ISO 5189:2023

(Main)Fine ceramics (advanced ceramics, advanced technical ceramics) - Methods for chemical analysis of metal impurities in silicon dioxide powders using inductively coupled plasma-optical emission spectrometry

Fine ceramics (advanced ceramics, advanced technical ceramics) - Methods for chemical analysis of metal impurities in silicon dioxide powders using inductively coupled plasma-optical emission spectrometry

This document specifies methods for the chemical analysis of metal impurities present in silicon dioxide powders used as a raw material for fine ceramics. It stipulates the methods for the determination of metal impurity elements in silicon dioxide powders that are decomposed by acid decomposition. The aluminium, cadmium, calcium, copper, iron, lead, lithium, magnesium, manganese, nickel, potassium, sodium, titanium, zinc and zirconium contents in the test solution are determined by inductively coupled plasma-optical emission spectrometry (ICP-OES).

General Information

Overview

ISO 5189:2023 specifies standardized chemical analysis methods for metal impurities in silicon dioxide (SiO2) powders used as raw materials for fine ceramics (advanced/technical ceramics). The standard defines sample preparation, acid decomposition, ICP-OES measurement and calculation/reporting procedures to determine Al, Cd, Ca, Cu, Fe, Pb, Li, Mg, Mn, Ni, K, Na, Ti, Zn and Zr in silica powders. Typical reporting is in mg/kg (dry basis) over the range 1.0–100 mg/kg using inductively coupled plasma–optical emission spectrometry (ICP‑OES).

Key topics and technical requirements

- Analytes & ranges: 15 metal impurity elements, each with a working range of 1.0 mg/kg to 100 mg/kg.

- Sample preparation: Follow ISO 8656‑1 sampling; dry 10 g at 110 °C ± 5 °C for 2 h; weigh 1.0 g ±0.1 mg test portion.

- Acid decomposition: Use analytical‑grade reagents. Typical decomposition: 15 mL HF + 3 mL HNO3, heat to dryness, then dissolve residue with HCl solution for Al/Fe/Ti/Mn or HNO3 solution for other elements; make up to 10 mL volumetric flask to produce the sample solution. Blank decomposition must be run in parallel.

- Reagents & instrumentation: HF, HNO3, HCl (and diluted mixtures), high‑purity water per ISO 3696, and ICP‑OES for element determination.

- Calibration & measurement: Prepare mixed standard (each element 5 mg/L) and calibration series (1, 5, 10, 15, 20 mL to 100 mL) using appropriate acid matrix. Choose ICP‑OES wavelengths free of spectral overlap (standard examples provided in ISO 5189:2023).

- Calculation & reporting: Compute element content from calibration curves and blank-corrected concentrations using the standard formula. Report values to two significant figures in mg/kg (dry). Repeat measurements and follow specified tolerance rules (5 mg/kg tolerance for amounts <50 mg/kg; 25 mg/kg for ≥50 mg/kg).

Practical applications

- Quality control of silicon dioxide raw materials for advanced ceramics, optics, electronics and high‑purity ceramic components

- Incoming raw material inspection for ceramic manufacturers and suppliers to ensure impurity limits that affect mechanical, thermal and electrical properties

- Laboratory method standardization for interlaboratory comparability when using ICP‑OES to quantify silica powder impurities

Who should use this standard

- Analytical and quality control laboratories performing silica impurity testing

- Manufacturers of fine/advanced ceramics and suppliers of SiO2 powders

- Materials engineers and R&D teams concerned with impurity-driven performance issues

- Regulatory and conformity assessment bodies evaluating material specifications

Related standards

- ISO 3696 - Water for analytical laboratory use

- ISO 8656‑1 - Sampling of refractory raw materials and unshaped products

Keywords: ISO 5189:2023, fine ceramics, silicon dioxide powders, ICP‑OES, metal impurities, chemical analysis, acid decomposition, silica powder impurities.

Frequently Asked Questions

ISO 5189:2023 is a standard published by the International Organization for Standardization (ISO). Its full title is "Fine ceramics (advanced ceramics, advanced technical ceramics) - Methods for chemical analysis of metal impurities in silicon dioxide powders using inductively coupled plasma-optical emission spectrometry". This standard covers: This document specifies methods for the chemical analysis of metal impurities present in silicon dioxide powders used as a raw material for fine ceramics. It stipulates the methods for the determination of metal impurity elements in silicon dioxide powders that are decomposed by acid decomposition. The aluminium, cadmium, calcium, copper, iron, lead, lithium, magnesium, manganese, nickel, potassium, sodium, titanium, zinc and zirconium contents in the test solution are determined by inductively coupled plasma-optical emission spectrometry (ICP-OES).

