SIST-TP CEN/TR 17739:2022

(Main)Algae and algae products - Specifications for chemicals and biofuels sector applications

Algae and algae products - Specifications for chemicals and biofuels sector applications

The purpose of this document is to provide an overview on how quality indicating parameters for algae and algae products and intermediates relevant for chemical and bioenergy applications can be handled and to identify the need for future standards development for chemicals, bioenergy and biofuels applications.

This document does not provide instructions on handling of technical requirements in existing legislations.

Algen und algenbasierte Produkte - Spezifikationen für Anwendungen im Chemie- und Biokraftstoffsektor

Algues et produits d’algues - Spécifications pour les applications dans le secteur de la chimie et de la bioénergie

L’objectif du présent document est de fournir une vue d’ensemble sur les possibilités pertinentes de gestion des paramètres indiquant la qualité des algues et produits d’algues utilisés pour les applications dans le secteur de la chimie et de la bioénergie et pour l’identification des futurs besoins en matière d’élaboration de normes pour les applications dans le secteur des produits chimiques, de la bioénergie et des biocarburants.

Le présent document ne fournit pas d’instructions relatives aux exigences techniques requises selon les législations existantes.

Alge in izdelki iz alg - Specifikacije za uporabo v kemijskem in bioenergetskem sektorju

To tehnično poročilo opisuje oznake kakovosti ter navedbe za alge in proizvode, pridobljene neposredno iz proizvodnje alg, ki jih zahtevajo proizvajalci kemikalij in biogoriv ter industrija. Ne velja za sektor hrane in krme.

Opomba: To tehnično poročilo ne vsebuje navodil za obstoječo obravnavo tehničnih zahtev v okviru obstoječe zakonodaje.

General Information

- Status

- Published

- Public Enquiry End Date

- 31-Oct-2021

- Publication Date

- 23-Jan-2022

- Technical Committee

- I13 - Imaginarni 13

- Current Stage

- 6060 - National Implementation/Publication (Adopted Project)

- Start Date

- 29-Dec-2021

- Due Date

- 05-Mar-2022

- Completion Date

- 24-Jan-2022

Overview - CEN/TR 17739:2021 (Algae and algae products)

CEN/TR 17739:2021 is a Technical Report from CEN/TC 454 that provides an overview of how quality‑indicating parameters for algae and algae products (whole biomass, extracts and derivatives) can be handled for the chemicals and biofuels sectors. The document identifies gaps and the need for future standards development for chemicals, bioenergy and biofuels applications. It is an informational reference - it does not replace or interpret existing legislation.

Key topics and technical requirements

- Scope and definitions: Covers terms such as raw material specification (RMS), technical data sheet (TDS), certificate of analysis (CoA), extracts, biofuels, bioliquids and advanced biofuels.

- Quality documentation: Recommends structured product information:

- RMS (detailed producer dossier)

- TDS (one-page technical specification for CoA alignment)

- CoA (lot‑specific laboratory test results)

- Product characterisation & test methods: Describes algal product characteristics and points to relevant test methods and identification techniques (microalgae, macroalgae, cyanobacteria).

- Applications as chemical raw materials: Guidance on multi‑constituent variability, minimum active component levels and bio‑based product claims (refers to EN 16848 / EN 16935).

- Biofuels from algae: Overview of algae‑derived biofuels, advanced biofuels, and interactions with fuel standards and fuel quality requirements.

- Sustainability and LCA: Discusses sustainable development principles and life cycle assessment (LCA) considerations specific to algae value chains.

- Informative annexes: Examples of raw material specifications, TDS/CoA templates, regulatory references (FPR), algae extracts, literature overview on algae biofuels and EU contaminants table.

Practical applications and target users

Who benefits from CEN/TR 17739:

- Algae producers and biorefineries - for preparing RMS, TDS and CoAs to meet buyer and regulatory expectations.

- Chemical manufacturers and biofuel producers - to assess feedstock quality, variability and suitability for conversion routes (oils, extracts, polymers).

- Testing laboratories and certification bodies - for aligning test reporting with TDS/CoA parameters.

- Purchasers, traders and OEMs - to set procurement specifications for algae biomass, extracts and intermediates.

- Policy makers and standards developers - to identify gaps and prioritize new standards for algae in chemicals and energy sectors. Practical uses include feedstock acceptance criteria, supplier quality contracts, R&D benchmarking and sustainability/LCA reporting.

Related standards and references

Key normative references cited in the report:

- EN 17399 (Terms and definitions for algae)

- EN 17477 (Identification of algae biomass)

- EN 14214, EN 590, EN 16709, EN 16734, EN 16723-1 (fuel specifications and methods)

- EN 14103 (FAME analysis)

- EN 16848 / EN 16935 (bio‑based product claims)

CEN/TR 17739 is a central guidance resource for aligning algae product quality, documentation and sustainability practice across chemicals and biofuels supply chains.

Frequently Asked Questions

SIST-TP CEN/TR 17739:2022 is a technical report published by the Slovenian Institute for Standardization (SIST). Its full title is "Algae and algae products - Specifications for chemicals and biofuels sector applications". This standard covers: The purpose of this document is to provide an overview on how quality indicating parameters for algae and algae products and intermediates relevant for chemical and bioenergy applications can be handled and to identify the need for future standards development for chemicals, bioenergy and biofuels applications. This document does not provide instructions on handling of technical requirements in existing legislations.

The purpose of this document is to provide an overview on how quality indicating parameters for algae and algae products and intermediates relevant for chemical and bioenergy applications can be handled and to identify the need for future standards development for chemicals, bioenergy and biofuels applications. This document does not provide instructions on handling of technical requirements in existing legislations.

