ISO/PRF 23100

(Main)Decorative physical vapor deposition (PVD) coatings on kitchen and sanitary ware fittings — Specification and test methods

Decorative physical vapor deposition (PVD) coatings on kitchen and sanitary ware fittings — Specification and test methods

This document specifies the evaluation of the color, discoloration resistance, corrosion resistance, abrasion resistance, and adhesion of decorative coatings on kitchen and sanitary ware products by physical vapor deposition (PVD), including the specific test methods.

Titre manque

General Information

Buy Standard

Standards Content (Sample)

International

Standard

ISO 23100

First edition

Decorative physical vapor

deposition (PVD) coatings on

kitchen and sanitary ware fittings —

Specification and test methods

PROOF/ÉPREUVE

Reference number

ISO 23100:2024(en) © ISO 2024

ISO 23100:2024(en)

© ISO 2024

All rights reserved. Unless otherwise specified, or required in the context of its implementation, no part of this publication may

be reproduced or utilized otherwise in any form or by any means, electronic or mechanical, including photocopying, or posting on

the internet or an intranet, without prior written permission. Permission can be requested from either ISO at the address below

or ISO’s member body in the country of the requester.

ISO copyright office

CP 401 • Ch. de Blandonnet 8

CH-1214 Vernier, Geneva

Phone: +41 22 749 01 11

Email: copyright@iso.org

Website: www.iso.org

Published in Switzerland

PROOF/ÉPREUVE

ii

ISO 23100:2024(en)

Contents Page

Foreword .iv

Introduction .v

1 Scope . 1

2 Normative references . 1

3 Terms and definitions . 1

4 Decorative PVD coating process . 1

4.1 Principle .1

4.2 Coating process .2

4.2.1 Pre-treatment .2

4.2.2 Coating.3

5 Requirements . 3

5.1 Discoloration resistance .3

5.2 Abrasion resistance . . .3

5.3 Corrosion resistance .3

5.4 Adhesion .4

5.4.1 Metal substrate .4

5.4.2 Organic substrate .4

6 Test methods . 4

6.1 Discoloration resistance .4

6.2 Abrasion resistance . . .4

6.2.1 Brush requirements .4

6.2.2 Mud preparation .5

6.2.3 Test procedure.5

6.3 Corrosion resistance .5

6.4 Adhesion .5

6.4.1 Metal substrate .5

6.4.2 Organic substrate .6

7 Test report . 6

Bibliography . 7

PROOF/ÉPREUVE

iii

ISO 23100:2024(en)

Foreword

ISO (the International Organization for Standardization) is a worldwide federation of national standards

bodies (ISO member bodies). The work of preparing International Standards is normally carried out through

ISO technical committees. Each member body interested in a subject for which a technical committee

has been established has the right to be represented on that committee. International organizations,

governmental and non-governmental, in liaison with ISO, also take part in the work. ISO collaborates closely

with the International Electrotechnical Commission (IEC) on all matters of electrotechnical standardization.

The procedures used to develop this document and those intended for its further maintenance are described

in the ISO/IEC Directives, Part 1. In particular, the different approval criteria needed for the different types

of ISO document should be noted. This document was drafted in accordance with the editorial rules of the

ISO/IEC Directives, Part 2 (see www.iso.org/directives).

ISO draws attention to the possibility that the implementation of this document may involve the use of (a)

patent(s). ISO takes no position concerning the evidence, validity or applicability of any claimed patent

rights in respect thereof. As of the date of publication of this document, ISO had not received notice of (a)

patent(s) which may be required to implement this document. However, implementers are cautioned that

this may not represent the latest information, which may be obtained from the patent database available at

www.iso.org/patents. ISO shall not be held responsible for identifying any or all such patent rights.

Any trade name used in this document is information given for the convenience of users and does not

constitute an endorsement.

For an explanation of the voluntary nature of standards, the meaning of ISO specific terms and expressions

related to conformity assessment, as well as information about ISO's adherence to the World Trade

Organization (WTO) principles in the Technical Barriers to Trade (TBT), see www.iso.org/iso/foreword.html.

This document was prepared by Technical Committee ISO/TC 107, Metallic and other inorganic coatings,

Subcommittee SC 9, Physical vapor deposition coatings.

Any feedback or questions on this document should be directed to the user’s national standards body. A

complete listing of these bodies can be found at www.iso.org/members.html.

