oSIST prEN 845-2:2010

(Main)Specification for ancillary components for masonry - Part 2: Lintels

Specification for ancillary components for masonry - Part 2: Lintels

This part of EN 845 specifies requirements for prefabricated lintels up to a maximum clear span of 4,5 m made from autoclaved aerated concrete, fired clay units, calcium silicate units, natural or manufactured stone, concrete and steel or using a combination of these materials. Product characteristics linked to ER1 are flexural resistance, shear load resistance and stiffness.

Festlegungen für Ergänzungsbauteile für Mauerwerk - Teil 2: Stürze

Dieser Teil von EN 845 legt Anforderugnen an vorgefertigte Stürze mit einer lichten Weite von maximal 4,5 m aus Porenbeton, gebrannten Mauerziegeln, Kalksandsteinen, Natursteinen oder Betonwerksteinen, Beton oder Stahl oder aus einer Kombination dieser Materialien fest. Anmerkung 1: Stürze werden in einem Stück zur Baustelle geliefert. Sie können auf der Baustelle mit Beton oder Mauerwerk (teilweise vorgefertigte bauseits ergänzte Stürze) oder mit einem anderen Sturz (zusammengesetzte Stürze) ergänzt werden; sie sollten aber im Anlieferungßustand in der Lage sein, eine Last zu übertragen.

Spécifications pour composants accessoires de maçonnerie - Partie 2: Linteaux

Cette partie de la norme EN 845 spécifie les exigences relatives aux linteaux préfabriqués d'une portée maximum de 4,5 m réalisés à partir de béton cellulaire autoclavé, d'éléments en terre cuite, d'éléments en silico-calcaire, en pierre naturelle ou artificielle, en béton et en acier ou qui combinent ces matériaux. Note 1: Les linteaux sont livrés sur le chantier en une seule pièce. Ils peuvent être complétés sur le chantier par du béton ou des éléments de maçonnerie (linteau composite) ou par un autre linteau (linteau combiné), mais ils doivent être à même de supporter une charge dans l'état où ils sont livrés

Specifikacija za dodatne komponente zidovja - 2. del: Preklade

General Information

- Status

- Not Published

- Public Enquiry End Date

- 19-Apr-2010

- Technical Committee

- CAA - Mineral binders and masonry

- Current Stage

- 98 - Abandoned project (Adopted Project)

- Start Date

- 28-Oct-2011

- Due Date

- 02-Nov-2011

- Completion Date

- 28-Oct-2011

- Directive

- 89/106/EEC - Construction products

Relations

- Effective Date

- 08-Mar-2023

- Effective Date

- 08-Mar-2023

- Effective Date

- 08-Jun-2022

- Effective Date

- 01-Mar-2010

Overview

The oSIST prEN 845-2:2010 standard, developed by CEN (European Committee for Standardization), provides detailed specifications for ancillary masonry components, focusing specifically on prefabricated lintels. This standard applies to lintels made from a variety of materials including steel, autoclaved aerated concrete, fired clay units, calcium silicate units, natural or manufactured stone, concrete, or combinations of these materials. The lintels covered here span openings up to a maximum clear span of 4.5 meters. The key product performance characteristics linked to this standard include flexural resistance, shear load resistance, and stiffness.

This specification supports the EU Construction Products Directive and aims to harmonize technical requirements, ensuring consistency and reliability in lintel design and installation across Europe. It supersedes the earlier EN 845-2:2003 and incorporates additional technical requirements based on the latest market and regulatory feedback.

Key Topics

Scope and Applicability:

- Applies to prefabricated lintels used over masonry wall openings up to 4.5 m.

- Covers lintels manufactured entirely from or as composites of materials such as steel, reinforced concrete, autoclaved aerated concrete, fired clay, calcium silicate, and natural or manufactured stone.

- Excludes timber lintels, on-site made lintels, and unreinforced natural stone lintels.

Materials and Construction:

- Specifications detail steel lintels, concrete lintels (reinforced or prestressed), masonry lintels with shell casing units, combined lintels (multiple structural elements), and composite lintels (prefabricated part with complementary in-situ masonry or concrete).

Product Requirements:

- Dimensions, mass, and allowable deviations.

- Mechanical performance evaluations, including flexural resistance and shear resistance testing.

- Durability criteria covering resistance to water penetration, freeze/thaw cycles, fire, water absorption, and water vapor permeability.

- Detailed requirements for corrosion protection, especially for steel components.

Testing and Conformity:

- Initial type testing, factory production control, sampling methods.

- Normative and informative annexes provide test methods, load assessment, installation recommendations, corrosion protection schemes, and factory control schemes.

Marking and Designation:

- Specifies labeling and product identification requirements to facilitate traceability and compliance verification.

Applications

oSIST prEN 845-2:2010 lintels are crucial components in construction projects involving masonry walls, providing structural support above openings such as doors and windows. The standard's practical value lies in:

- Ensuring lintels meet essential load-bearing and safety requirements to support masonry above openings.

- Guiding manufacturers to produce lintels with consistent quality standards across different European markets.

- Assisting architects, engineers, and builders in selecting appropriate lintel materials and types suitable for various environmental and loading conditions.

- Facilitating the specification of lintels that conform to durability, thermal, and fire resistance standards, ensuring long service life and compliance with building regulations.

- Supporting the use of innovative materials and composite designs, thereby enabling more efficient construction methods while maintaining structural integrity.

Common sectors benefiting from this standard include residential, commercial, and infrastructure masonry construction, where standardized lintels contribute to safer, durable, and cost-effective building solutions.