This document specifies methods for the chemical analysis of metal impurities present in silicon dioxide powders used as a raw material for fine ceramics. It stipulates the methods for the determination of metal impurity elements in silicon dioxide powders that are decomposed by acid decomposition. The aluminium, cadmium, calcium, copper, iron, lead, lithium, magnesium, manganese, nickel, potassium, sodium, titanium, zinc and zirconium contents in the test solution are determined by inductively coupled plasma-optical emission spectrometry (ICP-OES).

ISO 5189:2023 is classified under the following ICS (International Classification for Standards) categories: 81.060.30 - Advanced ceramics. The ICS classification helps identify the subject area and facilitates finding related standards.

You can purchase ISO 5189:2023 directly from iTeh Standards. The document is available in PDF format and is delivered instantly after payment. Add the standard to your cart and complete the secure checkout process. iTeh Standards is an authorized distributor of ISO standards.

Standards Content (Sample)

INTERNATIONAL ISO

STANDARD 5189

First edition

2023-09

Fine ceramics (advanced ceramics,

advanced technical ceramics) —

Methods for chemical analysis of

metal impurities in silicon dioxide

powders using inductively coupled

plasma-optical emission spectrometry

Reference number

© ISO 2023

All rights reserved. Unless otherwise specified, or required in the context of its implementation, no part of this publication may

be reproduced or utilized otherwise in any form or by any means, electronic or mechanical, including photocopying, or posting on

the internet or an intranet, without prior written permission. Permission can be requested from either ISO at the address below

or ISO’s member body in the country of the requester.

ISO copyright office

CP 401 • Ch. de Blandonnet 8

CH-1214 Vernier, Geneva

Phone: +41 22 749 01 11

Email: copyright@iso.org

Website: www.iso.org

Published in Switzerland

ii

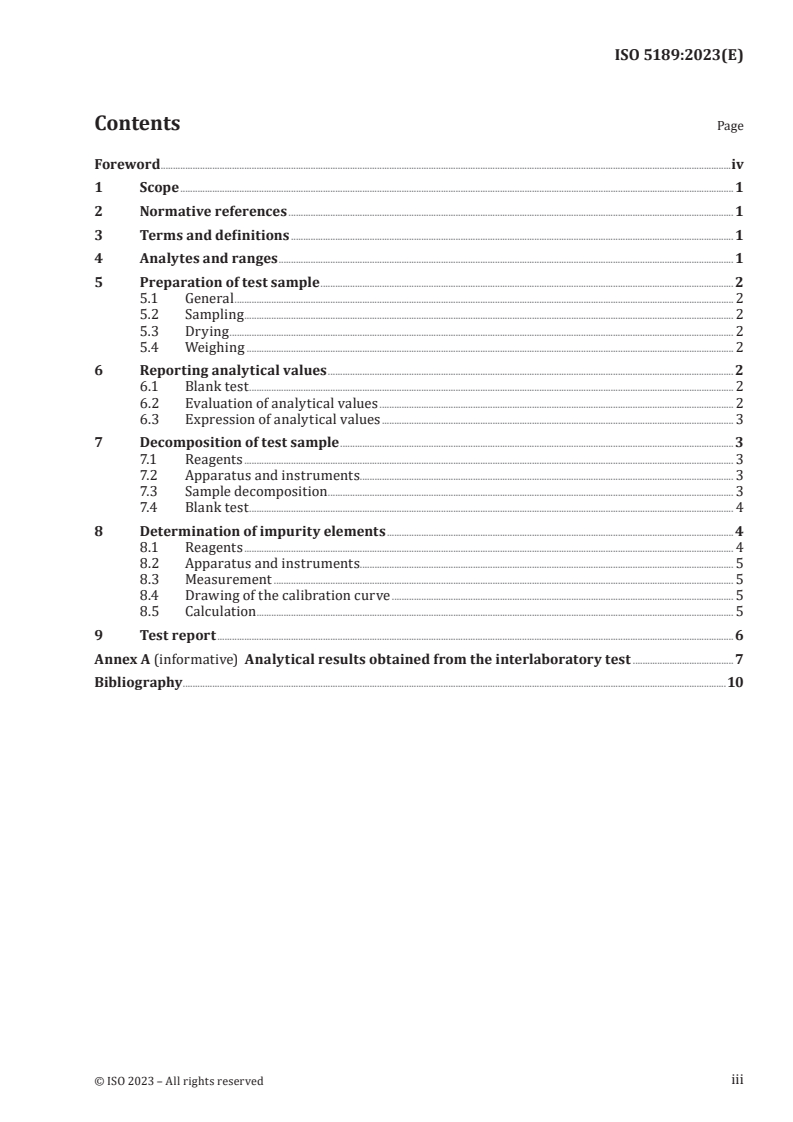

Contents Page

Foreword .iv

1 Scope . 1

2 Normative references . 1

3 Terms and definitions . 1

4 Analytes and ranges . 1

5 Preparation of test sample . 2

5.1 General . 2

5.2 Sampling . 2

5.3 Drying . 2

5.4 Weighing . 2

6 Reporting analytical values . 2

6.1 Blank test . 2

6.2 Evaluation of analytical values . 2

6.3 Expression of analytical values . 3

7 Decomposition of test sample .3

7.1 Reagents . 3

7.2 Apparatus and instruments. 3

7.3 Sample decomposition . 3

7.4 Blank test . 4

8 Determination of impurity elements .4

8.1 Reagents . 4

8.2 Apparatus and instruments. 5

8.3 Measurement . 5

8.4 Drawing of the calibration curve . 5

8.5 Calculation . 5

9 Test report . 6

Annex A (informative) Analytical results obtained from the interlaboratory test .7