PROOF/ÉPREUVE

iv

ISO 23100:2024(en)

Introduction

Physical vapor deposition (PVD) is a group of dry coating technologies used for decorative coating, tool

coating and other substrate coatings under a vacuum environment. During the PVD process, the target

material is transferred atom by atom from solid phase to vapor phase and back to solid phase as a thin film

coating on the substrate. Thus, PVD is an eco-friendly technique which can produce coatings with a variety

of colour, textures, and functions over traditional methods.

The PVD process is capable of producing bright and hard coatings on many metals and plastic substrates. A

luxurious metallic finish and a wide range of colours can be obtained using various metal sputtering targets,

such as chromium, zirconium, titanium, titanium—aluminium alloys and niobium. Therefore, PVD coatings

have become a popular choice for decorative finishes for many products where durability, aesthetics and

functionality are important considerations. In particular, PVD coatings are well established as decorative

coatings on kitchen and sanitary wares.

Decorative PVD coatings are applied to the surface of objects in order to get better appearance and longer

durability. Common kitchen and sanitary substrate including copper alloy, zinc alloy, stainless steel,

aluminium alloy and ABS. The colour of PVD coating can include gold, bronze, rose gold, silver, black, smoke

grey, copper, brown, purple, blue, wine red and others.

This document specifies and recommends test methods for discoloration resistance, corrosion, abrasion,

and adhesion of the decorative PVD coatings applied on kitchen and sanitary wares.

PROOF/ÉPREUVE

v

International Standard ISO 23100:2024(en)

Decorative physical vapor deposition (PVD) coatings on kitchen

and sanitary ware fittings — Specification and test methods

1 Scope

This document specifies the performance and test methods of decorative physical vapor deposition (PVD)

coatings on kitchen and sanitary ware fittings.

This document is applicable to performance evaluation for decorative PVD coatings on kitchen and sanitary

ware fittings.

2 Normative references

The following documents are referred to in the text in such a way that some or all of their content constitutes

requirements of this document. For dated references, only the edition cited applies. For undated references,

the latest edition of the referenced document (including any amendments) applies.

ISO 9227, Corrosion tests in artificial atmospheres — Salt spray tests

ISO 10289:1999, Methods for corrosion testing of metallic and other inorganic coatings on metallic substrates

— Rating of test specimens and manufactured articles subjected to corrosion tests

3 Terms and definitions

For the purpose of this document, the terms and definitions given in ISO 10289 and the following apply.

ISO and IEC maintain terminological databases for use in standardization at the following addresses:

— ISO Online browsing platform: available at https:// www .iso .org/ obp

— IEC Electropedia: available at https:// www .electropedia .org/

3.1

CIELAB value

three-dimensional, approximately uniform colour space, produced by plotting, in rectangular coordinates

L*, a*, b*

[SOURCE: ISO/TS 21331:2020, 3.3.5]

3.2

discoloration resistance

ability of a material to maintain its original colour or appearance despite exposure to external factors that