Related Standards

oSIST prEN 845-2:2010 integrates references and requirements from numerous related European standards, enhancing its comprehensiveness:

- EN 771 series - Specifications for various masonry units including clay, calcium silicate, concrete, autoclaved aerated concrete, manufactured stone, and natural stone masonry units.

- EN 846 series - Test methods related to ancillary masonry components like lintel flexural and shear resistance.

- EN 13501-2 - Fire classification for construction products including masonry elements.

- EN 998-2 - Specification for masonry mortar used in conjunction with lintels.

- EN 1090-1, EN 12602, EN 13225 - Related to steel and concrete structural components but excluded from this lintel-specific standard.

- EN ISO 1461 - Hot-dip galvanized coatings for steel lintel corrosion protection.

- EN 1745 - Methods for determining thermal design values relevant to masonry components.

- Additional standards on steel grades, coatings, corrosion protection, and concrete performance are referenced to ensure material compatibility and durability.

By conforming to oSIST prEN 845-2:2010, stakeholders can ensure the specification, production, testing, and installation of prefabricated lintels meet rigorous European standards necessary for reliable masonry construction. This leads to improved structural safety, performance, and regulatory compliance across diverse building projects.

Frequently Asked Questions

oSIST prEN 845-2:2010 is a draft published by the Slovenian Institute for Standardization (SIST). Its full title is "Specification for ancillary components for masonry - Part 2: Lintels". This standard covers: This part of EN 845 specifies requirements for prefabricated lintels up to a maximum clear span of 4,5 m made from autoclaved aerated concrete, fired clay units, calcium silicate units, natural or manufactured stone, concrete and steel or using a combination of these materials. Product characteristics linked to ER1 are flexural resistance, shear load resistance and stiffness.

This part of EN 845 specifies requirements for prefabricated lintels up to a maximum clear span of 4,5 m made from autoclaved aerated concrete, fired clay units, calcium silicate units, natural or manufactured stone, concrete and steel or using a combination of these materials. Product characteristics linked to ER1 are flexural resistance, shear load resistance and stiffness.

oSIST prEN 845-2:2010 is classified under the following ICS (International Classification for Standards) categories: 91.060.10 - Walls. Partitions. Facades; 91.080.30 - Masonry. The ICS classification helps identify the subject area and facilitates finding related standards.

oSIST prEN 845-2:2010 has the following relationships with other standards: It is inter standard links to SIST EN 846-13:2002, SIST EN 845-2:2002, SIST EN 845-2:2004, SIST EN 845-2:2004. Understanding these relationships helps ensure you are using the most current and applicable version of the standard.

oSIST prEN 845-2:2010 is associated with the following European legislation: EU Directives/Regulations: 89/106/EEC; Standardization Mandates: M/116. When a standard is cited in the Official Journal of the European Union, products manufactured in conformity with it benefit from a presumption of conformity with the essential requirements of the corresponding EU directive or regulation.

You can purchase oSIST prEN 845-2:2010 directly from iTeh Standards. The document is available in PDF format and is delivered instantly after payment. Add the standard to your cart and complete the secure checkout process. iTeh Standards is an authorized distributor of SIST standards.

Standards Content (Sample)

SLOVENSKI STANDARD

01-marec-2010

Specifikacija za dodatne komponente zidovja - 2. del: Preklade

Specification for ancillary components for masonry - Part 2: Lintels

Festlegungen für Ergänzungsbauteile für Mauerwerk - Teil 2: Stürze

Spécifications pour composants accessoires de maçonnerie - Partie 2: Linteaux

Ta slovenski standard je istoveten z: prEN 845-2

ICS:

91.060.10 Stene. Predelne stene. Walls. Partitions. Facades

Fasade

91.080.30 Zidane konstrukcije Masonry

2003-01.Slovenski inštitut za standardizacijo. Razmnoževanje celote ali delov tega standarda ni dovoljeno.

EUROPEAN STANDARD

DRAFT

NORME EUROPÉENNE

EUROPÄISCHE NORM

January 2010

ICS 91.080.30 Will supersede EN 845-2:2003

English Version

Specification for ancillary components for masonry - Part 2:

Lintels

Spécifications pour composants accessoires de Festlegungen für Ergänzungsbauteile für Mauerwerk - Teil

maçonnerie - Partie 2: Linteaux 2: Stürze

This draft European Standard is submitted to CEN members for enquiry. It has been drawn up by the Technical Committee CEN/TC 125.

If this draft becomes a European Standard, CEN members are bound to comply with the CEN/CENELEC Internal Regulations which

stipulate the conditions for giving this European Standard the status of a national standard without any alteration.

This draft European Standard was established by CEN in three official versions (English, French, German). A version in any other language

made by translation under the responsibility of a CEN member into its own language and notified to the CEN Management Centre has the

same status as the official versions.

CEN members are the national standards bodies of Austria, Belgium, Bulgaria, Croatia, Cyprus, Czech Republic, Denmark, Estonia,

Finland, France, Germany, Greece, Hungary, Iceland, Ireland, Italy, Latvia, Lithuania, Luxembourg, Malta, Netherlands, Norway, Poland,

Portugal, Romania, Slovakia, Slovenia, Spain, Sweden, Switzerland and United Kingdom.

Recipients of this draft are invited to submit, with their comments, notification of any relevant patent rights of which they are aware and to

provide supporting documentation.

Warning : This document is not a European Standard. It is distributed for review and comments. It is subject to change without notice and

shall not be referred to as a European Standard.