SIST-TP CEN/TR 17739:2022 is classified under the following ICS (International Classification for Standards) categories: 13.020.55 - Biobased products. The ICS classification helps identify the subject area and facilitates finding related standards.

SIST-TP CEN/TR 17739:2022 is associated with the following European legislation: EU Directives/Regulations: 2009/128/EC; Standardization Mandates: M/547. When a standard is cited in the Official Journal of the European Union, products manufactured in conformity with it benefit from a presumption of conformity with the essential requirements of the corresponding EU directive or regulation.

You can purchase SIST-TP CEN/TR 17739:2022 directly from iTeh Standards. The document is available in PDF format and is delivered instantly after payment. Add the standard to your cart and complete the secure checkout process. iTeh Standards is an authorized distributor of SIST standards.

Standards Content (Sample)

SLOVENSKI STANDARD

01-marec-2022

Alge in izdelki iz alg - Specifikacije za uporabo v kemijskem in bioenergetskem

sektorju

Algae and algae products - Specifications for chemicals and biofuels sector applications

Algen und algenbasierte Produkte - Spezifikationen für Anwendungen im Chemie- und

Biokraftstoffsektor

Algues et produits d’algues - Spécifications pour les applications dans le secteur de la

chimie et de la bioénergie

Ta slovenski standard je istoveten z: CEN/TR 17739:2021

ICS:

13.020.55 Biološki izdelki Biobased products

2003-01.Slovenski inštitut za standardizacijo. Razmnoževanje celote ali delov tega standarda ni dovoljeno.

CEN/TR 17739

TECHNICAL REPORT

RAPPORT TECHNIQUE

December 2021

TECHNISCHER BERICHT

ICS 13.020.55

English Version

Algae and algae products - Specifications for chemicals and

biofuels sector applications

Algues et produits d'algues - Spécifications pour les Algen und algenbasierte Produkte - Spezifikationen für

applications dans le secteur de la chimie et de la Anwendungen im Chemie- und Biokraftstoffsektor

bioénergie

This Technical Report was approved by CEN on 5 December 2021. It has been drawn up by the Technical Committee CEN/TC

454.

CEN members are the national standards bodies of Austria, Belgium, Bulgaria, Croatia, Cyprus, Czech Republic, Denmark, Estonia,

Finland, France, Germany, Greece, Hungary, Iceland, Ireland, Italy, Latvia, Lithuania, Luxembourg, Malta, Netherlands, Norway,

Poland, Portugal, Republic of North Macedonia, Romania, Serbia, Slovakia, Slovenia, Spain, Sweden, Switzerland, Turkey and

United Kingdom.

EUROPEAN COMMITTEE FOR STANDARDIZATION

COMITÉ EUROPÉEN DE NORMALISATION

EUROPÄISCHES KOMITEE FÜR NORMUNG

CEN-CENELEC Management Centre: Rue de la Science 23, B-1040 Brussels

© 2021 CEN All rights of exploitation in any form and by any means reserved Ref. No. CEN/TR 17739:2021 E

worldwide for CEN national Members.