may cause discoloration, fading or staining

4 Decorative PVD coating process

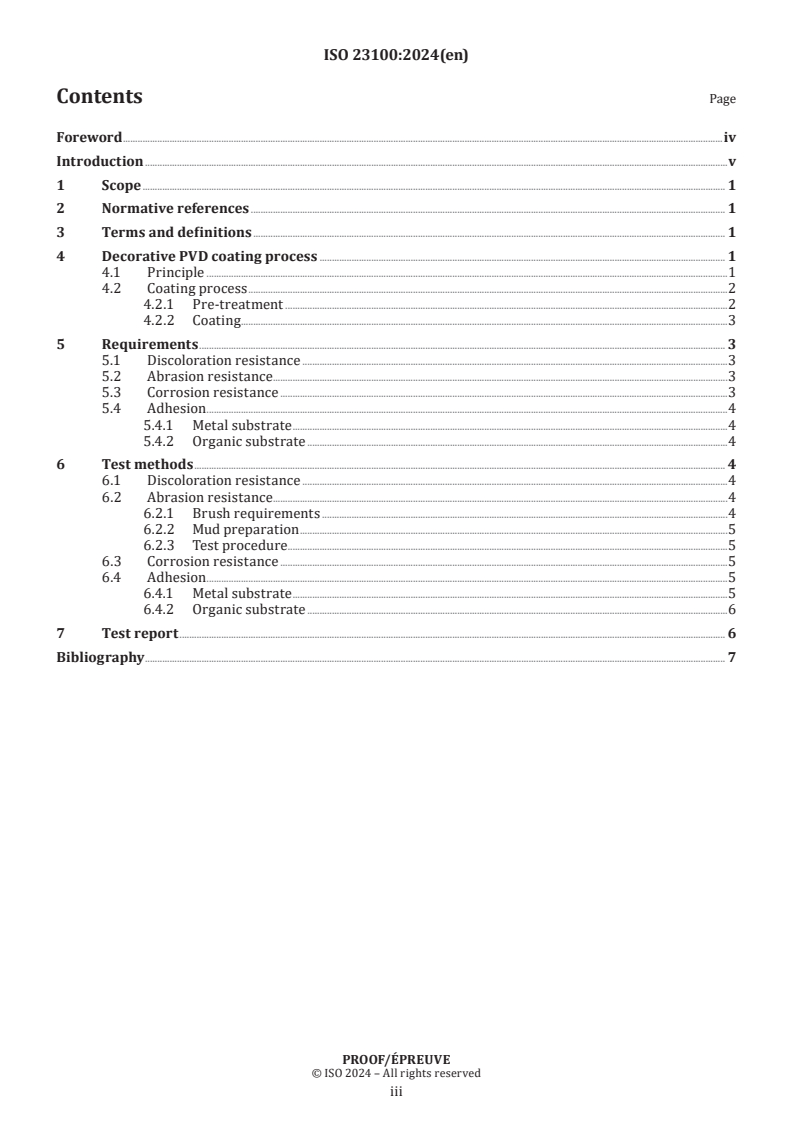

4.1 Principle

The source material is heated to evaporate, and a plasma of metal atoms are formed. These atoms then

travel through the vacuum chamber and deposit onto the substrate, forming a thin film. The thickness of the

film could be controlled by adjusting the time and rate of deposition. The decorative PVD coatings process is

shown in Figure 1.

PROOF/ÉPREUVE

ISO 23100:2024(en)

Key

1 roughing valve 9 lifter

2 cryo pump 10 pedestal

3 gas valve 11 bake out lamp

4 magnet 12 DC power

5 cooling water 13 mass flow controller (where the gas enters)

6 wafer 14 motor

7 shield 15 target

8 clamp ring

Figure 1 — Equipment diagram of the decorative PVD coating process

4.2 Coating process

4.2.1 Pre-treatment

Clean surfaces ensure good adhesion of the coating. Pre-treat and clean the substrate of the kitchen and

sanitary ware fittings by the following procedures (each procedure takes 5 min to 30 min):

a) alkali degreasing

b) washing with deionized water

c) acid activation

d) washing with deionized water

PROOF/ÉPREUVE

ISO 23100:2024(en)

4.2.2 Coating

The coating shall be prepared using the following recommended procedures:

-2 -4

a) Pump down the cha

...

ISO /PRF 23100:2024(en)

ISO/TC 107/SC 9

Secretariat: SAC

Date: 2024-08-3010-07

Decorative physical vapor deposition (PVD) coatings on kitchen and

sanitary ware fittings — Specification and test methods

PROOF

All rights reserved. Unless otherwise specified, or required in the context of its implementation, no part of this publication

may be reproduced or utilized otherwise in any form or by any means, electronic or mechanical, including photocopying,

or posting on the internet or an intranet, without prior written permission. Permission can be requested from either ISO

at the address below or ISO’s member body in the country of the requester.

ISO copyright office

CP 401 • Ch. de Blandon netBlandonnet 8

CH-1214 Vernier, Geneva

Phone: + 41 22 749 01 11

EmailE-mail: copyright@iso.org

Website: www.iso.orgwww.iso.org

Published in Switzerland

ii © ISO 2024 – All rights reserved

ii

ISO /PRF 23100:2024(en)

