ISO 2244:1985

(Main)Packaging — Complete, filled transport packages — Horizontal impact tests (horizontal or inclined plane test; pendulum test)

Packaging — Complete, filled transport packages — Horizontal impact tests (horizontal or inclined plane test; pendulum test)

Emballages — Emballages d'expédition complets et pleins — Essais de choc horizontal (essai sur plan horizontal ou incliné; essai au pendule)

Embalaža - Celovita, napolnjena transportna embalaža - Preskus z vodoravnim udarcem na vodoravni ali nagnjeni ravnini - preskus z nihalom

General Information

Relations

Buy Standard

Standards Content (Sample)

International Standard

INTERNATIONAL ORGANIZATION FOR STANDARDIZATION.MElK~Yt1APO~HAR OPrAHM3ALWlR f-l0 CTAHAAPTM3AL(MM~ORGANISATION INTERNATIONALE DE NORMALISATION

Packaging - Complete, filled transport packages -

Horizontal impact tests (horizontal or inclined plane test;

pendulum test)

Essais de choc horizontal fessai sur plan horizontal ou inclinh; essai

Emballages - Emballages d’expedition complets et pleins -

au pendulel

Second edition - 1985-11-01

Ref. No. ISO 22444985 (E)

U DC 621.798.1 : 620.165.7

Descriptors : packing, transport packing, complete-and filled packages, tests, impact tests.

Price based on 3 pages

---------------------- Page: 1 ----------------------

Foreword

ISO (the International Organization for Standardization) is a worldwide federation of

national Standards bodies (ISO member bodies). The work of preparing International

Standards is normally carried out through ISO technical committees. Esch member

body interested in a subject for which a technical committee has been established has

the right to be represented on that committee. International organizations, govern-

mental and non-governmental, in liaison with ISO, also take patt in the work.

Draft International Standards adopted by the technical committees are circulated to

the member bodies for approval before their acceptance as International Standards by

the ISO Council. They are approved in accordance with ISO procedures requiring at

least 75 % approval by the member bodies voting.

International Standard ISO 2244 was prepared by Technical Committee ISO/TC 122,

Packaging.

. This second edition cancels replaces the first

ISO 2244 was first published in 1972

edition, which has been technically revised as follows :

-

a horizontal plane test method has been specified;

-

a new clause on “Package preparation” has been added.

Users should note that all International Standards undergo revision from time to time

and that any reference made herein to any other International Standard implies its

latest edition, unless othetwise stated.

0 International Organkation for Standardkation, 1995

Printed in Switzerland

---------------------- Page: 2 ----------------------

ISO 2244-1985 (E)

INTERNATIONAL STANDARD

Packaging - Complete, filled transport packages -

Horizontal impact tests (horizontal or inclined plane test;

pendulum test)

The impact surface shall be sufficiently rigid not to deflect more

1 Scope and field of application

than 0,25 mm when a load of 160 kg/cm* is applied anywhere

on the surface.

This International Standard specifies methods of horizontal im-

patt testing (horizontal or inclined plane test and pendulum

In addition, the apparatus shall meet the requirements and

test) on a complete, filled transport package. The test may be

tolerantes specified in clause 7.

performed either as a Single test to investigate the effects of

horizontal impact or as part of a sequence of tests designed to

distribution

measure the ability of a package to withstand a

4.2 Optional interposed hazards, to be used when it is re-

System that includes a horizontal impact hazard.

quired to concentrate the impact in a particular area of the test

package.

2 References

The dimensions, material and location of the interposed hazard

shall be carefully specified.

ISO 2206, Packaging - Complete, filled transport packages -

Example: A steel beam with a length of 200 mm and a cross-

ldentification of Parts when testing.

section of 100 ( + 1) mm x 100 ( * 1) mm with rounded edges of

ISO 2233, Packaging - Complete, filled transport packages - radius 5 + 0,l mm, placed centrally in the impact sutface (4.1).

Conditioning for testing.

4.3 Impact testing apparatus: Types of apparatus that

may be used are described in 4.3.1, 4.3.2 and 4.3.3.