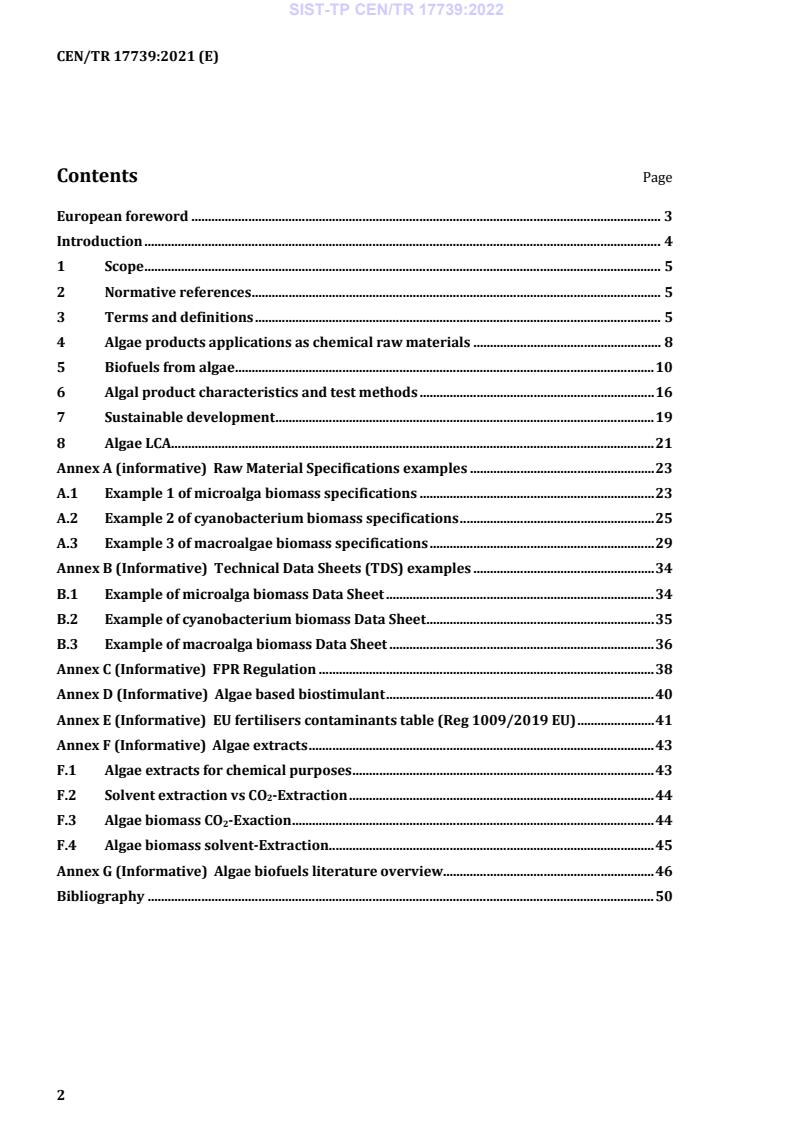

Contents Page

European foreword . 3

Introduction . 4

1 Scope . 5

2 Normative references . 5

3 Terms and definitions . 5

4 Algae products applications as chemical raw materials . 8

5 Biofuels from algae . 10

6 Algal product characteristics and test methods . 16

7 Sustainable development . 19

8 Algae LCA. 21

Annex A (informative) Raw Material Specifications examples . 23

A.1 Example 1 of microalga biomass specifications . 23

A.2 Example 2 of cyanobacterium biomass specifications . 25

A.3 Example 3 of macroalgae biomass specifications . 29

Annex B (Informative) Technical Data Sheets (TDS) examples . 34

B.1 Example of microalga biomass Data Sheet . 34

B.2 Example of cyanobacterium biomass Data Sheet . 35

B.3 Example of macroalga biomass Data Sheet . 36

Annex C (Informative) FPR Regulation . 38

Annex D (Informative) Algae based biostimulant . 40

Annex E (Informative) EU fertilisers contaminants table (Reg 1009/2019 EU) . 41

Annex F (Informative) Algae extracts . 43

F.1 Algae extracts for chemical purposes . 43

F.2 Solvent extraction vs CO -Extraction . 44

F.3 Algae biomass CO -Exaction . 44

F.4 Algae biomass solvent-Extraction . 45

Annex G (Informative) Algae biofuels literature overview. 46

Bibliography . 50

European foreword

This document (CEN/TR 17739:2021) has been prepared by Technical Committee CEN/TC 454 “Algae

and algae products”, the secretariat of which is held by NEN.

Attention is drawn to the possibility that some of the elements of this document may be the subject of

patent rights. CEN shall not be held responsible for identifying any or all such patent rights.

The European committee for Standardisation (CEN) was requested by the European Commission (EC) to

draft European standards or European standardisation deliverables to support the implementation of

Article 3 of Directive 2009/28/EC for algae and algae products or intermediates. The request presented

as Mandate M/547, also contributes to the Communication on “Innovating for Sustainable Growth: A Bio

economy for Europe”.

The former working group CEN Technical Board Working Group 218 “Algae” was created in 2016 to

develop a work programme as part of the Mandate. The technical committee CEN/ TC 454 “Algae and

algae products” was established to carry out the work program the secretariat of which is held by NEN.

CEN TC 454 set up a number of topic specific working Groups listed below to develop standards for algae

and algae products.

This document has been prepared by Working Group 5 “Specifications for the chemicals and fuels

applications sector” with the support of UNI as the secretariat, in close collaboration with the other CEN

TC 454 working groups:

CEN TC 454 WG 1 “Terminology”

CEN TC 454 WG 2 “Identification”

CEN TC 454 WG 3 “Productivity”

CEN TC 454 WG 4 “Specifications for food/feed sectors applications”

CEN TC 454 WG 6 “Product test methods”

The interest in algae and algae-based products or intermediates as a renewable and sustainable source

of carbohydrates, proteins, lipids and pigments has increased significantly in Europe.

Algae-based products and intermediates, in this TR referred to as ‘products’, are defined as whole

biomass, extracts or derivatives from algae, including algae oil and algal meal.

This document will allow the stakeholders to have access to a clear point of reference on the use of algae

in technical applications.

Algae as raw materials have specific challenges and show a wide potential from sustainability and blue

economy point of view. This document aims helping to fill this gap.

Any feedback and questions on this document should be directed to the users’ national standards body.

A complete listing of these bodies can be found on the CEN website.

According to the CEN/CENELEC Internal Regulations, the national standards organisations of the

following countries are bound to announce this Technical Specification: Austria, Belgium, Bulgaria,

Croatia, Cyprus, Czech Republic, Denmark, Estonia, Finland, France, Germany, Greece, Hungary, Iceland,

Ireland, Italy, Latvia, Lithuania, Luxembourg, Malta, Netherlands, Norway, Poland, Portugal, Republic of

North Macedonia, Romania, Serbia, Slovakia, Slovenia, Spain, Sweden, Switzerland, Turkey and the United

Kingdom.

Introduction

The interest in algae and algae-based products or intermediates as a renewable and sustainable source

of carbohydrates, proteins, lipids and pigments has increased significantly in Europe.

The biochemical composition of algae with regard to the ratio of usable components is unique and the

selected conversion pathway determines the kind of products that can be obtained.

Algae are available and used in many countries as fertiliser, biostimulant, animal feed, medicine, cosmetic

and food ingredients, and can provide different compounds depending on species. Due to the high interest

in replacing fossil feedstock for chemicals and fuels by biological ones, as algae, several pilot initiatives

have been undertaken in last decades. Results strongly vary, as many techno-economic parameters are

expected to influence the success of an algae related initiative.

Cultivation of algae has advantages over other sources of biomass, since they can be cultivated on

marginal lands and unused aquatic areas, generating new economic opportunities for poor soil and

aquatic areas, which would not have traditionally been used.

Due to their relatively simple cellular structure, algae have a large biomass productivity per unit area.

Algae are of great ecological importance, since they act in the capture of atmospheric CO and can be used

as wastewater treatment, due to their capacity to remove nutrients, as their growth requires sunlight,

water, CO and nutrients.