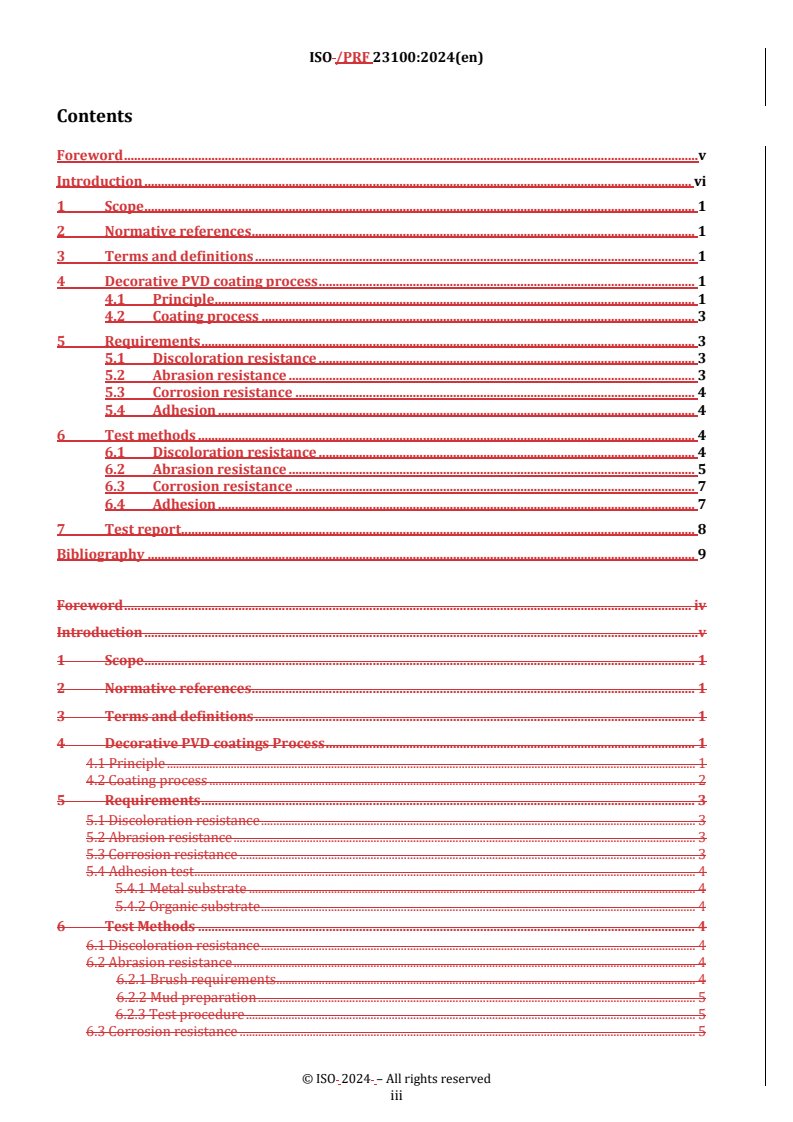

Contents

Foreword . v

Introduction . vi

1 Scope . 1

2 Normative references . 1

3 Terms and definitions . 1

4 Decorative PVD coating process . 1

4.1 Principle . 1

4.2 Coating process . 3

5 Requirements . 3

5.1 Discoloration resistance . 3

5.2 Abrasion resistance . 3

5.3 Corrosion resistance . 4

5.4 Adhesion . 4

6 Test methods . 4

6.1 Discoloration resistance . 4

6.2 Abrasion resistance . 5

6.3 Corrosion resistance . 7

6.4 Adhesion . 7

7 Test report . 8

Bibliography . 9

Foreword . iv

Introduction . v

1 Scope . 1

2 Normative references . 1

3 Terms and definitions . 1

4 Decorative PVD coatings Process . 1

4.1 Principle . 1

4.2 Coating process . 2

5 Requirements . 3

5.1 Discoloration resistance . 3

5.2 Abrasion resistance . 3

5.3 Corrosion resistance . 3

5.4 Adhesion test . 4

5.4.1 Metal substrate . 4

5.4.2 Organic substrate . 4

6 Test Methods . 4

6.1 Discoloration resistance . 4

6.2 Abrasion resistance . 4

6.2.1 Brush requirements . 4

6.2.2 Mud preparation . 5

6.2.3 Test procedure . 5

6.3 Corrosion resistance . 5

© ISO 2024 – All rights reserved

iii

6.4 Adhesion . 5

6.4.1 Metal substrate . 5

6.4.2 Organic substrate . 6

7 Test report . 6

Bibliography . 7

iv © ISO 2024 – All rights reserved

iv

ISO /PRF 23100:2024(en)

Foreword

ISO (the International Organization for Standardization) is a worldwide federation of national standards

bodies (ISO member bodies). The work of preparing International Standards is normally carried out through

ISO technical committees. Each member body interested in a subject for which a technical committee has been

established has the right to be represented on that committee. International organizations, governmental and

non-governmental, in liaison with ISO, also take part in the work. ISO collaborates closely with the

International Electrotechnical Commission (IEC) on all matters of electrotechnical standardization.