EUROPEAN COMMITTEE FOR STANDARDIZATION

COMITÉ EUROPÉEN DE NORMALISATION

EUROPÄISCHES KOMITEE FÜR NORMUNG

Management Centre: Avenue Marnix 17, B-1000 Brussels

© 2010 CEN All rights of exploitation in any form and by any means reserved Ref. No. prEN 845-2:2010: E

worldwide for CEN national Members.

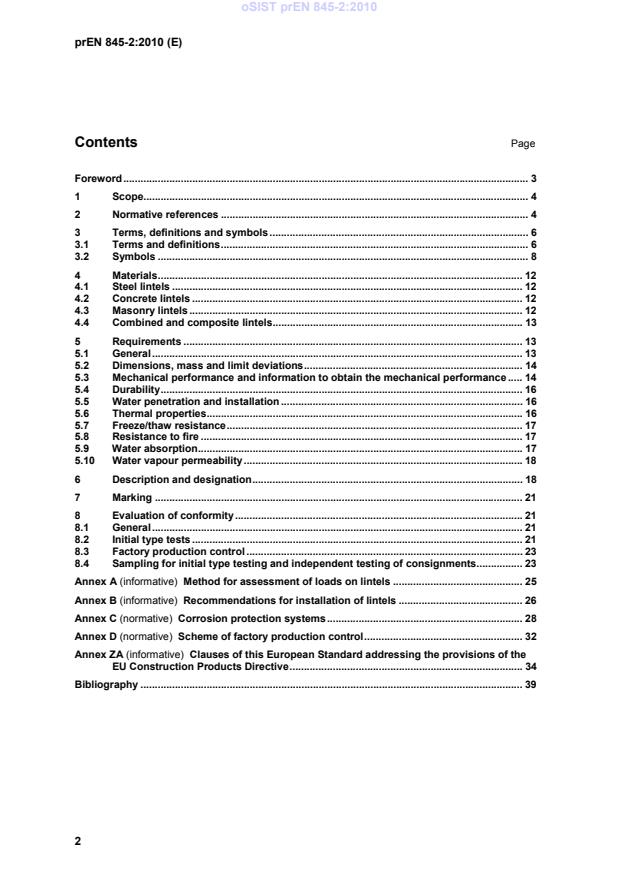

Contents Page

Foreword . 3

1 Scope. 4

2 Normative references . 4

3 Terms, definitions and symbols . 6

3.1 Terms and definitions . 6

3.2 Symbols . 8

4 Materials . 12

4.1 Steel lintels . 12

4.2 Concrete lintels . 12

4.3 Masonry lintels . 12

4.4 Combined and composite lintels . 13

5 Requirements . 13

5.1 General . 13

5.2 Dimensions, mass and limit deviations . 14

5.3 Mechanical performance and information to obtain the mechanical performance . 14

5.4 Durability . 16

5.5 Water penetration and installation . 16

5.6 Thermal properties . 16

5.7 Freeze/thaw resistance . 17

5.8 Resistance to fire . 17

5.9 Water absorption . 17

5.10 Water vapour permeability . 18

6 Description and designation . 18

7 Marking . 21

8 Evaluation of conformity . 21

8.1 General . 21

8.2 Initial type tests . 21

8.3 Factory production control . 23

8.4 Sampling for initial type testing and independent testing of consignments . 23

Annex A (informative) Method for assessment of loads on lintels . 25

Annex B (informative) Recommendations for installation of lintels . 26

Annex C (normative) Corrosion protection systems . 28

Annex D (normative) Scheme of factory production control . 32

Annex ZA (informative) Clauses of this European Standard addressing the provisions of the

EU Construction Products Directive . 34

Bibliography . 39

Foreword

This document (prEN 845-2:2010) has been prepared by Technical Committee CEN/TC 125

“Masonry”, the secretariat of which is held by BSI.

This document is currently submitted to the CEN Enquiry.

This document will supersede EN 845-2:2003.

This European Standard has been prepared under a mandate given to CEN by the European

Commission and the European Free Trade Association and supports the essential requirements of the

EU Construction Products Directive (89/106/EEC).

For relationship with EU Directives, see informative Annex ZA which is an integral part of this standard.

In this European Standard the Annexes A and B are informative and the Annexes C and D are normative.

This Part has been modified, including the introduction of additional requirements, taking into account

the detailed answer by CEN/TC 125 to EC mandate M116 for masonry as well as details of the

relationship of this new harmonized European Standard with the EU Directives.

EN 845 “Specification for ancillary components for masonry” consists of the following Parts:

— Part 1: Wall ties, tension straps, hangers and brackets.

— Part 2: Lintels.

— Part 3: Bed joint reinforcement of steel meshwork.

1 Scope

This European Standard specifies requirements for prefabricated lintels for spans over clear openings

in a masonry wall up to a maximum of 4,5 m and made from steel, autoclaved aerated concrete,

manufactured stone, concrete, fired clay units, calcium silicate units, natural stone units, or using a

combination of these materials. Concrete and steel beams conforming to EN 1090-1, EN 12602 and

EN 13225, as appropriate, are not covered by this Standard.

Prefabricated lintels can be either complete lintels or the prefabricated part of a composite lintel.

This European Standard is not applicable to:

a) Lintels completely made on site;

b) Lintels of which, the tensile parts are made on site;

c) Timber lintels;

d) Natural stone lintels, not reinforced.

Linear components spanning clear openings greater than 4,5 m in masonry walls and linear

components intended for use independently in a structural role (e.g. beams) are not covered by this

standard.

