SIST EN 14404-1:2024

(Main)Personal protective equipment - Knee protectors for work in the kneeling position - Part 1: Test methods

Personal protective equipment - Knee protectors for work in the kneeling position - Part 1: Test methods

This document specifies the test methods for knee protectors intended to protect the knee while working in a kneeling position.

This document does not apply to knee protectors that are medical devices or are intended for sports and motorcycles.

Persönliche Schutzausrüstung - Knieschutz für Arbeiten in kniender Haltung - Teil 1: Prüfverfahren

Dieses Dokument legt die Prüfverfahren für Knieschützer fest, die zum Schutz des Knies während des Arbeitens in kniender Haltung vorgesehen sind.

Dieses Dokument ist nicht anwendbar für Knieschützer, die ein Medizinprodukt sind oder für Sport und Motorräder vorgesehen sind.

Équipements de protection individuelle - Protecteurs de genoux pour le travail à genoux - Partie 1 : Méthodes d'essai

Le présent document spécifie les méthodes d’essai relatives aux protecteurs de genoux destinés à protéger les genoux lors du travail à genoux.

Le présent document ne s’applique pas aux protecteurs de genoux qui sont des dispositifs médicaux ou sont destinés aux sports et aux motos.

Osebna varovalna oprema - Ščitniki za kolena za delo v klečečem položaju - 1. del: Preskusne metode

Ta del standarda določa preskusne metode za ščitnike za kolena, namenjene za delo v klečečem položaju.

General Information

- Status

- Published

- Public Enquiry End Date

- 29-May-2019

- Publication Date

- 15-Sep-2024

- Technical Committee

- OVP - Personal protecting equipment

- Current Stage

- 6060 - National Implementation/Publication (Adopted Project)

- Start Date

- 21-Aug-2024

- Due Date

- 26-Oct-2024

- Completion Date

- 16-Sep-2024

Relations

- Effective Date

- 01-Oct-2024

Overview

EN 14404-1:2024 - Personal protective equipment - Knee protectors for work in the kneeling position - Part 1: Test methods is a CEN standard that defines the laboratory test methods used to evaluate knee protectors designed for occupational kneeling. It specifies conditioning, examination, mechanical and ergonomic tests to assess performance and safety of knee protectors (excluding medical devices and products intended for sports or motorcycles). EN 14404-1:2024 replaces EN 14404:2004+A1:2010 and forms Part 1 of a six-part series covering requirements and combinations of knee protection.

Key Topics

- Scope & exclusions: Test methods apply to knee protectors for work in the kneeling position but not to medical, sports or motorcycle knee protectors.

- Specimen preparation: Conditioning at (20 ± 2) °C and (65 ± 5) % RH for ≥24 h; tests carried out at (20 ± 2) °C or within 30 minutes after conditioning.

- Visual and dimensional examination: Inspection for hard/sharp edges, marking orientation, measurement of protection zone shapes and dimensions.

- Penetration resistance: Measured per EN 863 using a spike at (100 ± 10) mm/min; five tests across the protection zone.

- Force distribution: Uses a defined test knee apparatus (e.g., the “Kandy” test knee) equipped with three force transducers; transducer surfaces shaped to match knee profile and system accuracy requirements (recording accuracy ±1 N).

- Impact / peak transmitted force: Procedures for measuring peak force transmitted through the knee protector during impact tests.

- Restraint, water resistance & bend tests: Includes restraint testing, water resistance assessment, and a new bend test for interoperable knee pads.

- Ergonomic testing & strap compliance: Evaluates comfort, ease of position change (important for venous drainage), and strap/performance requirements for interoperable systems.

- Interoperability checks: Test pocket and test knee pad dimensions to verify interoperable knee pads and garment pockets fit and recover shape.

Applications

EN 14404-1:2024 is primarily used by:

- Manufacturers and product designers to develop and validate knee protectors for occupational use.

- Testing laboratories and certification bodies to run standardized tests and generate compliant test reports.

- Procurement and safety officers in construction, utilities, flooring, and other industries where kneeling work is frequent to specify compliant PPE.

- Occupational health professionals assessing product suitability for long-duration kneeling tasks.