The procedures used to develop this document and those intended for its further maintenance are described

in the ISO/IEC Directives, Part 1. In particular, the different approval criteria needed for the different types of

ISO document should be noted. This document was drafted in accordance with the editorial rules of the

ISO/IEC Directives, Part 2 (see www.iso.org/directives).

ISO draws attention to the possibility that the implementation of this document may involve the use of (a)

patent(s). ISO takes no position concerning the evidence, validity or applicability of any claimed patent rights

in respect thereof. As of the date of publication of this document, ISO had not received notice of (a) patent(s)

which may be required to implement this document. However, implementers are cautioned that this may not

represent the latest information, which may be obtained from the patent database available at

www.iso.org/patents.www.iso.org/patents. ISO shall not be held responsible for identifying any or all such

patent rights.

Any trade name used in this document is information given for the convenience of users and does not

constitute an endorsement.

For an explanation of the voluntary nature of standards, the meaning of ISO specific terms and expressions

related to conformity assessment, as well as information about ISO's adherence to the World Trade

Organization (WTO) principles in the Technical Barriers to Trade (TBT), see

www.iso.org/iso/foreword.htmlwww.iso.org/iso/foreword.html.

This document was prepared by Technical Committee ISO/TC 107, Metallic and other inorganic coatings,

Subcommittee SC 9, Physical vapor deposition coatings.

Any feedback or questions on this document should be directed to the user’s national standards body. A

complete listing of these bodies can be found at www.iso.org/members.htmlwww.iso.org/members.html.

© ISO 2024 – All rights reserved

v

Introduction

Physical vapor deposition (PVD) is a group of dry coating technologies used for decorative coating, tool coating

and other substrate coatings under a vacuum environment. During the PVD process, the target material is

transferred atom by atom from solid phase to vapor phase and back to solid phase as a thin film coating on

the substrate. Thus, PVD is an eco-friendly technique which can produce coatings with a variety of colour,

textures, and functions over traditional methods.

The PVD process is capable of producing bright and hard coatings on many metals and plastic substrates. A

luxurious metallic finish and a wide range of colours can be obtained using various metal sputtering targets,

such as chromium, zirconium, titanium, titanium—aluminium alloys and niobium. Therefore, PVD coatings

have become a popular choice for decorative finishes for many products where durability, aesthetics and

functionality are important considerations. In particular, PVD coatings are well established as decorative

coatings on kitchen and sanitary wares.

Decorative PVD coatings are applied to the surface of objects in order to get better appearance and longer

durability. Common kitchen and sanitary substrate including copper alloy, zinc alloy, stainless steel,

aluminium alloy and ABS. The colour of PVD coating can include gold, bronze, rose gold, silver, black, smoke

grey, copper, brown, purple, blue, wine red and others.

This document specifies and recommends test methods for discoloration resistance, corrosion, abrasion, and

adhesion of the decorative PVD coatings applied on kitchen and sanitary wares.

vi © ISO 2024 – All rights reserved

vi

Decorative physical vapor deposition (PVD) coatings on kitchen and

sanitary ware fittings – — Specification and Test Methodstest methods

1 Scope

This document specifies the performance and test methods of decorative physical vapor deposition (PVD)

coatings on kitchen and sanitary ware fittings.

This document is applicable to performance evaluation for decorative PVD coatings on kitchen and sanitary

ware fittings.

2 Normative references

The following documents are referred to in the text in such a way that some or all of their content constitutes

requirements of this document. For dated references, only the edition cited applies. For undated references,

the latest edition of the referenced document (including any amendments) applies.

ISO 9227, Corrosion tests in artificial atmospheres — Salt spray tests

ISO 10289:1999, Methods for corrosion testing of metallic and other inorganic coatings on metallic substrates

— Rating of test specimens and manufactured articles subjected to corrosion tests

3 Terms and definitions

For the purpose of this document, the terms and definitions given in ISO 10289 and the following apply.

ISO and IEC maintain terminological databases for use in standardization at the following addresses:

— — ISO Online browsing platform: available at https://www.iso.org/obphttps://www.iso.org

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.