1 Scope

The purpose of this document is to provide an overview on how quality indicating parameters for algae

and algae products and intermediates relevant for chemical and bioenergy applications can be handled

and to identify the need for future standards development for chemicals, bioenergy and biofuels

applications.

This document does not provide instructions on handling of technical requirements in existing

legislations.

2 Normative references

The following documents are referred to in the text in such a way that some or all of their content

constitutes requirements of this document. For dated references, only the edition cited applies. For

undated references, the latest edition of the referenced document (including any amendments) applies.

EN 17399:2020, Algae and algae products - Terms and definitions

EN 14214, Liquid petroleum products - Fatty acid methyl esters (FAME) for use in diesel engines and heating

applications - Requirements and test methods

EN 590, Automotive fuels - Diesel - Requirements and test methods

EN 16734, Automotive fuels - Automotive B10 diesel fuel - Requirements and test methods

EN 16709, Automotive fuels - High FAME diesel fuel (B20 and B30) - Requirements and test methods

EN 16723-1, Natural gas and biomethane for use in transport and biomethane for injection in the natural

gas network - Part 1: Specifications for biomethane for injection in the natural gas network

EN 14103, Fat and oil derivatives - Fatty Acid Methyl Esters (FAME) - Determination of ester and linolenic

acid methyl ester contents

EN 17477, Algae and algae products - Identification of the biomass of microalgae, macroalgae,

cyanobacteria and Labyrithulomycetes - Detection and identification with morphological and/or molecular

methods

3 Terms and definitions

For the purposes of this document, the terms and definitions given in EN 17399:2020 and the following

apply.

ISO and IEC maintain terminological databases for use in standardization at the following addresses:

• IEC Electropedia: available at https://www.electropedia.org/

• ISO Online browsing platform: available at https://www.iso.org/obp

3.1

Raw Material Specification

RMS

technical dossier, several pages long, about the product, usually prepared by manufacturer, directed to

provide all product approval information to the customer and usually attached to commercial contract

Note 1 to entry: Examples of models of RMS for some algae categories are reported in Annex A.

3.2

Technical Data Sheet

TDS

technical document, one (or few) page long, showing the technical (bio- and physicochemical)

parameters adopted to characterize the product and therefore being the paradigm of the Certificate of

Analysis (CoA)

Note 1 to entry: It includes ranges of different parameters used to define the product characteristics or applicable

regulatory limits.

Note 2 to entry: Examples of Models of TDS for some algae categories are reported in Annex B.

Note 3 to entry: In cases where the producer wants to make statements regarding the algal product as a bio-based

product EN 16848 and EN 16935 should be used.

3.3

Certificate of Analysis

CoA

one (or few) page document issued from a laboratory (or laboratories) and reporting test results for a

specific lot, usually in front of TDS parameters, including references to test method

Note 1 to entry: It may or may not have legal value.

3.4

Material Safety Data Sheet

MSDS

SDS

document issued with the aim of providing information about product compliance in respect of human

health and safety at the workplace and protection of the environment

Note 1 to entry: The MSDS should comply with Reg 1907/2006 (REACH).

3.5

sustainable development

development that meets the environmental, social and economic needs of the present without

compromising the ability of future generations to meet their own needs

[SOURCE: ISO Guide 82:2019, definition 3.2]

3.6

extracts

products of liquid, solid or intermediate consistency, obtained from algal biomass and containing

components present in and/or derived from the algal biomass

Note 1 to entry: For some preparations, the biomass to be extracted undergoes a preliminary treatment, for

example, inactivation of enzymes, grinding or freezing.

3.7

energy from renewable sources

energy from renewable non-fossil sources, namely wind, solar (solar thermal and solar photovoltaic) and

geothermal energy, ambient energy, tide, wave and other ocean energy, hydropower, biomass, landfill

gas, sewage treatment plant gas and biogas

[SOURCE: Directive (EU) 2018/2001 of the European Parliament and of the Council of 11 December 2018

on the promotion of the use of energy from renewable sources (recast) [6]]

3.8

bioliquids

liquid fuel for energy purposes other than for transport, including electricity and heating and cooling,

produced from biomass

[SOURCE: Directive (EU) 2018/2001, ibid. [6]]

3.9

biofuels

liquid fuel for transport produced from biomass

[SOURCE: Directive (EU) 2018/2001, ibid. [6]]

3.10

advanced biofuels

biofuels which technology is more innovative and less mature that are produced from feedstock which

has low indirect land-use change impacts

Note 1 to entry: this feedstock includes algae if cultivated on land in ponds or photobioreactors.

[SOURCE: Directive (EU) 2018/2001, ibid. [6]]

3.11

biomass fuels

gaseous and solid fuels produced from biomass

[SOURCE: Directive (EU) 2018/2001, ibid. [6]]

3.12

biogas

gaseous fuels produced from biomass

[SOURCE: Directive (EU) 2018/2001, ibid. [6]]

3.13

guarantee of origin

an electronic document which has the sole function of providing evidence to a final customer that a given

share or quantity of energy was produced from renewable sources

[SOURCE: Directive (EU) 2018/2001, ibid. [6]]

3.14

low indirect land-use change-risk biofuels, bioliquids and biomass fuels

biofuels, bioliquids and biomass fuels, the feedstock of which was produced within schemes which avoid

displacement effects of food and feed-crop based biofuels, bioliquids and biomass fuels through improved

agricultural practices as well as through the cultivation of crops on areas which were previously not used

for cultivation of crops

Note 1 to entry: Crops which were produced in accordance with the sustainability criteria for biofuels, bioliquids

and biomass fuels laid down in Article 29 of Directive (EU) 2018/2001.