Practical benefits include consistent performance verification, improved user safety, and clearer specification language for interoperable knee protection systems.

Related Standards

- EN 14404-2 to EN 14404-6 (requirements for Types 1–4: wearable knee protectors, combinations, interoperable systems, knee mats, kneeling systems)

- EN 863 (puncture/penetration test method)

- EN ISO 5084 (thickness of textiles)

- EN ISO 4014 (bolts)

Frequently Asked Questions

SIST EN 14404-1:2024 is a standard published by the Slovenian Institute for Standardization (SIST). Its full title is "Personal protective equipment - Knee protectors for work in the kneeling position - Part 1: Test methods". This standard covers: This document specifies the test methods for knee protectors intended to protect the knee while working in a kneeling position. This document does not apply to knee protectors that are medical devices or are intended for sports and motorcycles.

This document specifies the test methods for knee protectors intended to protect the knee while working in a kneeling position. This document does not apply to knee protectors that are medical devices or are intended for sports and motorcycles.

SIST EN 14404-1:2024 is classified under the following ICS (International Classification for Standards) categories: 13.340.50 - Leg and foot protection. The ICS classification helps identify the subject area and facilitates finding related standards.

SIST EN 14404-1:2024 has the following relationships with other standards: It is inter standard links to SIST EN 14404:2005+A1:2010. Understanding these relationships helps ensure you are using the most current and applicable version of the standard.

SIST EN 14404-1:2024 is associated with the following European legislation: EU Directives/Regulations: 2016/425. When a standard is cited in the Official Journal of the European Union, products manufactured in conformity with it benefit from a presumption of conformity with the essential requirements of the corresponding EU directive or regulation.

You can purchase SIST EN 14404-1:2024 directly from iTeh Standards. The document is available in PDF format and is delivered instantly after payment. Add the standard to your cart and complete the secure checkout process. iTeh Standards is an authorized distributor of SIST standards.

Standards Content (Sample)

SLOVENSKI STANDARD

01-oktober-2024

Nadomešča:

SIST EN 14404:2005+A1:2010

Osebna varovalna oprema - Ščitniki za kolena za delo v klečečem položaju - 1. del:

Preskusne metode

Personal protective equipment - Knee protectors for work in the kneeling position - Part

1: Test methods

Persönliche Schutzausrüstung - Knieschutz für Arbeiten in kniender Haltung - Teil 1:

Prüfverfahren

Équipements de protection individuelle - Protecteurs de genoux pour le travail à genoux -

Partie 1 : Méthodes d'essai

Ta slovenski standard je istoveten z: EN 14404-1:2024

ICS:

13.340.50 Varovanje nog in stopal Leg and foot protection

2003-01.Slovenski inštitut za standardizacijo. Razmnoževanje celote ali delov tega standarda ni dovoljeno.

EN 14404-1

EUROPEAN STANDARD

NORME EUROPÉENNE

May 2024

EUROPÄISCHE NORM

ICS 13.340.50 Supersedes EN 14404:2004+A1:2010

English Version

Personal protective equipment - Knee protectors for work

in the kneeling position - Part 1: Test methods

Équipements de protection individuelle - Protecteurs Persönliche Schutzausrüstung - Knieschutz für

de genoux pour le travail à genoux - Partie 1 : Arbeiten in kniender Haltung - Teil 1: Prüfverfahren

Méthodes d'essai

This European Standard was approved by CEN on 20 June 2022.

CEN members are bound to comply with the CEN/CENELEC Internal Regulations which stipulate the conditions for giving this

European Standard the status of a national standard without any alteration. Up-to-date lists and bibliographical references

concerning such national standards may be obtained on application to the CEN-CENELEC Management Centre or to any CEN

member.

This European Standard exists in three official versions (English, French, German). A version in any other language made by

translation under the responsibility of a CEN member into its own language and notified to the CEN-CENELEC Management

Centre has the same status as the official versions.

CEN members are the national standards bodies of Austria, Belgium, Bulgaria, Croatia, Cyprus, Czech Republic, Denmark, Estonia,

Finland, France, Germany, Greece, Hungary, Iceland, Ireland, Italy, Latvia, Lithuania, Luxembourg, Malta, Netherlands, Norway,

Poland, Portugal, Republic of North Macedonia, Romania, Serbia, Slovakia, Slovenia, Spain, Sweden, Switzerland, Türkiye and

United Kingdom.