2 Normative references

This European Standard incorporates by dated or undated reference, provisions from other

publications. These normative references are cited at the appropriate places in the text and the

publications are listed hereafter. For dated references, subsequent amendments to or revisions of any

of these publications apply to this European Standard only when incorporated in it by amendment or

revision. For undated references the latest edition of the publication referred to applies (including

amendments).

EN 206-1, Concrete — Part 1: Specification, performance, production and conformity.

EN 771-1, Specification for masonry units — Part 1: Clay masonry units.

EN 771-2, Specification for masonry units — Part 2: Calcium silicate masonry units.

EN 771-3, Specification for masonry units — Part 3: Aggregate concrete masonry units. (Dense and

light-weight aggregates)

EN 771-4, Specification for masonry units — Part 4: Autoclaved aerated concrete masonry units.

EN 771-5, Specification for masonry units — Part 5: Manufactured stone masonry units.

EN 771-6, Specification for masonry units — Part 6: Natural stone masonry units.

EN 772-1, Methods of test for masonry units — Part 1: Determination of compressive strength.

EN 772-11, Methods of test for masonry units — Part 11: Determination of water absorption of

aggregate concrete, manufactured stone and natural stone masonry units due to capillary action and

the initial rate of water absorption of clay masonry units.

EN 772-22, Methods of test for masonry units — Part 22: Determination of freeze/thaw resistance of

clay masonry units.

EN 846-9, Methods of test for ancillary components for masonry — Part 9: Determination of flexural

resistance, and shear resistance of lintels.

EN 846-11, Methods of test for ancillary components for masonry — Part 11: Determination of

dimensions and bow of lintels.

EN 846-13, Methods of test for ancillary components for masonry — Part 13: Determination of

resistance to impact, abrasion and corrosion of organic coatings.

EN 990, Test methods for verification of corrosion protection of reinforcement in autoclaved aerated

concrete and lightweight aggregate concrete with open structure.

EN 998-2, Specification for mortar for masonry — Part 2: Masonry mortar.

EN 1090-1, Steel and aluminium structural components — General delivery conditions.

EN 1745, Masonry and masonry products — Methods for determining design thermal values.

EN 10025-1, + new titles to add.

EN 10025-2, + new titles to add.

EN 10080, Steel for the reinforcement of concrete — Weldable reinforcing steel — General.

EN 10088-1, Stainless steels — Part 1: List of stainless steels.

EN 10088-2, Stainless steels — Part 2: Technical delivery conditions for sheet/plate and strip of

corrosion resisting steels for general purposes.

EN 10088-3, Stainless steels — Part 3: Technical delivery conditions for semi-finished products, bars,

rods, wire, sections and bright products of corrosion resisting steels for general purposes.

EN 10111, Continuously hot rolled low carbon steel sheet and strip for cold forming — Technical

delivery conditions.

EN 10130, Cold rolled low carbon steel flat products for cold forming — Technical delivery conditions.

prEN 10138 Parts 1, 2 and 3, Prestressing steels + titles to add.

EN 10143, Continuously hot-dip coated steel sheet and strip — Tolerances on dimensions and shape.

EN 10326, Continuously hot dip coated strip and sheet of structural steels — Technical delivery

conditions.

EN 10327, Continuously hot-dip coated strip and sheet of low carbon steelfor cold forming —

Technical delivery conditions.

EN 12602, Prefabricated reinforced components of autoclaved aerated concrete.

EN 12620, Aggregates for concrete.

EN 13225, Precast concrete products — Linear structural elements.

EN 13501-2, Fire classification of construction products and building elements — Part 2: Classification

using data from fire resistance tests excluding ventilation services.

EN ISO 1461, Hot dip galvanized coatings on fabricated iron and steel articles — Specifications and

test methods (ISO 1461:1999).

EN ISO 1463, Metallic and oxide coatings. Measurement of coating thickness — Microscopical

method (ISO 1463:2003).

3 Terms, definitions and symbols

3.1 Terms and definitions

For the purposes of this European Standard the following terms and definitions apply.

NOTE 1 Examples of lintel types are shown in Figures 1 to 3. The figures are only for illustration of lintel types.

Other details such as bearings, thermal insulation systems and damp proof courses are not shown.

NOTE 2 General dimensions defined in clause 3 are illustrated in Figures 3 and 4.

3.1.1

autoclaved aerated concrete lintel

lintel manufactured using reinforced autoclaved aerated concrete

3.1.2

bearing length

length of the end of a lintel which bears on its support

3.1.3

built-in length

minimum length needed to anchor the reinforcing bars

3.1.4

clear opening

clear distance between lintel supports

3.1.5

combined lintel

lintel consisting of two or more structural elements each one acting with compression and tension

zones

3.1.6

composite lintel

lintel comprising a prefabricated part and a complementary element of in-situ masonry or concrete

above, acting together

3.1.7

composite lintel height

overall height of the tension and compression zones of a composite lintel

3.1.8

concrete lintel

3.1.9

lintel manufactured using reinforced or prestressed concrete

declared value

value for a product property, determined in accordance with this standard, that a manufacturer is

confident of achieving bearing, in mind the variability of the manufacturing process

3.1.10

effective span

distance between the centres of the bearing of a lintel, or the clear opening spanned by the lintel plus

the overall height of the lintel including any complementary element, whichever is the lesser

3.1.11

flexural resistance

mean uniformly distributed load at which failure of a sample of lintel specimens occurs (or a lower

load at which tests are stopped in accordance with the recommendations of the manufacturer of the

lintel)