[SOURCE: Directive (EU) 2018/2001, ibid. [6]]

4 Algae products applications as chemical raw materials

4.1 General

For multi-constituent natural ingredients, with variable composition, it is essential that the producers

provide clearly defined specifications in view of the range of variability of the components.

The variability should not change significantly and minimum levels of active components should be

specified.

In cases where the producer wants to make statements regarding the algal product as a bio-based product

EN 16848 and EN 16935 should be used.

4.2 Bioplastics from algae

A considerable attention has been paid, in recent years, to alternative feedstock for bioplastics

production. Microbial production of exopolysaccharides (EPSs) is an interesting field of research, in view

of the increasing demand for natural biofilm products for medical, and industrial applications. Microalgal

EPSs have potential antioxidant, antibacterial, and emulsifying activities and may be potentially obtained

from direct extraction from algae. Specifically, polymers such as starch or polyhydroxyalkanoates (PHAs),

which are already being used in plastic production, are of interest. Starch on the other hand is not a

polymer with plastic properties. It can be modified with additives to achieve thermoplastic properties or

used as a filler in other plastics. Similarly, saccharides found in algae can be used as feedstock for the

production of building blocks for bio-based plastic, such as lactic and succinic acid [1] [2] [3].

Moreover, PHAs are widely produced by heterotrophic bacteria. These compounds can replace

commercial plastics, such as polyethylene and polypropylene, because of their high biodegradability and

biocompatibility. One of the best-studied and commercially available biopolymers is poly-b-

hydroxybutyrate (PHB) see Figure 1, which constitutes the intracellular components of microbial cells,

and that can be accumulated in significant amount under specific growth conditions. PHAs possess

inherent thermoplastic properties and will not need to be modified to create a plastic film.

Figure 1 — Chemical structure of P3HB

Properties will depend on the exact structure of the PHA, the purity of the extracted material, molecular

weight and the extracted amount of PHAs.

However, if a plastic is produced with PHAs and additives or fillers the degradation process can become

more complex.

Life-Cycle analysis has been a valuable tool to assess the environmental impact of bio-plastics along their

life cycle. Taking into account the various challenges of this field and the constant development, a specific

methodology was proposed in order to assess the potential environmental impacts of the use of

alternative feedstocks (biomass, recycled plastics, CO ) in comparison to current feedstocks (oil and gas)

[4].

EN 16760 "Bio-based products – Life cycle assessment" is applicable for bioplastics produced from algae,

see also clause 8.

Beside LCA issues, methodology for assessing standards for alternative feedstock for bioplastic

production is a field still under development. The current production relies on few feedstocks, and there

is a need to enlarge the basket of potential alternatives, if the sector aims to continue on the current

growth.

It could be of interest to focus the analysis of the current legislative framework on the availability of

quality standards for alternative feedstock, including algae as potential interesting and widely available

source.

4.3 Fertilisers

Fertilisers are defined and regulated by Reg 1009/2019 EU (Fertiliser Product Regulation, FPR) [5].

Whereas microalgae only recently got this application due to high cost, and mainly as biostimulants,

seaweeds have long history of use as fertilisers since 3000 BC thanks to availability from wild gathering,

which action improved the sea life environment and helped to prevent the accumulation of dead seaweed

on the shores and in the deep sea.

According to FPR, algae are included together with plants as i) raw material for EU fertiliser product or

ii) input material for the production of biogas in anaerobic fermenters, from which the digestate can be

contained in EU fertiliser product. However, in both cases cyanobacteria (“blue-green algae”) are

excluded; this gap excludes actually Arthospira sp. (Spirulina) from EU fertiliser and might be fixed by

appropriate amendment of FPR, e.g. inclusion of safe cyanobacteria in microorganism category. More

information about FPR is given in Annex C.

4.4 Biostimulants

Plant biostimulants are substances, mixtures and micro-organisms which, differently from straight

fertilisers, are not as such inputs of nutrients, but nevertheless stimulate plants’ natural nutrition

processes. They act in addition to fertilisers, with the aim of optimising the efficiency of those fertilisers

and reducing the nutrient application rates and are by nature more similar to fertilising products than to

most categories of plant protection products. Such products are therefore eligible for CE marking under

Reg 1009/2019 and excluded from the scope of Reg (EC) No 1107/2009 on Plant protection products

(e.g. pesticides).

Plant biostimulants constitute Product Function Category (PFC) 6 of fertilisers, products made to

stimulate plant nutrition processes independently of the product’s nutrient content with the sole aim of

improving one or more of the following characteristics of the plant or the plant rhizosphere:

a) nutrient use efficiency;

b) tolerance to abiotic stress;

c) quality traits; or

d) availability of confined nutrients in the soil or rhizosphere.

An example of main product requirements and conformity assessment for a plant biostimulant composed

of algae-based material (under FPR) to be marketed as EU fertiliser is given in Annex D.

A table of regulated contaminants filled from Reg 1009/2019 EU is given in Annex E.

5 Biofuels from algae

5.1 General

The product characteristics specified from clause 5.2 to clause 5.5 should comply with the relevant

standards and regulations.

In case the product characteristics are referred to algae and algae products raw materials, existing

standards are referenced when applicable and recommendations for possible developments provided.

In the current worldwide energy matrix, there is a strong dependence on non-renewable energy sources,

mainly coal, oil and natural gas. Considering the production of sustainable energy sources, the use of

biofuels has become an important alternative, due to a reduction in CO emissions into the atmosphere.