EUROPEAN COMMITTEE FOR STANDARDIZATION

COMITÉ EUROPÉEN DE NORMALISATION

EUROPÄISCHES KOMITEE FÜR NORMUNG

CEN-CENELEC Management Centre: Rue de la Science 23, B-1040 Brussels

© 2024 CEN All rights of exploitation in any form and by any means reserved Ref. No. EN 14404-1:2024 E

worldwide for CEN national Members.

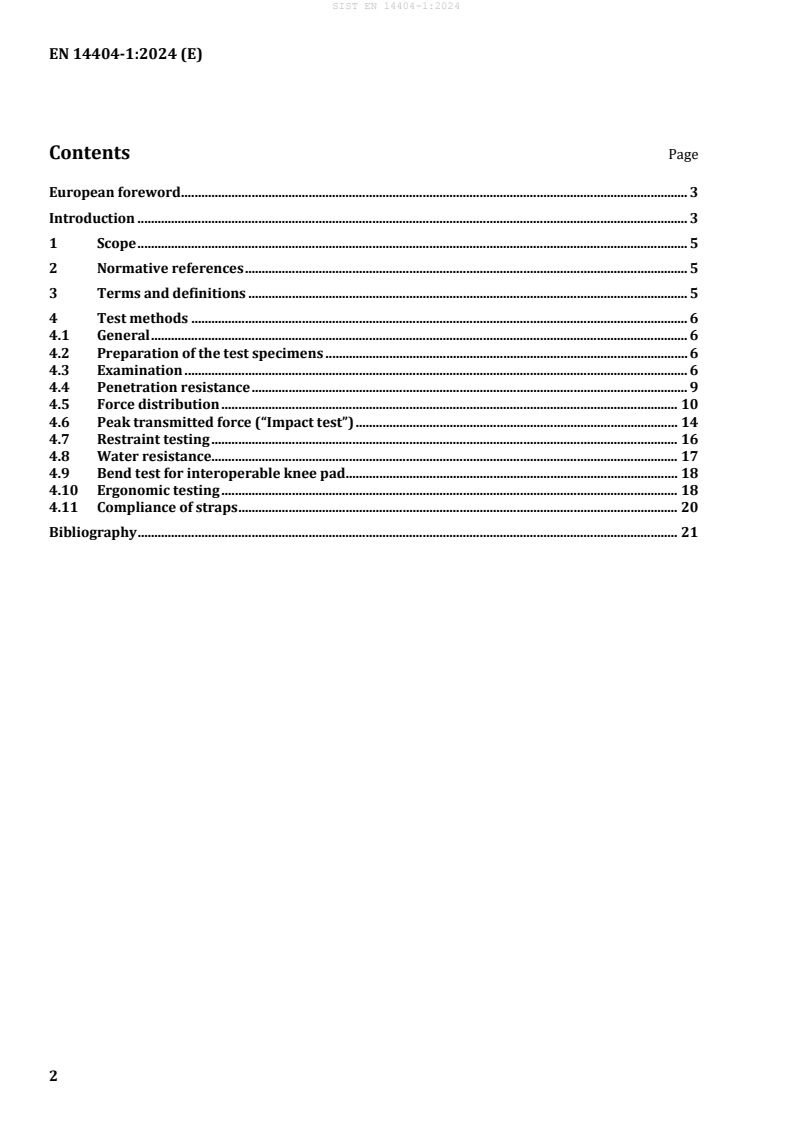

Contents Page

European foreword . 3

Introduction . 3

1 Scope . 5

2 Normative references . 5

3 Terms and definitions . 5

4 Test methods . 6

4.1 General . 6

4.2 Preparation of the test specimens . 6

4.3 Examination . 6

4.4 Penetration resistance . 9

4.5 Force distribution . 10

4.6 Peak transmitted force (“Impact test”) . 14

4.7 Restraint testing . 16

4.8 Water resistance . 17

4.9 Bend test for interoperable knee pad . 18

4.10 Ergonomic testing . 18

4.11 Compliance of straps . 20

Bibliography . 21

European foreword

This document (EN 14404-1:2024) has been prepared by Technical Committee CEN/TC 162 “Protective

clothing including hand and arm protection and life jackets”, the secretariat of which is held by DIN.