3.1.12

lintel

lineal element supporting load over an opening in a masonry wall

3.1.13

lintel height

overall height of the prefabricated part of a lintel

3.1.14

lintel length

overall length of the prefabricated lintel

3.1.15

load bearing capacity

mean value for a sample of lintels of the total of the uniformly distributed load at failure or at an

extreme deflection, whichever is the lesser

3.1.16

load ratio

the ratio of inner leaf load to outer leaf load on a lintel supporting a double-leaf or cavity wall

3.1.17

masonry lintel

lintel comprising one or more shell casing units completed by the incorporation within the shell casing

of reinforced or prestressed concrete

3.1.18

shear resistance

mean shear load at which failure of a sample of lintel specimens occurs (or a lower load at which tests

are stopped in accordance with the recommendations of the manufacturer of the lintel)

3.1.19

shell casing unit

preformed component with one or more channels into which is incorporated either reinforced or

prestressed concrete

3.1.20

single lintel

prefabricated lintel acting alone

3.1.21

declared deflection

the deflection at one third of the declared load capacity of the lintel

3.1.22

steel lintel

lintel manufactured from steel

3.1.23

structural shell casing unit

shell casing unit which is made of a material with a compressive strength not less than that of the infill

concrete

3.2 Symbols

NOTE General dimensions are illustrated in Figures 3 and 4.

b is the smallest width of a structural shell casing unit specimen, in mm, (see Figure 5);

s

b is the bearing length, in mm;

d is the height of the prefabricated part of the composite lintel;

ppcl

d is the composite lintel height, in mm;

c

d is the lintel height, in mm;

l

δ is the declared deflection in a vertical direction, in mm;

dv

δ is the declared deflection in a horizontal direction, in mm;

dh

h is the height of the masonry unit;

u

t is the thickness of the bedjoint;

bj

h is the cut length of a structural shell casing unit specimen, in mm, (see Figure 5);

s

l is the lintel length, in mm;

l is the clear opening, in mm;

o

l is the effective length, in mm;

e

Key

1 Supported masonry

2 Single lintel

Figure 1 — Example of a single lintel (see 3.1.19)

Key

1 Supported masonry

2 Complementary element (masonry or concrete)

3 Prefabricated part

Figure 2 — Example of a composite lintel (see 3.1.4)

d

l

d

c

d

l

Key

1 supported masonry - outer leaf 3 Inner leaf lintel

2 Outer leaf lintel 4 Supported masonry – inner leaf

Figure 3 — Example of a combined lintel (see 3.1.3)

d

l

l

b

l

l

E

Key

1 Lintels other than composite lintels

2 Composite lintel

Figure 4 — General dimensions

d

l

d

l

d

c

4 Materials

4.1 Steel lintels

Steel lintels shall be fabricated from carbon steel conforming to EN 10025, EN 10136, EN 10137,

EN 10130, EN 10111, or from stainless steels conforming to EN 10088.

4.2 Concrete lintels

Concrete lintels shall be fabricated from reinforced or prestressed concrete with or without non

structural shell casing units.

Steel for the reinforcement of concrete shall conform to EN 10080.

Stainless steel reinforcement shall conform to EN 10088.

Prestressing steels shall conform to EN 10138.

For lintels covered by this standard, wire diameters shall be 2,5 mm or greater.

The concrete shall conform to EN 206-1 (material requirement clauses only).

Autoclaved aerated concrete shall conform to EN 12602 (definition and material requirement clauses

only).

4.3 Masonry lintels

Masonry lintels shall be fabricated using reinforced or prestressed concrete, masonry mortar, and

structural or non-structural shell casing masonry units in accordance with the following standards:

a) concrete and steel (see 4.2);

b) masonry mortar (see EN 998-2);

c) shell casing units shall be made from:

1) clay (see EN 771-1, materials clauses only);

2) calcium silicate (see EN 771-2, materials clauses only);

3) aggregate concrete (see EN 771-3, materials clauses only);

4) autoclaved aerated concrete (see EN 771-4, materials clauses only);

5) manufactured stone (see EN 771-5, materials clauses only);

6) natural stone (see EN 771-6, materials clauses only).

NOTE All shell casing units may contribute to the mechanical performance of the lintel. However, where

their contribution is verified by calculation methods or the shell casing units are taken into account in

providing cover to the reinforcement, they are deemed to be structural shell casing units.

The compressive strength of structural shell casing units shall be determined in accordance with the

principles of EN 772-1 using a cut specimen. Specimen set up and dimensional relationships are

given in Figure 5.

The compressive strength may also be determined on the basis of a single test specimen tested in

accordance with EN 846-9.

Key

1 Two specimens tested together to achieve symmetrical loading

2 Cut length h equals smallest width b

s s

Figure 5 — Specimens for compressive strength test on structural shell casing units

Corresponding mortar joints shall be selected to meet the design performance requirements of the

e

lintel, see footnote to Table C.3.

4.4 Combined and composite lintels

If the declaration or additional information for composite lintels includes an assumption about

materials or components needed, but not supplied by the lintel manufacturer, to complete the lintel,

then the required properties shall be specified in accordance with this or other relevant European

Standards or European Technical Approvals.

5 Requirements

5.1 General

The requirements and properties specified in this standard shall be defined in terms of the test

methods and procedures referred to in this European Standard.

NOTE 1 Guidance on the use and installation of lintels is given in Annexes A and B.

NOTE 2 The conformity criteria given in 5.2 to 5.10 inclusive relate to initial type tests (see 8.2) and, where

relevant, consignment testing (see 8.4).

For production evaluation, conformity criteria in the factory production control documentation shall be

defined.