An overview on algae biofuels literature is given in Annex G.

Biomass production aimed for biofuels has general sustainability standards: ISO 13065 as well as

EN 16214-1, EN 16214-3 and EN 16214-4, where the first is applicable to all types of bioenergy.

Concerning liquid biofuels, it is usual to classify them as first, second and third generation. The most well-

known first-generation biofuel is ethanol, extracted from the fermentation of sugar and starch present in

plants in addition to biodiesel produced from oilseed plants. Second-generation biofuels are those

produced from the processing of the lignocellulosic fraction of biomass from higher plants. Biofuels from

algae are often mentioned as third generation.

Algae are explicitly mentioned in The Renewable Energy Directive recast (RED II) [6] as feedstock for the

production of biogas for transport and advanced biofuels, and can be counted twice if cultivated on land

in ponds or photobioreactors. Additionally, algae are listed in RED II as feedstock that can be processed

only with advanced technologies. Feedstock that can be processed into biofuels, or biogas for transport,

with mature technologies, such as used cooking oils and animal fats, have a share limited to 1,7% (energy

content).

Bioethanol, biohydrogen, biodiesel and biogas (biomethane) have been proposed from algae through

processes such as fermentation, dark fermentation/photobiological production, lipid

extraction/transesterification and anaerobic digestion, respectively. On the other hand, different

thermochemical processes have been proposed for algae, such as pyrolysis, gasification, torrefaction and

hydrothermal liquefaction, depending on process conditions (pressure, temperature, reaction time,

oxygen availability and feedstock water content, among others). Thermochemical conversion processes

yield bio-oil (which can be eventually converted in drop-in liquid biofuels), biogas/syngas and char.

There is still need for algae-based process development and intensification in order to make full use of

the wide range of bio-based products, biofuels and environmental services algae and algae products can

generate (such as CO2 and other GHG biosequestration, waste water treatment – phycoremediation- and

heavy metals tertiary treatment, among others). Besides bioenergy production from algae, a wide range

of commercially valuable bio-based products/materials and/or high added value products can be

extracted, fractionated and purified, following the biorefinery approach. For commercial viability, a

matrix approach leading to numerous products is preferred for successful operation of algal biorefineries.

5.2 Fuel specifications

Fuels are characterized by energy density and technical parameters related to engine suitability (e.g.

cetane or octane number, impurities, ash content, oxidation stability, etc.).

No algae fuels are currently present in the market even if several Institutions (EU Commission, U.S.

Department of Energy) are interested and several Companies are working on that topic. According to

available literature, algae derived fuel feedstock allow for entering in already developed conversion

pathways, e.g. gaseous fuels like biomethane, and liquid fuels for diesel substitution like biodiesel or

alternative fuels for aviation sector.

It is worth to note that algae are considered for their photosynthetic potential as alternatives to terrestrial

plants (the actual main source of biodiesel, hydrogenated vegetable oil (HVO) and biogas besides waste

products) whereby the carbon-based molecule is biosynthesized converting solar energy in chemical

energy. Algae have neither to be considered as an intermediate nor as a finished fuel, but as a raw material

for certified fuels production, therefore no algae specific standards have to be mentioned in this section.

NOTE The only relevant exemption is represented by the aviation sector. In aviation not only the final fuel, but

also the conversion process has to be fully certified.

The American Society for Testing and Materials (ASTM) issued two technical norms regulating the sector:

ASTM D4054 (Standard Practice for Qualification and Approval of New Aviation Turbine Fuels and Fuel

Additives), which describes the qualification process for an alternative fuel to be considered compliant

for use in ASTM D7566– 17a (Standard Specification for Aviation Turbine Fuel Containing Synthesized

Hydrocarbons).

Currently eight production pathways are already fully certified for blending with fossil aviation jet fuel.

These aviation biofuels are drop-in fuels: they can be directly blended with fossil (ASTM D1655:

Specification for Aviation Turbine Fuels) but with different blending limits.

At the time of writing, no specific algae-based pathway results certified for aviation [7].

5.3 Liquid biofuels from algae

5.3.1 General

A first categorisation of liquid fuels can be performed on the base of their possibility to be directly mixed

to regular fuel without specific limitations. The term “drop-in” fuel is generally used to describe an

alternative fuel, that can be blended into a regular fuel, without compromising any functionality of the

engine. Hydrogenated Vegetable Oil (HVO) is usually recognised as a drop-in fuel, while biodiesel and

bioethanol are not.

The final characteristics of the alternative fuels, which derive from the feedstock/conversion process

couple, determines whether the final product can be considered a drop-in fuel or has to respect a blending

limit.

Liquid fuels from algae currently under development can be divided in two main groups, e.g. fuels derived

from algae oil (biodiesel, HVO) and alcohols, usually ethanol, obtained by fermentation of algae

carbohydrates. In principle, alcohols and other algae derived molecules can be used to synthesize drop-

in liquid fuels (i.e. Fischer-Tropsch fuels from algal biomethane, jet fuel from algal alcohols).

5.3.2 Product characteristics of liquid fuels from algae lipids

5.3.2.1 General

The lipid content in microalgae is very diverse. The cell structure, cell wall characteristics, the lipid

binding with proteins and carbohydrates and lipids for energy storage vary from species to species and

even within species depending on cultivation (culture age, growth phase and nutrient availability) or

extraction condition. The extraction methods will affect not only the total extraction yield, but, in some

cases, the fatty acid profile, especially when extraction yield is low. Therefore, a general recommendation

on a specific algae or extraction method cannot be given. However, heterotrophic algae and phototrophic

algae under starvation (metabolic induction, e.g. by nitrogen depletion in the last culture phase) are

known to have increased lipid content.

