatus . 3

5.2 Abrasive material . 4

5.3 Balance . 4

6 Test specimens. 4

6.1 Test specimens . 4

6.2 Conditioning . 4

7 Procedures . 4

7.1 Abrasive and load selection . 4

7.2 Preparation and installation of the wheel . 4

7.3 Adjustment of loading system . 4

7.4 Test atmosphere . 5

7.5 Procedure of the preliminary abrasion . 5

7.6 Procedure of the main test . 5

7.7 Test for the remaining specimens . 5

8 Evaluation of the main test . 6

8.1 Wear mass . 6

8.2 Wear resistance . 6

8.3 Specific wear rate. 6

9 Precision . 6

10 Test report . 7

Annex A (informative) Precision . 8

Annex B (informative) Typical test apparatus .11

Annex C (informative) Linear relationship between number of reciprocations and wear mass .12

Bibliography .14

Foreword

ISO (the International Organization for Standardization) is a worldwide federation of national standards

bodies (ISO member bodies). The work of preparing International Standards is normally carried out

through ISO technical committees. Each member body interested in a subject for which a technical

committee has been established has the right to be represented on that committee. International

organizations, governmental and non-governmental, in liaison with ISO, also take part in the work.

ISO collaborates closely with the International Electrotechnical Commission (IEC) on all matters of

electrotechnical standardization.

The procedures used to develop this document and those intended for its further maintenance are

described in the ISO/IEC Directives, Part 1. In particular, the different approval criteria needed for the

different types of ISO documents should be noted. This document was drafted in accordance with the

editorial rules of the ISO/IEC Directives, Part 2 (see www .iso .org/ directives).

Attention is drawn to the possibility that some of the elements of this document may be the subject of

patent rights. ISO shall not be held responsible for identifying any or all such patent rights. Details of

any patent rights identified during the development of the document will be in the Introduction and/or

on the ISO list of patent declarations received (see www .iso .org/ patents).

Any trade name used in this document is information given for the convenience of users and does not

constitute an endorsement.

For an explanation of the voluntary nature of standards, the meaning of ISO specific terms and

expressions related to conformity assessment, as well as information about ISO's adherence to the

World Trade Organization (WTO) principles in the Technical Barriers to Trade (TBT), see www .iso .org/

iso/ foreword .html.

This document was prepared by Technical Committee ISO/TC 61, Plastics, Subcommittee SC 2,

Mechanical behaviour.

Any feedback or questions on this document should be directed to the user’s national standards body. A

complete listing of these bodies can be found at www .iso .org/ members .html.

This corrected version of ISO 20329:2020 incorporates the following corrections:

— in the introduction, minor editorial corrections have been applied;

— in Clause 4 and 8.1, editorial corrections have been applied to clarify the procedure;

— in 8.2, a note regarding the number of reciprocations has been added.

iv © ISO 2020 – All rights reserved

Introduction

The reciprocating test specimen method is an abrasive wear test, based on frictional force generated at

the contact surface between test specimen and abrasive material. Frictional force is applied repeatedly

over the wear surface, by an abrasive material under load being applied to it in a perpendicular direction

and horizontal reciprocating motion of test specimen. In this test method, abrasive wear resistance

is usually evaluated by measuring wear mass per unit number of reciprocations or by specific wear

rate, which is wear mass per unit load and unit sliding distance. Specific wear rate is one parameter for

evaluating wear resistance in the field of tribology.

When conducting abrasive wear tests with abrasive contact, it is important to take into consideration

the changes in grinding force of the abrasive material due to clogging. In this test method, an abrasive

material is attached to the circumference of a wheel. The wheel itself is rotated by a small angle for

each reciprocating motion (the wheel does not rotate during the reciprocating motion). Therefore,

after each reciprocating motion, unused section of the abrasive material comes in contact with the

test specimen. Also, the test specimen is installed with the surface to be tested facing down, where

the abrasive material is placed into contact from underneath the test specimen, and wear particles or

debris are not likely to collect in the wear surface. Due to the above factors, the influence of changes in

grinding force of abrasive material due to clogging on test results is reduced, and wear mass per unit

number of reciprocations is consistent. As a result, specific wear rate irrespective of sliding distance

can be obtained.

INTERNATIONAL STANDARD ISO 20329:2020(E)

Plastics — Determination of abrasive wear by

reciprocating linear sliding motion

1 Scope

This document specifies a test method for the determination of abrasive wear resistance of plastics using

abrasive material on a reciprocating motion. It also specifies calculation method for specific wear rate.

2 Normative references

The following documents are referred to in the text in such a way that some or all of their content

constitutes requirements of this document. For dated references, only the edition cited applies. For

undated references, the latest edition of the referenced document (including any amendments) applies.

ISO 291, Plastics — Standard atmospheres for conditioning and testing

ISO 80000-1:2009, Quantities and units — Part 1: General

3 Terms and definitions

For the purposes of this document, the following terms and definitions apply.

ISO and IEC maintain terminological databases for use in standardization at the following addresses:

— ISO Online browsing platform: available at https:// www .iso .org/ obp

— IEC Electropedia: available at http:// www .electropedia .org/

3.1

abrasive wear

progressive loss of material from the abrading surface of a plastics material resulting from the cutting

or scratching action of the abrasive contact

3.2

load

W

force applied to the specimen

Note 1 to entry: Expressed in units of N.

3.3

wear resistance

R

resistance to wear, which is expressed as wear mass per reciprocation in this test method

Note 1 to entry: Expressed in the unit of “mg / reciprocation” [see 8.2, Formula (1)].

Note 2 to entry: This mass is actually force measured in a scale.

3.4

specific wear rate

w

s

wear mass per unit sliding distance and unit load

Note 1 to entry: Expressed in the unit of “mg / N•m” [see 8.3, Formula (3)].

Note 2 to entry: This mass is actually force measured in a scale.

4 Principle

A test specimen is installed horizontally onto a specimen stage so that the test surface faces down, and

the test surface is abraded from below. The test specimen is fixed in place by being pressed against the

specimen stage from above with a specimen holder, in order to maintain the horizontal position on the

specimen stage.

A section of an abrasive material in strip form, which is attached to the circumference of the wheel

by avoiding any overlaps or gaps, comes in contact with the installed test specimen from underneath.

A load is applied onto the abrasive contact from below in perpendicular upward direction. With the

specimen stage, along with the test specimen, going through reciprocating motions in horizontal

direction with a specified stroke length, frictional force in the horizontal direction between the test

specimen and the abrasive material is generated. The reciprocating motions are repeated at a specified

reciprocating frequency (reciprocation / min), and the frictional force is applied repeatedly to the same

wear surface, and the wear of the test specimen continues to progress with the increased number of

reciprocations.

At the completion of each reciprocating motion of the test specimen, the wheel rotates 0,9° to expose

an unused section of the abrasive material to contact the specimen. The wheel does not rotate during

reciprocating motions. When the wheel finishes making a full rotation, the abrasive material is replaced

so that the same section of the abrasive material is never reused again.

Figure 1 describes this principle. The mass of test specimen is measured after preliminary abrasion

and after the main test. The wear mass is calculated from the difference in the measured values.

NOTE 1 The method of installing test specimen with its test surface facing down is developed in order to

minimize the amount of wear debris collected on the wear surface of the test specimen.

NOTE 2 A wheel is used in order to present unused section of abrasive material as contact surface. Abrasive

wear in this test method is due to sliding friction and not due to rolling friction.

2 © I

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.