This European Standard shall be given the status of a national standard, either by publication of an

identical text or by endorsement, at the latest by November 2024 and conflicting national standards shall

be withdrawn at the latest by November 2024.

Attention is drawn to the possibility that some of the elements of this document may be the subject of

patent rights. CEN shall not be held responsible for identifying any or all such patent rights.

This document, together with EN 14404-2 to EN 14404-6, supersedes EN 14404:2004+A1:2010.

EN 14404 "Personal protective equipment — Knee protectors for work in the kneeling position" is split into

6 parts:

— Part 1: Test methods;

— Part 2: Requirements for wearable knee protectors (type 1);

— Part 3: Requirements for the individual combination of knee pads and garments (type 2);

— Part 4: Requirements for the combination of interoperable knee pads and garments (type 2);

— Part 5: Requirements for knee mats (type 3);

— Part 6: Requirements for kneeling systems (type 4).

With the splitting of the standard, the following changes were made:

— definition of the protection zone;

— new combination of interoperable knee pads with interoperable garments (EN 14404-4);

— a bend test for interoperable knee pad was introduced;

— normative references were updated, further normative references were included;

— an uneven test surface and test was introduced;

— no more "UNISIZE" size; adjustment of size designation;

— additional markings were added.

Any feedback and questions on this document should be directed to the users’ national standards body.

A complete listing of these bodies can be found on the CEN website.

According to the CEN-CENELEC Internal Regulations, the national standards organizations of the

following countries are bound to implement this European Standard: Austria, Belgium, Bulgaria, Croatia,

Cyprus, Czech Republic, Denmark, Estonia, Finland, France, Germany, Greece, Hungary, Iceland, Ireland,

Italy, Latvia, Lithuania, Luxembourg, Malta, Netherlands, Norway, Poland, Portugal, Republic of North

Macedonia, Romania, Serbia, Slovakia, Slovenia, Spain, Sweden, Switzerland, Türkiye and the United

Kingdom.

Introduction

Kneeling is a frequently occurring working position, but one which is problematic from an occupational

health viewpoint. Without knee protectors, workers can suffer immediate injuries from hard surfaces and

small stones and similar objects lying on the surfaces. However, no knee protector can ensure that

workers will not suffer medical complications if they are required to kneel for long periods.

It is important that knee protectors do not compromise venous drainage in the leg while kneeling or

standing up. Therefore, it is important that it is easy for workers to change position and to stand up to re-

establish a normal blood circulation at frequent intervals while wearing knee protectors.

Work in a kneeling position involves the risk of chronic diseases such as prepatellar bursitis and cartilage

injuries caused by continuous pressure on the knees. Knee protection is therefore recommended for all

work in the kneeling position. The protection should distribute forces evenly and prevent small hard

objects on the ground causing injuries. Many workers have pre-existing damage to their knees,

particularly to their cartilage from sports injuries and from previous work. These injuries will be made

worse by further kneeling. Wearing knee protectors cannot correct existing damage but should slow

down further damaging effects.

Work in a kneeling position can expose the skin of the shins, knees and thighs to toxic and corrosive

materials normally kept off the body while walking and standing by waterproof or water-resistant

footwear. Knee protectors and trousers for use with such wet materials and particularly wet cement,

should take this into account and provide adequate protection.

For working in a kneeling position, four types of knee protectors exist:

— wearable knee protectors (type 1),

— knee pads in combination with garments (type 2),

— knee mats (type 3), and

— kneeling systems (type 4).

1 Scope

This document specifies the test methods for knee protectors intended to protect the knee while working

in a kneeling position.

This document does not apply to knee protectors that are medical devices or are intended for sports and

motorcycles.

2 Normative references

The following documents are referred to in the text in such a way that some or all of their content

constitutes requirements of this document. For dated references, only the edition cited applies. For

undated references, the latest edition of the referenced document (including any amendments) applies.