5.3.2.2 Algae lipids

Algae lipids are defined as class of natural organic substances characterized by very low water solubility,

high solubility in organic solvents, high carbon and hydrogen content, biosynthesized for energy storage

and/or metabolic and structural functions. Several test methods for total lipids content of marine tissues

were applied to algae since the fifties (Bligh&Dyer [8], Folch [9], Smedes [10]) ending in the highly

recommended need for a standard, which is currently developed in CEN/TC 454, see below, and the one

described in clause 6.7.

5.3.2.3 Algae oil

Algae oil is defined as glyceridic fraction of lipids derived from algae (EN 17399:2020, 3.2).

The detailed composition and molecular profile of lipids is required for reporting on oil quality and

biomass valorisation and will be highly influential when targeting particular bioproduct markets, for

example for biodiesel or green diesel. Not all lipids can be considered equally valuable for fuel or even

food or feed applications. The lipid composition, with respect to polar (phospho- and glycolipids) and

non-polar (triglycerides and sterols) lipids and the respective impurities found in each fraction, is highly

dependent on the origin and type of biomass. Autotrophically grown algae are rich in polar lipids, waxes,

sterols, and pigments, whereas heterotrophic cultivation will yield triglyceride-rich oil similar to plant-

derived oils, but often with very different fatty-acid profiles. Traditionally, lipids have been measured

gravimetrically after solvent extraction. The completeness of extraction depends on composition,

therefore on the biochemistry of the alga and on the recent physiological conditions experienced by the

organism. Therefore the extraction solvent polarity must cope with the lipid molecule polarity and the

extraction conditions used, in order to avoid inconsistent lipid yields. Inevitably, the extractable oil

fraction will contain non-fuel components (e.g. chlorophyll, other pigments, proteins, and soluble

carbohydrates). Thus, it may be very useful to assess its fuel fraction (i.e. fatty acid content) by

transesterification followed by quantification of the fatty acid methyl esters (FAMEs). However, due to

the large number of variables, it is necessary to standardize the extraction-based total lipid quantification

procedure [11] in order to be in position to refer the fatty acids content to lipids and not only to whole

biomass. There are two extraction systems currently in use across analytical laboratories: conventional

Soxhlet extractor systems and the Randall extraction systems with the more recently developed

pressurized fluid extraction systems. However modified Bligh-Dyer [13] or Smedes [10] dual solvents

extraction method were recommended for complex matrixes of marine origin such as fish tissue [11]

[12]. Since most microalgae and seaweeds are marine organisms and show lipids patterns similar to fish

tissue and very different from terrestrial oilseeds, a more powerful extraction system than Soxhlet and

its variations is necessary. Immersion extraction and sonication over freeze dried test portions provided

best accuracy and precision with appropriate and well standardized protocol which was demonstrated

to work also with algae showing composition similar to oilseeds, such as heterotrophs. [13]. The basic

principles of such protocol are: 1) to extract quantitatively all lipids by proper mixed solvent

(chloroform/methanol), high solvent/solid ratio and multiple washes, 2) to purify the extract by removal

of non-lipids fractions through liquid-liquid purification. For certain microalgae with a very hard cell wall,

a pre-treatment of bead beating is provided.

This protocol is going to become the new standard as the reference test method for total lipid content.

As an alternative to extraction, for routinary purposes of multiple testing of the same alga there is a

growing emphasis on the quantification of lipids through a direct (or in situ) transesterification of whole

algal biomass and to application of rapid indirect measurement of lipids by near infrared spectroscopy

(NIR) and nuclear resonance spectroscopy (NMR).

However this methods have two major drawbacks: 1) the need for case by case calibration by absolute

method (e.g. extraction and gravimetry) and 2) the need of sophisticated and expensive apparatuses.

Finally, qualitative or semi-quantitative (after calibration) lipids data can be gathered through high-

throughput methodologies that are based on hydrophobic (lipophilic) fluorescent dyes such as Nile Red

[14].

While fatty acids measurement by direct transesterification and gas chromatography (GC) cannot

substitute extraction for total lipids, it is a powerful tool for algae oil quality characterization. The process

consists of either a two-step alkaline and subsequent acid hydrolysis of the biomass, or a single-step acid

catalysis, followed by the methylation of the fatty acids to fatty acids methyl esters (FAME) and

quantification by GC. These procedures have been demonstrated to be robust across species and their

efficacy is less dependent on the parameters listed above that influence lipid extraction. However, if the

relative composition of intact lipids is required (e.g. polar versus neutral lipid content), an extraction

process may be the only way to isolate intact lipids from the rest of the biomass, with the utilization of

advanced instrumentation, such as liquid chromatography for the characterization of the lipid molecular

profile.

Fatty acid profile and content of vegetable fats and oils can be measured according the standards of

ISO 12966. It is strongly recommended that for fatty acids determination in algae ISO 12966 is examined.

5.3.3 Algae oil for biodiesel

5.3.3.1 General

Algae oil, i.e. fatty acids, either free or bound (on glycerol), could be converted into FAME, also known as

biodiesel. The product shall comply with the biodiesel standard EN 14214 for its usage, either pure or as

blending component for a diesel fuel according EN 590, EN 16734 or EN 16709.

The share of FAME in mineral diesel is limited in EN 590 to 7,0 %v/v, in EN 16734 to maximum of 10,0

%v/v and in EN 16709 to a maximum of 30,0 %v/v.

Several parameters of EN 14214 are related to the fatty acid profile of the raw material, as they will not

be changed significantly in the biodiesel process. As consequence, these parameters should already be

fulfilled by the algae oil, or the algae oil should be blended with other fats and oils to meet the parameters.