3 Principle

4.3.1 Inclined plane tester, consisting of the following items:

Applying a horizontal velocity to the test package and bringing

it to a halt by impact with a vertical impact surface. The at-

mospheric conditions, the horizontal velocity and the attitude

Two-rail steel track, inclined at 10° to the horizon-

4.3.1.1

of the package are predetermined. Particular conditions of im-

tal. The distance along the incline shall be graduated at inter-

patt may be simulated by placing appropriately profiled inserts

vals of 50 mm. (See figure 1.)

between the impact surface and the impacting face or edge of

the test package.

4.3.1.2 Rolling carriage or dolly: The surface friction be-

tween the rolling carriage/dolly and the test package shall be

such that during movement from rest to impact the package

4 Apparatus

will not move in relation to the carriage, but such that upon im-

patt the package will move freely.

4.1 Impact surface, which should be either

4.3.1.3 Impact surface (or bumper), meeting the specifi-

a) a plane inclined to the vertical at 10 + l” (for the in-

cations of 4.1, placed at the bottom of the track with its face

clined plane test), or

perpendicular to the direction of movement of the carriage

b) a plane vettical to within l” (for the horizontal or

down the track.

pendulum test).

NOTES

The dimensions of the impact sur-face shall be greater than

1 A suitable impact surface comprises a number of heavy timbers

those of the impacting face, or selected patt, of the test mounted horizontally across the face of the structure such that the op-

tional interposed hazard (4.2) tan be fitted easily when required.

package.

1

---------------------- Page: 3 ----------------------

ISO 22444985 (E)

Test package

/ r Two-rail steel track

Imr>act of sut-face

Figure 1 - Inclined plane tester

,

2 lt is recommended that the bumper be made in such a way that the

carriage tan travel underneath it for about 100 mm so that the package

t/““lu

impacts the bumper before the carriage Stops.

\

\

3 The apparatus should preferably be equipped with a dev

...

SLOVENSKI STANDARD

SIST ISO 2244:1996

01-marec-1996

Embalaža - Celovita, napolnjena transportna embalaža - Preskus z vodoravnim

udarcem na vodoravni ali nagnjeni ravnini - preskus z nihalom

Packaging -- Complete, filled transport packages -- Horizontal impact tests (horizontal or

inclined plane test; pendulum test)

Emballages -- Emballages d'expédition complets et pleins -- Essais de choc horizontal

(essai sur plan horizontal ou incliné; essai au pendule)

Ta slovenski standard je istoveten z: ISO 2244:1985

ICS:

55.180.40 Celovita, napolnjena Complete, filled transport

transportna embalaža packages

SIST ISO 2244:1996 en

2003-01.Slovenski inštitut za standardizacijo. Razmnoževanje celote ali delov tega standarda ni dovoljeno.

---------------------- Page: 1 ----------------------

SIST ISO 2244:1996

---------------------- Page: 2 ----------------------

SIST ISO 2244:1996

International Standard

INTERNATIONAL ORGANIZATION FOR STANDARDIZATION.MElK~Yt1APO~HAR OPrAHM3ALWlR f-l0 CTAHAAPTM3AL(MM~ORGANISATION INTERNATIONALE DE NORMALISATION

Packaging - Complete, filled transport packages -

Horizontal impact tests (horizontal or inclined plane test;

pendulum test)

Essais de choc horizontal fessai sur plan horizontal ou inclinh; essai

Emballages - Emballages d’expedition complets et pleins -

au pendulel

Second edition - 1985-11-01

Ref. No. ISO 22444985 (E)

U DC 621.798.1 : 620.165.7

Descriptors : packing, transport packing, complete-and filled packages, tests, impact tests.

Price based on 3 pages

---------------------- Page: 3 ----------------------

SIST ISO 2244:1996

Foreword

ISO (the International Organization for Standardization) is a worldwide federation of

national Standards bodies (ISO member bodies). The work of preparing International

Standards is normally carried out through ISO technical committees. Esch member

body interested in a subject for which a technical committee has been established has

the right to be represented on that committee. International organizations, govern-

mental and non-governmental, in liaison with ISO, also take patt in the work.

Draft International Standards adopted by the technical committees are circulated to

the member bodies for approval before their acceptance as International Standards by

the ISO Council. They are approved in accordance with ISO procedures requiring at

least 75 % approval by the member bodies voting.