EN 863, Protective clothing - Mechanical properties - Test method: Puncture resistance

EN 14404-2, Personal protective equipment - Knee protectors for work in the kneeling position - Part 2:

Requirements for wearable knee protectors (type 1)

EN 14404-3, Personal protective equipment - Knee protectors for work in the kneeling position - Part 3:

Requirements for the individual combination of knee pads and garments (type 2)

EN 14404-4:2024, Personal protective equipment - Knee protectors for work in the kneeling position -

Part 4: Requirements for the combination of interoperable knee pads and garments (type 2)

EN 14404-5, Personal protective equipment - Knee protectors for work in the kneeling position - Part 5:

Requirements for knee mats (type 3)

EN 14404-6, Personal protective equipment - Knee protectors for work in the kneeling position - Part 6:

Requirements for kneeling systems (type 4)

EN ISO 4014, Hexagon head bolts - Product grades A and B (ISO 4014)

EN ISO 5084, Textiles - Determination of thickness of textiles and textile products (ISO 5084:1996)

3 Terms and definitions

For the purposes of this document, the terms and definitions in EN 14404-2, EN 14404-3, EN 14404-4,

EN 14404-5 and EN 14404-6 apply.

ISO and IEC maintain terminology databases for use in standardization at the following addresses:

— ISO Online browsing platform: available at https://www.iso.org/obp/

— IEC Electropedia: available at https://www.electropedia.org/

4 Test methods

4.1 General

Measuring instruments unless otherwise specified shall be accurate to ±2 % of the pass/fail level of the

characteristic being measured.

The test specimen shall at least attain the required requirement value.

4.2 Preparation of the test specimens

4.2.1 Condition atmosphere

Knee protectors (and garments) shall be conditioned for at least 24 h at a temperature of (20 ± 2) °C and

a relative humidity of (65 ± 5) % prior to testing.

4.2.2 Testing atmosphere

The tests shall be carried out at (20 ± 2) °C or within 30 min after removal from the conditioning

atmosphere.

4.3 Examination

4.3.1 Visual and tactile examination

Knee protectors shall be examined visually and by hand to locate any hard or sharp edges, seams, buckles,

or other items that might injure the user or others during normal use (innocuousness). The marking of

the orientation needs to be checked, if applicable.

4.3.2 Sizes and dimension

The dimensions of the product, the defined zone of protection, the restraint systems and settings shall be

measured with suitable measuring tapes or other devices. Curved areas shall be determined in their

unwound length and width within the inner edges of the knee protector. The shape of the minimum

protection zone is shown in Figure 1 (top view). The results shall be recorded in the test report.

All sizes shall be examined to determine whether their construction appears to provide similar protection

throughout the required zone of protection. Areas with seemingly reduced protection shall be marked

for the mechanical test so that tests occur there.

Key

l1 length of the zone of protection

l width of the zone of protection

r1 radius of curvature of a proximal (upper) corner of the zone of protection

r2 radius of curvature of a distal (lower) corner of the zone of protection

a) wearable knee protector (type 1)

b) knee protector (type 2)

c) knee mat (type 3)

Figure 1 — Shapes of the zones of protection of knee protectors

The dimensions of the zone of protection are given in EN 14404-2 to EN 14404-6.

4.3.3 Fitting test for interoperable knee pad using the test pocket

The interoperable knee pad has to fit into the test pocket.

The inner dimensions of the test pocket have to be:

Length: (265 ± 1) mm

Width: (175 ± 1) mm as described in Figure 2

Figure 2 — Picture of test pocket

The woven fabric of the test pocket shall be made of a single material and shall be non-stretchable.

NOTE A 100 % Polyamide woven fabric covered with a PU-coating (PU: Polyurethan) with a mass per unit area

of about 265 g/m has been found suitable.

The test pocket has to be a separate unit that is not sewed up a trouser leg or other clothes. Three sides

of the test pocket have to be sewn up; the top width side has to be open. The seams shall be at the nooks.

The test shall be evaluated as “fail”, when the knee pad

— does not fit into the test pocket,

— protrudes at the opening of the test pocket,

— is unable to return to its original shape when placed in the test pocket.

4.3.4 Thickness of interoperable knee pad

The thickness of interoperable knee pad shall be tested according to EN ISO 5084.