5.3.3.2 Fatty acid profile

The fatty acid profile related parameters should be fulfilled in the final biodiesel according to EN 14214.

As unsaturated fatty acids are vulnerable for oxidation, they are limited by several parameters. Oxidation

products can damage the engine [15]. However, due to this oxidizability, biodiesel is more easily

biodegradable than fossil fuels.

5.3.3.3 Other chemical parameters of oils

The iodine value is a measure for the content of unsaturated fatty acids. It describes the mass of halogen,

expressed as iodine, absorbed by the test portion when determined in accordance with the procedure

specified in EN ISO 3961, divided by the mass of the test portion [16]. The limit for the iodine value is

maximum 120 g iodine /100 g. The iodine can be measured according to EN ISO 3961 by titration or

EN 16300 via the fatty acid profile.

The linolenic acid methyl ester (C18:3) content is limited with maximum 12,0 %(m/m). In the final

product it should be measured according EN 14103.

The content of polyunsaturated methyl ester (PUFA) shall be below 1,0 %(m/m), whereas in this case

polyunsaturated is defined as “more or equal 4 double bounds” in the fatty acid chain. Its content is

measured according EN 15779 which covers the usual predominant four PUFA (C20:4, C20:5, C22:5,

C22:6). Short chain PUFA, which might be present in algae oil, e.g. C16:4, are not considered but might

have an influence on the oxidation stability of the fuel.

The oxidation stability [15] is related to the fatty acid profile and to the presence of natural antioxidants

in the oil. However, if a distillation is required as purification step of the FAME, natural antioxidants will

remain in the distillation residue and therefore oxidation stabilizer must be added to the distilled

product.

Saturated fatty acids influence the cold weather properties, the cold filter plugging point (CFPP) and the

cloud point (CP). The cold filter plugging point is the highest temperature at which a given volume of fuel

fails to pass through a standardized filtration device in a specific time, when cooled under standardized

conditions as described in EN 16329.

The CP is the temperature at which a cloud of crystals first appears in a liquid when it is cooled under

specific conditions as described in EN ISO 3015. Both values are lowered with increasing content of

saturated FAME. The limit for CFPP is given for biodiesel usage as 100% fuel, the CP of biodiesel is

required to use it as blending component.

The climate-depending requirements are set for seasonal grades by the national standardization bodies

and can be found in the national annex of EN 14214.

The ester content of the final product shall be higher than 96,5 %m/m, it is measured according

EN 14103. This method is based on the usage of a C19:0 methyl ester as internal standard, this fatty acid

is not present in vegetable oils or animal or waste fats. However, it is recommended to check the algae oil

for that specific C19:0 FAME. Its presence in the algae oil may reduce the result of the ester content

significantly.

The ester content may also be reduced by other algae lipids co-extracted especially when polar lipids

were used. These lipids may contain a lower amount of fatty acids. Additionally a high content of

unsaponifiable matter (see 6.9 below) may reduce the ester content. A distillation may reduce these kinds

of lipids so that the distilled product has an increased ester content.

Several other parameters can be found in high concentrations in algae oil, which are limited in biodiesel.

5.3.3.4 Phosphorous

Phosphorous is originated from phospholipids membrane lipids of the algae. Its content is also influenced

by the polarity of the extraction solvent. A high content of phospholipids may hinder required phase

separation in the biodiesel process. As the final content in FAME must be below 4 mg/kg according to

EN 14214, special attention shall be taken in the purification of the FAME. Rectification, a multi stage

distillation, can be used to appropriately reduce the phosphorous content.

5.3.3.5 Sulphur

The limit of sulphur in FAME is maximum 10,0 mg/kg and can be much higher in algae oil due to the

presence of sulpholipids. It can also be reduced by a rectification unit.

5.3.3.6 Magnesium

Magnesium is limited in the FAME together with calcium as metals II with a maximum 5,0 mg/kg.

Magnesium can be present in significant amounts in algae oil since it is present in chlorophyll, which is

co-extracted with the oil from the biomass.

In FAME, it can be removed by distillation as it remains in the distillation residue.

5.3.4 Algae oil for hydrogenation

Hydrogenation is a process in which hydrogen is chemically bound to the algal oil. The process involves

the usage of hydrogen at high pressure in the presence of a catalyst. The product of this process is called

“paraffinic diesel fuel from synthesis or hydrogenation” and is specified in EN 15940.

In contrast to biodiesel there will be no oxygen in the product, which contain only hydrocarbons, the fatty

acid profile has no influence on the product quality. The cold weather properties of the hydrogenated

algae oil may allow its usage as aviation fuel.

The hydrogenation catalyst is sensitive to metals, e.g. magnesium from co-extracted chlorophyll.

Especially phosphorous may reduce the lifetime of the catalyst enormously, so that only a few ppm is

recommended.

It would be possible to use a distilled biodiesel as raw material for hydrogenation as the most unwanted

impurities are already removed during the final purification.

Details considering maximum allowable contamination with metals and phosphorous must be discussed

with the catalyst supplier.

5.4 Algae for alcohols

As algae can store relevant amounts of carbohydrates/polysaccharides, they have been considered as a

source of alcohol production, including ethanol, butanol and others [17] [18] [19] [20]. Ethanol from

fermentation is widely produced, and feedstock for this process is typically characterized by its sugar

content.

Main technological challenges for converting algae into alcohol are related to pre-treatment. For

terrestrial biomass, biomass pre-treatment aims at separating and providing easier access to th

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.

Loading comments...