International Standard ISO 2244 was prepared by Technical Committee ISO/TC 122,

Packaging.

. This second edition cancels replaces the first

ISO 2244 was first published in 1972

edition, which has been technically revised as follows :

-

a horizontal plane test method has been specified;

-

a new clause on “Package preparation” has been added.

Users should note that all International Standards undergo revision from time to time

and that any reference made herein to any other International Standard implies its

latest edition, unless othetwise stated.

0 International Organkation for Standardkation, 1995

Printed in Switzerland

---------------------- Page: 4 ----------------------

SIST ISO 2244:1996

ISO 2244-1985 (E)

INTERNATIONAL STANDARD

Packaging - Complete, filled transport packages -

Horizontal impact tests (horizontal or inclined plane test;

pendulum test)

The impact surface shall be sufficiently rigid not to deflect more

1 Scope and field of application

than 0,25 mm when a load of 160 kg/cm* is applied anywhere

on the surface.

This International Standard specifies methods of horizontal im-

patt testing (horizontal or inclined plane test and pendulum

In addition, the apparatus shall meet the requirements and

test) on a complete, filled transport package. The test may be

tolerantes specified in clause 7.

performed either as a Single test to investigate the effects of

horizontal impact or as part of a sequence of tests designed to

distribution

measure the ability of a package to withstand a

4.2 Optional interposed hazards, to be used when it is re-

System that includes a horizontal impact hazard.

quired to concentrate the impact in a particular area of the test

package.

2 References

The dimensions, material and location of the interposed hazard

shall be carefully specified.

ISO 2206, Packaging - Complete, filled transport packages -

Example: A steel beam with a length of 200 mm and a cross-

ldentification of Parts when testing.

section of 100 ( + 1) mm x 100 ( * 1) mm with rounded edges of

ISO 2233, Packaging - Complete, filled transport packages - radius 5 + 0,l mm, placed centrally in the impact sutface (4.1).

Conditioning for testing.

4.3 Impact testing apparatus: Types of apparatus that

may be used are described in 4.3.1, 4.3.2 and 4.3.3.

3 Principle

4.3.1 Inclined plane tester, consisting of the following items:

Applying a horizontal velocity to the test package and bringing

it to a halt by impact with a vertical impact surface. The at-

mospheric conditions, the horizontal velocity and the attitude

Two-rail steel track, inclined at 10° to the horizon-

4.3.1.1

of the package are predetermined. Particular conditions of im-

tal. The distance along the incline shall be graduated at inter-

patt may be simulated by placing appropriately profiled inserts

vals of 50 mm. (See figure 1.)

between the impact surface and the impacting face or edge of

the test package.

4.3.1.2 Rolling carriage or dolly: The surface friction be-

tween the rolling carriage/dolly and the test package shall be

such that during movement from rest to impact the package

4 Apparatus

will not move in relation to the carriage, but such that upon im-

patt the package will move freely.

4.1 Impact surface, which should be either

4.3.1.3 Impact surface (or bumper), meeting the specifi-

a) a plane inclined to the vertical at 10 + l” (for the in-

cations of 4.1, placed at the bottom of the track with its face

clined plane test), or

perpendicular to the direction of movement of the carriage

b) a plane vettical to within l” (for the horizontal or

down the track.

pendulum test).

NOTES

The dimensions of the impact sur-face shall be greater than

1 A suitable impact surface comprises a number of heavy timbers

those of the impacting face, or selected patt, of the te

...

Norme internationale @ 2244

INTERNATIONAL ORGANIZATION FOR STANDARDIZATIONOMEMYHAPOLlHAR OPTAHHJAUHR no CTAHAAPTH3AUHHWRGANlSATlON INTERNATIONALE DE NORMALISATION

Emballages - Emballages d'expédition complets et pleins -

c

Essais de choc horizontal (essai sur plan horizontal ou

incliné; essai au pendule)

Packaging - Complete, filled transport packages - Horizontal impact tests (horizontal or inclined plane test; pendulum test)

Deuxième édition - 1985-11-01

CDU 621.738.1 : 620.165.7 Réf. no : IS0 2244-1985 (FI

5

Descripteurs : emballage, emballage d'exp6dition. emballage complet et plein, essai, essai au choc.