4.3.5 Fitting test for interoperable pockets using the test knee pad

The garment shall be laid out with the interoperable pockets uppermost on a table.

The test knee pad has to fit into each interoperable pocket of one garment.

The dimensions of the test knee pad shall be:

— Length: (250 ± 1) mm

— Width: (150 ± 1) mm

— Thickness: (24 ± 1) mm

3 3

The material of the test knee pad shall be made of foam with a density between 35 kg/m and 50 kg/m .

The test shall be evaluated as “fail”, when the test knee pad

— does not fit into the interoperable pocket of the garment,

— protrudes at the opening of the interoperable pocket of the garment,

— is unable to return to its original shape when placed in the interoperable pocket of the garment,

— has a displacement in the interoperable pocket of more than 1 cm in width (from left to right or vice

versa),

— has a displacement in the interoperable pocket of more than 3 cm in length (from top to bottom or

vice versa).

4.4 Penetration resistance

The penetration resistance shall be measured according to EN 863 at a velocity of (100 ± 10) mm/min.

The test spike shall be applied to the outer face of the knee protector so that the spike can reach the zone

of protection. Five tests shall be made distributed throughout the zone of protection of the knee protector,

including potentially weak points.

The zone to be tested is restricted to the orthogonal projection area of the zone of protection (see

Figure 3).

Key

1 zone of protection

2 orthogonal projection of the protection zone

Figure 3 — Orthogonal projection of the protection zone

4.5 Force distribution

4.5.1 Apparatus

4.5.1.1 Test knee

A test knee shall be used. It shall be made out of hard plastics, wood or metal.

The test knee is illustrated in Figures 4 and 5. It shall be equipped with three force transducers placed as

shown in Figures 4 and 5. The surface of the transducers shall be shaped to match the surface of the

“Kandy” knee at the points where they are inserted. The surfaces shall follow the profile of the “Kandy”

knee with a tolerance of ±0,5 mm. The transducers shall have the dimensions shown in Figure 5. The force

transducers shall be connected to a recording system. The overall accuracy of the system shall be ±1 N.

A horizontal test surface shall be used to support a knee protector for the test. This forms the horizontal

plane. The test knee shall be attached to the cross head of a compression tester. The test knee shall be

orientated in the apparatus so that the inclined plane (4) contacting the centre line of the knee at two

points (6 and 7) a distance l (170 ± 30) mm apart is at an angle α (5,0 ± 0,5)° to the horizontal plane.

The IFA (Institut für Arbeitsschutz) test knee “Kandy” is suitable. Further technical details are available at the

CEN/TC 162.

a) Top view of the

test knee with

transducer A, B, C

(front view of the

medial side of the

left knee and upper

shin).

b) Schematic side

view of the test knee

(medial view of the

left knee and upper

shin)

Key

1 force transducer C

2 centre of the face of the middle force transducer B (this is the lowest point of the test knee)

3 direction down the shin towards the ankle

4 inclined plane

5 horizontal plane (even test surface)

6 7 contact points with the inclined plane

8 designation of the force transducers (A=upper (front); B=middle; C=lower (rear))

l distance between 6 and 7 (300 ± 10) mm.

α angle between the inclined plane and the horizontal plane (5,0 ± 0,5)

A force transducer

B force transducer

C force transducer

Figure 4 — Shape of the test knee “Kandy” with the positions of the force transducers

Key

1 force transducer

l Dimension for the height difference between the top sides of the force transducers and the surface of the

“Kandy” test knee. The distance between the surface of the transducer and the surface of the “Kandy” test

knee around it shall be within [0,0; 1,0] mm.

l distance between the centres of the force transducers, (28 ± 2) mm

l diameter of the force transducers, (10 ± 0,1) mm

r1 radius of curvature of the corners of the force transducers, (1,0 ± 0,1) mm

Figure 5 — Dimensions of force transducers and their relationship to the test knee surface

4.5.1.2 Uneven surface

The uneven surface comprises a support plate (non-deforming wooden board or comparable material)

on which M8 bolts are attached introduced from below (underside) and symmetrically offset. These are

secured by a nut on the upper side. The hexagon bolts with shaft shall correspond to EN ISO 4014.

The screw thread with the nut protrudes over the support plate. The scre

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.

Loading comments...