B

H

5.2 Dimensions, mass and limit deviations

5.2.1 Dimensions

The length, width and height of the lintel shall be declared and, in the case of non rectangular shapes

or cross sections, a drawing of the configuration with dimensions shall be given.

5.2.2 Mass per unit area

The mass and the mass per unit area on elevation of the lintel shall be declared. The mass shall be

determined from specimens sampled in accordance with clause 8 using instruments capable of

measuring and weighing the specimen to an error limit of 0,1 % of each reading. The mean mass of

the specimens shall be divided by the product of the mean overall length and the mean overall height

to give the mass per unit area on elevation. The deviation from the declared value of mass shall not

exceed 5 %.

5.2.3 Built-in length

The required minimum built-in length needed to anchor the reinforcing bars, which shall be not less

than 100 mm, shall be declared.

5.2.4 Deviation from declared values

When sampled in accordance with clause 8 and measured by the method of EN 846-11, the

deviations from the declared values for dimensions and intended shapes or cross-sections shall not

exceed those given in Table 1.

Table 1 — Dimensional deviations

Dimension Limit deviation

Length ± 15 mm

Width and height ± 5 mm

Straightness or bow (horizontal and 0,5 % of the length, subject to a maximum value of

vertical curvature) 10 mm from the intended profile

Camber of prefabricated part of the 0,7 % of the length from the intended profile

composite lintel

5.3 Mechanical performance and information to obtain the mechanical performance

5.3.1 Single lintels, combined lintels and composite lintels as defined in 3.1

5.3.1.1 General

The load bearing capacity shall be declared from the results of tests, using test methods specified in

this standard, or from their interpretation.

Calculation models may be used to interpret and extend the results obtained from testing. The

calculation models should be based on a mechanical approach and appropriate material properties.

Historic test data may be used to demonstrate the validity of the calculation model.

The manufacturer may also declare the failure mode appropriate to the declared value (shear,

anchorage, compression or tension).

The ultimate demonstration of compliance with this standard shall be by testing in accordance with the

methods in EN 846-9, samples selected in accordance with Clause 8; the load bearing capacity

obtained from tests shall be greater than the declared value.

NOTE See 3.1.9 for definition of the term ‘declared value’.

5.3.1.2 Load bearing capacity and load ratio

The requirements for flexural resistance in accordance with 5.3.1.3 and shear load resistance in

accordance with 5.3.1.5 shall be met in all cases.

NOTE The declared value of load bearing capacity is based on the lesser of the flexural resistance

(see 5.3.1.3) and twice the shear load resistance (see 5.3.1.5).

The load bearing capacity in kN/m of the lintel shall be declared. Unless otherwise stated, this shall be

the value corresponding to the applicable maximum clear opening taking into account the declared

values of the required minimum bearing length and the length of the lintel.

Where lintels are intended to support two or more leaves of masonry, any restrictions on the

distribution of load across the width of the lintel in terms of the range of load ratios that can be used

shall be declared.

5.3.1.3 Flexural resistance

When sampled in accordance with clause 8 and tested by the method of EN 846-9, the flexural

resistance shall be greater than or equal to the declared value of load bearing capacity in accordance

with 5.3.1.2 and no individual value of flexural failure load shall be less than 90 % of the declared

value of load bearing capacity.

5.3.1.4 Deflection

The vertical deflection, δ and also the horizontal deflectionδ when relevant, at one third of the

dv, dh

declared load bearing capacity shall be declared. When sampled in accordance with clause 8 and

tested in accordance with EN 846-9, for flexural resistance, the appropriate mean deflections of the

sample, as relevant, measured at one third of the declared load bearing capacity shall be less than or

equal to the declared deflections δ andδ .

dv dh

NOTE It is only necessary to declare the horizontal deflection δ if it is relevant.

dh

5.3.1.5 Shear resistance

When sampled in accordance with clause 8 and tested by the method of EN 846-9, the shear

resistance shall be greater than or equal to 50 % of the declared value of load bearing capacity in

accordance with 5.3.1.2 and the shear failure load of any individual specimen shall be not less than

45 % of the declared value of load bearing capacity.

5.3.2 Prefabricated part of composite lintels

If the load bearing capacity of a composite lintel is not declared by the manufacturer, the following

parameters shall be declared for the prefabricated part:

Geometry and configuration of the prefabricated part of the lintel including the position, diameter

and yield strength of the reinforcement.

Tensile strength capacity of the prefabricated part of the lintel in the ultimate limit state. If relevant

for durability, the tensile strength shall also be given in the serviceability limit state.

Initial shear strength between the prefabricated part of the lintel and the mortar in the bed joint

above. The declaration may either be made on the basis of fixed values or tests. The

manufacturer shall declare whether the value of bond strength has been obtained from fixed

values or from test. When the declaration is based on fixed values the characteristic initial shear

strength may be declared by reference to EN 998-2, annex C. When the declared value is based

on test then the test shall follow the procedure given in EN xxx-xx.

NOTE When the initial shear strength between the prefabricated part of the lintel and the mortar in the

bed joint above is declared the shear resistance of specimens when sampled in accordance with clause 8

and tested by the method given in EN xxx-xx shall be greater than or equal to the declared value.

5.4 Durability

5.4.1 General

The materials for the manufacture of the lintels and their corrosion protection systems shall be

selected in accordance with 5.4.2 or 5.4.3 and the material/coating reference in accordance with

Annex C shall be declared.

NOTE The durability of performance characteristics against corrosion is dependent on both the condition of

exposure of the masonry and the material/coating specification. This European Standard follows the state of the

art by giving material/coating specifications to suit.