# -

$

M

Prix basé sur 3 pages

---------------------- Page: 1 ----------------------

Avant-propos

L‘ISO (Organisation internationale de normalisation) est une fédération mondiale

d’organismes nationaux de normalisation (comités membres de I’ISO). L‘élaboration

des Normes internationales est confiée aux comités techniques de I’ISO. Chaque

comité membre intéressé par une étude a le droit de faire partie du comité technique

créé à cet effet. Les organisations internationales, gouvernementales et non gouverne-

mentales, en liaison avec I’ISO, participent également aux travaux.

Y

Les projets de Normes internationales adoptés par les comités techniques sont soumis

aux comités membres pour approbation, avant leur acceptation comme Normes inter-

nationales par le Conseil de I‘ISO. Les Normes internationales sont approuvées confor-

mément aux procédures de I’ISO qui requièrent l‘approbation de 75 % au moins des

comités membres votants.

La Norme internationale IS0 2244 a été élaborée par le comité technique ISO/TC 122,

Emballages.

La Norme internationale IS0 2244 a été pour la première fois publiée en 1972. Cette

deuxième édition annule et remplace la première édition, qui a fait l‘objet de la révision

technique suivante:

-

une méthode d’essai de choc sur plan horizontal a été spécifiée;

-

un nouveau chapitre relatif à la préparation de l’emballage (chapitre 5) a été

ajouté.

L’attention des utilisateurs est attirée sur le fait que toutes les Normes internationales

sont de temps en temps soumises à révision et que toute référence faite à une autre

Norme internationale dans le présent document implique qu’il s‘agit, sauf indication

contraire, de la dernière édition.

O Organisation internationale de normalisation, 1985 0

Imprimé en Suisse

---------------------- Page: 2 ----------------------

IS0 2244-1985 (FI

NORM E INTER NAT1 ON ALE

Emballages - Emballages d’expédition complets et pleins -

Essais de choc horizontal (essai sur plan horizontal ou

incliné; essai au pendule)

La surface de choc doit être suffisamment rigide pour ne pas

1 Objet et domaine d’application

présenter de déformation supérieure à 0,25 mm au moment de

l’application d’une charge de 160 kg/cm2 en un point quel-

La présente Norme internationale spécifie une méthode d‘essai

conque de la surface.

de choc horizontal des emballages d‘exp6dition complets et

pleins (essai sur plan horizontal ou incliné et essai au pendule).

L-

L‘appareillage doit, en outre, satisfaire aux prescriptions et tolé-

Un tel essai peut être effectué comme essai simple dans le but

rances indiquées au chapitre 7.

d’examiner les effets d’un choc horizontal, ou il peut faire partie

d’une série d‘essais destinés à mesurer la résistance d‘un

emballage dans un système de distribution qui comprend un

4.2 Obstacle interposé facultatif, devant être utilisé

risque de choc horizontal.

lorsqu‘il est nécessaire de concentrer le choc sur une surface

particulière de l’emballage soumis à l‘essai.

Les dimensions, le matériau et l’emplacement de l’obstacle

2 Références

interposé doivent être précisés de manière détaillée.

IS0 2206, Emballages - Emballages d‘expédition complets et

Exemple: Une poutrelle en acier d‘une longueur de 200 mm et

pleins - Identification des dHérentes parties en vue des essais.

d’une section de 100 ( f 1) mm x 100 ( f 1) mm, avec des

bords arrondis d‘un rayon de 5 f O, 1 mm, placée au centre de

IS0 2233, Emballages - Emballages d‘expédition complets et

la surface de choc (4.1).

pleins - Conditionnement en vue des essais.

4.3 Appareillage d’essai de choc: Les types d‘appareillage

pouvant être utilisés sont décrits en 4.3.1, 4.3.2 et 4.3.3.