Bibliography .10

iii

Foreword

ISO (the International Organization for Standardization) is a worldwide federation of national standards

bodies (ISO member bodies). The work of preparing International Standards is normally carried out

through ISO technical committees. Each member body interested in a subject for which a technical

committee has been established has the right to be represented on that committee. International

organizations, governmental and non-governmental, in liaison with ISO, also take part in the work.

ISO collaborates closely with the International Electrotechnical Commission (IEC) on all matters of

electrotechnical standardization.

The procedures used to develop this document and those intended for its further maintenance are

described in the ISO/IEC Directives, Part 1. In particular, the different approval criteria needed for the

different types of ISO document should be noted. This document was drafted in accordance with the

editorial rules of the ISO/IEC Directives, Part 2 (see www.iso.org/directives).

ISO draws attention to the possibility that the implementation of this document may involve the use

of (a) patent(s). ISO takes no position concerning the evidence, validity or applicability of any claimed

patent rights in respect thereof. As of the date of publication of this document, ISO had not received

notice of (a) patent(s) which may be required to implement this document. However, implementers are

cautioned that this may not represent the latest information, which may be obtained from the patent

database available at www.iso.org/patents. ISO shall not be held responsible for identifying any or all

such patent rights.

Any trade name used in this document is information given for the convenience of users and does not

constitute an endorsement.

For an explanation of the voluntary nature of standards, the meaning of ISO specific terms and

expressions related to conformity assessment, as well as information about ISO's adherence to

the World Trade Organization (WTO) principles in the Technical Barriers to Trade (TBT), see

www.iso.org/iso/foreword.html.

This document was prepared by Technical Committee ISO/TC 206, Fine ceramics.

Any feedback or questions on this document should be directed to the user’s national standards body. A

complete listing of these bodies can be found at www.iso.org/members.html.

iv

INTERNATIONAL STANDARD ISO 5189:2023(E)

Fine ceramics (advanced ceramics, advanced technical

ceramics) — Methods for chemical analysis of metal

impurities in silicon dioxide powders using inductively

coupled plasma-optical emission spectrometry

1 Scope

This document specifies methods for the chemical analysis of metal impurities present in silicon dioxide

powders used as a raw material for fine ceramics.

It stipulates the methods for the determination of metal impurity elements in silicon dioxide powders

that are decomposed by acid decomposition. The aluminium, cadmium, calcium, copper, iron, lead,

lithium, magnesium, manganese, nickel, potassium, sodium, titanium, zinc and zirconium contents in

the test solution are determined by inductively coupled plasma-optical emission spectrometry (ICP-

OES).

2 Normative references

The following documents are referred to in the text in such a way that some or all of their content

constitutes requirements of this document. For dated references, only the edition cited applies. For

undated references, the latest edition of the referenced document (including any amendments) applies.

ISO 3696, Water for analytical laboratory use — Specification and test methods

ISO 8656-1, Refractory products — Sampling of raw materials and unshaped products — Part 1: Sampling

scheme

3 Terms and definitions

No terms and definitions are listed in this document.

ISO and IEC maintain terminology databases for use in standardization at the following addresses:

— ISO Online browsing platform: available at https:// www .iso .org/ obp

— IEC Electropedia: available at https:// www .electropedia .org/

4 Analytes and ranges

a) Aluminium (Al), range of 1,0 mg/kg to 100 mg/kg.

b) Cadmium (Cd), range of 1,0 mg/kg to 100 mg/kg.

c) Calcium (Ca), range of 1,0 mg/kg to 100 mg/kg.

d) Copper (Cu), range of 1,0 mg/kg to 100 mg/kg.

e) Iron (Fe), range of 1,0 mg/kg to 100 mg/kg.

f) Lead (Pb), range of 1,0 mg/kg to 100 mg/kg.

g) Lithium (Li), range of 1,0 mg/kg to 100 mg/kg.

h) Magnesium (Mg), range of 1,0 mg/kg to 100 mg/kg.

i) Manganese (Mn), range of 1,0 mg/kg to 100 mg/kg.

j) Nickel (Ni), range of 1,0 mg/kg to 100 mg/kg.

k) Potassium (K), range of 1,0 mg/kg to 100 mg/kg.

l)

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.

Loading comments...