5.4.2 Steel lintels

Steel lintels, other than those made from austenitic stainless steel, shall be protected against

corrosion in accordance with the requirements of C.1.

NOTE The corrosion protection required in any individual application will depend on the type of lintel,

whether a separate damp proof system is used, the degree of exposure and the climatic conditions and therefore

several grades of protection are given.

5.4.3 Concrete lintels and masonry lintels

The reinforcement of concrete and masonry lintels shall be protected against corrosion in accordance

with the requirements of C.2 and C.3.

The joints between the structural shell casing units and any grooves they contain shall be filled with

concrete or mortar. Where the joints are not filled, the units shall be considered to be non-structural.

5.5 Water penetration and installation

All necessary information on the correct procedure for installing the lintel to avoid the risk of water

penetration shall be provided.

NOTE For installation see Annex B.

5.6 Thermal properties

Details shall be provided of the thermal properties of the materials from which the lintel is made by

reference to thermal conductivity values given in EN 1745, or, where not given in that standard, by

reference to thermal conductivity values given in European Standards for the materials of construction.

5.7 Freeze/thaw resistance

5.7.1 General

When relevant to the uses for which the lintel is put on the market and in all cases for lintels intended

to be used in external elements, lintels shall be declared as ‘freeze/thaw resistant’ or ‘not freeze/thaw

resistant’.

5.7.2 Steel lintels

Steel lintels may be classified as freeze/thaw resistant.

5.7.3 Concrete lintels

Lintels made with concrete conforming to EN 206-1 and meeting the requirements for exposure

class XF1 of EN 206-1:2000 may be classified as ‘freeze thaw/resistant’.

5.7.4 Masonry lintels

Masonry lintels may be classified as ‘freeze/thaw resistant’ where the following conditions are met:

a) the concrete part meets the requirements of 5.7.3 to be classified as freeze/thaw resistant and;

b) the masonry material is similar to that used for masonry units conforming to the freeze/thaw

resistance requirements of the relevant Part of EN 771.

5.8 Resistance to fire

Where relevant to the uses for which the lintel type is put on the market, the resistance to fire shall be

classified on the basis of testing of a lintel, either as part of a wall with or without fire separating

function or as a beam, in accordance with prEN 13501-2. Alternatively, the classification may be

based on tabulated values for the material type and form as given in the appropriate European

Standards.

NOTE All lintels can form part of a fire resisting construction when suitably protected. Where classification is

relevant, a lintel type may be classified for use in particular forms of construction, as verified from tabulated

values or by the interpretation of test data. Where a lintel type is intended for use in more than one form of

construction, tests may need to be performed on one or more test systems.

5.9 Water absorption

5.9.1 General

Where relevant to the uses for which the lintel is put on the market and in all cases for concrete and

masonry lintels to be used in exposed external elements, the water absorption coefficient due to

capillary action or the initial rate of water absorption, as relevant, shall be declared.

5.9.2 Steel lintels

Steel lintels may be classified as having a water absorption coefficient of zero.

5.9.3 Other lintels

When lintels other than steel lintels are sampled in accordance with clause 8 and tested by the

method of EN 772-11, for immersion times as specified in the relevant Part of EN 771, the initial rate

of water absorption of clay masonry lintels and the coefficient of water absorption of other lintels shall

be not greater than the declared values.

5.10 Water vapour permeability

When relevant to the uses for which a lintel, other than a steel lintel, is put on the market, the water

vapour diffusion coefficient (lower and upper values) in accordance with EN 1745 shall be declared.

NOTE This characteristic is not relevant for steel lintels.

6 Description and designation

The information to be supplied shall be as given in Tables 2, 3 and 4.

Table 2 — Information to be provided for single lintel and combined lintel

Information

reference Single lintel and combined lintel

number

1 Load bearing capacity, in kN/m

2 Failure mode where relevant

Deflection δ and δ if relevant, at one-third of the load bearing capacity

dv, dh

4 Water absorption of masonry unit, concrete and mortar components

5 Water vapour permeability where relevant

6 Mass (kg) and Mass per unit area of the lintel, in kg/m

7 freeze/thaw resistance where relevant

8 Material/coating specification in accordance with Annex C

9 Thermal performance

Resistance to fire (where relevant)

11 Lintel type

12 Minimum built-in length, in mm

13 Length, in mm

14 Width and Height, in mm

15 Configuration

16 Whether concrete lintels and masonry lintels are required to be rendered

17 Whether a damp proof course is required

18 Where relevant, the component parts of a combined lintel that are not supplied as

part of the product

Table 3 — Information to be provided for composite lintel,

when the load bearing capacity is declared

Information

reference Composite lintel

number

1 Load bearing capacity in kN/m

2 Failure mode where relevant

Deflection δ and δ if relevant, at one-third of the load bearing capacity

dv, dh

4 Water absorption of masonry unit, concrete and mortar components

5 Water vapour permeability where relevant

6 Mass (kg) per unit area on elevation of the prefabricated part only of the lintel, in kg/m

7 freeze/thaw resistance where relevant

8 Material/coating specification in accordance with Annex C

9 Thermal performance

10 Resistance to fire

11 Lintel type

12 Minimum built-in length, in mm

13 Length, in mm

14 Width and height of the prefabricated part, in mm

15 Configuration

16 Minimum width of the complementary element, in mm

17 Height of the complementary element, in mm

18 Whether concrete lintels and masonry lintels are required to be rendered

19 Whether a damp proof course is required

20 Types of masonry units that may be used

21 Specification of the materials in the complementary element including the minimum

compressive strength of masonry units in the direction parallel to the span of the lintel,

in N/mm

22 Minimum mortar strength, in N/mm²

23 Minimum strength class of concrete

24 Instructions for the propping the lintel during construction including the maximum

spacing of props, in mm, and the load that can be applied during the installation of the

lintel.