3 Principe

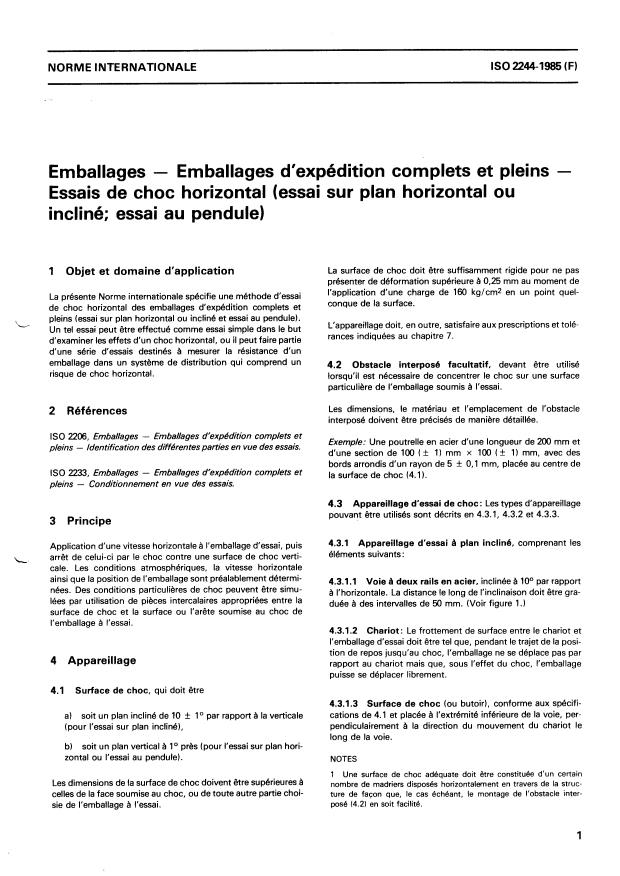

Appareillage d’essai à plan incliné, comprenant les

4.3.1

Application d’une vitesse horizontale à l‘emballage d’essai, puis

éléments suivants:

arrêt de celui-ci par le choc contre une surface de choc verti-

cale. Les conditions atmosphériques, la vitesse horizontale

ainsi que la position de l’emballage sont préalablement détermi-

4.3.1.1 Voie à deux rails en acier, inclinée à IOo par rapport

nées. Des conditions particulières de choc peuvent être simu-

à l’horizontale. La distance le long de l’inclinaison doit être gra-

lées par utilisation de pièces intercalaires appropriées entre la

duée à des intervalles de 50 mm. (Voir figure 1 .I

surface de choc et la surface ou l’arête soumise au choc de

l‘emballage à l‘essai.

4.3.1.2 Chariot: Le frottement de surface entre le chariot et

l’emballage d’essai doit être tel que, pendant le trajet de la posi-

tion de repos jusqu’au choc, l’emballage ne se déplace pas par

4 Appareillage

rapport au chariot mais que, SOUS l’effet du choc, l’emballage

puisse se déplacer librement.

4.1 Surface de choc, qui doit être

4.3.1.3 Surface de choc (ou butoir), conforme aux spécifi-

soit un plan incliné de 10 k lo par rapport à la verticale cations de 4.1 et placée à l’extrémité inférieure de la voie, per-

a)

pendiculairement à la direction du mouvement du chariot le

(pour l’essai sur plan incliné),

long de la voie.

b) soit un plan vertical à lo près (pour l’essai sur plan hori-

zontal ou l’essai au pendule).

NOTES

1 Une surface de choc adéquate doit être constituée d‘un certain

Les dimensions de la surface de choc doivent être supérieures à

nombre de madriers disposés horizontalement en travers de la struc-

ture de facon que, le cas échéant, le montage de l’obstacle inter-

celles de la face soumise au choc, ou de toute autre partie choi-

posé (4.2) en soit facilité.

sie de l’emballage à l‘essai.

1

---------------------- Page: 3 ----------------------

IS0 2244-1985 (FI

Emballage d'essai

Voie à deux rails en acier

'111

/ -"I-

Figure l - Appareillage d'essai à plan incliné

2 II est recommandé que la surface de choc (ou butoir) soit conçue de

façon que le chariot puisse passer au-dessous de celle-ci, sur une dis-

tance d'environ 100 mm, pour que l'emballage frappe la surface de

/\ \

choc avant que le chariot ne s'arrête.

Tiges en acier, ou c

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.