Table 4 — Information to be provided when only the properties of the

prefabricated part of composite lintel are declared

Information

reference Prefabricated part of composite lintel

number

1 Water absorption of masonry unit, concrete and mortar components

2 Water vapour permeability where relevant

3 Mass (kg) Mass per unit area on elevation of the prefabricated part only of the lintel,

in kg/m

4 freeze/thaw resistance where relevant

5 Material/coating specification in accordance with Annex C

6 Thermal performance

7 Resistance to fire

8 Lintel type

9 Minimum built-in length, in mm

10 Length, in mm

11 Width and height of the prefabricated part, in mm

12 Geometry and configuration of the prefabricated part including the position, diameter

and yield strength of the reinforcement

13 Whether concrete lintels and masonry lintels are required to be rendered

14 Whether a damp proof course is required

15 Tensile strength capacity of the prefabricated part of the lintel. If relevant the tensile

strength capacity in the serviceability limit state also

16 Initial shear strength between the prefabricated part of the lintel and the mortar in the

bed joint above. Fixed value or tested value

7 Marking

The following information shall be clearly and indelibly marked on the lintel or on its packaging,

delivery note, invoice or in the accompanying documentation, supplied with the product, the following

information:

a) The number and date of issue of this European Standard, EN 845-2;

b) The name or identifying mark and registered address of the manufacturer, or the manufacturer’s

authorised representative;

c) A unique reference number, name or code which will identify the product type, and relate it to its

description and designation and intended use.

In addition, the lintel shall be suitably marked to indicate its orientation in use and in the case of lintels

intended to support more than one masonry leaf that portion of the lintel which is to carry the inner

leaf and that which is to carry the outer.

NOTE For CE marking and labelling, ZA.3 applies. When annex ZA.3 requires the CE marking to be

accompanied by the same information as required by this clause the requirements of this clause can be

considered to have been met.

8 Evaluation of conformity

8.1 General

The manufacturer or his agent shall demonstrate compliance for his product with the requirements of

this European Standard and with the declared values for the product properties by carrying out both:

initial type testing of the product (see 8.2);

factory production control (see 8.3).

Alternative methods of test to the methods specified in this European Standard may be adopted

except for the initial type tests and in case of dispute, provided that these alternative methods satisfy

the following:

a) a relationship can be shown to exist between the results from the specified test and those from

the alternative test; and

b) the information on which the relationship is based is available.

8.2 Initial type tests

After completion of the development of a new product type and before commencement of

manufacture and offering for sale, appropriate initial type tests shall be carried out to confirm that the

properties predicted from the development meet the requirements of this standard and the values to

be declared for the product. The manufacturer shall also consider what constitutes a product type and

whether variations in certain dimensions in a specific range of lintels, especially length of the lintel,

can be encompassed within that product type for the purposes of determining the relevant product

performance characteristics. Whenever a change in the basic materials or manufacturing procedures

occurs, leading to what is considered to constitute a new product type being produced, the

appropriate initial type tests shall be repeated.

The tests to be conducted shall be the tests and/or interpretations as described in this standard for

the properties selected from the following list consistent with the product type's intended use:

Single lintels, combined lintels and composite lintels as defined in 3.1

a) material properties (compressive strength of shell casing units only)(see clause 4);

b) dimensions, mass and limit deviations (see 5.2);

c) load bearing capacity (see 5.3.1);

d) deflection δ and δ where relevant (see 5.3.1.4);

dv, dh

e) durability (see 5.4);

f) fire resistance (see 5.8);

g) water absorption (see 5.9).

Prefabricated part of composite lintels

h) material properties (compressive strength of shell casing units only)(see clause 4);

i) dimensions, mass and limit deviations (see 5.2);

j) geometry and configuration of the prefabricated part (see 5.3.2)

k) initial shear strength between the prefabricated part of the lintel and the mortar in the bed joint

above (see 5.3.2)

l) tensile strength capacity of the prefabricated part of the lintel (see 5.3.2)

m) durability (see 5.4);

n) fire resistance (see 5.8);

o) water absorption (see 5.9).

The results of initial type tests shall be recorded and be available for inspection. Sampling for initial

type testing shall be in accordance with 8.4.

NOTE For the performance characteristics to be determined in order to address the CE marking provisions

(see Table ZA.1).

When a manufacturer wishes to use a calculation model as a basis for the declaration of the load

capacity of a new product as part of the ITT the following shall form the basis for the calculation model:

where no experience exists, the test programme forming the basis for the calculation model shall

make it possible to establish a safe relationship between the static scheme following the rules of

applied mechanics, geometry of the product, variation in the material properties and the boundary

conditions.

where the product has the same static scheme following the rules of applied mechanics as

another product for which a calculation model exists, but when some characteristics of the

performance of the new product are different from the ones forming the basis for the calculation

model, then the existing calculation model can be adopted, if it is shown by a test program

consisting of a small number of tests that the boundary conditions for the new product are safe

compared with the ones valid for the existing model.

where the product has the same design and the same characteristics as one produced by

another manufacturer and for which a calculation model exists that model can be adopted by

agreement between the partys.

The manufacturer shall keep available a copy of the report used in the development of the calculation

method and shall be make it available on request to relevant parties.

When a calculation method is used the determination of the relevant properties needed for th

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.

Loading comments...